People recognized formic acid long before chemistry became a science. Early naturalists first drew attention to its presence in red ants, after watching their stingers discharge something that burned and smelled sharp. In 1671, British naturalist John Ray started distilling crushed ants and named the compound “formic acid,” using the Latin “formica” for ant. Early chemists got their first taste of real extraction by cooking up batches from insect bodies and leaves, but the industrial revolution changed everything. By the 1800s, researchers started working out ways to produce formic acid more efficiently. Hydrogen cyanide treatment and oxalic acid reduction methods offered scalability well before modern catalytic processes took root. The last century saw a shift; formic acid’s production grew up alongside the chemical industry itself, with synthetic ways like carbon monoxide hydrolysis becoming the preferred choice for industrial tonnage.

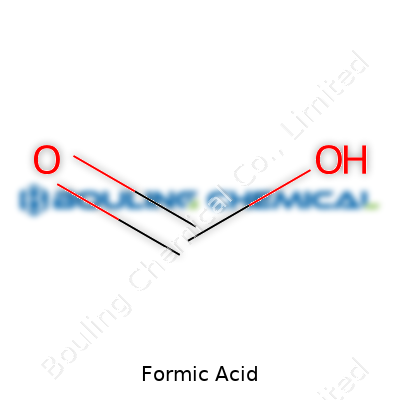

Formic acid, HCOOH, carries much weight despite its single carbon. Its sharp, pungent odor and stingy taste led to both careful handling and creative use. Production now commonly uses reactions between carbon monoxide and methanol, much more efficient than squeezing insects or fermenting wood. Globally, demand for high-purity formic acid mainly grows from textile finishing, rubber coagulation, leather tanning, animal feed preservation, and pharmaceuticals. I have seen small-scale local factories adopt more sustainable formic acid recovery techniques to reduce environmental impact, showing demand isn’t only about industrial giants. Agriculture and food preservation sectors often depend on its antimicrobial properties, keeping molds and bacteria at bay.

Formic acid looks unassuming: a colorless, mobile liquid, utterly soluble in water and many organic solvents. Its characteristic odor won’t soon leave a lab coat. Volatile and corrosive, it brings a biting acidity, pKa around 3.75, with impressive reducing properties. Boiling comes at 100.8°C, melting near 8.4°C—close enough to water and ice that improper storage could spell trouble. As a carboxylic acid, it reacts fiercely, especially with bases, alcohols, or metals, often giving off hydrogen. From my days in the lab, I’ll never forget how quickly formic acid attacks skin or causes metal tools to fizz and pit. Chemically, purity grades matter: technical, food, and reagent grades differ by water and contaminant content, with trace metals and organic residues tightly controlled for pharmaceutical use.

Commercial supplies usually label formic acid by assay, with 85%, 90%, and 98–99% solutions most common. Technical bulletins require strict hazard pictograms—flammable, corrosive, environmental hazard. Manufacturers must state batch number, purity, date of manufacture, and supplier details. Labs track hazardous waste protocols by referencing these labels, ensuring safe handling. Spec sheets detail water content, color, iron level, and other impurities using parts per million. UN number 1779 covers international transport. Many countries require Safety Data Sheets at every industrial site, and my experience taught me to check those sheets before any large-scale job, since even a small labeling mistake can turn a routine day into a disaster.

Today, most formic acid comes from methyl formate hydrolysis. High-pressure reaction between methanol and carbon monoxide creates methyl formate, which then gets split by water to yield formic acid and regenerate methanol. Producers recapture and recycle methanol, driving down waste and cost. Before this, companies often heated oxalic acid with glycerol, or distilled wood chips in the hope of decent yield—methods too laborious for modern needs. In a high school experiment, I once tried electrolytic oxidation of sodium formate, getting just enough acid to notice the smell, not enough for any real use. Several academic labs investigate greener methods: direct CO2 hydrogenation uses renewable energy to make formic acid both a product and a hydrogen carrier, betting on future energy needs.

Formic acid pulls its weight across plenty of transformations. It acts as a reducing agent, cleaning up gold and platinum salts in precious metal purification. Dehydration gives carbon monoxide—useful in itself—while oxidation results in carbon dioxide and water. With alcohols, it forms esters, delivering that signature apple scent in flavor chemistry. Amides, salts (formates), and other derivatives open the door for pharmaceuticals and specialty chemicals. In textile labs, where I once worked, we’d use formic acid’s ability to release carbon monoxide for synthetic chemistry, but remain wary: too much heat or the wrong catalyst could fill a fume hood with toxic gas quickly. Its hand in hydrogen storage pushes formic acid research closer to a future where chemical batteries rely less on ancient carbon and more on accessible, renewable sources.

Market names can vary depending on region and end use. Common synonyms include methanoic acid, aminic acid, hydrogen carboxylic acid, and ant acid, though regulatory bodies usually prefer “formic acid” to avoid confusion. CAS Number 64-18-6 remains the gold standard for inventory and traceability. Products sometimes reach shelves as “formylic acid” in legacy documentation, but modern suppliers aim for clarity and safety in all product codes, especially when shipping across regulatory boundaries.

Direct contact with formic acid demands respect. It can burn skin and eyes, inflame airways, and its vapors corrode metals and electronics. Personal protective equipment ranks as non-negotiable—safety goggles, acid-resistant gloves, and proper fume hoods are bare minimums. I’ve seen minor spills cause real headaches, with neutralization often handled using sodium bicarbonate, but only after full evacuation. International guidelines from OSHA and the EU set exposure limits in workplace air around 5 ppm, with immediate evacuation protocols for anything above. Storage needs acidsafe containers made from PTFE, glass, or stainless steel to avoid dangerous leaks. Emergency showers and eyewash stations must sit within easy reach in any production or research plant. Proper training goes hand in hand with regular audits and drills, as most incidents stem from human error rather than equipment flaws.

Use cases span from animal feed preservatives to laundry detergents and car leather production. Food companies rely on it for antibacterial treatment of silage, keeping crops safe for livestock and reducing agricultural waste. Textile mills use it in dyeing and finishing fabrics, shifting shades and improving water resistance with a minimal chemical footprint. Pharmaceuticals depend on formic acid to synthesize active ingredients and intermediates. I’ve worked in tanneries where formic acid kept leathers supple, helping control pH to avoid brittle, low-quality hides. Rubber manufacturers count on its coagulation strength, squeezing water out of latex with near-perfect efficiency. More recently, it powers direct fuel cell prototypes and helps break down hazardous waste, leading researchers to test its role in sustainable agriculture and green energy.

Universities and R&D labs take a special interest in the hydrogen economy, using formic acid both as a convenient carrier and as a clean hydrogen source. Catalytic decomposition methods see daily improvement, targeting lower temperatures and faster rates. Pharmaceutical teams keep investigating new derivatives for antibacterial and antiviral drugs, hoping to crack resistance in staph and MRSA strains with analogs based on formic acid’s reactive backbone. Material chemists push into ester synthesis, aiming for biodegradable plastics and specialty polymers. I’ve read papers charting new pathways for formic acid from biomass and CO2, blending green chemistry principles with industrial necessity. Safety research in these labs highlights not just acute toxicity but long-term health risks and environmental fate after production and use.

Formic acid’s toxicity profile warrants close study. It can enter through skin, inhalation, or ingestion, causing burns, metabolic acidosis, or nerve damage at high doses. Chronic exposure leads researchers to monitor blood biomarkers, especially in those working with large volumes day after day. Animal models show both dose-dependent hazards and safe thresholds, guiding regulatory standards in agriculture, food, and pharmaceuticals. In the environmental context, soil and aquatic studies track degradation rates and byproducts. I’ve seen risk assessments that weigh not only production worker safety, but also pollution in surrounding soil and waterways. Biodegradability serves as a double-edged sword, as breakdown byproducts can drift through soil profiles, impacting non-target species.

Formic acid’s future looks tied to how society manages energy, carbon, and food security. Chemists around the world trial novel solar-driven production techniques, sequestering carbon dioxide into stable formic acid for later use as both feedstock and fuel. Hydrogen storage through formic acid offers a bridge between fossil fuels and a renewable-powered world, letting vehicles run on chemical energy with zero net emissions. Agriculture continues to search for natural, residue-free alternatives to antibiotics and synthetic preservatives, with formic acid’s robust antimicrobial activity as a cornerstone. Ongoing studies on its metabolites and environmental breakdown build trust for larger rollouts in food and pharmaceutical applications. Training, safety upgrades, and risk management become all the more important as usage spreads from megafactories to farms and local labs, as the gap between innovation and public safety remains narrow in chemical industries.

Out on the farm, formic acid is a workhorse most folks don’t notice. Livestock feed often faces the threat of mold, especially in damp climates. Farmers use it to preserve silage and hay, which means cows and sheep have more to eat and throw away less. According to the Food and Agriculture Organization, feed losses drop by as much as a third when formic acid enters the picture. Not only does it keep animal food fresher, but formic acid also controls bacteria during the harvest, helping farmers avoid the risk of spoiled feed making their animals sick.

Leather workers rely on formic acid to process hides. It sets dyes and helps remove hair and unwanted bits from skins during tanning. If the process skips this acid, leather weakens and color fades. As a lifelong wearer of boots, I can attest that proper leather feels firmer and lasts longer. Textile folks also turn to formic acid for dyeing wool and other fibers. Colors lock in more deeply. The textile industry gets brighter fabrics with fewer chemicals lingering in the wastewater.

Commercial beekeepers keep colonies strong using it to control varroa mites. These pests ruin entire hives. Formic acid, applied just right, wipes out mites without hurting bees or their honey. The U.S. Environmental Protection Agency supports its use because it breaks down quickly in nature.

In the cleaning aisle, it’s tough on lime scale, so it lands in many descalers and detergents. Old coffee machines and kettles get a new lease on life. I’ve seen restaurants use it for deep cleaning, especially where hard water leaves stains.

While most people never buy pure formic acid, they run into it through other things. The chemical industry uses it to make other substances—from rubber to plastics. It acts as a reducing agent, sparking key chemical reactions. Tire factories, for example, use it for rubber coagulation. The packaging from electronics giants often owes its flexibility and strength to this hidden ingredient.

Formic acid contributes to the manufacture of medicines and pesticides too. Recent years have seen a push to replace tougher, nastier chemicals with something that leaves a lighter footprint. Environmental groups, such as Greenpeace, mention that formic acid’s biodegradability makes it a better choice than many older products, especially for cleaning up after oil spills or treating wastewater.

Formic acid proves that simple molecules can punch above their weight. It solves problems for farmers, tanners, beekeepers, and factory managers alike. Safety matters, since it can burn skin and eyes, yet with clear rules and responsible use, the benefits stack up. Its many jobs—food preservation, leather making, mite control, industrial cleanups—signal a future where safer chemicals take center stage. By backing well-documented uses, scientists and regulators help communities trust what goes into their food, clothing, and even the air around them.

Most folks don’t spend their days thinking about formic acid, but this chemical shows up in places you wouldn’t expect—preserving animal feed, cleaning industrial equipment, and even in the sting of an ant. The thing is, its presence in daily life doesn't mean it's harmless if you come into direct contact with it.

Formic acid isn’t just another liquid sitting on a shelf. Even at relatively low concentrations, it can be tough on skin and eyes. Splash it on your hands, redness and burning follow. Get it in your eyes, it can trigger serious damage—potentially even blindness, according to medical case studies. Its vapors irritate the nose and lungs, especially in crowded or poorly ventilated spaces.

Some workers in agriculture or industrial cleaning have brushed off early warnings, thinking gloves or masks get in the way. After hearing stories from folks who ended up with burns or breathing problems, that attitude tends to shift. A hospital visit because of a chemical burn sticks in your memory much longer than a little inconvenience on the job.

OSHA and similar agencies set strong guidelines for a reason. Proper gloves, goggles, and good ventilation are non-negotiable with formic acid. Not all types of gloves keep the acid at bay—for example, thin latex offers little protection compared to thicker nitrile or neoprene. I’ve seen people swap out safety gear for regular cleaning gloves, thinking they're the same. It doesn’t end well.

Spills also demand quick thinking. A small puddle on a hard surface releases fumes fast, especially indoors. Clean-up needs proper absorbent material, and just throwing old rags at the problem exposes skin and lungs to risk. I’ve watched workers suffer from cuts or raw skin for weeks because small leaks or mistakes didn’t get real attention until it was too late.

Even after getting past the initial sting, regular exposure leaves a mark. Workers who breathe low levels of formic acid week after week report chronic cough and chest tightness. Safety reports from manufacturing plants document higher rates of skin conditions too. The World Health Organization lists formic acid among chemicals that can damage skin, mucous membranes, and lungs, especially if exposure keeps happening.

Many accidents happen because someone underestimated how potent a clear, colorless liquid can be. I’ve noticed positive changes where training doesn't just cover “rules” but shares real stories and demonstrates best practices right on the factory floor. Reading an instruction manual doesn’t stick as well as watching someone suit up and handle the chemical carefully.

Some companies look for alternative cleaning agents or preservatives with less sting. It’s smart business and protects workers’ health. Switching costs and training do slow these innovations down, but discussions across the industry keep pushing the boundaries for safer choices.

Whether handling small bottles or drums, real respect for formic acid goes a long way. Simply put, the risks are real, but so are the solutions with the right attitude and tools.

Ask anyone who's handled formic acid long enough, and they'll tell you: this chemical packs a punch. With its sharp smell and strong burn, it’s clear why it gets respect in the lab, factory, or on the farm. Over the years, accidents and wasted stock have happened from careless storage. Damage to containers, ruined floors, even dangerous exposure—none of it happens out of nowhere. Most problems start with storage mistakes.

A lot of folks remember the basics—keep it in a container and label it. That’s not enough. Formic acid eats through many materials. Metals like steel and aluminum react fast. I’ve seen old jugs left on metal shelves turn ugly in months. Some plastics do better, but only if you choose the right kind. High-density polyethylene (HDPE) stands up the longest. With strong acids like this, relying on thin, questionable plastics is like riding a bike downhill with loose brakes.

Formic acid loves water, nearly as much as it loves corroding metal. Humidity in the air can seep in over time, turning pure acid into a weaker and less useful solution. Leaky lids or poorly closed drums lose product year after year. Those fumes do more than chase people from the room—they’re also bad news for machines and storage racks. Stainless steel alloys, especially grades like 316, show much better resistance. Ordinary shelving without a chemical-safe lining won’t last in a busy shop or warehouse.

Temperature swings cause formic acid to build up pressure. A hot storage room in summer can send fumes rushing out whenever someone opens the cap. If you’ve ever inhaled those vapors, you know it’s not an experience you want to repeat. Drums or containers should sit away from direct sunlight, so the acid doesn’t expand, react, or build internal pressure that might split a seam.

Putting formic acid next to bleach, ammonia, or even strong alkalis kicks up the risk. Accidental spills, even small ones, create real trouble. Mixing with incompatible chemicals can release toxic gases. It’s safer to store acids by themselves, in a well-marked spot with good ventilation—and not at eye-level where spills could splash directly onto someone’s face. Someone on staff should inspect storage every week, checking caps for tightness and checking labels for fading.

From my time in manufacturing, dedicated acid cabinets save hassle in the long run. These cabinets line up on a concrete floor, away from employee traffic. Some workplaces install small exhaust fans above storage shelves, pulling stray vapors away before they collect. Inside, only acid-resistant shelves and trays go near the containers. Cabinets keep extra absorbent material on hand for emergencies—think vermiculite or acid-neutralizing spill pads. Having an eyewash station nearby seems basic, but it saves vision if something splashes. Staff training always adds peace of mind. It doesn’t matter whether folks have a degree—what counts is showing how to handle and store formic acid safely, every time.

Communities demand safety checks after chemical accidents. It’s not just about meeting codes—careful storage protects workers, neighbors, and the whole business. By securing the right storage materials, managing the room’s climate, and keeping acids away from incompatible substances, anyone can avoid most risks linked to formic acid. Experience keeps proving that safe habits around strong chemicals never go out of style.

Formic acid shows up in a surprising number of products. It’s found in everything from animal feed additives to textile processing chemicals. For folks like me working in agriculture, spotting formic acid on a label makes me stop and think about what I’m actually using. Not all acids carry the same punch, and formic acid stands out due to its effectiveness as a preservative and its knack for controlling unwanted bacteria. The number on the label that states its concentration isn’t just regulatory box-ticking—it’s information that impacts real-world application, safety protocols, and even the bottom line.

Digging into the bottle or package, the focus sharpens on the stated concentration. Take agriculture: a 85% formic acid product can help keep silage fresh and limit mold growth far better than a version with 30% strength. People want to get their money’s worth. A more dilute acid would mean you have to use twice as much, pushing the cost up and giving less control. My experience with different suppliers has shown that the higher the transparency about concentration, the simpler it is to avoid accidents and to achieve predictable results. This is true for labs, workshops, and on the farm alike.

With cleaning products, knowing the exact percentage means the difference between blasting through a limescale problem and accidentally damaging a surface. My first attempt using a strong formic acid solution ended in etching a sink and a harsh lesson about misreading the fine print. A single digit increase in concentration can cause burns or create unsafe fumes. Mistakes from unclear labeling or poor advice can hurt someone’s health or a company’s reputation.

Users rely on the details on the product’s data sheet for safe storage and handling. Concentration data drives decisions around ventilation, eye protection, and spill response. The law backs this up—the European REACH regulation, among others, lays out solid requirements for chemical labeling and conveyance of hazard details. Without strict data on concentration, users are gambling with their safety and regulators have nothing to hold onto for holding suppliers accountable.

Health professionals pay close attention to these details too. Poison control centers ask first about strength in cases of accidental exposure. If concentration isn’t clear, doctors have a harder time judging the possible risks and tailoring treatment.

Earning people’s trust depends on upfront communication. Product manufacturers carry the responsibility of disclosing accurate information. This is more than a paperwork exercise. A customer who knows what’s inside a purchase can plan usage, comply with local rules, and look after employees. Regular lab testing and precise labeling can reinforce trust. Traceability means that customers have recourse if anything feels amiss, and batch test results can be made available to back up claims.

Clear answers to questions about formic acid concentration let people make wise choices, protect health, and avoid waste—three values that never go out of style. Building habits of quality-assurance testing, transparent labeling, and open communication results in safer workplaces and products that can be used with confidence. That’s good news for users, manufacturers, and anyone else depending on these chemicals in daily life.

Formic acid sounds simple but it packs a punch. Its strong acidity and volatile nature mean the wrong packaging can lead to leaks, workplace injuries, or severe environmental headaches. Back in my student days, a cracked bottle of diluted formic acid shut down the entire chemistry lab. That cleanup drove home the lesson: packaging details aren’t just for compliance—they protect real people every day.

Most producers stick to three main types: high-density polyethylene (HDPE) drums, intermediate bulk containers (IBCs), and steel drums. Each serves a purpose, and costs—or safety—determine the best fit.

These plastic barrels show up everywhere chemicals are stored. They handle formic acid’s corrosive bite better than metal, especially in concentrations up to about 85%. HDPE doesn’t react with the acid, so leaks from chemical attack stay unlikely. A standard drum holds either 25 or 200 liters and includes tight-fit seals for transport.

With formic acid, exposure risk grows when containers get jostled. HDPE provides some flex under pressure or shock, which is a helpful buffer if drums fall off a pallet in a busy warehouse. A minor dent usually doesn’t spell disaster, making HDPE a common sight in small-scale industrial settings and laboratories.

Companies moving large quantities get more mileage out of IBCs. These big, cube-shaped plastic tanks come wrapped in a metal cage for reinforcement. They usually hold 1000 liters. Most have a valve at the bottom to let out the acid into smaller jugs or for quick mixing with water.

Quality always matters: only use IBCs made from acid-resistant HDPE. During a visit to a food processing plant, I saw what happens when the wrong plastic gets used—acid eats through the wall and you’re left with a pool on the floor and anxious workers. Regular visual checks and proper labels become part of safety routines for just this reason.

Steel offers strength but not so much chemical resistance. For pure formic acid, any direct contact with plain steel leads to corrosion. That’s why manufacturers will line steel drums with special coatings like epoxy resin. These coatings take the hit from the acid, letting companies ship higher concentrations with less risk of punctures or burst seams.

Transport regulations often decide steel versus plastic. Shipping overseas? Certain ports block plastic drum imports, favoring lined steel instead. Cost plays into it, but shipping and insurance fees quickly eat up any savings if something leaks.

Waste disposal rules put tight clamps on how packaging gets managed after use. HDPE and IBCs in good condition go back for refilling or recycling. Damaged drums become hazardous waste, bringing heavy penalties if dumped illegally. In regions chasing stricter environmental rules, more companies move to packaging that meets both chemical safety and recycling standards.

At the end of the day, the packaging choice means more than just price or storage space. The consequences of bad calls show up fast—spills, health scares, or costly lawsuits. Formic acid demands respect, and the right container forms the first barrier. Producers, shippers, and users need solid training, clear labeling, and a willingness to pay a little more for materials that last. In this business, safety always comes before shortcuts.

| Names | |

| Preferred IUPAC name | Methanoic acid |

| Other names |

Methanoic acid Hydrogen carboxylic acid Aminic acid Formylic acid Hydrogencarboxylic acid |

| Pronunciation | /ˈfɔː.mɪk ˈæs.ɪd/ |

| Identifiers | |

| CAS Number | 64-18-6 |

| Beilstein Reference | 505907 |

| ChEBI | CHEBI:30751 |

| ChEMBL | CHEMBL715 |

| ChemSpider | 579 |

| DrugBank | DB01942 |

| ECHA InfoCard | 03b38eaf-4b57-49d0-8d3d-5b34643d0d1d |

| EC Number | 200-001-8 |

| Gmelin Reference | Gmelin Reference: **1156** |

| KEGG | C00047 |

| MeSH | D006996 |

| PubChem CID | 284 |

| RTECS number | LR0350000 |

| UNII | 9G82F2K86H |

| UN number | UN1779 |

| Properties | |

| Chemical formula | HCOOH |

| Molar mass | 46.03 g/mol |

| Appearance | Colorless liquid with a pungent, penetrating odor |

| Odor | Pungent, penetrating |

| Density | 1.22 g/cm³ |

| Solubility in water | Miscible |

| log P | -0.54 |

| Vapor pressure | 43 mmHg (20°C) |

| Acidity (pKa) | 3.75 |

| Basicity (pKb) | 10.33 |

| Magnetic susceptibility (χ) | χ = -20.2 × 10⁻⁶ |

| Refractive index (nD) | 1.371 |

| Viscosity | 1.57 mPa·s (at 25°C) |

| Dipole moment | 1.41 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 130.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -425 kJ mol⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | –254.0 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | D08AX01 |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS07 |

| Pictograms | GHS05,GHS06 |

| Signal word | Danger |

| Hazard statements | H226, H301, H311, H314 |

| Precautionary statements | P234, P260, P264, P280, P301+P330+P331, P303+P361+P353, P305+P351+P338, P312, P363, P405, P501 |

| NFPA 704 (fire diamond) | 3-2-2-A |

| Flash point | 69 °C |

| Autoignition temperature | 601°F (316°C) |

| Explosive limits | 3.7–33% |

| Lethal dose or concentration | Lethal Dose (LD₅₀) oral, rat: 730 mg/kg |

| LD50 (median dose) | LD50 (median dose): 730 mg/kg (oral, rat) |

| NIOSH | B026 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) of Formic Acid: 5 ppm (parts per million) |

| REL (Recommended) | 30 mg/m³ |

| IDLH (Immediate danger) | 30 ppm |

| Related compounds | |

| Related compounds |

Methanol Formate esters Sodium formate Acetic acid Oxalic acid Carbon monoxide Carbon dioxide |