Thiophene-2-thiol stands as a reminder of where chemical research has taken us and how the work of generations continues to turn basic lab curiosity into tools with broad impact. Back in the late 19th century, thiophene itself showed up as a pesky impurity when German chemists worked with coal tar to isolate benzene. It didn’t take long for someone to wonder what happened if you threw a sulfur group into the ring, and within a few decades, researchers started experimenting with different substitutions. The story only really picked up after the Second World War, when organic synthesis took off and sulfur-containing rings stopped being regarded as chemical troublemakers and started driving new material and pharmaceutical work. Today, thiophene-2-thiol gets more than just a footnote in the discussion of heterocycles. Its journey shows what’s possible when chemists look past the obvious and stick with molecules that keep showing up in unlikely places.

Give this stuff a sniff and you’ll never forget it: a kind of burnt and rubbery odor, not exactly welcome but unmistakable. Thiophene-2-thiol takes hold as a building block and reagent. Somewhere between basic research and specialty manufacturing, folks rely on its ability to introduce both sulfur and aromaticity into more complicated molecules. It’s a commercially available liquid, typically shipped in tightly sealed amber containers to fight off both light and air, since it reacts with oxygen and easily loses punch. In my bench days, a sealed container on the shelf always seemed a little like finding an aggressive but useful dog behind a fence—powerful and worth respect.

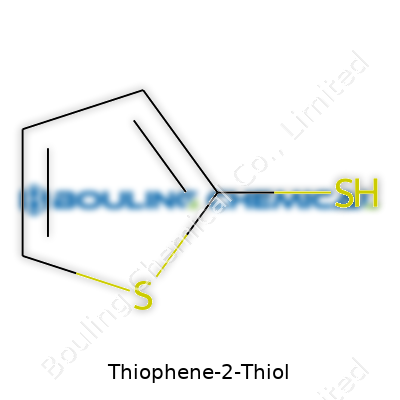

Colorless in the pure state but amber with age and light, thiophene-2-thiol has the chemical formula C4H3SH. With a boiling point hovering around 172 to 174°C and a melting point close to -7°C, the liquid is volatile but manageable below room temperature. It dissolves well in organic solvents like diethyl ether, ethanol, and benzene. A low flashpoint and an obvious, piercing smell mean you never forget precautions during handling. This compound reacts strongly with oxidizing agents, and even traces of air start degrading its quality, so chemists rely on freshly opened stocks for reaction work and run inert gas lines when necessary.

On the label, you usually find a purity figure: above 97% is the benchmark for synthetic applications, while analytical chemistry expects above 99%. Reputable suppliers tag each bottle with CAS No. 137-26-8 and print hazard symbols for flammable and toxic substances. The molecular weight reads 100.15 g/mol. Safety data sheets warn about skin absorption, inhalation, and water reactivity, so handy pictograms and clear English—no jargon, just blunt warnings—appear everywhere. Even with technical specs, it always feels like common sense comes before paperwork: minimize exposure, use ventilation, and keep emergency supplies within reach.

Old chemistry books list several routes to thiophene-2-thiol, but most current processes start with thiophene itself, relying on selective chlorination followed by thiolation. For years, I saw researchers debate the merits of sodium hydrosulfide versus hydrogen sulfide over acid catalysts; both work, but modern setups reduce by-product formation and waste. Industrial labs often use batch reactors under inert atmosphere with careful temperature control. Yields usually run above 60% when conditions are fine-tuned. With increased pressure to reduce environmental impact, folks are now shifting toward greener solvents and minimization of volatile organic compounds.

The thiol group at the 2-position makes this chemical a versatile partner. You get a playground for nucleophilic substitutions, cross-coupling reactions, and metal-catalyzed transformations. Standard reactions include alkylation, acylation, and Suzuki-type couplings, with the sulfur providing a convenient entry point for further functionalization. In my own hands, it worked well in thioether and disulfide synthesis. Subtle differences in catalytic conditions make the difference between success and a wasted afternoon. Lab stories pass down through generations about carefully controlled temperature ramps to avoid runaway exotherms or by-product headaches, a reminder that this chemistry rewards patience and attention more than bravado.

The world of chemical nomenclature never skips the chance to confuse: among the alternatives, you’ll run into 2-Mercaptothiophene, Thiophen-2-ylmercaptan, and 2-Thiophenethiol. Some older catalogs list "a-thiophenethiol," but most modern databases stick with the IUPAC system. Regional standards rarely differ, but buyers do need to check product numbers and synonyms when sourcing from unfamiliar suppliers. This small detail, often overlooked, becomes crucial for international research teams juggling paperwork or regulatory checks.

Chemical safety never feels optional with thiophene-2-thiol. Its low flashpoint and high vapor pressure demand fume hood work, eye shields, and gloves. Splash hazards often go hand-in-hand with strong odors, which linger in lab coats and fixtures. The MSDS is blunt: wear PPE, store below 25°C, keep away from ignition sources, and never pour down the drain. Disposal follows hazardous waste protocols—incineration with off-gas scrubbing, never landfill. Regulatory agencies track storage and transport, with limits placed on volume and secondary containment. Labs that take shortcuts usually end up paying more in clean-up and ventilation repairs than if they followed the book in the first place.

Most people outside chemistry circles never hear about thiophene-2-thiol, but major industries do. Medicinal chemists turn to this building block when developing new anti-inflammatory compounds or metabolic probes. Electronic materials use it as a precursor for conductive polymers, handy in organic solar cells and flexible displays. Agrochemical companies value sulfur heterocycles in fungicides and pesticides. Custom synthesis shops produce thiophene-based dyes for analytical detection or imaging. Whenever I hear about a new organic optoelectronic device or high-sensitivity sensor, chances are some sulfur-ridden thiophene derivative had a hand in its discovery.

In the lab, thiophene-2-thiol opens doors for new reactions, new sensors, and even new drugs. The challenge often revolves around fine-tuning its reactivity—balancing stability and ease of transformation. Recent projects in my circles focus on developing more selective catalysts and less toxic byproducts. Universities and private labs test new ligands for metal coordination, aiming to speed up synthesis steps in complex molecule construction. Every year, a handful of patents cite thiophene-2-thiol as a key intermediate for a finished pharmaceutical or specialty monomer. The demand for higher-purity samples continues to drive advances in separation and purification technologies.

Toxicologists don’t take shortcuts here. Rodent models show that exposure above threshold levels leads to respiratory and neurological stress. Chronic low-level contact causes skin sensitization and liver impact in animal tests. Consumption or inhalation brings out both acute and delayed symptoms, such as headaches, nausea, and signs of sulfur toxicity. These findings put added pressure on users to minimize occupational exposure: robust ventilation, strict PPE protocols, and regular monitoring of air quality in storage and handling areas. Regulations in Europe and North America keep inching upward, making safe management not just a legal issue but a day-to-day practical concern. Many research groups now publish detailed exposure scenarios with any new publication that cites thiophene-2-thiol, showing a shift toward transparency and worker safety over productivity at any cost.

The future for thiophene-2-thiol doesn’t look dim. With electronics pushing for new organic conductors and pharma chasing unique molecular scaffolds, this chemical stays relevant. Ongoing work explores new sustainable synthesis approaches, where renewable feedstocks may cut down reliance on finite resources. Innovations in catalyst development and waste minimization remain key industrial goals. As synthetic biology keeps inching closer to merging with organic synthesis, I expect labs to find new biocatalytic approaches for thiophene modifications, maybe even engineered microbes that crank out sulfur-rich compounds on demand. The need for safer, more efficient use will drive both regulation and practice, but the molecule’s versatility promises a continued presence wherever sulfur-organic chemistry finds a foothold.

Thiophene-2-thiol pops up in labs and production floors for one reason: it brings a sulfur element that chemists can easily tap for creative work. The compound comes in handy across pharmaceuticals, materials science, and even the flavors and fragrances you find in daily life, though its uses aren’t always front-page news.

This molecule runs in a family of thiophenes—aromatic rings with a sulfur atom in place of one carbon, which adds versatility. Its thiol group (a -SH unit) makes reactions quick and reliable, unlike some alternatives that bog down projects with slower or unpredictable chemistry. If the goal is to attach a sulfur atom to another molecule, thiophene-2-thiol offers a shortcut you can count on. I’ve seen organic synthesis jobs move faster just by swapping in this compound instead of more stubborn sulfur sources. The result? Fewer headaches, less waste, and quicker access to important intermediates.

This chemical quietly supports drug research. Scientists rely on it to build more complex structures for testing as possible medicines, including molecules that might tackle cancer or infections. It’s not the star of the show, but a key supporting actor. One example: research groups produce kinase inhibitors with this thiol, looking for results that can outsmart growing antibiotic resistance. Seeing promising compounds come together from basic reagents like thiophene-2-thiol, and knowing they might turn into tomorrow’s treatments, makes all the bench work worthwhile.

This molecule turns up in the search for new organic electronics. Manufacturers want flexible circuits for displays or solar panels that can bend and stretch. The sulfur atom in thiophene rings helps conduct electricity, and chemists have linked up lots of these rings to make longer chains called polythiophenes—crucial for organic LEDs and solar cells. You need materials that survive manufacturing and deliver performance when people plug them in, and thiophene-2-thiol acts as a building block for that. Its reliability has paved the way for large-scale production of materials that once looked out of reach.

Even the smell of thiophene-2-thiol catches attention—a strong, onion- or garlic-like kick, useful for crafting some savory flavors when used in very low amounts. Flavorists turn to this chemical for its punch, giving sauces or snacks a unique, lingering note. In perfumery, it brings depth to some blends that need just a whisper of earthiness or spicy undertones. Used carelessly, it will overpower everything, but in the right hands, it rounds out other aromas.

Thiophene-2-thiol doesn’t come without baggage. It has a strong odor and can be an irritant, which means labs must keep ventilation and safety tight. Those using it in big batches have to watch for its environmental load, as sulfur compounds can create disposal problems. While regulations around some chemicals stay patchy, industry should push for clear labeling and best practices to avoid accidental releases and long-term contamination. Developing better waste treatment and greener synthetic routes could keep benefits flowing while trimming hazards.

More industries search for robust, flexible molecular tools, and thiophene-2-thiol has a secure place in future labs—especially with researchers chasing cleaner, smarter technologies. As synthesis gets more sustainable and regulations tighten, the way we handle and transform this compound will keep evolving. With collaboration between chemists, safety experts, and policymakers, thiophene-2-thiol can continue pushing along medical discoveries, stronger electronics, and even the taste of our food, without piling up unwanted risks.

Thiophene-2-thiol comes from the thiophene family—a group of compounds often found in dyes, pharmaceuticals, and some polymers. Chemically, this molecule carries a formula of C4H4S2. Each molecule holds four carbon atoms, four hydrogens, and two sulfur atoms. Molecular weight lands at 132.21 g/mol. That may feel like just a string of numbers unless you've seen firsthand how precise measurements shape chemistry in labs and factories.

Working in a lab, I’ve learned that getting molecular formulas wrong doesn’t just waste time—it risks safety, destroys costly materials, and can lead to unpredictable reactions. Small differences in a formula cause massive changes for pharmaceuticals or specialty chemicals. That’s especially true for things like thiols, which come with both reactive sulfur atoms and a distinct odor profile, making them valuable and tricky to control.

Some researchers look at thiophene-2-thiol as a building block for complex molecules. For example, modifying its aromatic sulfur ring can turn it into a candidate for anti-inflammatory drugs or fuel additives. Each carbon and sulfur atom plays a role. The weight tells chemists how much to use in a reaction—they run calculations for doses, yields, and safety thresholds. An error even below a gram can snowball if you’re making large batches.

Sulfur-containing compounds often raise red flags in the workplace. Inhalation or skin exposure can irritate, and environmental release can linger due to sulfur’s persistence. I’ve worked with enough sulfur compounds to respect their power—a whiff in the air, and you know it’s time to check ventilation and personal protection right away. Knowing the formula C4H4S2 also means you understand what's being released if a spill happens and what you need for cleanup. Molecular weight helps emergency responders match protective gear and response plans for these exact chemicals.

Chemists and engineers think about thiophene-2-thiol as more than just ink in a lab manual. People use it for flavor chemistry, in some specialty rubbers, and in research targeting better drugs. In these scenarios, balancing safety, odor management, and purity isn't academic—it's a daily challenge. Knowing the right numbers means projects move forward without dangerous surprises.

I’d like to see more open sharing of best practices, especially among small-scale labs and startups. Clear labeling based on accurate chemical formulas could help avoid costly mistakes. Weight calculations deserve double checks before each reaction scale-up, and training on chemical hazards pays off in the long term. With sulfur-rich molecules like thiophene-2-thiol, that combination of scientific rigor and respect for safety can save both dollars and lives. Focusing on the right details creates opportunities, from new materials to targeted medications, while protecting the people and places where discovery happens.

Thiophene-2-thiol isn’t a household name, but for anyone working in a laboratory with this compound, it demands real respect. Most folks working in chemical research know that a mistake in storage or a sloppy approach to handling can turn a normal day into a hazardous one. The sulfur in thiophene-2-thiol brings a pungent odor—sometimes enough to ruin a break room for hours with just a splash. The bigger risk hides in its ability to form flammable vapor and corrosive fumes, which invites trouble if left unchecked. Over the years, I've seen what happens when warning labels get ignored: ambitious graduate students forced to evacuate a lab or explain odd stains on a favorite jacket.

Storing thiophene-2-thiol away from heat sources isn’t a suggestion—heat kicks off those fumes and can build up unwanted pressure. Shelves in a dedicated flammables cabinet, far from direct sunlight, suit this substance best. I always check that these cabinets stay closed and that bottles remain tightly sealed. One leaky cap can turn a lab into a problem area no one volunteers to clean. Keeping containers upright avoids possible spills, and clear labeling keeps confusion at bay, especially when fatigue sets in late at night.

Damp environments and warm rooms speed up degradation and risk. Storing thiophene-2-thiol at room temperature, away from humid air, extends its shelf life and cuts down on nasty surprises during experiments. I choose storage rooms set up with proper ventilation, so lingering fumes won’t hang around. Silica gel packets help inside cabinets that deal with humidity, though frequent checks on seals and desiccant packs help spot trouble early.

Personal protective gear becomes as important as the compound itself. Nitrile gloves, eye protection, and a lab coat form a solid shield, but more goes into safe handling than just gear. A fume hood pulls away dangerous fumes at their source. Pouring underneath a fume hood, with the sash lowered as much as possible, prevents accidental whiffs that sting the nose and scratch the throat. There’s no bravado in skipping these steps—everyone who cuts corners has a story they’d rather forget.

Quick action keeps small mistakes from turning into riddles for a safety committee. I always stash spill kits nearby, complete with absorbent pads and the right neutralizers for sulfur chemicals. Double-bagging waste and labeling it for hazardous pickup gives environmental compliance officers fewer headaches. Pouring remnants down the sink invites big fines and long lectures.

Every new researcher learns from senior colleagues—mistakes from the past get retold, usually with a nervous chuckle. Building a culture where questions around safety don’t get brushed off reduces problems for everyone. Encouraging others to read the latest safety data sheets and sharing stories are reminders that the small details matter.

Relying on proper storage and careful handling isn’t just a rule—it’s a daily habit. By treating thiophene-2-thiol with the caution it deserves, labs not only avoid unnecessary emergencies, but everyone leaves work in better shape than when they arrived.

Thiophene-2-thiol isn’t a household name, but people in labs know the sharp, sulfur-heavy scent all too well. Used in organic synthesis, this compound pops up in pharmaceutical and agrochemical research. It’s the kind of substance that demands respect: anything containing both sulfur and aromatic rings often does. Thiophene-2-thiol sits in a family of chemicals recognized for their usefulness but also their risks.

Coming face to face with this substance, my hands would tremble a bit. Not from fear, but from a steady respect for its reputation. According to the European Chemical Agency, skin contact, inhalation, and ingestion can all cause harm. It’s not just about the rotten egg smell – it’s about what’s sneaking past your natural defenses. Reports from laboratory incidents highlight that even short-term skin exposure leads to irritation. Its vapors attack the respiratory system, causing coughing, throat pain, and difficulty breathing. It’s one of those chemicals no one wants in their eyes, as splashes can do real damage.

Health isn’t the only concern. Thiophene-2-thiol can disrupt the environment if spills go unchecked. Its volatility makes it likely to evaporate, but that only spreads the risk. Chronic exposure, even at low levels, raises red flags. Reference data hints at possible effects on liver and kidney function after repeated exposure.

In my lab years, safety training always taught that quick reactions and a solid spill kit can mean the difference between a small incident and lingering consequences. This chemical shows how careful handling can’t just be a box you tick on a list. It’s about staying alert and never cutting corners.

Regulations demand the basics: gloves, goggles, fume hoods. Those standards exist for a reason. Fume hoods aren’t just guidelines—they’re survival tools. Neglecting them turns a worrying hazard into a real emergency. It helps to keep MSDS sheets on the bench, not buried in a binder. Spills need immediate attention with proper absorbents; ventilation must be functional, not optional.

Some universities and industries step up training, drilling response plans until the steps become second nature. Prudent managers label bottles clearly and inspect storage areas often. Teams that discuss safety risks before every experiment face fewer crises. Real protection doesn’t come from posters and pledges, but from active vigilance and a willingness to slow down.

Reliable resources, like PubChem and government safety guidelines, paint a consistent picture: this isn’t a risk you can ignore. Documented cases show that minor lapses in attention have sent workers to emergency care. Compared to much friendlier solvents, thiophene-2-thiol’s hazards are neither abstract nor imaginary. Not everyone wants to pore through safety data sheets, but those who do tend to finish their shifts with all senses and skin intact.

An old professor once said, “respect the compound, protect yourself, and ask questions if you’re uncertain.” That advice applies to thiophene-2-thiol and nearly every substance a chemist encounters. Familiarity never breeds invincibility. Avoiding shortcuts, relying on evidence, and keeping safety routines solid are lessons that never lose their relevance.

As someone who has spent years tracking down specialty chemicals for research, I know that searching for a compound like Thiophene-2-Thiol isn’t just about typing it into a search bar and picking the cheapest supplier. This compound, also called 2-Mercaptothiophene, shows up in a handful of catalogs—think Sigma-Aldrich, TCI, Alfa Aesar, and a few other global chemical suppliers. Most of these companies only sell to businesses, universities, or government labs. If someone is shopping for personal or hobby use, they will quickly run into restrictions. The flags go up when a compound has potential use in pharmaceuticals, synthesis, or sometimes less savory applications.

A trusted source like Sigma-Aldrich lists Thiophene-2-Thiol under its research chemicals with CAS number 137-06-6. TCI and Alfa Aesar have it, often with different catalog numbers. Orders go through various checks, and registration as a legitimate research entity is required. The best suppliers offer data sheets, safety documentation, and details on purity. Sigma-Aldrich, for example, usually offers above 97% purity, sometimes reaching 99%, and always discloses the main impurities if they're there.

It’s easy to take these details for granted, but purity truly matters in chemical synthesis. Low-purity compounds throw off results, create unpredictable byproducts, and can wreck expensive research. Clean materials mean less troubleshooting, more reliable procedures, and reproducible data. Third-party labs test their batches—this usually shows up in certificates of analysis, which come with the product or can be requested. Someone who’s had a batch contaminated by an unknown sulfur impurity won’t forget the lesson.

For folks in academia, pharmaceutical research, or advanced synthesis, a small impurity can mean wasted months. If a bottle says 97% pure, the remaining 3% is a mystery unless the supplier discloses what’s in that fraction. A reliable supplier lists significant side products. Many reputable labs also run NMR or GC-MS purity checks themselves after receiving a shipment, especially for sensitive reactions.

Online marketplaces without a track record should raise skepticism. Wild claims about purity—especially “100%”—without analytical evidence, often end in disappointment. Regulatory agencies stress that researchers stick to licensed dealers for purchase. Dodging this fact risks not only poor results but legal headaches. Customs and health departments sometimes scrutinize chemical orders, and a missing permit can spell lost money and possible charges.

Colleagues working in synthetic chemistry tell me that they save time and protect their work by always asking for a copy of the supplier’s certificate of analysis. Even reliable brands occasionally ship lots with different impurity profiles. Experienced teams keep backup suppliers, compare batches, and test for their own peace of mind. Nobody wants to arrive at the thesis defense or the product approval stage and admit the experiment failed due to dirty starting materials.

Reaching out directly to sales representatives—explaining the experimental need and required purity—often makes the difference. Reputable sellers are more willing to help when they know it’s a real project with compliance in order. If technical support dodges questions about batch analysis or documentation, that’s a red flag.

Buying Thiophene-2-Thiol relies on going through proper channels, weighing the reputation of the supplier, and making sure the batch data backs up any purity claims. The stakes are high in chemistry, and anyone who cares about reliable results knows the value of starting with genuine, high-purity materials and documentation you can trust.

| Names | |

| Preferred IUPAC name | thiophene-2-thiol |

| Other names |

2-Mercaptothiophene 2-Thiophenethiol Thiophen-2-yl mercaptan 2-Thiohydroxythiophene |

| Pronunciation | /θaɪˈoʊfiːn tuː ˈθaɪɒl/ |

| Identifiers | |

| CAS Number | 137-08-6 |

| Beilstein Reference | 1209240 |

| ChEBI | CHEBI:38529 |

| ChEMBL | CHEMBL419129 |

| ChemSpider | 12669 |

| DrugBank | DB08538 |

| ECHA InfoCard | 100.011.507 |

| EC Number | 205-736-8 |

| Gmelin Reference | 7956 |

| KEGG | C02371 |

| MeSH | D013872 |

| PubChem CID | 6979 |

| RTECS number | XM8225000 |

| UNII | Z02I7R02C6 |

| UN number | UN3335 |

| Properties | |

| Chemical formula | C4H4S2 |

| Molar mass | 114.21 g/mol |

| Appearance | Light yellow to brown liquid |

| Odor | unpleasant |

| Density | 1.17 g/mL at 25 °C (lit.) |

| Solubility in water | slightly soluble |

| log P | 1.97 |

| Vapor pressure | 0.4 hPa (20 °C) |

| Acidity (pKa) | 6.60 |

| Basicity (pKb) | 0.97 |

| Magnetic susceptibility (χ) | -37 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.610 |

| Viscosity | 0.995 cP (20°C) |

| Dipole moment | 1.61 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 205.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -5.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -475.0 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS06, GHS07 |

| Pictograms | GHS06, GHS08 |

| Signal word | Warning |

| Hazard statements | H301 + H311 + H331, H315, H319, H335 |

| Precautionary statements | P210, P260, P273, P301+P310, P305+P351+P338, P370+P378 |

| NFPA 704 (fire diamond) | 1-2-0-W |

| Flash point | 52 °C |

| Autoignition temperature | 380 °C |

| Lethal dose or concentration | LD50 oral rat 2000 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 = 117 mg/kg |

| NIOSH | UK2450000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Thiophene-2-Thiol: "PEL: 0.1 ppm (skin), OSHA |

| REL (Recommended) | 0.05 mL |

| Related compounds | |

| Related compounds |

Thiophene 2-Bromothiophene 2-Chlorothiophene Thiophene-2-carboxylic acid Thiophene-2-aldehyde 2-Iodothiophene Thiophenol |