Chemists have poked around sulfur-containing rings since the 19th century, drawn by their odd mix of stability and reactivity. Thiophene turned heads long before anyone focused on its substituted cousins. Thiophene-3-ethanol came about as researchers started sticking all sorts of groups onto the thiophene nucleus, hoping to unlock fresh properties and applications. Early organosulfur pioneers noticed that adding an ethanol group could tweak solubility and reactivity. As organic synthesis advanced, easy access to building blocks like 3-bromothiophene made it possible to reliably produce thiophene-3-ethanol in labs across the globe. Modern interest picked up with the growth of high-performance materials and pharmaceuticals, and demand continues as laboratories look for versatile and tunable compounds.

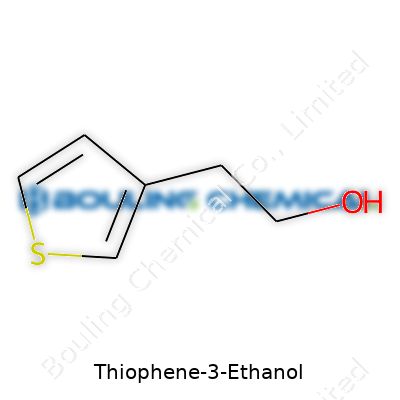

Thiophene-3-ethanol, with the chemical formula C6H8OS and molecular weight around 128.19 g/mol, features a five-membered aromatic ring with a sulfur atom at its core and a two-carbon ethanol side chain. This small change opens the door to custom chemistry, making the molecule a handy intermediate for synthetic chemists. Its structure lets it step into a variety of transformations, pulling weight across several fields.

You’ll find thiophene-3-ethanol as a colorless to faintly yellow liquid. It’s got a melting point around -18°C and a boiling point near 243°C under standard pressure. The density hovers just above 1 g/cm³, making it a touch heavier than water. It blends well with most common organic solvents, especially ethanol and diethyl ether, but doesn’t dissolve much in water. The molecule stands up reasonably well to air, though it’s best to keep it sealed and away from strong oxidizers. The ethanol group introduces hydrogen bonding potential, so expect some stickiness in polar environments, and a distinct, slightly sweet sulfurous odor.

Quality standards for thiophene-3-ethanol usually specify a purity of 97% or higher for most research and tech-grade stock. Labels on shipping containers must show proper hazard pictograms according to GHS, fully spell out the chemical’s name and any synonyms, list the CAS number, batch number, and supply the key storage and handling information. Reliable suppliers always include the Certificate of Analysis, typically checking for minor byproducts from synthesis like unreacted thiophene, higher alcohols, or oxidized derivatives. HPLC and GC-MS serve as standard tools to confirm product identity and purity.

Laboratories often synthesize thiophene-3-ethanol through the nucleophilic substitution of 3-bromothiophene, which is commercially available, with ethylene glycol under basic conditions, followed by reduction. Another common approach starts with 3-thiophenecarboxaldehyde, which gets reduced with sodium borohydride to the corresponding alcohol. This method gives high yields and minimizes the formation of over-reduced or ring-opened byproducts. Industrial processes might scale up using more robust catalysts or continuous-flow reactors, but most users work with batch-derived material. In my own work, the sodium borohydride route offered reliable results and a clean workup, minimized stinky waste streams, and scaled up smoothly when extra product was needed for a long project.

The ethanol side chain gives chemists a launching pad for further modification. It’s easy to oxidize to the carboxylic acid using traditional oxidants like potassium permanganate or chromium reagents. Tinkering with protective groups can produce ethers or esters tailored for downstream synthetic steps. The aromatic ring plays nicely with electrophilic substitution, allowing halogenation, sulfonation, or cross-couplings at other positions. Thioether chemistry brings reactivity toward various transition metals, feeding into catalyst development and even materials science. The alcohol can react in esterifications and carbamate formations, opening doors for drug modification and bioconjugation. In polymer labs, folks use this alcohol group to link thiophene units into larger networks or functionalized surfaces.

Think of thiophene-3-ethanol and a few alternate handles come up, such as 3-(2-Hydroxyethyl)thiophene, 3-Thienylethanol, and 3-Thiophen-3-ylethanol. Some catalogs might list it under its systematic name, 2-(Thiophen-3-yl)ethanol. The CAS registry number 1879-09-0 cuts through all ambiguity, helping seasoned researchers and new lab techs alike track it down in stockrooms or databases. Reputable producers and distributors highlight all known names to avoid confusion and slips in ordering.

Working with thiophene-3-ethanol needs basic chemical sense—lab coats, gloves, and goggles always, decent ventilation, and careful handling to avoid splashing or inhaling vapors. It’s flammable and can cause skin or eye irritation, so don’t skip the gloves or fume hood. GHS labeling asks for hazard statements H315 and H319, warning about irritation to skin and eyes. Any accidental spills should get neutralized fast with absorbent pads and washed down with copious water. Storage containers need solid seals and should stay in a cool, light-protected rack away from oxidizers and acids. Compared to larger thiophene compounds, the ethanol group makes cleanup easier, and residuals wash up well with standard solvents.

Materials scientists appreciate thiophene-3-ethanol as a functional handle for surface modification on electrodes, sensors, and flexible films. Its alcohol group attaches snugly to silanes and organometallic scaffolds, so it plays a role in tailored coatings and analytic probes. Pharmaceutical researchers leverage the thiophene core for bioactivity—sometimes as is, sometimes after further tweaking at the alcohol. Organic chemists see the molecule as a platform for synthesizing advanced heterocycles, coupling partners, or intermediates on the way to more complex drugs and biologically active agents. In my own work with conjugated polymers, adding the ethanol-modified thiophene improved solubility and processing without ruining conductivity—showcasing its role in balancing performance with processability.

Academic and industrial labs regularly turn to thiophene-3-ethanol for new catalyst frameworks, sensors, and as a versatile handle for attaching functional groups in supramolecular chemistry. Ongoing R&D focuses on attaching the ethanol group to nanostructures for better biomolecule attachment, opening opportunities in biosensors and medical diagnostics. Research also points to the molecule as a flexible scaffold in medicinal chemistry, able to support a wide array of modifications while keeping metabolic stability. Most recently, green chemists have pushed for cleaner, more efficient synthesis pathways to cut out harsh oxidants, trim byproduct streams, and cut down on dangerous solvents. Lab techs see the molecule’s stability and versatility, but the main value lies in how easily it links into broader systems, whether for bioactive research or advanced electronics.

Animal studies and cell culture tests suggest low acute toxicity, though data remains spotty and should never be taken as a green light for careless handling. Like most heterocyclic alcohols, repeated skin or respiratory exposure can lead to irritation or mild sensitization. If ingested by accident, gastrointestinal distress shows up, with prolonged inhalation possibly causing headaches or dizziness. Both OSHA and REACH recommend limiting exposure, working exclusively in properly ventilated areas, and keeping all containers tightly sealed outside of use. Disposal demands full combustion or secure collection by licensed waste handlers to keep residues out of water streams or landfill. Frequent reviews of published toxicity studies help keep protocols up-to-date, ensuring lab safety officers and workers never grow complacent.

Looking ahead, thiophene-3-ethanol’s role in functional materials shines brightest. Researchers are busy exploring bio-compatible polymers, smart sensors, and surface coatings that use the alcohol handle for site-specific modification. Pharmaceutical teams draw on its ease of derivatization to create leads in anti-inflammatory and anti-infective research. Advances in green chemistry promise synthesis pathways with lower carbon footprints, cheaper catalysts, and less hazardous waste, making production friendlier and more sustainable. With the growth of personalized medicine, configurable molecules like thiophene-3-ethanol sit well-positioned for rapid adaptation, and the research community continues to push the boundaries of what’s possible with cyclized sulfur scaffolds. Every fresh application feeds a cycle of discovery, offering new ways to improve processes, products, and patient safety.

Thiophene-3-ethanol might sound like a mouthful, but it’s a chemical that shows up in more places than most folks realize. It’s an organic compound with a structure combining a thiophene ring and an alcohol group. This mix of properties gives it a versatility valued by scientists and manufacturers. Its clear liquid form and distinctive aroma might not catch much attention outside the lab, but under the microscope, this molecule has sparked plenty of interest and innovation.

Pharmaceutical companies often look toward thiophene-3-ethanol as a starting point for drug development. The structure offers a useful building block when designing molecules that interact with biological systems. For medicinal chemists, introducing the thiophene ring boosts a drug’s stability or improves how it dissolves in the body. As a result, thiophene-based structures can appear in medication for infections, neurological issues, or even in early-stage cancer research. One journal highlight from the past decade noted that thiophene derivatives, including thiophene-3-ethanol, are featured in experimental treatments due to their unique binding abilities.

The food and fragrance industries draw on chemistry to create new aromas and flavors. Thiophene-3-ethanol adds a subtle, earthy scent, sometimes described as slightly mushroom-like or reminiscent of truffles. Working as a minor additive, it deepens certain flavors in food products or enriches the notes of synthetic perfumes. My time working alongside a food analyst taught me how a dash of the right compound can tip a formulation from bland to unforgettable. Reports from flavor houses mention the compound in new earthy notes for specialty products, although it stays well below any health safety thresholds.

Material scientists invest a lot of energy in designing new organic electronics and plastic polymers, and thiophene-3-ethanol draws interest here as well. Incorporating the compound into novel materials can tweak electrical conductivity or improve mechanical resilience. Whenever I visited a materials lab, researchers described how blending building blocks like thiophene-3-ethanol into polymers led to advances in solar cells, transistors, or flexible displays. Scientific literature reports thiophene derivatives paving the way for more efficient, durable, and even biodegradable plastics, supporting cleaner manufacturing practices. Because the compound bonds well with other molecules, it lets designers fine-tune results in the final product.

Like most chemicals with specialized applications, thiophene-3-ethanol requires careful handling. Studies from regulatory agencies include it in chemical inventories, and established safety guidelines direct proper use. Long-term effects haven’t triggered major alarms, but researchers and industrial users rely on gloves, ventilation, and smart storage practices. Information from the European Chemicals Agency and other regulatory bodies reinforces the need to respect the substance, tracking exposure and ensuring it doesn’t make its way into public waterways or food supplies by accident.

Demand for sustainable innovation keeps rising, and chemists continue exploring thiophene-3-ethanol’s potential. Whether that’s designing a better pain reliever, engineering a readable electronic label, or cooking up richer flavor profiles for non-animal cuisine, this compound is staying on the radar. Industry reports hint at new patents and ongoing academic research, showing that attention on thiophene-3-ethanol isn’t slowing down. Its track record proves that when expertise and careful experimentation meet a molecule like this, progress usually follows.

In everyday lab work, a compound’s name hints at both its architecture and its behavior. Thiophene-3-ethanol gives us two good clues right away: a thiophene backbone and an ethanol group at the third position. Every time I grab a bottle of it from the stockroom, that sulfur smell and slight viscosity tell me right away I’m dealing with something more than a standard alcohol.

The formula, C6H8OS, looks simple, but there’s a lot packed into those characters. Each carbon counts toward the ring and the ethanol side chain, while the single sulfur atom sits where one might expect an oxygen in furan or a nitrogen in pyrrole. As straightforward as it seems, thiophene itself stands out thanks to that sulfur in the ring—a feature that changes how it behaves in reactions and in solvents.

Tracing the structure, thiophene by itself looks like a five-membered ring: four carbons and the sulfur. Numbering starts at the sulfur, so the position marked ‘3’ sits right across the ring. The ethanol tail grows off carbon three, which sets this compound apart from its similar cousins. The two-carbon chain with its terminal alcohol means one end of the molecule can play in both polar and non-polar environments. That’s a reason I see it pop up in synthesis routes or as a building block for more complex molecules.

From experience, that combination—aromaticity from thiophene, hydrogen bonding from ethanol—offers flexibility in research. In a flask, it mingles with polar solvents, but the ring stays happy with hydrophobic partners, too. That’s a handy balance when tweaking reaction selectivity or designing targeted probes for sensors.

Structure isn’t just an academic concern. In practical chemistry, even small changes in position or side chain length shift the landscape. The difference between a two- and three-position substitution on thiophene can influence reactivity, solubility, and how easily the molecule attaches to other fragments. In the world of organic electronics, researchers use thiophene derivatives for everything from solar cells to flexible displays. Ethanol groups offer anchor points for bigger assemblies or open the door to hydrogen bonding in crystal packing.

When I’ve worked with sensors, thiophene-3-ethanol’s unique polarity helped with surface binding and signal transmission. Other times, collaborators in medicinal chemistry highlighted this compound’s value as a starting chunk for designing ligands, because it slips easily into aromatic-rich receptor sites.

In practice, one doesn’t just grab an unfamiliar bottle and charge ahead. It pays to know that thiophene-3-ethanol, while less volatile than its parent ring, still carries some risk. Good ventilation, nitrile gloves, and splash goggles belong on the bench. Consult updated safety data—sources like the CDC, NIOSH, and peer-reviewed chemical handbooks give clear, evidence-supported guidelines. Responsible handling comes from personal experience combined with well-documented procedures in the field.

Researchers continually test what they can coax out of simple building blocks like thiophene-3-ethanol. With sustainability and innovation guiding discovery, flexibility in molecular design remains crucial. Whether a goal involves assembling conductive polymers for greener energy storage or targeting new pharmaceutical pathways, tools like this one sit ready for the next scientific step. Strong documentation, a working knowledge of chemical structure, and a respect for the risks never go out of style in any lab using compounds like thiophene-3-ethanol.

Thiophene-3-ethanol sounds like something only a chemist would care about. Actually, it’s a compound that crops up in research, and sometimes in manufacturing. Whenever a substance like this shows up, the most natural question is: does it pose a risk to people or the environment? In day-to-day life, most of us don't come into contact with chemicals straight out of a bottle, but scientists and workers who do deserve real answers—not just regulatory jargon.

For most folks, thiophene-3-ethanol doesn’t lurk in household products. Its use centers around chemical research and perhaps the specialty synthesis of pharmaceuticals or advanced materials. I recall my own research days, surrounded by bottles labeled with names even longer than this one. We never grabbed a bottle without checking a safety sheet first. That habit probably saved my skin more than once.

Thiophene-3-ethanol hasn’t become notorious like benzene or lead. Reliable toxicology data on it remains thin, but drawing from similar compounds, there are a couple of things science does tell us. If managed carelessly, many thiophene-related chemicals carry risks—skin or eye irritation, sometimes headaches or drowsiness with heavy exposure. It matters that workers wear gloves, goggles, and lab coats, especially since the compound can pass through skin and find its way into the bloodstream.

Official agencies, such as the European Chemicals Agency (ECHA), list thiophene-3-ethanol as an irritant for eyes and skin. Prolonged or repeated exposure often signals a call for caution, even if no immediate poisoning happens. The Responsible Care movement in the chemical industry keeps pushing for better workplace monitoring. No one should take for granted that “not famous” equals “not dangerous.”

Think about what happens if this stuff gets washed down the drain or dumped without care. Much like its chemical cousins, thiophene-3-ethanol breaks down slowly. Studies suggest that thiophenes hold onto their structure in soil and water, which means wildlife could face problems if concentrations climb. It’s not acutely toxic to fish or plants in small amounts, but accumulation rarely brings good news. Over time, small leaks can add up.

Industrial sites carry a bigger burden. Tracking chemical inventories, treating waste on-site, and keeping signals clear for emergency responders all rank as basic steps. In real-world emergencies, fast information saves lives. During an internship at a pharmaceutical plant years ago, color-coded labels on pipes guided everyone, even visiting interns like me, away from risk zones. Simple structure and common sense—nothing fancy—go a long way.

As a general rule, working with chemicals demands respect. Getting complacent just isn’t worth it. Thiophene-3-ethanol doesn’t call for panic, but it rewards paying attention. Use fume hoods, store bottles tightly closed, and never treat the drain as a garbage can. A culture of respect—not just rules on a page—protects workers, neighbors, and the local river. Chemicals like this made me recognize the value of a thorough safety walkthrough, asking questions, and erring on the side of caution.

Anytime a new molecule shows up in industry or the lab, it’s wise to mix vigilance with curiosity. Push for better data, read the safety sheet, and keep an eye on what goes down the sink. No alarm needed, only honest awareness and steady habits. As more information comes in, keeping those old habits sharp will limit problems—before they ever start.

Thiophene-3-ethanol plays a big role in chemical research and flavor chemistry. Scientists often need this compound with a purity that helps keep experiments accurate and predictable. Standard commercial supplies often reach purities of 97% or more, which works for most applications. Some rigorous tests—for example, pharmaceutical development or advanced material science—ask for even finer purity, but hitting 97–99% covers most user needs. Lower purity introduces uncertainty into research and can skew results or add unwanted byproducts.

Impurities don’t just throw off results; some of them can be reactive or toxic. From personal experience in a synthesis lab, working with imperfect chemicals once wrecked a full week's work and introduced headaches into our analyses. It also cost extra time and money to repeat experiments just to rule out contamination. Buying an extra-pure batch at the start often saves a lot of trouble down the line.

Storage isn’t just an afterthought here. Thiophene-3-ethanol is a small molecule with a functional alcohol group; it pulls moisture from the air and slowly degrades if left open. Warmth speeds up unwanted reactions like oxidation. Glass bottles with airtight caps block out air and water vapor best, and darker glass helps keep out light, which can also trigger breakdown. I still remember seeing a bottle left loosely capped on a benchtop—within a month, it looked cloudy and gave off a weird smell, making it unusable.

Most labs keep this chemical cool—under 8°C, or in a standard refrigerator. Not freezing, just chilled. Higher temperatures nudge the compound to react with oxygen. Even a little oxidation can make it lose its intended qualities and introduce new flavors or properties. Keeping containers sealed, using nitrogen purging for especially sensitive situations, and shielding containers from direct sunlight go a long way.

Storing chemicals wrong isn’t just a matter of wasted money. Spoiled stock creates safety hazards and can even put research teams at risk. Quality assurance teams often check chemical integrity with GC (gas chromatography) or NMR (nuclear magnetic resonance) before use. Discoloration or strange odors are obvious red flags. Regular checks keep everyone safe and research valid.

Expired or contaminated chemicals put people in harm’s way. In some cases, I’ve seen teams tracking each chemical’s purchase date and opening date, using labeling systems or digital logs. These record-keeping habits guard against accidental use of spoiled chemicals, and they help track how fast supplies run down for future orders.

A few habits make storage and purity less of a question mark. Split chemicals from bulk containers into smaller, single-use bottles soon after delivery, because repeated opening and closing increases the risk of contamination. Never pipette directly from the primary storage bottle; pour small quantities into working flasks.

Good lab practice recommends labeling every container with date of receipt, date of opening, and initials. Every few months, run a quick test batch to confirm the chemical still matches expected specs. If there’s any change in physical appearance—cloudiness, color shift, odd scent—dispose of the bottle safely and update records. Protecting purity and stability isn’t about following protocol for its own sake; it’s about trust in results and, ultimately, in the discoveries that come from using reliable starting materials.

Lab safety isn’t an empty checkbox for compliance—it protects people who work day in and day out with substances that don’t get headlines but still come with real risks. Thiophene-3-ethanol falls right in this category. Walk into any research space where it’s used, and you can smell the faint sulfurous note—never a countryside breeze. Even small exposures can bother sensitive noses or skin, so ignoring the smell means turning a blind eye to what might later become an irritating rash or persistent headache.

Talking with chemists, the consensus is clear: Keep open bottles away from shared desks, especially since some folks develop skin irritation after frequent contact. It doesn’t eat away flesh like some high-octane acids, but letting it linger on your skin invites redness or itchiness for a surprising number of people. Stories float around about working through a long synthesis and realizing hands were pruney and stung for the rest of the shift.

Thiophene-3-ethanol isn’t considered carcinogenic, and the acute effects rarely escalate into emergencies for adults, but that easiness lulls folks into skipping gloves or eye protection. Splash this stuff into your eyes, and the irritation—burning or redness—ruins productivity fast. Several material safety data sheets flag potential respiratory issues if folks spend hours without fume extraction, especially during warm summer months when labs push their ventilation systems. Friends have shared how even low vapor exposure sparked tickling throats and lightheadedness after a morning’s work.

Using appropriate nitrile gloves isn’t about being overly cautious. For people who work with chemicals every day, skin contact adds up. Decades in the field show there’s no prize for “toughing it out.” Wearing safety glasses isn’t overkill; it’s just practicality gained from witnessing accidents that were preventable in seconds.

Ventilation stands out as something every laboratory controls. Fume hoods offer the most effective layer of protection. Running reactions or pouring from larger containers outside the hood just invites exposure. My own experience with a broken sash once led to a runny nose that wouldn’t quit until I left the building. Real-world proof that ignoring airflow isn’t harmless.

Out of the bottle, thiophene-3-ethanol doesn’t present as an obvious threat, so complacency builds over time. I’ve seen students leave bottles uncapped, trusting that nobody will nudge them—even as vapors slowly fill the room and the cleaning crew wonders what stinks.

Keep bottles tightly sealed. That advice isn’t just a line from a safety poster. A small spill on a shelf spreads its odor quickly, and leaving residues increases the risk of skin or eye exposure. I remember mopping up a spill with a paper towel and regretting the decision an hour later, after my palms stung and reeked of sulfur.

For years, I’ve kept a spill kit in arm’s reach, with absorbents that neutralize minor messes and gloves that actually fit. Immediate cleanup and proper labeling avoid confusion and cross-contamination. Colleagues know the headache of discovering chemical leftovers during an end-of-year inventory—the bottle sticky, label faded, nobody sure who last used it.

At the end of the day, chemical safety runs on shared responsibility. Learning from each other’s mishaps saves more trouble than following dry protocols. Thiophene-3-ethanol lacks the drama of some lab hazards, but it deserves respect. Handling this compound wisely—and passing those lessons to new students—keeps everyone working and learning, not dealing with avoidable health annoyances or cleanup headaches.

| Names | |

| Preferred IUPAC name | 2-(Thiophen-3-yl)ethan-1-ol |

| Other names |

3-(2-Thienyl)ethanol 3-Thienylethanol 2-(3-Thienyl)ethanol |

| Pronunciation | /θaɪˈoʊ.fin θri ˈɛθ.ə.nɒl/ |

| Identifiers | |

| CAS Number | [18721-24-1] |

| Beilstein Reference | 1121075 |

| ChEBI | CHEBI:39758 |

| ChEMBL | CHEMBL45858 |

| ChemSpider | 88521 |

| DrugBank | DB08338 |

| ECHA InfoCard | 100.034.387 |

| EC Number | 226-727-0 |

| Gmelin Reference | 7446 |

| KEGG | C09694 |

| MeSH | D017330 |

| PubChem CID | 69758 |

| RTECS number | YN8225000 |

| UNII | 9I1QD6Q8RU |

| UN number | UN2810 |

| Properties | |

| Chemical formula | C6H8OS |

| Molar mass | 114.18 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | aromatic |

| Density | 1.145 g/mL at 25 °C (lit.) |

| Solubility in water | Slightly soluble |

| log P | 0.84 |

| Vapor pressure | 0.0163 mmHg (25°C) |

| Acidity (pKa) | 15.49 |

| Basicity (pKb) | pKb = 15.26 |

| Magnetic susceptibility (χ) | -59.14·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.557 |

| Viscosity | 1.219 mPa·s (25 °C) |

| Dipole moment | 1.6904 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 318.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -49.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2875.7 kJ/mol |

| Pharmacology | |

| ATC code | N07XX11 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H315, H319, H335 |

| Precautionary statements | Precautionary statements: "Wash thoroughly after handling. Wear protective gloves/protective clothing/eye protection/face protection. IF ON SKIN: Wash with plenty of water. |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | 61°C |

| Autoignition temperature | 185°C |

| Lethal dose or concentration | LD50 (oral, rat): >2000 mg/kg |

| LD50 (median dose) | LD50 (median dose) of Thiophene-3-Ethanol: Oral rat LD50 > 2000 mg/kg |

| NIOSH | SNH9840000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 30 mg |

| IDLH (Immediate danger) | Not established |

| Related compounds | |

| Related compounds |

Thiophene Thiophene-2-ethanol Thiophene-3-carboxylic acid Thiophene-2-carboxaldehyde Thiophene-3-boronic acid |