Chemists looking for building blocks that streamline synthesis often come across intermediates like Tert-Butyl Piperazine-1-Carboxylate. This compound started gaining attention in the mid-late 20th century as pharmaceutical and agrochemical research took off, demanding reliable protective groups that keep piperazine rings from unwanted side reactions. Back then, basic protection groups like the Boc group—tert-butoxycarbonyl—delivered a real shift in how labs handled complicated syntheses. You can see its spread from small academic syntheses to large commercial labs as catalogs expanded and more efficient ways to make and use it came along. Its role as a staple for process optimization reflects the drive for speed, purity, and reproducibility that motivated much of modern organic chemistry’s progress.

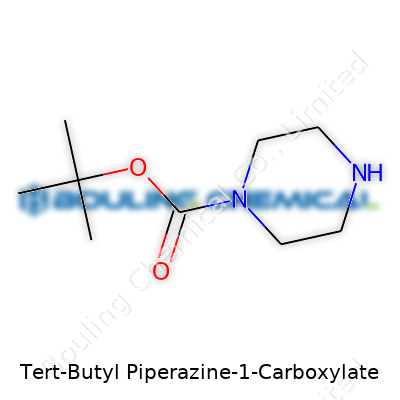

Tert-Butyl Piperazine-1-Carboxylate carries a reputation as a trusted protected amine. Its chemical structure has two nitrogens in a six-membered piperazine ring with one nitrogen carrying the Boc protective group. This design might look routine, but it means a lot for drug development and fine chemicals production, especially when chemists need to mask amines and reveal them in later steps. The substance comes as a white crystalline powder, handled in labs and manufacturing sites across continents. Availability isn’t limited to any one region—scores of chemical suppliers and catalogues keep it stocked because demand never seems to slow, especially as new piperazine-based drugs move through the research pipeline.

You’ll find Tert-Butyl Piperazine-1-Carboxylate listed with a molecular formula of C9H18N2O2, a melting point generally near 120-125°C, and low solubility in water. Yet, dissolve it in most organic solvents and it responds well—its neutral, crystalline nature fits with many extraction and purification steps. The Boc group’s bulkiness lends some hydrophobicity and makes it easy to separate from unprotected piperazine. Color, consistency, and odor can flag sample purity, so solid samples ought to stay white and free from smell. Decomposition shows up at higher temperatures, especially if exposed too long to the air, so those storing larger batches keep it sealed and dry.

Specifications in commerce usually demand high-purity samples, above 98%, and controlled moisture below 0.5%. Batch certificates, especially for regulated sectors like pharmacy, include detailed NMR, HPLC, and mass spec data. Containers have hazard codes—because of mild irritation risks, labels include GHS information, storage instruction, and lot numbers for traceability. The chemical is offered in small milligram vials for initial research as well as kilogram drums for industrial users. Tracking origin and batch date helps when regulatory reviews need proof of supply chain transparency.

Making Tert-Butyl Piperazine-1-Carboxylate takes two main starting materials: piperazine and di-tert-butyl dicarbonate, widely called Boc anhydride. Most syntheses use an organic base—commonly triethylamine or sodium bicarbonate. The reaction takes place in aprotic solvents like dichloromethane or acetonitrile, keeping the temperature cool to avoid side reactions. After letting the mixture stir a few hours, chemists wash the product, dry it, and strip off the solvent. Crystallization in ether or hexane then pulls out the finished compound. That’s a classic approach in medicinal chemistry labs, though process engineers in bulk plants tweak solvents and ratios to drive throughput, keep costs down, and limit environmental impact.

Most chemists purchase this compound as an intermediate for further chemical work. The Boc group comes off when exposed to acids like trifluoroacetic acid or hydrochloric acid under room temperature, making it a handy tool for multiphase syntheses where amine reactivity gets controlled stepwise. Functional groups on the other nitrogen give room for new linkages or side chains—borrowing from my lab experience, coupling these sites with peptide chains or aryl groups lets researchers build up complexity without losing the original scaffold. You see it featured in a slew of patents, ranging from antivirals to enzyme inhibitors, always as a way to safeguard sensitive functions until the right reaction stage.

Industry catalogues and scientific databases list many names for this substance: N-Boc-piperazine, 1-Boc-piperazine, Piperazine, 1-(tert-butoxycarbonyl)-, and tert-Butyl 1-piperazinecarboxylate. Each name points to the same structure but pops up depending on the context—some lab techs go by the IUPAC version, while folks in pharma research use the shorthand like “Boc-piperazine.” When tracking inventory for regulatory compliance or GMP audited processes, sticking to consistent naming standards prevents costly mistakes and repeat testing.

While not an acutely toxic material, Tert-Butyl Piperazine-1-Carboxylate can irritate skin, eyes, and mucous membranes. People working with it daily rely on gloves, dust masks, and goggles. Proper ventilation is key—especially on larger scales where dust or vapors get stirred up. Spill kits and clear material safety data sheets (MSDS) support safe handling. In the rare case of contact ingestion or spillage, immediate rinsing is critical. Chemical hygiene plans in research and production outline step-by-step protocols, including responsible disposal of wash solvents and solid residues—many of which get sent to chemical waste contractors that meet local environmental laws.

Few molecules find their way into as many pharmaceutical research projects as Tert-Butyl Piperazine-1-Carboxylate. Its biggest impact shows up in early-stage drug synthesis, allowing R&D teams to store building blocks before the need to expose precious amines. Beyond medications, it’s also valued in crop protection compound development, custom syntheses for specialty chemicals, and advanced materials where piperazine motifs pop up. For anyone investing resources into structure-activity relationship (SAR) studies or working through multi-step syntheses, it’s tough to overlook the value this intermediate brings to the bench.

Research teams in academia and industry keep improving how efficiently they deploy tert-butyl piperazine-1-carboxylate. Some groups chase faster coupling reactions or lower waste solvent output, pressed by sustainability goals in green chemistry. Improved purification, scale-up strategies, and safer handling protocols matter more as demand grows. Synthesis articles and patents describe tweaks that improve yields, control impurity profiles, or integrate continuous flow methods. A few projects even use machine learning to model reaction conditions and cut down trial-and-error runs. As the push for personalized medicine and next-generation agrochemicals expands, this protected piperazine finds itself attached to new targets in computational design and combinatorial chemistry.

Boc-protected piperazines don’t pose dramatic acute toxicity, but most studies err on the side of caution, keeping focus on chronic exposure. Animal studies show mild irritation or reversible effects with standard exposures, and researchers track metabolite breakdown products for unwanted bioactivity. The main concern for labs and manufacturing worksites isn’t carcinogenicity or mutagenicity, but rather preventing inhalation and splashing into eyes. Good ventilation, regular health surveillance, and chemical waste containment remain practical approaches, especially on industrial lines where quantities handled spike well above bench-scale work.

Chemical building blocks like Tert-Butyl Piperazine-1-Carboxylate keep seeing steady demand as pharmaceutical pipelines shift to more complex, multifunctional molecules. Green chemistry researchers look for ways to trim waste and streamline large-scale syntheses, making new process tweaks around solvent recycling and catalyst reuse. Machine learning models keep helping predict protective group behavior, possibly unlocking new protecting groups with more selective activation or easier removal. As chemical regulation tightens in major economies, supply chain visibility and batch validation still matter. The compound’s versatility in structure-based drug design, plus new uses in specialty materials and catalysis, suggest it won’t fall out of favor soon.

Tert-Butyl Piperazine-1-Carboxylate sounds like a mouthful, but in practice, it’s a building block that keeps the pharmaceutical engine running. Walk through any drug lab, you’ll find bottles of this powder tucked away near other specialty reagents, ready to play a part in making complex medicines. Chemists rely on this compound for what’s called a “protecting group.” It guards sensitive parts of a molecule while other changes take place, like a glove shielding fingers when handling rough work. Afterward, the glove comes off, leaving the important parts intact. This protects the piperazine ring—a structure that shows up in anti-cancer agents, psychiatric medications, and anti-parasitic drugs.

People spend years in labs searching for molecules that fight diseases in clever ways, but the process isn’t a straight shot. Side reactions spoil promising pathways. Tert-Butyl Piperazine-1-Carboxylate gives chemists a way to control reactivity, which helps save time, money, and reduces chemical waste. That kind of reliability shapes real progress in drug pipelines. Companies like Pfizer, Novartis, and Roche lean on compounds like this one as they chase more effective and safer medicines. Every extra hour shaved off the discovery process lowers costs, which makes treatments more accessible after approval.

Decades back, new drug development crawled at a slow pace, with major breakthroughs arriving every few years. Chemistry now moves faster, and widely available lab tools make the difference. Useful reagents such as Tert-Butyl Piperazine-1-Carboxylate help bring pharmaceutical projects from research benches to pharmacy shelves. From personal experience working with biotech startups, I know cash flow only stretches so far. Every shortcut that speeds synthesis without sacrificing purity means researchers can focus on the next experiment.

Safe handling always matters. Because of its chemical reactivity, those working with Tert-Butyl Piperazine-1-Carboxylate need solid training, the right gloves, and reliable fume hoods. Shortcuts on safety can harm careers and health. Over the past few years, online suppliers popped up promising cheap access. Without solid supply-chains and transparency, counterfeit chemicals put entire research projects at risk. Labs that verify sources—through trusted vendors with certification—seriously reduce the risk of setbacks.

Chemistry evolves, and so do the ways we use building blocks like this one. As automation and digital record-keeping improve, the workflow for making new drugs should get safer, cleaner, and faster. Investing in education for lab technicians and students ensures that proper technique and respect for potent chemicals stays front and center. Governments and research institutions do their part by funding programs that track and monitor the distribution of these reagents.

People often overlook the unsung chemicals that enable discoveries behind the scenes. Tert-Butyl Piperazine-1-Carboxylate gives scientists tools to create treatments that improve lives. Reliable supply chains, strong training, and trust in materials form the foundation for the next wave of medicine. This is why small molecules, managed right, mean big progress for public health.

Tert-Butyl piperazine-1-carboxylate isn’t just a mouthful. Chemists and researchers work with it for particular reasons. Its chemical formula reads as C9H18N2O2. That’s not just a bunch of numbers and letters thrown together. Every atom in this formula means something for the way this molecule behaves and why people care about it.

Breaking the name down unlocks some clues. The piperazine ring forms the backbone, which holds two nitrogen atoms opposite each other. Some may picture the tert-butyl group as a bulky extra piece attached to the ring—offering the molecule a certain “protection." That bulky group shapes how the molecule reacts with other chemicals.

Looking up reputable sources like PubChem, scientific journals, or trusted chemical supply catalogs brings up this same molecular formula. This adds weight to its credibility. Chemical information needs to come from strong documentation—especially in research, medical, or chemical supply fields, where accuracy prevents costly mistakes.

Many see this compound in the world of drug synthesis. Protecting groups are essential tools in organic chemistry, and tert-butyl piperazine-1-carboxylate fits the bill. The tert-butyl group shields the nitrogen until it’s time to reveal it later. That makes the compound handy in complex reaction chains. Certain pharmaceuticals call for a step where piperazine must be protected and then revealed so other molecules can be added at the right point.

Research teams working on new treatments or chemical modifications want predictable, reproducible results. With C9H18N2O2, they know the atoms line up the way they expect. Products that reach the market—such as potential cancer drugs or central nervous system agents—often start with building blocks like this one.

Getting the formula right isn’t just academic. Mistakes can drive up costs, lead to wasted materials, or create safety issues. In the lab, I’ve seen how mixing up compounds can throw off experiments, break research timelines, or even force entire projects to start over. Chemical suppliers feel pressure to get their documentation right because one small error can ripple through an entire supply chain.

Researchers depend on reliable chemical data. Regulatory standards in the United States, Europe, and Asia all stress documentation. Anyone reading a bottle or certificate wants confidence that C9H18N2O2 points to the correct molecule. Consistency in naming and formula helps protect intellectual property, delivers safety, and ensures raw materials behave as expected.

Precision leads to innovation and safety. If everyone working with tert-butyl piperazine-1-carboxylate references the correct formula, development speeds up, errors drop, and new products hit the market faster. Communicating chemical information in plain terms helps students, researchers, and professionals avoid costly errors.

Overall, getting the chemical formula right for tert-butyl piperazine-1-carboxylate—C9H18N2O2—matters for research, industry, and the future of new medical discoveries. Keeping chemical details accurate ensures scientific progress does not stall or slip up at the smallest hurdle.

Some chemicals sound intimidating, but they’re just compounds with clear routines. Tert-Butyl Piperazine-1-Carboxylate isn’t an everyday term outside of chemistry circles, but its safe handling matters anywhere it shows up, from academic labs to industry. Mistakes with chemicals rarely forgive, so relying on hope or memory is not enough. The chemical structure tells us part of the story—tert-butyl groups bring some bulk, the piperazine ring builds stability, and the carbamate formation offers a level of protection. Still, the right storage decides how safe and usable the material stays.

Nothing degrades a chemical’s quality like moisture. Tert-Butyl Piperazine-1-Carboxylate breaks down when humid air finds its way in. Small amounts of water spark side reactions, creating byproducts nobody invited. Desiccators packed with dry silica gel work well for personal stocks. In bigger spaces, a climate-controlled dry room makes sense. Drier conditions mean fewer ruined samples and a lower risk of artifacts in critical experiments.

Heat shortens shelf life and speeds up reactions. Many labs hold to the practice of storing heat-sensitive materials below room temperature. This one stays stable in sealed bottles in a 2-8°C refrigerator. Overheated storerooms or benchtop piles lead to faster decomposition. Sunlight doesn’t help either—UV rays scramble stable bonds and make fresh batches useless far sooner. Amber bottles and metal canisters both add an extra shield against light, keeping things consistent batch after batch.

Cross-contamination causes more headaches than most admit. Sharing scoops or spatulas between reagents—especially with sticky powders like this one—leads to batch failures. I always label utensils and dedicate them to specific chemicals. If you ever climbed into a storeroom and saw pools of spilled reagents mixing, you know the frustration it brings. Clean workspace, clear labeling, and keeping containers tightly sealed means the next person finds what they expect, not a chemistry project gone wrong.

The tert-butyl group lifts the flashpoint, but that shouldn't spark complacency. Many organics catch fire given the right push. Store this compound away from open flames, heat sources, or reactive acids and bases. Experience teaches that once a fire starts, cleanup turns into paperwork and lost time, not just charred jars. Good fume hood habits mean less exposure to accidental vapors, besides controlling dust in the air. Fire-rated cabinets with chemical-resistant liners handle long-term storage better than old wood cupboards.

Accidents still happen. I keep spill kits right around the chemical bench—absorbent pads, neutralizers, and a working eyewash station. Safety data sheets hang where anyone can grab them. Training new lab users on these basics never wastes time. Regular checks for degraded containers and expired material let everyone work without guesswork. No one wants an emergency, but real readiness keeps small mistakes from turning into hospital trips.

Tert-Butyl Piperazine-1-Carboxylate brings value to labs when given the right respect. Moisture-free, cool, dark, and clean storage make the biggest difference. Every lab member plays a part in making safety routine. Years in the lab taught me that small habits allow us to focus on research, not crisis control. The right habits protect health, wallets, and the work we care about.

Working with fine chemicals like Tert-Butyl Piperazine-1-Carboxylate means more than just handling powders or pouring clear liquids. It pulls you into a world where a little carelessness could lead to skin burns, eye damage, or worse. My own hands got nicked once by a cracked flask, and a few drops reminded me real fast that safety isn’t an abstract idea; it’s today’s to-do list. No one forgets the sting of chemical exposure.

Late nights or quick experiments tempt scientists to skip basic personal protective gear, especially gloves and goggles. Tert-Butyl Piperazine-1-Carboxylate often arrives as a solid, sometimes as a solution, and either form can irritate skin and eyes. The push against contact comes straight from its chemical reactivity. I’ve seen senior chemists reach for goggles after a splash, not before — it’s always regret, not foresight. Thin latex gloves work for short work, but longer projects call for thicker nitrile. Eyes need sealed protection, since chemical splashes rarely knock first.

Many labs run ventilation hoods for show but forget regular checks. This chemical gives off vapors that irritate the respiratory tract. Breathing trouble slowly sneaks up and can take hours to fade. Small consultancies use open windows and box fans, but that doesn’t stop fumes for neighboring desks. Maintaining certified fume hoods and actually sealing bottles after each use makes a massive difference.

I’ve seen mystery jars on shelves, labels faded or missing, and no one wants to open them. Tert-Butyl Piperazine-1-Carboxylate keeps best in tight, labeled containers, away from acids, strong bases, or oxidizers. Chemical regulators and experienced lab techs both push properly labeled storage for a reason. The wrong whiff or accidental mixing leads to toxic gas or uncontrollable reactions. Tossing leftovers or disposing of them the same day sounds wasteful, but it’s less risky compared to gambling with forgotten vials.

Sweeping floors and wiping benches seems like grunt work, until fine powders reappear on your keyboard or coffee mug. Tert-Butyl Piperazine-1-Carboxylate clings to gloves and sleeves, so it spreads easily. Regular cleaning—soap, water, a bit of elbow grease—keeps it from turning up in your lunch or, worse, getting spread by new trainees. Training sessions do help, but people look out for each other most effectively by keeping the group routine strict and everyday surfaces clean.

Even experienced chemists get splashed, drop bottles, or mix up containers. Quick access to an eyewash station, emergency shower, and spill kits proves its value at the worst possible moment. Practicing the route and running drills with new hires brings speed in a real emergency. I’ve seen someone freeze up, seconds tick away, and the delay cost them days in recovery. Knowing what to do before a disaster means recovery, not regret.

Regulations and training set the standard, but group culture locks it in. I’ve worked in labs with excellent manuals and watched corners get cut because “nothing ever happens here.” It’s only after an incident that rules turn into habits. Tert-Butyl Piperazine-1-Carboxylate doesn’t care if you’re new or seasoned. Daily reminders, frequent checks, and calling out skipped steps protect everyone involved.

Choosing the right purity for any chemical often feels a bit like picking produce at a market. You want the best for your recipe, and sometimes “good enough” doesn’t cut it. Tert-Butyl Piperazine-1-Carboxylate lands right in that territory, especially in settings like pharmaceutical labs or research centers. The purity of this compound impacts everything from how reactions proceed, to the reliability of your data, to the safety and stability of the final product you’re pushing forward.

Ask around a chemistry department and you’ll find that tert-butyl piperazine-1-carboxylate usually comes in several grades. Pharmaceutical grade is what I’d want if the stakes rose beyond the research bench, since anything heading toward clinical trials or drug development needs to meet strict regulations. People working in early-stage R&D often settle for laboratory or technical grade, especially if budget limits come into play. In my experience, rolling with a technical grade for a pilot test only makes sense if side reactions, color, or residue aren’t going to throw off the final measure.

Manufacturers often disclose purity levels on certificates of analysis, with numbers like 98%, 99%, or even 99.5% staring back at you. That 1.5% gap sounds minor until you spot trace contaminants either setting off a chain of unexpected reactions or gumming up your purification steps. Lower purities sometimes don’t just mean a bit more “stuff”; they risk introducing water, residual solvents, metal ions, or leftover byproducts from synthesis. In regulated industries, something as small as a 0.2% unknown might spark a compliance review, or even a hold on production.

Some folks aiming for med-chem breakthroughs or sensitive material synthesis ask for “ultra-high” or “analytical” grade. I’ve seen this drive costs up pretty fast, and storage headaches can follow, since ultra-pure materials pick up moisture or degrade quicker if handled carelessly. Still, if you’re tracking yield with surgical precision, there’s often no way around paying for that extra decimal of purity. HPLC or GC data usually back up those purity claims, but asking suppliers for those reports remains part of due diligence.

People spend a lot of time chasing discounts and deals, yet the real cost often creeps in unseen when an experiment fails or gets delayed. I’ve learned over several projects that investing a few extra dollars on certified or higher purity material pays back in reliability. Asking suppliers about their purification steps, or even visiting their facilities, goes a long way in establishing trust. Reliable suppliers understand that some batches need extra care—sometimes running a compound through one more chromatography column makes the difference.

I’ve run into batches that fit the supplier’s technical specs, but performed well below expectations in synthesis. Checking a real, full certificate of analysis—looking for information about heavy metals, water content, or residual solvents—has saved me more than once from costly restarts. Even if a supplier claims 99% purity, what’s in that last 1% makes all the difference for both reproducibility and regulatory review. In my view, buying cheap or skipping the checks only serves to complicate things down the road.

Picking the right purity grade helps keep projects on schedule, lab teams safe, and end users protected. It’s a choice that deserves real thought, every single time.

| Names | |

| Preferred IUPAC name | tert-Butyl piperazine-1-carboxylate |

| Other names |

tert-Butyl 1-piperazinecarboxylate Boc-piperazine 1-Boc-piperazine 1-(tert-Butoxycarbonyl)piperazine |

| Pronunciation | /ˈtɜːtˈbjuːtɪl paɪpəˈreɪziːn wʌn kɑːbɒksɪleɪt/ |

| Identifiers | |

| CAS Number | 57260-71-6 |

| 3D model (JSmol) | `3D model (JSmol)` string for **Tert-Butyl Piperazine-1-Carboxylate**: ``` CC(C)(C)OC(=O)N1CCNCC1 ``` |

| Beilstein Reference | 1709904 |

| ChEBI | CHEBI:148842 |

| ChEMBL | CHEMBL4184271 |

| ChemSpider | 21737317 |

| DrugBank | DB08308 |

| ECHA InfoCard | 03b3886d-9027-4898-bf6f-2740f202c813 |

| Gmelin Reference | 1469204 |

| KEGG | C14106 |

| MeSH | Carbamates |

| PubChem CID | 125267 |

| RTECS number | XT3157000 |

| UNII | LQN5KVN0R6 |

| UN number | UN3439 |

| Properties | |

| Chemical formula | C9H18N2O2 |

| Molar mass | 202.28 g/mol |

| Appearance | White to off-white solid |

| Odor | Odorless |

| Density | 1.05 g/cm3 |

| Solubility in water | Insoluble |

| log P | 0.63 |

| Vapor pressure | 1.7E-2 mmHg (25°C) |

| Acidity (pKa) | 14.6 |

| Basicity (pKb) | 3.83 |

| Refractive index (nD) | 1.453 |

| Dipole moment | 4.53 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 222.1 J·mol⁻¹·K⁻¹ |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes serious eye irritation. May cause respiratory irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07, GHS08 |

| Signal word | Warning |

| Hazard statements | H302, H319, H335 |

| Precautionary statements | P261, P305+P351+P338 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | 104.8 °C |

| LD50 (median dose) | LD50 (median dose) of Tert-Butyl Piperazine-1-Carboxylate: "LD50 (oral, rat) > 5000 mg/kg |

| NIOSH | RN875-44-7 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 500 mg |

| IDLH (Immediate danger) | Not established |

| Related compounds | |

| Related compounds |

Piperazine 1-Boc-piperazine N-Boc-piperazine Piperazine-1-carboxylic acid Tert-Butyl carbamate 4-Methylpiperazine N-Methylpiperazine |