Piperazine-1,4-diethanol traces its roots back to an era shaped by the search for efficient and flexible organic compounds. Chemists have experimented with piperazine derivatives for over a century, drawn by the structure’s potential in everything from crop protection to medicine. The move toward diethanol substitution grew from an interest in enhancing water solubility and providing more options for modifying the core piperazine structure. Early academic research in the mid-20th century often focused on basic physical properties, sometimes highlighting challenges in purification or consistency, but persistent work led to scalable processes. Over time, industrial players started rolling out production, giving researchers a new toolkit that reached into pharmaceuticals, manufacturing, and analytical chemistry. Piperazine-1,4-diethanol became more than a laboratory oddity—it turned into an anchor for several industries.

You can hold a bottle of piperazine-1,4-diethanol up to the light and see a clear, almost syrupy liquid, but what sits in that bottle helps power a surprising range of applications. The presence of two ethanol groups on either end of the piperazine ring means it can participate in reactions or serve as a building block for molecules crossing over into drug design or specialty coatings. I’ve seen plant operators handle drums of it with respect, always aware of its place in the broader toolkit of amine derivatives. Companies buy it in bulk to get the benefits of its unique structure, combining flexibility and reactivity in a way few other chemicals manage.

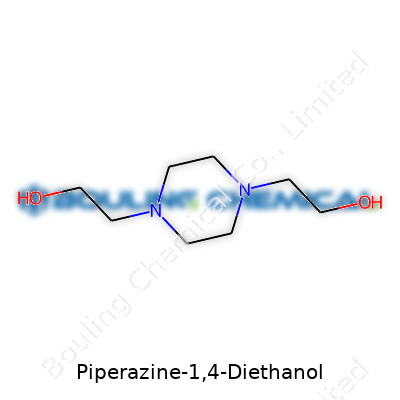

Piperazine-1,4-diethanol comes as a hygroscopic liquid at room temperature, with boiling points sitting high enough that you won’t see much evaporation during normal handling. Its density tips past that of water, and it slips easily into solution with most polar solvents. The two hydroxyethyl groups add some heft, bringing the molecular weight up, but they also help drive reactivity. With each hydroxy group sitting on opposite sides of the piperazine ring, the molecule remains symmetrical, which simplifies predicted reaction pathways but delivers complexity in downstream chemistry. In a laboratory, you always watch for water pickup—this compound pulls moisture out of the air, and those handling it should keep bottles tightly sealed.

Most companies that supply piperazine-1,4-diethanol provide it in high-purity form, often over 98%, along with batch-specific certificates of analysis. Packaging information remains critical—wrong labeling can trigger regulatory headaches or operational mistakes, which nobody wants. Labels must spell out hazards and offer guidance on storage, with clear information about shelf life and purity. In my experience, shipments include safety data sheets upfront, and those are checked and rechecked by receiving teams before a drum makes it into storage. All technical specs aim for clarity, and regulators want to see traceability at every stage of handling.

Industry often turns to direct alkylation of piperazine using ethylene oxide or ethylene chlorohydrin, reacting under controlled conditions to avoid side products. Operators prefer continuous reactors to batch systems, since this ensures even distribution of heat and reactants—scaling up always exposes any quirks in mixing or side reactions. Post-reaction, the mixture undergoes vacuum distillation or crystallization to remove unreacted starting materials. Quality checks at this point catch off-odors and color changes; any deviation signals potential downstream reactivity issues. Plants invest a lot in containment and scrubbers, especially since ethylene oxide remains a notorious risk for exposure. From my time in pilot plants, minimizing contamination and controlling pressure are the two most common stress points.

Piperazine-1,4-diethanol opens doors to a whole family of reaction possibilities. Each ethanol group can undergo esterification, oxidation, or serve as a tether for linking the piperazine ring to polymers or pharmacophores. Chemists often use it to branch larger, more complicated molecules—acting as a bridge between two functional units. The piperazine ring itself can accept further substitutions without much fuss, and the compound has played a role in producing specialty surfactants as well as anti-parasitic agents. In the lab, each reaction tells its own story: some run smooth with little color change, others bubble and demand constant monitoring. At scale, managing reaction intermediates safely becomes just as important as optimizing yield.

Walk through any chemical catalog, and you might spot piperazine-1,4-diethanol under several aliases. Names include 1,4-Bis(2-hydroxyethyl)piperazine, Diethanolpiperazine, or in some older references, just its molecular shorthand. The IUPAC naming system spells everything out, but most purchasing agents and warehouse teams stick with the shortest, most familiar tag to avoid confusion. Mislabeling or misidentification doesn’t just result in paperwork headaches—it can lead to safety lapses or chemical incompatibility on the shop floor.

Piperazine-1,4-diethanol sits on several safety radars. It isn’t as dangerous as some amine derivatives, but direct contact still deserves respect. Skin and eye contact cause irritation; inhalation of mists can bring on headaches or respiratory discomfort. Responsible shops supply gloves, goggles, and, in poorly ventilated labs, even respirators. Regulatory standards set out exposure limits, and most large plants monitor air quality so nobody risks long-term health effects. Spill kits and emergency showers stand ready near storage rooms. Training doesn’t stop at orientation—shops run yearly drills so nobody forgets protocols. Over the years, I’ve seen how adopting a culture of caution saves people from repeatable, preventable incidents.

Pharmaceutical labs prize piperazine-1,4-diethanol for its dual functionality, bringing both stability and reactivity to drug design. Its structure helps produce antihistamines, locally acting anesthetics, and even some antipsychotic compounds. Beyond the pill bottle, specialty coatings manufacturers lean on its chemical backbone to deliver tough, flexible films that shrug off moisture and chemical attack. You’ll find it woven into textiles, too, as part of crosslinking formulations for finishes. Crop scientists put it to work in specialty herbicides and pesticides, tapping into its ability to anchor active ingredients. Each application taps a different side of the molecule—solubility for one, amine reactivity for another.

Molecular innovation never slows in the world of piperazine-1,4-diethanol. Academic groups investigate it as a scaffold for designing new enzyme inhibitors or anti-cancer leads, layering on functional groups in an effort to tweak biological affinity. Industrial teams push for cleaner, greener production—reducing energy use, cutting waste, and moving away from legacy solvents. Multi-step synthesis challenges chemists to squeeze every bit of value from a precursor, and I’ve watched teams iterate dozens of formulations before settling on the right balance. Research isn’t just about end-use products; it’s also about finding safer, more efficient processes and pushing beyond current performance limitations.

Toxicologists have spent years mapping out risks from piperazine-1,4-diethanol. Acute exposure testing shows limited but real irritation potential, especially for eyes and mucous membranes. In repeated-dose animal studies, moderate liver effects showed up, especially at high exposure levels. Researchers work to better understand metabolic pathways, looking for any problematic breakdown products that could pose environmental or occupational risks. Chronic risk appears low under normal use, but manufacturers have learned not to take anything for granted; risk assessments get updated with every new finding. Many safety teams use this data to design better containment systems, monitor wastewater, and train staff to treat the compound with the right amount of respect.

The future of piperazine-1,4-diethanol depends on innovation—a mix of regulatory pressure, business need, and scientific curiosity. Markets demand safer, higher-performing materials; research teams keep searching for ways to use the molecule in green chemistry and high-value medical applications. I expect advances in bio-based synthesis to offer sustainable supply routes, reducing dependence on petrochemical feedstocks. Pharmaceutical developers will likely find new therapeutic targets where the dual alcohol-amine structure gives an edge. As environmental scrutiny rises, attention to lifecycle and downstream metabolites becomes just as important as price or ease of synthesis. Teams that treat every batch, every shipment, as a chance to do better—those are the groups shaping what comes next for this ever-adaptable molecule.

Few people outside of science circles talk about Piperazine-1,4-Diethanol, but this chemical shapes more of daily life than most realize. Chemists call it a “building block.” Most consumers never notice the impact, but manufacturers depend on it to keep their systems running smoothly and products safe.

Piperazine-1,4-Diethanol earns its keep inside factories and labs for one key reason: versatility. It acts as a chemical helper, letting manufacturers create finished products that would be tough or nearly impossible without it. Think epoxy resin hardeners or specialty coatings. Tough, durable plastics and adhesives come alive during the curing stage because of molecules like Piperazine-1,4-Diethanol. Its structure lets other components connect, set, and perform under stress.

In my years researching chemicals and materials science, I saw firsthand how it appears on chemicals lists for corrosion inhibitors too. Pipelines and boilers carry water, and untreated water isn’t kind to steel. Piperazine-1,4-Diethanol finds its way into corrosion inhibitor blends for industrial systems, pulling double duty: keeping metal safe and preventing system failures from rust. Efficiency in heavy machinery and large-scale water treatment plants depends on formulas that quietly include this compound.

The drug industry uses it as well. Not as a medicine directly, but as part of processes that create active pharmaceutical ingredients. Creating drugs isn’t something most people associate with odd-named chemicals or raw materials. During scale-up from laboratory batches to full production, Piperazine-1,4-Diethanol sometimes gets involved as a reagent. The exact details sit behind trade secrets, but chemical companies recognize its importance for efficient synthesis. Shorter process times or better yields often mean patients get access to treatments faster — that matters when timelines stretch on for months or years during drug development.

There’s always another side to reliance on chemicals. Proper handling and safety measures, both at the plant and downstream, protect workers and communities. Research shows Piperazine-based substances need careful oversight to limit exposure. Managers I’ve worked with train teams and invest in monitoring to keep levels safe. Waste from chemical production carries risks, so facilities use waste management strategies that limit the impact on local ecosystems.

Environmental regulations aren’t just rules on paper — they reflect lessons learned when companies missed the mark. Responsible manufacturers look beyond compliance. By adopting green chemistry and new synthesis routes, some groups now lower their environmental footprint. These changes don’t always come easily, but community pressure and global sustainability efforts push the industry forward.

Some researchers chase better replacement molecules with less toxicity and more biodegradable profiles. The real world isn’t quick to change. Factories need reliable supply chains, and reformulating entire product lines takes serious investment. Sharing data and lessons learned with academic groups and across the industry makes a difference. By focusing on both performance and societal impact, the chemical field adapts. I’ve seen innovation come not just from big corporations, but also from small research groups determined to improve safety.

Behind every finished car, water-treated building, or durable tool, there’s usually a chain of unsung chemicals like Piperazine-1,4-Diethanol. Awareness grows as more groups push for safe practices and lower emissions. My experience tells me that smart decisions—by both producers and policymakers—start with understanding what every ingredient in the supply chain actually does. Piperazine-1,4-Diethanol stands as a reminder that even low-profile compounds have big stories.

Piperazine-1,4-diethanol carries the chemical formula C8H18N2O2. This combination means there are eight carbons, eighteen hydrogens, two nitrogens, and two oxygens in a single unit. The two ethanol groups attach to the piperazine ring, and the structure opens a lot of possibilities in chemical synthesis and industry. Most folks in the lab see this compound as an easy-to-handle, stable substance, and I have noticed it doesn’t bring the unpredictability that comes with some other amines or alcohols.

Learning about a chemical’s formula might seem dry, but knowing the actual atoms inside gives chemists plenty of clues about behavior and safety. In a practical sense, this formula points to molecular weight, solubility, and routes for further modification. Working with C8H18N2O2 in the lab, I've seen firsthand how the two hydroxyl (-OH) groups give it an edge in water solubility. It dissolves far better than plain piperazine or its relatives, making it much easier to handle in solution-based projects. Mix it with water or alcohol, and you get right to work without a lot of fuss.

That same solubility means folks can use it in pharmaceuticals where drug delivery needs a boost. Drug makers rely on predictable behavior, and a known formula with two clear functional groups helps with that. Based on published studies, derivatives of piperazine-1,4-diethanol have shown the ability to act as scaffolds for antipsychotic or antifungal drugs. Rather than looking for exotic molecules, chemists trust these building blocks to create new medicines with less hassle.

Looking at the formula doesn’t just inform what we can build; it signals safety concerns, too. Organic chemists go through gallons of piperazine derivatives, so exposure becomes a real question. The two ethanol arms mean this molecule behaves a lot like both alcohols and amines, so it’s essential to respect gloves and goggles at the bench. According to the European Chemicals Agency, it doesn’t show extreme acute toxicity, but skin and eye irritation do pop up as risks.

People tend to forget that molecular structure also influences environmental risk. The presence of nitrogen atoms in piperazine-1,4-diethanol suggests possible issues if it gets into waterways. Similar piperazine compounds break down slowly, so waste handling matters. Before dumping anything down the drain, labs need to treat or collect leftover material. Simple policies on disposal, like segregating amines and alcohols, go a long way to keep the environment safer.

Teaching chemists to look past names and dig into actual formulas—like C8H18N2O2—helps everyone make better decisions. I’ve seen new researchers only memorize names, missing vital information hiding in the formula. Bringing hands-on workshops focused on interpreting molecular structure, involving real lab work, could bridge the gap.

Sharing clear safety guidelines based on the actual formula also benefits both small labs and big factories. Companies sometimes cut corners, but having routine training and reminder posters about correct disposal and PPE gives everyone a better shot at a safe workplace.

So next time someone asks for a chemical formula, it pays to remember: each letter and number packs plenty of knowledge, guiding safe, smart work with every molecule handled.

Piperazine-1,4-Diethanol, often found in chemical synthesis and water treatment plants, doesn’t stand out like some of the more notorious compounds. Still, it brings a set of risks that deserve attention. Industrial labs rely on this chemical for specific reactions, and plant operators become familiar with its presence quickly. Handling it is less dramatic than dealing with fuming acids or volatile solvents, but that doesn’t mean people can ignore the safety basics.

Anyone who has worked with organic reagents knows a little carelessness increases the odds of trouble. Piperazine-1,4-Diethanol brings both immediate and long-term health risks, mainly through skin and eye contact and inhalation. Spills can go unnoticed because the substance looks unremarkable, but direct contact often leads to irritation or even chemical burns, depending on concentration and exposure length.

A peer once shrugged off minor splashes while preparing a batch, thinking gloves alone would cut it. Later, skin turned red and started burning, showing that it’s not a gamble you want to take. Chemical Safety Data Sheets back up this experience, warning about skin and eye irritation, suggesting the need for goggles and protective clothing. Inhalation sometimes leads to headaches, dizziness, and respiratory discomfort. It’s important to understand that vapors and dried residues remain hazardous, especially in warm, poorly ventilated spaces.

Regulators don’t flag Piperazine-1,4-Diethanol as acutely toxic or highly flammable, but they make clear recommendations for personal protective equipment and proper ventilation. The Occupational Safety and Health Administration places emphasis on handwashing and eye rinsing protocols. The European Chemicals Agency records suggest limiting repeated exposure, classifying it as an irritant and warning against careless disposal because it leaks into the water supply.

Some of the best habits come from staying vigilant: using chemical hoods, keeping emergency showers accessible, and storing the substance in labeled containers away from acids or oxidizing materials. Storage sounds straightforward, but labels fade and containers sometimes get reused, which turns a routine day into a frantic clean-up.

Experience at chemical plants has shown that the most dangerous situations don’t erupt from intentional misuse but from routine: leftover drips, discarded gloves, or ignoring stains on the counter. Investing in staff training lowers these risks. Supervisors who run monthly safety drills and keep cleaning protocols simple never regret it. When new staff join, it helps to share “the one time somebody got burned” stories more than reciting guidelines. People remember real mishaps long after the textbook warnings fade.

Engineering teams have found that fume hoods with better airflow, automatic shutoff valves, and brightly colored spill kits reduce accidents. In workplaces that take this approach, accident rates drop and insurance claims stay manageable. Regular safety audits keep everyone aware—the sticker on the emergency shower reminding staff “last checked this week” builds confidence.

Chemical management keeps evolving, so active steps make a difference. Substituting with less hazardous alternatives works, if the chemistry allows it. Modern labs track inventories digitally, flagging substances that age or degrade, reducing the chance someone uncaps a forgotten bottle of piperazine-1,4-diethanol. Simple habits matter too: everyone wiping down benches at shift’s end keeps residues from accumulating.

Piperazine-1,4-Diethanol doesn’t send people to the hospital every day, but without attention, it finds ways to create problems. Real safety comes from knowing the material, sharing stories with co-workers, and keeping a steady eye on day-to-day routines. In practice, the small details build the strongest defense.

Piperazine-1,4-diethanol rarely turns up in dinner table conversation, but in chemical plants and research labs, it gets plenty of attention. The clear liquid carries two hydroxyethyl groups, making it more than just another chemical on the shelf. People who work in chemistry or chemical engineering have seen it showing up in the textbooks, as a go-to intermediate for plenty of other molecules.

If you ever used a dishwasher detergent tablet and noticed a spotless shine on your glasses, you might have chelating agents to thank. These agents help soften hard water, break up mineral buildup, and boost cleaning power. Piperazine-1,4-diethanol is essential in making some of the most effective chelators found in cleaning products and water treatment solutions. Its structure gives manufacturers the flexibility to tweak molecular designs so they latch onto unwanted metal ions and make removal easier.

Medicinal chemists looking to design drugs for specific diseases often turn to a menu of reliable building blocks, and this compound makes the list. Its skeleton supports the creation of molecules with antiparasitic properties and even some compounds designed for psychiatric applications. In the veterinary world, piperazine derivatives can help manage worm infestations in pets and livestock. Every time a veterinarian prescribes a dewormer for a puppy, there’s a chance the roots of that product lie in a chemical like this one.

Industrial-scale manufacturing has its own unsung heroes, and foam stabilizers belong in that group. Polymers and foams used in mattresses, insulation, and packaging often don’t perform well if the foam bubbles pop too soon. Piperazine-1,4-diethanol works as a key ingredient to stabilize these bubbles, providing an even, consistent structure inside the final product. People expect comfort and durability from their mattresses and reliable protection from their packaging, and reliable chemical inputs make that possible.

Textile finishing and dyeing rely on a controlled chemical environment. Workers in textile mills depend on correct pH for dyes to set and fibers to soften properly. Piperazine-1,4-diethanol gets added to chemical blends that manage this balance. The process helps fabric absorb dye uniformly, so those favorite blue jeans or printed t-shirts sport color that lasts through many washes. Without the right chemicals in the mix, garments could come out patchy or faded long before their time.

So many benefits come from the chemical sector, but it isn’t all upside. Manufacturing creates waste and can expose people and ecosystems to risk. I’ve seen factories invest in improved filtration and stricter handling guidelines after local communities raised concerns about runoff. Industry experts suggest closed-loop systems and better real-time monitoring as realistic steps forward. Making sure chemicals like piperazine-1,4-diethanol stay contained and tracked from start to finish helps build trust and keep accidental releases in check.

Markets and regulations keep pushing the industry toward cleaner, safer production methods. Teams in academic and corporate settings are exploring alternatives that work just as well but carry fewer side effects. Chemistry carries promise, but the people working in labs and factories shoulder a big responsibility. In practical terms, that means every drum of piperazine-1,4-diethanol gets the respect and oversight that something this effective—and potentially hazardous—deserves.

A lot of folks working with chemicals tend to focus first on using them, not storing them. From what I've seen, how a substance like Piperazine-1,4-Diethanol gets stored can make or break both safety and performance. Too many stories circulate about leaks, spills, or product quality issues all tracing back to poor storage. One slipup can mean health risks and wasted materials, both of which no one wants to deal with.

This chemical doesn’t play nice with extreme heat or cold. On warm days, the vapor pressure climbs and pressure could build up inside sealed containers. If things get too chilly, you risk thickening or solidification, which just makes handling a pain and can damage containers. Best bet: store at room temperature, somewhere between 20°C and 25°C. Plenty of studies highlight how temperature swings cause degradation or container failure. Keeping things steady saves a lot of headaches.

Piperazine-1,4-Diethanol attracts water from the air, which leads to contamination and messes with chemical purity. Extra water doesn’t just mess with experiments, it can corrode steel drums or create pressure inside storage tanks. Protecting the substance means sealing up containers right after each scoop or pour. It’s simple – use airtight caps and check them after every use. Over the years, I’ve seen what happens when lids don’t get closed tight: ruined batches and sticky clean-up jobs.

Regular plastic buckets or old paint cans just don’t cut it. Go with high-density polyethylene or stainless steel, since these stand up to chemical exposure. Thin-walled drums or reused containers develop leaks and cracks over time. Before filling, it helps to check for fine cracks and dents, since weak points get worse faster with chemicals like this one. Every chemical safety manual I’ve read makes this clear, but plenty of people still cut corners. Reliable containers don’t just prevent spills — they save money long-term by keeping product loss to a minimum.

Most accidents happen during storage, not usage. That stings a bit when you realize a simple label or proper shelving solves most of the problem. Clear hazard stickers and bold labels keep the odds of confusion low. Store out of reach of children and away from areas with food or drinking water, since cross-contamination can have serious consequences. Always keep spill kits and eye wash stations close. I’ve worked in places that skip this, and minor spills quickly spiral into emergencies.

Local fire marshals and environmental inspectors drop by workplaces for a reason. Laws often put Piperazine-1,4-Diethanol in the category of materials with storage restrictions. You might face strict guidelines about ventilation, fire protection, and permissible quantities on site. Insurance companies take these rules seriously, too. Cutting corners rarely ends well, and it’s worth remembering that one mistake puts both employees and neighbors at risk.

Regular inspections and a logbook help spot issues before they get out of hand. Replace old containers, clean up spills fast, and invest in staff training. Set up routine reminders for checking temperature and container seals. I’ve seen organizations pay for costly chemical incidents, and every time it ties back to forgetfulness or “good enough” attitudes.

There’s no big secret to storing Piperazine-1,4-Diethanol — just respect the material and put safety first. One extra minute double checking containers and labels beats hours of cleanup or injury reports. In my experience, a well-organized shelf turns even a busy workplace into a spot where safety comes naturally.

| Names | |

| Preferred IUPAC name | 2-[4-(2-Hydroxyethyl)piperazin-1-yl]ethan-1-ol |

| Other names |

1,4-Bis(2-hydroxyethyl)piperazine Diethanolpiperazine Piperazine diethanol 1,4-Di(2-hydroxyethyl)piperazine DHEP |

| Pronunciation | /paɪˈpɛrəziːn waɪ ˈdiːˌɛθənɒl/ |

| Identifiers | |

| CAS Number | 4004-05-1 |

| Beilstein Reference | 397680 |

| ChEBI | CHEBI:81977 |

| ChEMBL | CHEMBL1437 |

| ChemSpider | 12441 |

| DrugBank | DB06798 |

| ECHA InfoCard | 03e1f87a-fbb6-416e-929c-bcaa323b88cc |

| EC Number | 203-041-4 |

| Gmelin Reference | 115102 |

| KEGG | C06534 |

| MeSH | D010880 |

| PubChem CID | 8457 |

| RTECS number | HK8575000 |

| UNII | 365BG7PA2P |

| UN number | UN2810 |

| CompTox Dashboard (EPA) | DTXSID7020827 |

| Properties | |

| Chemical formula | C8H18N2O2 |

| Molar mass | 174.25 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | Odorless |

| Density | 1.107 g/cm3 |

| Solubility in water | Soluble in water |

| log P | -1.5 |

| Vapor pressure | 0.000017 mmHg (25°C) |

| Acidity (pKa) | 9.8 |

| Basicity (pKb) | 7.93 |

| Magnetic susceptibility (χ) | -60.4e-6 cm³/mol |

| Refractive index (nD) | 1.485 |

| Viscosity | 20 mPa·s (25 °C) |

| Dipole moment | 3.17 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 563.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -589.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4633.8 kJ/mol |

| Pharmacology | |

| ATC code | A07AC02 |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes serious eye irritation. Causes skin irritation. May cause respiratory irritation. |

| GHS labelling | GHS07, GHS05 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H315, H319, H373 |

| Precautionary statements | P261, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | 113°C |

| Autoignition temperature | 260 °C (500 °F) |

| Explosive limits | Explosive limits: 1.7–10.8% |

| Lethal dose or concentration | LD50 Oral Rat ≥ 5000 mg/kg |

| LD50 (median dose) | 5,080 mg/kg (Rat, oral) |

| NIOSH | SQ9600000 |

| PEL (Permissible) | PEL: Not established |

| REL (Recommended) | 5 mg/m³ |

| IDLH (Immediate danger) | Unknown |

| Related compounds | |

| Related compounds |

Piperazine Diethanolamine Piperazine citrate Piperazine adipate Piperazine hexahydrate |