Methylpyrrolidine began leaving a mark in organic chemistry circles as scientists pushed past the confines of natural products in the late 19th and early 20th centuries. Synthetic curiosity led some of the earliest European laboratories to distill and modify pyrrolidine derivatives, soon realizing methyl-substituted versions offered different physical tweaks and chemical behaviors compared to the parent ring. Advances in industrial chemistry through the mid-20th century, coupled with growing pharmaceutical ambitions, brought new demand for cyclic amines, prompting efficient routes for methylpyrrolidine production. By the 1970s, its essential hand in both large-scale synthesis and specialty fine chemicals was well recognized, turning what was once a laboratory oddity into a staple of industrial and academic shelves.

Methylpyrrolidine stands as a five-membered heterocycle, a cousin of pyrrolidine with one methyl group attached. Its commercial forms—clear, colorless liquids—come in technical, analytical, and pharmaceutical grades, shaped by differing end-use purity needs. Chemical suppliers handle it in drums or smaller glass containers, given its volatility and sensitivity. Each container typically arrives with batch data, purity percentages (widely 98% and up), and water content, which can make or break a downstream process. This compound also hits the mark for versatility: chemists leverage it as a building block, intermediate, and even a platform for chiral exploration.

Lightweight yet powerful, methylpyrrolidine maintains a boiling point range from 82°C to 100°C depending on where the methyl lands on the ring. It dissolves in a snap in polar solvents like water and alcohols, but resists mixing with heavier oils. A sharp, amine-like odor signals its presence, and a density usually hovers near 0.86 g/cm³. With basicity thanks to the nitrogen atom, it happily snags protons or partners up in nucleophilic substitution. Its chemical neighbors, like dimethylpyrrolidine, share many traits, but the single methyl group on this molecule keeps reactivity sharp and certain stereochemical quirks in play.

No chemist grabs a vial of methylpyrrolidine without consulting technical specs—GC assays specify the main compound on a percentage scale, and labels record the water content, color, and trace impurities. Laboratories often demand less than 1% contamination by other pyrrolidines or residual starting materials. Any container hitting the pharmaceutical marketplace needs batch traceability and a shelf-life date, with clear hazard icons since it can irritate skin and eyes or create a dangerous vapor if mishandled. An SDS (Safety Data Sheet) is not a luxury but a baseline requirement, spelling out both physicochemical hazards and emergency instructions.

Synthesizing methylpyrrolidine kicks off either from pyrrolidine itself or common precursors like γ-butyrolactone and methylamine. One method lets chemists pop a methyl group onto the pyrrolidine ring by alkylation—usually via a methyl halide like methyl iodide, under basic conditions. Some processes involve direct cyclization, combining 1,4-diaminobutane with an excess of formaldehyde and acid catalyst, then introducing methyl groups at specific steps. Industrial facilities scale these batches through careful distillation and solvent processing, improving yields by meticulous temperature control and tight exclusion of water, since hydrolysis can eat into product output.

Methylpyrrolidine’s reactive amine function opens the door to a wave of transformations. Acylation produces stable amides, useful in dye chemistry and medicinal intermediate work. Alkylation, both at the nitrogen and on the ring, spins off new derivatives for advanced pharmaceutical research. Reductive amination can tailor the ring to push the envelope in catalytic projects. People use this compound as a chiral building block, too—its methyl position acts as a handle for making enantiomeric products in asymmetric hydrogenations. In my own experience, even a small tweak in reaction temperature or methyl placement unlocks a completely different set of downstream properties, which can mean the difference between a useful reagent and a missed opportunity.

Walk into any chemical supply warehouse and methylpyrrolidine’s many aliases pop out—among them, N-methylpyrrolidine, 1-methylpyrrolidine, and methylated pyrrolidine. Catalogs sometimes lump it with substituted cyclic amines based on isomer location: 2-methylpyrrolidine and 3-methylpyrrolidine mark common commercial choices, each bearing slightly different boiling points and applications. Pharma companies sometimes brand formulations under proprietary research codes before broader naming settles in; specialists can tell them apart quickly from CAS numbers and shorthand not used by casual buyers.

No one takes handling methylpyrrolidine lightly. Skin contact brings irritation, and inhalation of vapors can throw off a technician’s health rapidly, especially without good ventilation. Labs and plants install strict protocols: goggles, nitrile gloves, and fume hoods stand as basic gear. Spill kits with absorbents are kept at-hand, and storage calls for cool, flame-free rooms sealed from oxidizers. Emergency showers and eye stations aren’t optional; they’re essentials in any place using liters of the stuff. Employees drill before using new batches, tracking any exposure since chronic contact may mean neurological risks—reports flag repeated inhalation as a hazard that can linger for months.

Methylpyrrolidine finds a home across several scientific and industrial map points. In pharma, it’s a precursor for antipsychotics, antidepressants, and medicines investigating new CNS targets. Polymer scientists blend it into specialty plastics for strength modification and unique flexibility. The agrochemical field seeds it into pesticide intermediates, helping improve crop yields and resistance profiles. Analytical chemists value its ring structure in derivatization methods for chromatography, snapping on groups that streamline detection. Even fragrance engineers tap into its volatility and subtle amine tang for certain aromatic bases, showing just how versatile a small heterocyclic amine can grow through creative formulations.

Academic labs, commercial R&D teams, and specialized startups probe methylpyrrolidine as they chase new drugs and functional materials. Medicinal chemists dig into isomer effects, testing how a methyl in one position tests brain-receptor affinities while another shifts solubility or safety. Polymer researchers race to design next-generation elastomers and coatings by embedding the ring into backbones, chasing extreme durability or electrical behavior. My time in a process development group taught me this: even a fractional improvement in synthetic yield or purity ripples downstream into cost, regulatory, and environmental advantages that multiply across thousands of kilos each year.

Toxicologists keep methylpyrrolidine in tight focus. Acute toxicity studies show it ranks as a moderate hazard—low-lethal doses by oral or dermal routes in lab animals, often triggering nervous system depression and respiratory effects. Chronic exposure studies suggest repeated handling might affect liver function and birth outcomes, making regulatory monitoring a high priority in both chemical and pharmaceutical spaces. Investigations into metabolites reveal quick breakdown in biological systems but flag the parent amine as the main concern. The move towards greener and less dangerous synthetic routes owes a lot to these findings, nudging the chemical industry to design safer analogs and robust containment strategies.

Methylpyrrolidine’s story keeps expanding as new materials, medicines, and even energy storage devices call for specialized nitrogen heterocycles. Synthetic biology groups consider slipstreaming it via engineered microbes, aiming to bypass traditional batch chemistry with cleaner, biocatalytic paths. Medicinal chemists test new methylated analogs against emerging neurological and immunological diseases, chasing patent protections and new approvals. As chemical manufacturing sharpens its sustainability focus, methylpyrrolidine’s manageable size, relative ease of synthesis, and adaptable structure may anchor a wave of cleaner intermediates for generations to come, opening the floor for creative minds ready to experiment far beyond the boundaries set by yesterday's textbooks.

You don’t find methylpyrrolidine on the front page, but its fingerprints show up everywhere in labs and factories. Chemists reach for it because this molecule does more than sit quietly in a bottle — it opens doors to making all kinds of things, from pills you might take to protective finishes on your furniture.

Drug makers treat methylpyrrolidine like a starter dough. It brings flexibility as a building block for complex molecules. You find its structure in medicine cabinets — inside some antibiotics or drugs for treating depression. It helps shape the frameworks that give those medicines the right twist, making them latch onto spots in the body’s chemistry like puzzles snapping together.

The best part? This molecule can get shaped and decorated with extra chemical groups, depending on the needs of the drug. That gives researchers choices when they're hunting for something that hits disease right where it hurts, without sticking to places it shouldn’t.

Walk through a cornfield in early summer, and there’s a good chance at least some of those yellow-green plants benefitted from agricultural chemicals built using methylpyrrolidine. Herbicides and pesticides often use it to craft active ingredients, since it helps ferry those molecules to the right places in a plant or pest. A structure like this becomes a tool for keeping crops healthy — fewer weeds, less damage from bugs.

Making specialty chemicals for high-end coatings or finishing products calls for molecular precision. Methylpyrrolidine gets added in these recipes because it changes how and where those coatings stick, making paints last longer or resist stains. Think of it as sandpaper for the molecular world — it helps smooth out processes and lets manufacturers dial in just the right finish. Without it, surfaces may crack, peel, or lose their shine too fast.

Chemists and industry workers keep a respectful eye on methylpyrrolidine for safety reasons. Its usefulness speaks for itself, but it doesn’t mean it’s gentle on the body when raw. Gloves and goggles stay on until it’s safely tucked inside another molecule, or mixed down to safe levels. Handling strictness keeps it out of drinking water and away from skin. Honest mistakes in disposal or leaks can lead to real problems for ecosystems, especially given how efficient this molecule can be at moving through soil and water.

Not everybody’s comfortable using strong chemicals, even for important work. That’s driving chemists to rethink how they use methylpyrrolidine. Some labs aim to swap in alternatives, or create safer versions that break down faster outside of factories and labs. Plant-based sources and clever recycling methods are on the rise. Cleaner processes could keep its benefits flowing, while limiting the headaches that come with it if it ever escapes the lab. Safer handling and smarter sourcing — those two things make sure methylpyrrolidine’s story stays positive, from medicine to the kitchen counter.

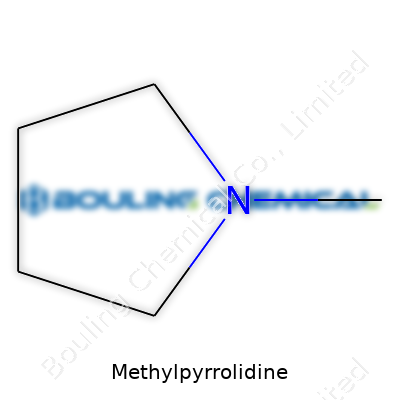

You don’t hear about methylpyrrolidine on the evening news. Most folks outside a lab haven’t even seen its name scribbled on a bottle. Yet once you start poking around the world of specialty chemicals, this little molecule pops up more often than your neighbor’s cat in your flower bed. Methylpyrrolidine looks simple enough — a five-membered ring with a nitrogen atom stitched in, and a single methyl group tagging along. This design shapes everything it does in a beaker, from how it smells to how dangerously it burns.

Pick up a vial of methylpyrrolidine, and the first thing that hits you is the smell. It’s sharp, not unlike ammonia, probably enough to steer anyone clear without gloves. The liquid inside flows thin, almost like water. Room temperature doesn't slow it down, since it stays a liquid unless the place gets colder than a typical deep freezer — below minus 62 degrees Celsius. Its boiling point sits just above 106 degrees Celsius. Pour some out and your nose tells you how readily this stuff heads into the air.

Color-wise, you’re dealing with something clear — as ordinary as water at a glance. It slips right into solvents like ethanol, chloroform, and doesn’t mind joining forces with water. This means chemists can dissolve it quickly without coaxing. In my years working in research, I came to appreciate chemicals that don’t act fussy in solution. A stubborn chunk at the bottom of the flask can ruin a whole morning in the lab.

Methylpyrrolidine draws a lot of its character from the nitrogen atom in its ring. That gives it basic strength, ready to grab a proton faster than a dry sponge soaks up water. The methyl group steps in too, pushing a bit more edge onto the ring, making reactions snappier. This basic flair makes it pop up as a handy building block in making medicines and agricultural compounds.

Its reactivity demands respect. Mix it with acids and you’ll get salts. Bring in oxidizers, and now you’re facing dangerous ground. In my early days in the lab, we drilled hard on keeping amines like this away from strong oxidizing agents. One slip, and you’re cleaning up a nasty mess or filing an accident report.

Because it evaporates so easily, you need proper ventilation — fume hoods aren’t up for debate. Direct skin contact becomes risky, not just for irritation but for long-term health effects. Don’t ignore those lab safety lessons; methylpyrrolidine can linger in your system if you’re careless. I’ve seen safety officers toss out worn-out gloves and demand a full wipe-down over even the smallest spills.

Storing methylpyrrolidine isn’t rocket science: tightly sealed bottles, away from light and strong heat, and definitely far from acids and oxidizers. I’ve seen labels scrawled with reminders about the need for dry, well-aired shelves. Folks who cut corners here end up calling hazmat teams instead of heading home for the night.

Methylpyrrolidine keeps showing its value in pharmaceutical labs and crop science. Its structure offers shortcuts to more complex molecules. At the same time, its volatility and reactivity mean we have to stay alert. Safer handling comes from simple fixes: tighter protocols, real training instead of paperwork checkboxes, and better ventilation gear. Every time someone finds a less toxic way to use or substitute for it, the whole lab world lets out a sigh of relief.

Methylpyrrolidine, a chemical you might spot on a safety data sheet at some research lab or chemical plant, doesn’t show up on many household ingredient lists, but that doesn’t mean we shouldn’t talk about it. This organic compound crops up in the production of specialty chemicals, acting as a building block for other molecules. The name sounds pretty technical, but it boils down to a ring-shaped molecule with a methyl group attached.

Methylpyrrolidine comes with its fair share of hazards. Based on what the industry and available studies report, this chemical acts as an irritant. Skin and eyes get the brunt, and those working with it can develop redness or a burning sensation. Inhalation may trigger coughing, dizziness, or headaches; high exposure can affect the central nervous system. These are not just guesses—the Globally Harmonized System (GHS) flags it for such risks.

Years ago, I worked in a lab where methyl-containing pyrrolidines popped up. We never handled them without gloves and goggles. If a bottle broke or vapor escaped, the ventilation fan clicked on in a hurry. Even short exposures felt uncomfortable if you skipped a mask. These personal rules matched the recommendations from chemical safety resources like the CDC and NIOSH. They treat this compound as something to respect, not ignore.

Long-term data looks a bit thin. Not many studies focus on chronic, low-level contact. Most evidence stems from similar chemicals—long-term inhalation can harm the liver, kidneys, or nervous system. The concern usually centers around repeated workplace exposure. Data on cancer risk or genetic damage appears limited, but that shouldn’t lead to complacency. Many chemicals thought “mostly harmless” decades ago turned out to be much more worrisome after closer analysis.

Chemicals do not stay confined to the lab or manufacturing line. Mishandling spills and leaks during transport, packaging, or storage can send vapors or residues further than people expect. Once in waterways or soil, they can travel. Community health depends on treating every step seriously—loading docks, ventilation, employee training, even disposal procedures.

Back in my lab days, the rules seemed strict—sometimes too strict—but incidents at other facilities proved why corners must not get cut. After one neighboring research campus had a small vapor release, some employees reported nausea and headaches. The response? Upgrading both the facility air filters and the emergency plans. Prevention always worked out cheaper and safer than cleanup after someone made a mistake.

Safety does not just mean warning labels. It means giving everyone the right gear, teaching the risks before the first day of work, and double-checking storage systems. For smaller businesses or schools, cost sometimes gets in the way. Sharing resources—regional hazardous material programs, pooled waste disposal networks—can bridge the gap. Open communication with local emergency responders prepares everyone if a spill or exposure happens.

Chemistry keeps moving forward, but so should our understanding and respect for it. The more people know what methylpyrrolidine can do, the safer everyone will be, from the lab coat wearers to neighbors down the block.

Methylpyrrolidine isn’t something most folks have sitting on a garage shelf at home. For people working in labs or industry, this chemical is serious business. I’ve seen a fair share of near-misses with volatile stuff, and it always reminds me that cutting corners with chemical safety invites trouble. Methylpyrrolidine won’t cut you any slack just because you’re busy or forgetful.

This compound, often used in chemical synthesis, has a sharp smell and catches fire easily. Once, during my university stint, a simple lapse led to fumes filling half the organic chemistry wing. Fumes from this stuff won’t just make your eyes water; breathing them comes with real health risks. Piles of safety data highlight problems: headaches, dizziness, even worse if you push your luck. Nobody enjoys an impromptu evacuation in the middle of running experiments.

Stick methylpyrrolidine in a flammables cabinet. Steel-cased, grounded if possible, away from ignition sources like open flames, hot plates, or even wiring that’s seen better days. Store it in bottles made of materials that won’t react, such as glass with well-fitted, chemical-resistant caps. Somebody once thought an old plastic jug would do the trick—clean-up taught the whole lab a lesson.

Temperature swings can trigger leaks or build pressure inside containers. A dry, cool spot well away from direct sunlight is the way to go. Label bottles clearly. Clutter is the enemy—stacking chemicals close together may lead to containers tumbling if someone bumps into the cabinet. Spilled methylpyrrolidine finds its way into the smallest cracks, and that sour stink stays for days.

Personal protective equipment is non-negotiable: splash goggles, gloves resistant to organic solvents, a decent lab coat. One morning, I watched someone skip gloves; red, irritated skin made them regret it within the hour. Fume hoods reduce the odds of breathing in vapors. Some newer tech labs have automated supply arms, but good old-fashioned caution works just as well if you stay present and focused.

Keep clear of food and drinks. A friend once had to explain to the safety officer why his lunchbox ended up next to chemical bottles. That kind of slip-up can turn an average day sour in seconds. If you splash any on yourself or the counter, soak it up with absorbent paper, pitch it into a proper waste bin—not down the drain. Pouring anything like this into the sewer doesn’t just break rules; rivers and groundwater pay for it, and so do we.

In our digital age, inventory software makes it tough to lose track of where things are and how old they are. Regular checks spot aging or degraded chemicals before trouble starts. Some companies have moved to barcodes and smart cabinets, which alert staff before supplies run out—or before they go bad and start leaking.

Responsibility doesn’t end with storage and daily use. Safety drills, team training, and honest conversations about mistakes all help keep people sharp. Every incident I’ve witnessed came down to someone rushing, assuming, or just forgetting basic procedures. Methylpyrrolidine deserves respect. Treat it right, and you’ll avoid the kind of excitement nobody wants.

Walk into any chemical lab or manufacturing plant and you’ll likely find a shelf with bottles labeled “Methylpyrrolidine.” The name might not get much attention, but this small organic compound helps keep a surprising number of wheels turning behind the scenes.

Chemists rely on methylpyrrolidine as a building block for bigger, more complex molecules. It’s not rare to see it pop up during pharmaceutical synthesis. Drug companies, trying to create new treatments, count on ingredients that can change easily during a reaction, but stay stable enough to store for months. Methylpyrrolidine fits that bill. Its five-membered ring and nitrogen atom create just the right handshake for forming new bonds with other molecules. This makes it a favorite starting point in drug discovery labs that push for targeted therapies—especially in areas like cancer or neurological diseases.

My work with a university research group gave me a firsthand look at methylpyrrolidine’s knack for smoothing tough reactions. We chased molecules riddled with kinks and double bonds, trying to add just the right side chain. This little ring-shaped compound offered a cleaner, reliable route compared to bulkier, fussier chemicals. Instead of long purification steps, reactions using methylpyrrolidine cut down both time and waste—an angle that matters if a single mistake means losing weeks of effort.

Methylpyrrolidine also steps up in the world of advanced materials. Companies push the limits of plastics, rubbers, and specialty adhesives for industries like electronics and automotive. They often aim for materials that flex without breaking or resist temperature swings. By mixing in methylpyrrolidine as a co-monomer, chemists tweak polymer backbones, giving engineers ways to build lighter car parts or flexible smartphone components. An entire subfield in materials science has blossomed around these modifications.

I once toured a startup on the edge of a big industrial park. The founders were tweaking anti-static coatings for airplane dashboards. They showed how swapping just one ingredient for methylpyrrolidine cut down static shocks and bumped up the coating’s resistance to wear. The switch didn’t break the budget, since this chemical sells at reasonable prices and doesn’t need fancy storage. Their project moved faster, ending years of headaches with cracking surfaces and sudden equipment failures.

The story doesn’t end in the lab. Methylpyrrolidine helps craft things most people see every day—inks, dyes, and sometimes fragrances. Industrial formulators mix it into pigments to improve color fastness, especially for products that see sunlight or lots of handling. Some textile dyes owe their wash resistance to this unassuming chemical.

Safety folk in research parks keep a close eye on handling practices. Methylpyrrolidine brings a certain set of risks—eye and skin contact cause problems, and inhaling vapors isn’t wise. Production lines today use improved ventilation and better training. Industrial chemists now pick up safety glasses and gloves almost without thinking. Accidents crop up less often, but keeping education steady for new workers never stops.

Looking ahead, methylpyrrolidine could take on a bigger role as industry shifts toward greener processes. Researchers have started testing it in new hydrogen storage methods and advanced batteries. If the push for sustainable tech stays strong, I expect to see methylpyrrolidine going from a background player to a headline star, especially as chemists hunt for safer, cleaner, and cheaper ingredients.

That’s just scratching the surface. In crowded labs or booming factories, this ring-shaped molecule finds fresh tasks with each new project, showing how a single chemical can quietly spark big changes.

| Names | |

| Preferred IUPAC name | 1-Methylpyrrolidine |

| Other names |

1-Methylpyrrolidine N-Methylpyrrolidine |

| Pronunciation | /ˌmɛθɪl.pɪˈrɒlɪdiːn/ |

| Identifiers | |

| CAS Number | 120-94-5 |

| 3D model (JSmol) | `Molecule Structure: CN1CCCC1` |

| Beilstein Reference | 1740837 |

| ChEBI | CHEBI:33167 |

| ChEMBL | CHEMBL44044 |

| ChemSpider | 12341 |

| DrugBank | DB08399 |

| ECHA InfoCard | 14d0a0be-6b56-493b-96b8-acae6a6e5d34 |

| EC Number | 123-75-1 |

| Gmelin Reference | 7877 |

| KEGG | C14189 |

| MeSH | D064370 |

| PubChem CID | 7518 |

| RTECS number | SY7875000 |

| UNII | W63KQ8255B |

| UN number | UN2810 |

| CompTox Dashboard (EPA) | DTXSID0027167 |

| Properties | |

| Chemical formula | C5H11N |

| Molar mass | 85.15 g/mol |

| Appearance | Colorless to light yellow liquid |

| Odor | amine-like |

| Density | 0.911 g/mL |

| Solubility in water | miscible |

| log P | -0.36 |

| Vapor pressure | 2.51 mmHg (at 25 °C) |

| Acidity (pKa) | 10.1 |

| Basicity (pKb) | 2.84 |

| Magnetic susceptibility (χ) | -25.3 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.4400 |

| Viscosity | 1.14 mPa·s (20 °C) |

| Dipole moment | 1.53 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 198.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -37.9 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4026.2 kJ/mol |

| Pharmacology | |

| ATC code | N05CM21 |

| Hazards | |

| GHS labelling | GHS02,GHS07 |

| Pictograms | GHS06,GHS08 |

| Signal word | Warning |

| Hazard statements | H226, H302, H314 |

| Precautionary statements | P264, P280, P301+P312, P305+P351+P338, P337+P313, P330, P501 |

| NFPA 704 (fire diamond) | 1-3-0 |

| Flash point | 53.6 °C |

| Autoignition temperature | 245 °C |

| Explosive limits | Explosive limits: 1.8–11.0% |

| Lethal dose or concentration | LD50 oral rat 475 mg/kg |

| LD50 (median dose) | LD50: 500 mg/kg (rat, oral) |

| NIOSH | NQ6475000 |

| PEL (Permissible) | PEL: Not established |

| REL (Recommended) | 0.5 ppm |

| IDLH (Immediate danger) | 100 ppm |

| Related compounds | |

| Related compounds |

Pyrrolidine N-Methylpyrrolidine 2-Methylpyrrolidine 3-Methylpyrrolidine 4-Methylpyrrolidine Piperidine |