People started paying attention to Tetrahydro Pyrrole, often called pyrrolidine, in the late nineteenth century. Early organic chemists discovered pyrrolidine by reducing pyrrole, a basic heterocycle that pops up in plenty of natural products. They didn’t just stumble upon it by accident—curiosity about the molecules making up everything from pharmaceuticals to pigments steered research right to this nitrogen-containing ring. Much of the first big progress came from scientists in Germany and France, who followed the nitrogen atom as it wound through the synthesis and breakdown of more complex chemicals. Decades later, the building block status of Tetrahydro Pyrrole put it in labs and factories around the globe, with new derivatives turning up in everything from crop protection to drug discovery. Tracing the arc of its development gives context to its wide range of uses today.

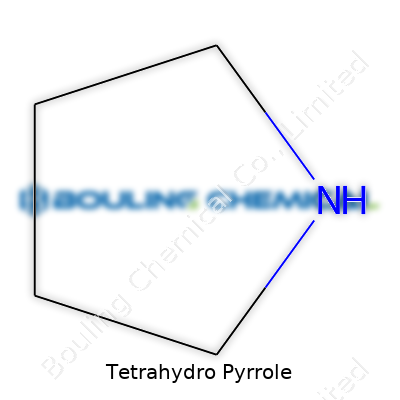

Tetrahydro Pyrrole boils down to a five-membered ring featuring four carbon atoms and one nitrogen atom. Anyone working in chemical synthesis will run into it sooner or later because its structure shows up in alkaloids, both natural and synthetic. Laboratories stock it as a colorless to pale yellow liquid, sharply pungent, easy to spot even in small amounts. For others outside chemistry, seeing pyrrolidine in industrial cleaning supplies, solvents, and even in some flavors and fragrances highlights its versatility. Makers list it under a stack of synonyms—pyrrolidine, azacyclopentane, or just THP for short. Looking back through catalogs and registers, the names vary but the product inside the bottle stays reliably the same.

Tetrahydro Pyrrole melts at about –66°C and boils around 87°C. Its density sits just under that of water, so it floats when mixed, and it mixes nearly as well with water as it does with most organic solvents. That mixability opens the door to a wide field of chemical reactions. The nitrogen atom in the ring offers a lone pair of electrons, turning pyrrolidine into a solid-base compound—chemists rely on it to deprotonate sensitive compounds or set off ring-forming reactions. Its volatility brings both promise in fast-evaporating solvents and challenges in storage and safety. Thanks to those physical details, it fits jobs on both the lab bench and the industrial scale, where handling and environmental impacts become a bigger deal.

Suppliers ship pyrrolidine in tightly sealed drums or bottles, using clear hazard labeling mandated by local safety laws. Reach for the technical sheet and you’ll mostly see minimum purity levels (98% or better for research, sometimes even hitting 99.5% in pharmaceuticals), details on residual water and byproducts, and safety notations warning about its flammability and corrosive vapors. The labeling follows international standards—signal words like “Danger” and “Flammable Liquid” stick out in red for a reason. Storage advice typically points toward cool, well-ventilated areas away from open flame or oxidizers. Chemical traceability, batch number, and manufacturing date are etched onto every container. These standards turn what could be chaos into predictable, manageable risk, both for workers and the environment.

On the industrial scale, factories make Tetrahydro Pyrrole from a simple precursor—pyrrole—by hydrogenation, passing the vapor over a metal catalyst such as palladium or nickel at elevated pressure. The hydrogenation method churns out liters by the barrel, supporting the high-volume needs of agriculture, pharmaceuticals, and specialty chemical industries. In research, labs often prefer sodium in ethanol or catalytic transfer hydrogenation for smaller batches. Some routes start from 1,4-dibromobutane and ammonia, driving cyclization under heat. Each method gives technicians choices around cost, safety, and scalability, which reflects in the global supply chain and influences pricing. My own experience tells me that every batch brings small quirks—temperature control, water purity, or catalyst fouling—reminders that even the cleanest chemistry still takes hands-on work.

The chemistry of Tetrahydro Pyrrole centers on its ring nitrogen. Reacting with acid chlorides or anhydrides, it forms N-acyl or N-alkyl derivatives—crucial for making pharmaceuticals from antihypertensives to anticonvulsants. Under oxidizing conditions, the ring can be opened or rearranged, building new scaffolds for materials science or pharma researchers. In the presence of formaldehyde or alkyl halides, pyrrolidine works as a nucleophile, snapping up carbon centers and forming new bonds quickly. That reactivity makes it a powerful engine in synthesizing everything from performance polymers to fine agrochemicals. Working with such a reactive molecule means keeping a close eye on both desired and side reactions. Nothing beats in-person troubleshooting on a reaction gone wild, where controlling pH, temperature, and solvent purity often tips the result from “waste” back to “yield.”

In catalogs, Tetrahydro Pyrrole goes by several names, reflecting both historical roots and modern applications. Pyrrolidine stands as the formal name. Other tags such as azacyclopentane, 1-azacyclopentane, and THP pop up. Pharmaceutical circles sometimes lean on IUPAC or legacy industry shorthand. Supply chain databases include all these for tracking, and chemical registries like CAS list 123-75-1 for global consistency. For users, especially procurement staff or researchers trying to match documentation, these synonyms keep confusion to a minimum, provided the paperwork keeps step with the ever-changing nomenclature.

Handling Tetrahydro Pyrrole calls for personal protective gear—goggles, gloves, lab coats, and strong ventilation. The strong odor alerts anyone nearby to spills, but short-term exposure to vapors can cause dizziness or nausea, and skin contact burns quickly. Factories and labs both carry material safety data sheets outlining spill protocols, fire extinguishing methods, and first aid. Facilities regulate air concentrations well below toxic thresholds, and run regular checks on ventilation. In industrial zones, teams train on evacuation routes and chemical neutralization for emergencies. These standards do more than tick off boxes—they make a real difference in worker health. I remember a close call early in my career, where fast response and good PPE kept a small spill from turning into a hospital visit. Rigid safety protocols exist for a reason.

Pharmaceutical industries draw on Tetrahydro Pyrrole for making backbone structures in medicines. Renin inhibitors, Parkinson’s drugs, and muscle relaxants revolve around its core ring structure. Makers of herbicides and fungicides value the nitrogen ring for boosting crop yields and cutting losses, while polymer chemists use pyrrolidine to tweak properties of synthetic fibers and elastomers. It even finds a home in the production of flavor and fragrance ingredients—usually under tight dose control, since high concentrations overwhelm with their pungency. In personal care chemistry, the ring brings new surfactant structures and helps build complex cosmetic formulations. Even in academic circles, students and postdocs see pyrrolidine in retrosynthesis exercises or total synthesis projects as a reliable, straightforward tool, reminding all where careful chemical management starts.

Universities and private R&D labs continue to look for new derivatives and applications for Tetrahydro Pyrrole. Synthetic chemists focus on greener, less hazardous preparation methods like biocatalysis or electrochemical routes that cut down on waste and energy. Drug researchers run through endless analogs, hoping to unlock new treatments with better selectivity or fewer side effects. Materials science teams adapt the ring structure into new polymers with enhanced strength or self-healing features. I’ve seen collaboration between biotech startups and old-line chemical companies speed up discovery, trading expertise in scaling up pilot processes and getting analytical data to market quickly. Open-access databases and machine learning techniques add new dimensions, trolling literature to map out reaction trends or predict toxicity. The pace of R&D keeps pushing pyrrolidine’s uses far beyond what the original discoverers ever imagined.

Scientists test Tetrahydro Pyrrole across animal and cell models to pin down safe exposure limits and understand long-term effects. Acute toxicity studies show moderate effects—high doses depress the central nervous system, but repeated low exposures haven’t demonstrated major chronic impacts in published work. Animal models point toward some liver and kidney strain with repeated handling, reinforcing the need for strict workplace controls. Environmental studies track how spills affect soil and water, since pyrrolidine breaks down slowly and can disrupt microbial ecosystems. Safety authorities draw lines for occupational limits and set protocols for emergency cleanup. Reviewing the data, I notice open questions remain about bioaccumulation or interaction with emerging contaminants, so ongoing research stays crucial. People living near chemical plants rely on these findings for peace of mind.

The next decade looks promising for Tetrahydro Pyrrole. Green chemistry movements drive the shift to less hazardous production methods, with new catalysts and renewable feedstocks cutting fossil input and emissions. Pharmaceutical exploration pushes for derivatives that break new ground in neurological and metabolic therapies. In agriculture, tighter regulations favor more targeted, biodegradable pesticides, and pyrrolidine rings help engineer molecules that hit pests with less collateral damage. Digitally driven labs—powered by AI-driven compound screens and automated synthesis machines—accelerate design and testing, shrinking the time from idea to application. With increased scrutiny on occupational safety and environmental exposure, industry and academia must keep updating exposure standards and waste management. Each new application brings chance as well as challenge, and lessons learned from past handling—plus strong regulations—shape a much safer, more productive future.

At first glance, tetrahydro pyrrole sounds like just another chemical from a high-school textbook. Those of us who spent time in laboratories know it better as pyrrolidine. This five-membered ring with four hydrogens attached to a nitrogen atom has genuine real-world uses. Its distinctive amine scent brings back memories of organic labs, but it’s also a backbone for some of the molecules that help shape products everywhere from drugstores to farm fields.

Pharmaceutical researchers and industrial chemists often grab tetrahydro pyrrole when they’re building drug candidates. Its ring shape makes it valuable for constructing medicines, especially those aimed at the nervous system. The sedative piracetam and the popular muscle relaxant baclofen both contain pyrrolidine features — without it, those compounds wouldn’t work as they do. In my own experience working with compounding pharmacists, I saw how these nitrogen rings help tweak activity in brain chemistry, offering tools to combat disorders like epilepsy and muscle spasticity.

Looking beyond finished drugs, laboratories turn to tetrahydro pyrrole as a building block for more complex chemicals. Chemists value it as a “scaffold” — a stable structure on which they can tack on all sorts of other groups. It acts almost like a blank canvas. This isn’t limited to academic curiosity. Companies have figured out that tweaking this skeleton leads to entirely new molecules for testing, potentially moving toward the next breakthrough.

Farms and greenhouses benefit from this chemical, too. Tetrahydro pyrrole forms part of the backbone for some herbicides, pesticides, and plant growth regulators. Monsanto and Syngenta have patented formulations using similar ring systems to manage weeds or boost crop yields. Farmers want products that break down quickly after doing their job and leave fewer residues, so researchers keep pushing to find even smarter tweaks to the ring.

Moving into specialty chemicals, tetrahydro pyrrole finds its way into corrosion inhibitors and paint additives. In my consulting work for an industrial coatings company, adding ring-containing amines sometimes helped slow down rust on steel packaging. Its high reactivity opens doorways for creating more durable polymers and protective layers. Makers of cleaning detergents and water treatment agents also pull it from supply shelves to speed up reactions or serve as a building block for surfactants.

Handling tetrahydro pyrrole means respecting its volatility and strong odor. Inhalation burns, headaches, and long-term effects can pop up if ventilation or protective gear gets skipped. Community watchdogs and regulatory agencies want more thorough impact studies, especially where manufacturing touches water supplies. Tighter regulations and green chemistry initiatives now urge producers to find alternatives or discover more biodegradable versions of these amines.

Emerging technology promises ways to make the molecule from renewable sources instead of petrochemical feedstocks. Biotech companies are testing fermentation approaches, aiming to shrink carbon footprints. Teaching students and young chemists to respect both the potential and the problems built into every intermediate compound forms a key part of moving toward safer and more responsible chemical manufacturing.

People who run experiments, work with chemicals, or manufacture products bump into tetrahydro pyrrole sooner or later. It’s not a household staple. Instead, it pops up in research labs, some pharmaceutical work, and specialty chemical production. Companies use it to study reactions or build more complex substances. Most folks off the street have never touched it, but for someone in the right industry, handling it is routine. The topic of safety isn’t just some paperwork hurdle; lives and long-term health can hang in the balance.

The first thing anyone trying tetrahydro pyrrole in the lab should get straight is that this isn't water or table salt. It gives off vapors with a distinct and often unpleasant smell. Breathing those fumes too much ruins a good day. Eye contact burns. Skin contact can irritate, sometimes badly. Swallowing it makes things worse. The body doesn’t thank anyone for mishandling this stuff.

Years ago during my own time in an organic chemistry lab, the safety sheets got drilled into us for a reason. Tetrahydro pyrrole figures on the Globally Harmonized System for chemical hazards. That label doesn’t show up just for kicks. Safety data spells out the details: wear gloves, goggles, and a lab coat—not the kind of thing you want in your eyes, lungs, or on your skin.

Organizations like NIOSH and OSHA keep track of workplace injuries, and many come from ignoring these common-sense steps. You wouldn’t believe how often workers skip the gear and regret it later. In one FDA published review of substance hazards, pyrroles sat in the “irritant” pile and demanded basic precautions. This isn’t exaggeration; the evidence stretches back years.

My mentor used to say, "Chemicals don’t forgive carelessness." If you treat tetrahydro pyrrole like a harmless liquid, you put yourself at risk. Care and respect keep emergencies out of the news. In a shared workspace, spills caused stress and sometimes forced evacuations. Proper training and quick reactions saved people from trips to urgent care. Doors needed to stay open, fume hoods worked overtime, and cleanup kits stayed within arm’s reach.

Someone once left a vial uncapped in a cramped workspace. The lingering vapor gave everyone a headache by lunch. That day hammered home a point: mistakes don’t only hurt the one who made them—others pay for sloppy habits, too.

Experience shows that following safety instructions is only half the story. A good setup matters. Ventilation pulls fumes away so people don’t breathe them in. Storage matters too: well-labeled containers, tight lids, and clear shelves cut down on accidents. Emergency eyewash stations and showers shouldn’t gather dust.

Training takes center stage—people who know what they’re doing rarely cut corners. Drills for emergencies shouldn’t stay once-a-year events. I’ve seen new hires pick up bad habits fast if the old crew gets lazy. Regular reminders, well-stocked safety gear, and leadership by example go further than posters on the wall.

The science behind tetrahydro pyrrole sets clear boundaries for what’s safe. Respecting those limits, looking out for coworkers, and keeping supplies in shape can turn a risky compound into a manageable one. People at the bench and management both play a part. Schedules and profits matter, but health always comes first.

No one has to learn the hard way. The data exists, the instructions are clear. Treat tetrahydro pyrrole seriously, and it rarely causes problems. Push past those boundaries, and the stories stop being just warnings—they become an ambulance ride for real.

Tetrahydro pyrrole, also known as pyrrolidine, gets a lot of attention in both academic and industrial chemistry. Its structure, C4H9N, means it’s made up of four carbons, nine hydrogens, and one nitrogen atom, arranged in a five-membered ring. This simple makeup hides its true potential, as tetrahydro pyrrole finds its way into scores of chemical processes and products that touch everyday life.

Pyrrolidine isn’t just another chemical formula scribbled on a textbook page. It’s a small, stable ring—a heterocycle—which means it contains at least one atom in the ring that's not carbon. In this case, nitrogen. That lone nitrogen brings basicity and reactivity, two qualities prized in pharmaceutical synthesis. Researchers use pyrrolidine’s formula, C4H9N, to steer synthetic reactions in directions that lead to pain medications, cognitive enhancers, and various alkaloids. You might not spot pyrrolidine in a pharmacy or a supermarket, but plenty of common products would look different without it.

Glancing back on organic chemistry lab work, trying to synthesize rings that stay together under pressure can feel like a struggle. That’s where pyrrolidine shines. Its ring isn’t just tough, it’s adaptable. Chemists can tweak its formula, pop in different atoms, and end up with new drugs or agrochemicals. For instance, ACE inhibitors for blood pressure management often owe their backbone to pyrrolidine rings. Crops protected by safer pesticides? Those agricultural marvels benefit from structures derived from tetrahydro pyrrole. Farmers invest in these advances because every yield counts.

Details make or break scientific advances. One carbon out of place, a hydrogen swapped, or a nitrogen missing, and a compound turns into something completely different—maybe dangerous, maybe useless. When teaching students or training lab technicians, showing the right formula—C4H9N—matters just as much as handling lab glassware safely. Even small mistakes in structural formulas can cause bigger problems in drug development or agricultural safety. Regulatory agencies keep a close watch on this, prioritizing safety and traceability throughout research and production chains.

Memorizing lists of formulas rarely helped anyone understand chemistry on a deeper level. Drawing C4H9N, breaking down what each atom contributes, and running examples in actual labs—these steps bridge theory and practice. It’s not just about passing an exam, but training minds to spot errors and design better molecules tomorrow.

Companies and universities can do more by investing in hands-on teaching and safety protocols. Encouraging critical thinking, making students double-check formulas, and giving workers a clear picture of each chemical’s risks and benefits build habits that protect health and speed meaningful discoveries. The humble formula of tetrahydro pyrrole represents much more than numbers and letters on a screen—it signals the next wave of chemical innovation and safe progress.

Working with chemicals like tetrahydro pyrrole isn’t just about following the Safety Data Sheet and ticking off compliance boxes. From my years dealing with labs and chemical storerooms, I’ve seen how small missteps end up escalating into expensive, sometimes dangerous, clean-ups or costly inventory loss. Tetrahydro pyrrole sits in that zone between not-too-scary and silently risky. Its volatility, flammability, and sensitivity to moisture can turn a moment’s oversight into a chemical spill or fire hazard in minutes.

Tetrahydro pyrrole needs a cool, steady environment. I once experienced a storeroom failing to hold temperature through a summer heatwave, and several bottles softened, leaking vapors into the air. This compound breaks down and emits fumes when the environment heats up, and those vapors ignite fast if a spark shows up. If you keep it near heat-generating equipment or under direct sunlight, you line up a recipe for trouble that anyone familiar with flammable solvents will want to avoid.

Any veteran lab tech recognizes why exposure to moisture ruins lots of sensitive chemicals. Tetrahydro pyrrole reacts with water, which can lead to hydrolysis. Sloppy lids or damaged containers pull in more than dust—they let in humidity that degrades quality. Using airtight containers isn’t just about cleanliness; it preserves both efficacy and safety. I remember a time a colleague skipped checking container seals, thinking things “looked fine.” That batch spoiled, and the clean-up consumed the whole afternoon. A good seal reduces headaches.

Plastic and glass both work for short-term storage, but glass gives more peace of mind for long-term use. Tetrahydro pyrrole sometimes reacts with certain plastics, especially if stored for months. My first chemistry instructor told us to always use amber glass—it shields light, fends off degradation, and resists chemical attack. Whenever we tried clear plastics, half the bottles showed discoloration after a season. If the budget allows, glass wins almost every time.

Access control is a big deal. Tetrahydro pyrrole shouldn’t sit in a catch-all closet with cleaning supplies. Segregate flammable chemicals in certified safety cabinets with clear labeling and spill trays. Every storeroom I’ve trusted kept up-to-date logs and trained staff never to stack incompatible materials together. There’s something reassuring in a system where everyone knows what’s in each cabinet, and misplaced bottles get flagged immediately. Walk into a place where chemical containers sit on the floor, and you’ll sense chaos waiting to happen.

There are specific regulations guiding the storage of volatile chemicals, and anyone working with tetrahydro pyrrole should respect those. But beyond the paperwork, having pride in your workspace consistently pays off. Every seasoned technician double-checks labels, shelf life, and the tightness of a cap before tucking away a bottle. Regular inspections, spill kits within reach, and clear signage save more than money—they keep people safe. If you’ve ever had to evacuate a lab over a preventable incident, you remember those lessons for life.

More open communication among staff lowers risks. Newcomers need hands-on walkthroughs, not just printed protocols. Technology helps too: Automated inventory and IoT sensors spot problems, like temp spikes, before they grow. Facilities that keep education ongoing and reporting easy show fewer accidents over time. By building a culture of active care, workplaces turn something as mundane as storing tetrahydro pyrrole into another point of pride—and avoid the nightmare stories you hear all too often.

Tetrahydro pyrrole shows up as a clear, colorless liquid, which most folks won’t notice unless they’re working in a chemistry lab. It has a faintly fishy smell—unpleasant to some but memorable if you’ve ever uncapped a bottle of this stuff. On the surface, it doesn’t seem all that interesting: no flash of color, no unusual texture, just a plain liquid sitting quietly in a flask.

The boiling point puts tetrahydro pyrrole just above regular water, landing at about 131°C. That means it will vaporize on a hot plate in a laboratory much more quickly than many common solvents. Meanwhile, the melting point hovers around -62°C. This keeps the substance liquid under pretty cold conditions, giving people who work with it more flexibility and fewer worries about it freezing in normal storage.

Density sits close to 0.866 grams per cubic centimeter at room temperature. Lighter than water, it floats if the two ever meet in the same container. I’ve seen this play out myself during basic solvent separation, and the way it forms distinct layers tells a lot about its non-polar character.

This liquid dissolves well in most organic solvents—think ether, acetone, or benzene. But it also mixes with water, which makes it unusual among many nitrogen-containing rings. That means it can cross into a few more chemical territories, from aqueous reactions to organic syntheses.

This property matters for pharmaceutical researchers. They often need solubility in both water and organic settings to get a new drug to behave or to carry a certain reaction forward. Tetrahydro pyrrole’s amphiphilic nature gives it a wider set of uses, making it a handy building block for more complex compounds.

Tetrahydro pyrrole, sometimes called pyrrolidine, is reactive. Left exposed to air, it can absorb carbon dioxide and water. If stored in poorly sealed containers, you’ll end up with a messier sample after a few weeks. I’ve learned through lab mistakes that even a short lapse in proper sealing changes the quality, impacting purity for sensitive reactions.

This property carries direct implications for chemical safety and reliability. Exposure to air speeds up the formation of impurities, especially when planning to use it in medical or chemical manufacturing. This is one of those cases where careful handling truly pays off. In busy academic settings or industry labs, proper storage keeps both workers and research data safe from unnecessary headaches.

For anyone dealing with tetrahydro pyrrole, the main solutions come down to two things. First, always use airtight containers—preferably glass with tight seals—and store them away from heat and direct sun. Second, keep the handling areas well-ventilated. Even though it isn’t highly toxic, strong smells and reactive vapors don’t help anybody’s workflow or health.

Better labeling on storage bottles helps too. The simple ritual of double-checking lid closures, combined with the occasional test for purity, can save labs from unnecessary costs and ruined batches. Having worked with both big companies and university labs, I’ve seen firsthand how these small attentions to detail shape safety and success rates in R&D work.

Tetrahydro pyrrole’s physical properties—low boiling and melting points, moderate density, strong solubility in both water and organics, and a tendency to react with air—build its reputation as both useful and tricky. It doesn’t call much attention to itself, but people who work with it day in and day out tend to respect this seemingly simple liquid for the flexibility and risks it brings into the lab.

| Names | |

| Preferred IUPAC name | pyrrolidine |

| Other names |

Pyrrolidine Azolidine Tetrahydropyrrole 1-Azacyclopentane |

| Pronunciation | /ˌtɛtrəˈhaɪdrəʊ pɪˈroʊl/ |

| Identifiers | |

| CAS Number | 123-75-1 |

| 3D model (JSmol) | `3D model (JSmol)` **string** for Tetrahydro Pyrrole (also known as Pyrrolidine): ``` C1CCNC1 ``` |

| Beilstein Reference | 63868 |

| ChEBI | CHEBI:35550 |

| ChEMBL | CHEMBL1231609 |

| ChemSpider | 12390 |

| DrugBank | DB04620 |

| ECHA InfoCard | ECHA InfoCard: 100.003.599 |

| EC Number | 210-484-7 |

| Gmelin Reference | 61779 |

| KEGG | C05953 |

| MeSH | D017670 |

| PubChem CID | 8064 |

| RTECS number | WQ6650000 |

| UNII | 5SV9E1X8N6 |

| UN number | UN1993 |

| CompTox Dashboard (EPA) | DB11299 |

| Properties | |

| Chemical formula | C4H9N |

| Molar mass | 71.12 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | amine-like |

| Density | 0.867 g/mL at 25 °C(lit.) |

| Solubility in water | Miscible |

| log P | -0.46 |

| Vapor pressure | 2.9 mmHg (25°C) |

| Acidity (pKa) | 11.3 |

| Basicity (pKb) | 8.86 |

| Magnetic susceptibility (χ) | -37.7×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.448 |

| Viscosity | 0.871 mPa·s |

| Dipole moment | 2.29 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 274.9 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -86.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3335 kJ/mol |

| Pharmacology | |

| ATC code | N05BC04 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02, GHS07 |

| Signal word | Danger |

| Hazard statements | H226, H302, H314, H411 |

| Precautionary statements | P261, P280, P304+P340, P305+P351+P338, P312 |

| NFPA 704 (fire diamond) | 2-3-0 |

| Flash point | -5 °C |

| Autoignition temperature | 280 °C |

| Explosive limits | 1.5–9.5% |

| Lethal dose or concentration | LD50 oral rat 3000 mg/kg |

| LD50 (median dose) | LD50: 680 mg/kg (rat, oral) |

| NIOSH | RN202 |

| PEL (Permissible) | PEL: 2 ppm |

| REL (Recommended) | 273 K |

| IDLH (Immediate danger) | 1000 ppm |

| Related compounds | |

| Related compounds |

Pyrrole 2-Pyrrolidone Pyrrolidine N-Methylpyrrolidone Proline |