Ethyl Piperazine-1-Carboxylate started making noise in laboratories back in the mid-20th century, tracing its path along with synthetic organic chemistry's rapid advancements. Chemists started with the broader family of piperazine derivatives, aiming to add structure and function to otherwise straightforward molecules. Over the decades, people working in medicinal chemistry realized the value of piperazine rings in developing pharmaceuticals. Adding the ethyl carboxylate group was more than a random tweak — it adjusted solubility, reactivity, and biological interactions in useful ways. The evolution of its synthesis paralleled growth in pharmaceutical demand, as more labs wanted building blocks offering controlled reactivity for drug scaffolds, crop protection molecules, and specialty materials.

Ethyl Piperazine-1-Carboxylate sits on a shelf as a colorless to pale yellow liquid or sometimes as a crystalline solid, depending on its storage conditions. It's used by chemists looking for a flexible intermediate, often thrown into the mix for various alkylation, acylation, or cyclization reactions. In medicinal chemistry, this compound helps build libraries of drug candidates. Technical teams familiar with pharmaceutical APIs and fine chemicals routinely recognize this molecule as indispensable for complex synthesis, especially in heterocycle-rich products.

Density figures often run close to 1.06 g/cm³ at room temperature, with a melting point around −15°C and a boiling point that hovers just above 250°C, often near 260°C. It dissolves well in standard organic solvents like dichloromethane, ethyl acetate, and acetonitrile, which comes in handy for downstream processing. The molecule isn’t particularly volatile or reactive with air, but it can show sensitivity toward strong acids or bases. That piperazine ring locks in conformational flexibility, while the ethyl carboxylate tail brings a measure of lipophilicity.

Chemicals in this class must meet purity standards set by regulatory agencies and in-house protocols. Reputable suppliers usually provide a COA (Certificate of Analysis) that lists minimum purity—often over 98% for pharmaceutical work—as well as important details like water content, residual solvents, and spectral data from NMR, IR, and LC-MS. The UN proper shipping name, hazard pictograms, batch number, and shelf-life also show up on each bottle, matching GHS requirements. If prepared for research, the label reminds users of its intended use—never for food, drug, or cosmetic applications.

People working in process chemistry synthesize Ethyl Piperazine-1-Carboxylate using ethyl chloroformate and piperazine under mild alkaline conditions, with solvents like dichloromethane or tetrahydrofuran helping to control exotherms. Reaction temperatures stay cool—ice bath to room temperature—because alkylation can run away if left unchecked. After the reaction, the mixture gets washed with brine, dried, and then concentrated, with chromatography or distillation applied as needed to yield a clean product. It’s efficient, but still demands a careful hand, especially at scale.

This compound offers an eye-opening set of downstream possibilities. Chemists often convert the ethyl ester group into other functionalities—hydrolyzing to the acid, coupling with amines to give amides, or reducing to alcohols. The piperazine ring tolerates alkylation and acylation on the secondary amine, which means it can serve as a linchpin for even more decorated molecules. In some setups, protecting groups on the nitrogen make selective chemistry easier, letting researchers fine-tune which part of the molecule reacts next. Because piperazine derivatives show up in antifungals, antivirals, and antipsychotics, this building block often appears in lead optimization campaigns across multiple therapeutic areas.

Ethyl Piperazine-1-Carboxylate goes by a handful of names in catalogs and papers. Piperylate, N-Ethoxycarbonylpiperazine, and Ethyl 1-piperazinecarboxylate pop up most frequently. Some inventory systems shorten it to EPC, while others stick with long names to avoid confusion. Academic and industry researchers trade these synonyms based on their SOPs, but CAS numbers and structural diagrams always take priority for traceability and safety.

Working with Ethyl Piperazine-1-Carboxylate in the lab requires solid ventilation. Direct skin or eye contact triggers irritation, and inhaling vapors—especially during large-scale synthesis—can provoke respiratory or mucosal effects. Gloves, lab coats, and goggles always show up in SOPs, while fume hoods and spill kits sit nearby. Waste streams feed into designated containers for halogenated solvents and amines, since unchecked drainage sets off compliance alarms and environmental headaches. Emergency shower and eyewash stations form part of the safety net. For shipping, the product travels in high-integrity, labeled packaging to dodge leaks or unauthorized access.

Ethyl Piperazine-1-Carboxylate sits at the crossroads of pharma, crop research, and specialty chemicals. Drug development teams turn to it for building kinase inhibitors, serotonin antagonists, and antifungal agents, linking its flexible chemistry to a wide roster of potential therapies. Agrochemical companies explore derivatives for new pesticides and herbicides, betting on the piperazine motif to yield better selectivity and lower toxicity. Polymer and dye manufacturers tool around with it to add nitrogen-containing groups, which can change solubility, dye uptake, or thermal properties. Across these industries, scientists leverage it not because it’s trendy, but because it gets results they can show to regulators, supervisors, and investors.

R&D teams push Ethyl Piperazine-1-Carboxylate into new synthetic routes chasing better yields, greener methods, and novel classes of bioactive compounds. Labs report using enzymatic ester hydrolysis and solvent-free conditions to cut waste and boost atom economy. Medicinal chemists build structure-activity relationships using analogs to map biological activity, aiming to land on winners for clinical trials. Analytical scientists working on process impurities hone new chromatographic techniques to guarantee purity and reproducibility. Research papers now discuss computer-aided design for piperazine derivatives, based on AI models that predict reaction outcomes and biological effects.

Mouse and rat studies on piperazine derivatives set red lines for allowable doses and workplace exposure. Acute toxicity appears mild to moderate, with oral LD50 values in the hundreds of milligrams per kilogram, though the exact number shifts depending on the modification. Chronic exposure data runs thin, which leaves employers defaulting to stricter limits and stronger PPE to keep staff out of the crosshairs. In cell assays, this molecule and its close cousins show variable cytotoxicity, demanding care in scaling up or switching from bench to pilot plant. Safety data sheets point out risks tied to amine-based compounds, including potential for sensitization and organ-system effects—making regular air monitoring and health surveillance a good investment.

Rising demand for innovative drug scaffolds and sustainable agrochemicals keeps Ethyl Piperazine-1-Carboxylate in the R&D spotlight. Advances in flow chemistry and automation hint at faster, safer synthesis. Companies keep funding alternative preparation routes—enzymatic catalysis, electrochemical methods, greener solvents—that bring lower footprints and better yields. With regulatory agencies tightening scrutiny on impurity profiling, future work on purification, analytical method validation, and life-cycle assessment is set to ramp up. Clinical and environmental studies on downstream products will likely bring sharper clarity on safe use, opening the door to new applications in diagnostics, biomaterials, and smart polymers.

Ethyl Piperazine-1-Carboxylate stands out as one of those chemicals that seems to fly under the radar, yet holds real weight in the science world. My first look at this compound came during a project on pharmaceutical intermediates, where the focus was never on headline-making drugs but rather on the nuts and bolts that make those drugs happen. Ethyl Piperazine-1-Carboxylate steps into some of the most vital chemical reactions in labs and factories making medicines. Without building blocks like this, many treatments wouldn’t make it past the laboratory.

Drug research often looks glamorous from the outside, but much of it sees chemists searching for more reliable ways to tweak molecules just so. The piperazine portion gives the compound flexibility, letting scientists shape it into all sorts of drugs—from antihistamines to antivirals. Most folks won’t see this name on a medicine bottle. It slips into the process as a starting material for synthesizing bigger and more complex molecules.

Cancer research and treatments for infectious diseases both lean on piperazine derivatives. In my conversations with pharmaceutical chemists, the recurring theme has always been versatility and consistency. Ethyl Piperazine-1-Carboxylate delivers those traits in spades, making it easier to keep costs and timelines under control in long drug development cycles.

One thing I often hear about chemical synthesis is the constant struggle with impurities and byproducts. This isn’t a niche issue. Low-quality ingredients slow everything down and sometimes lead to failed batches. In my own short stint working at a quality control lab, I saw entire shipments of medicines stopped because the intermediate chemicals didn’t meet purity standards. The reputation of a pharmaceutical company can hang on those batches. Ethyl Piperazine-1-Carboxylate, when made to a high standard, helps keep that risk in check.

Every time I’ve stepped into a laboratory, the posters on the walls serve as a reminder: chemicals like this one need care—gloves, goggles, the lot. Handling Ethyl Piperazine-1-Carboxylate requires attention because it can irritate the skin and eyes, and breathing in dust never ends well. Some small firms have run into trouble by cutting corners during storage or transport. Mishaps cost more than money; they can set back research timelines and erode trust. So, strong safety routines and training make a bigger impact than any promotional brochure ever could.

There’s a real trend toward more transparent sourcing, especially since regulators everywhere crank up scrutiny on chemical supply chains. Companies that buy and use this compound see growing pressure to double-check not only the quality but also the source. The more open labs and manufacturers are about this part of the pipeline, the easier it gets to build trust—with regulators and the public.

The backbone of progress in drug research depends on chemicals like Ethyl Piperazine-1-Carboxylate, not because the name leaps off the label but because the entire chain of treatment starts here. Committing to rigorous standards and putting care into every step—from sourcing to synthesis—helps lift the odds of getting better, safer medicines into the hands of those who really need them.

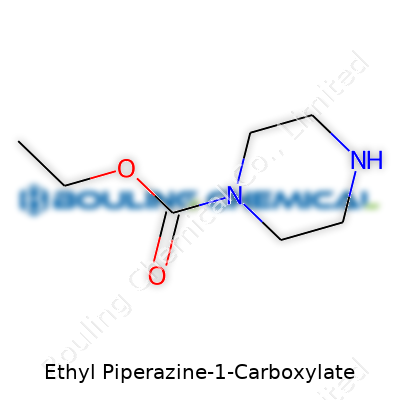

Ethyl Piperazine-1-Carboxylate shows up in research labs and chemical catalogs, sparking curiosity and sometimes confusion. Talking about its chemical formula opens up a world that connects basic chemistry to pharmaceuticals, material science, and more. The formula—C7H14N2O2—may seem like a bunch of letters and numbers, but it provides more insight than some realize.

To break it down: Piperazine forms the core. Imagine a ring where two nitrogen atoms sit opposite each other and the rest are carbons, forming a stable six-membered circle. Add onto that the carboxylate group, which introduces both a carbon and two oxygens. The ethyl part signals a small chain, giving unique properties for how the chemical interacts with others.

With this backbone, the compound offers flexibility in reactions and modifications. Chemists notice these details because tweaking the structure by even a single atom or group sometimes changes everything—solubility, reactivity, even safety. The formula C7H14N2O2 tells experienced eyes that this molecule sits in a sweet spot: not too bulky, not too simple, open for new uses.

This compound gets used in making medicines and specialty materials. The pharmaceutical industry often turns to piperazine derivatives for their roles in everything from antihistamines to antiparasitics. Those designing molecules for health know that the piperazine ring brings proven usefulness, while carboxylate and ethyl tweaks tune how the body absorbs, metabolizes, or rejects the drug.

The formula also informs safe handling. A balanced ratio of carbon, hydrogen, nitrogen, and oxygen suggests certain behaviors: how it dissolves, possible byproducts, risks if it spills. My own experience working with piperazine-based structures taught me respect for small changes. Adding an ethyl group or a carboxyl group can turn a mild compound into an irritant or change its toxicity. Safety data sheets rely on the formula for these predictions.

Mix-ups with formulas can cause real problems. Small errors in a synthesis sometimes ruin a whole batch, wasting time and resources. In regulated industries, providing the wrong chemical can endanger workers and consumers. Quality assurance teams scrutinize each step, matching received materials to formulas like C7H14N2O2 and running checks to catch substitution or contamination.

Research benefits, too. Scientists looking to publish or patent a new use for Ethyl Piperazine-1-Carboxylate must describe it exactly. Reviews of chemical literature often run into inconsistencies—sometimes a misplaced oxygen or off-by-one hydrogen. These slip-ups ripple downstream, leading to failed replications or safety incidents. Reliable science depends on attention to such details.

Modern labs use digital resources to cross-check chemical names and formulas. Access to trusted chemical databases and vigilance in double-checking every order prevents costly errors. Training lab workers to recognize structures and understand the reasoning behind formulas fosters a culture of accuracy. Companies invest in labeling tools, barcoding, and digital records so that everyone knows what’s on the shelf.

Taking formulas seriously—no matter how common the compound—means safer work, cleaner research, and fewer surprises when scaling up to production. In science and industry, even one missing carbon can throw off everything, proving that the details absolutely matter.

Anyone who has ever worked with chemicals in a lab or industrial setting realizes how quickly things can go wrong without the right storage habits. Ethyl Piperazine-1-Carboxylate, often used in pharmaceutical and fine chemical applications, isn’t something you can just leave on a shelf in the break room. Poor storage doesn’t just ruin a batch and waste money – it can put human health and the environment at risk. I’ve seen corrosive vapors eat through plastic and moisture turn perfectly good chemicals into gunky, unusable messes. Keeping things simple and safe doesn’t just help with compliance, it saves headaches down the line.

Ethyl Piperazine-1-Carboxylate prefers a cool, dry, and well-ventilated environment. From experience, anything prone to hydrolysis or sensitive to oxidation needs protection from humidity and air. Room temperature works if the area avoids temperature swings. Chemical stability drops off fast if temperatures spike above 30°C. Toss in a heatwave, and you’ll deal with discoloration or even decomposition.

Moisture spells trouble for this compound. I’ve watched humidity infiltrate a supposedly air-tight drum. Chemical suppliers usually recommend desiccators or at least sealed containers. Fumbling with a leaky cap or using glassware that doesn’t seat snugly raises the risk of water creeping in and ruining your product. I always double check for silica gel packs or other drying agents.

Direct sunlight shortens the lifespan of many pharmaceutical intermediates. UV light can set off unwanted reactions, so keeping containers in opaque cabinets or dark glass makes good sense. Relying on a windowsill or a bench near a sunbeam leads to disappointment. In a busy facility, labeled cabinets or dedicated chemical refrigerators reduce accidents and mix-ups.

Beyond quality control, there’s a health angle here, too. Exposure to vapors or accidental skin contact poses irritation risks. I’ve seen splash incidents from cracked or faulty containers take days to resolve. Spilled ethyl piperazine-1-carboxylate creates inhalation hazards, especially if stored near incompatible chemicals. Standard practice keeps incompatible classes apart – acids down one aisle, amines and esters down another. It sounds tedious until you witness a reaction gone wrong.

Manufacturers and researchers improve safety by setting up proper routines. Monitoring storage areas means more than glancing at thermometer strips. Regular checks for odd odors, softened plastics, or dusty residue help catch problems early. Labeling stays critical, not only for tracking but also for quick reference in emergencies. Training staff to notice changes in chemical appearance or smell saves a lot of trouble. Using chemical inventories and expiry tracking systems alerts teams well before problems arise.

From my time in procurement, I know that ordering only what you can use before the recommended shelf life pays off. Buying in bulk looks cheaper, but chemicals that expire or spoil cost more in disposal fees. Ethyl Piperazine-1-Carboxylate holds up well under recommended conditions, but as with most organics, fresher is always better. Good warehouse managers make rotation – that is, first-in, first-out – a core habit so nobody ends up with a forgotten, clumped drum in a back corner.

Setting up a practical, safe, and simple system for storing sensitive chemicals like Ethyl Piperazine-1-Carboxylate builds a safer workplace. Combined with training, proper storage helps keep supply chains secure, labs productive, and our air and water clean. This all comes down to treating chemicals with the respect they deserve every single day.

Moving between labs and industrial sites over the years teaches you to respect labels and safety sheets, especially for compounds that sound as technical as Ethyl Piperazine-1-Carboxylate. What worries folks—workers, researchers, or just the curious—is not just what a name implies, but how it might affect your health. This chemical’s applications reach into pharmaceuticals and specialty synthesis, but the information about its health effects doesn't always trickle down as quickly as everyone would like.

Reports and databases, such as those from PubChem and the European Chemicals Agency, show a pattern. Ethyl Piperazine-1-Carboxylate isn’t flagged among the worst offenders, but it hasn’t been cleared either. Animal research and cell studies suggest caution: inhalation, prolonged skin contact, or ingestion can irritate or harm the body. Even chemicals with lower acute toxicity can cause problems with repeated use, especially if handled without gloves, goggles, or working ventilation.

From firsthand experience, irritation from organic compounds creeps up on you. Eyes sting, skin reddens, throat grows scratchy. Ignoring minor symptoms tempts fate, since low-level exposure can stack up over time. Without solid long-term research, people working with this compound benefit most from taking established safety protocols seriously. It’s better to prevent direct contact than to run damage control later.

I remember a case in a polymer lab where safety slips let a simple spill turn into a bigger deal. Someone brushed off rinsing their hands after handling a substance that looked harmless. A little rash seemed like no big deal—until it grew and spread. That same attitude toward Ethyl Piperazine-1-Carboxylate risks both short-term irritation and longer-term uncertainty. Personal protective equipment seems like a hassle until the cost of a moment’s carelessness becomes clear.

Looking beyond immediate hazards, the compound also raises questions about waste disposal and contamination. Surfaces and tools tracked the substance beyond the workspace, reminding everyone that diligence doesn’t stop at the lab door. Simple habits—proper labeling, double-checking containers, keeping spills contained—offer the first line of defense. Chemicals like this one don’t always smell strong or look dangerous, so visual checks and warning signs matter.

Improved labeling and clear safety data can help people avoid guessing the risks. Too often, ingredients show up in fine print or technical bulletins, away from everyday eyes. Training that focuses on what can be seen and felt—signs of exposure, routes of entry, symptoms—prepares workers better than a wall of text. Clear communication saves more skin than technical jargon.

On the industry side, substitution plays a role. Sometimes greener or less reactive chemicals can do the same job with a lighter safety burden. Where substitution isn’t possible, treating Ethyl Piperazine-1-Carboxylate with the same care reserved for the worst offenders is the safest bet. Reviewing and refreshing safety skills every few months keeps the right habits fresh, especially for those who see dozens of chemical names in a shift.

So much talk about chemical safety misses the lived experience of the people handling the actual stuff. Ethyl Piperazine-1-Carboxylate, like many organics, reminds us that pushing past basic caution brings long-term payoffs. Gloves, eyewash stations, and good ventilation sound simple until you need them and they’re not there. That’s why building a system that supports real-world safety—clear signs, honest reporting of symptoms, substitution where possible—matters just as much as any technical data sheet.

Purity isn't just a nice-to-have for Ethyl Piperazine-1-Carboxylate; it's a requirement rooted in safety, performance, and regulatory compliance. In research labs and pharmaceutical production lines, impurities can spoil results, trigger failed batches, or even pose unexpected risks to those who work with the chemical. Trust begins with knowing exactly what’s in every drum or bottle, and how much of it is actually the intended compound.

Common practice in industry holds purity specifications near or above 98%, stated as HPLC (High-Performance Liquid Chromatography) purity. Trusted suppliers offer certificates of analysis with each lot, detailing purity level along with any detected impurities, water content, and sometimes trace metal analysis.

In my experience, rigorous quality control separates a reliable supplier from a mediocre one. One shipment veering below its spec can ripple through an entire process—imagine running a series of reactions only to find downstream problems caused by a suspected contaminant. The financial and scientific losses add up fast.

Labs look to precise instruments—HPLC, GC (Gas Chromatography), and NMR (Nuclear Magnetic Resonance). These methods reveal the percentage of pure Ethyl Piperazine-1-Carboxylate and pick up everything else hiding in the sample. For a compound destined for synthesis, especially in a regulated environment, those tiny unknowns matter a lot. They can show up as by-products or trace solvents clinging to the main material, and just a fraction of a percent sometimes tips the balance in sensitive pharmaceutical reactions.

Every batch arriving with thorough documentation reflects the company's attention to quality. The industry stresses full transparency: certificates of analysis, reference to international pharmacopoeias if available, and batch traceability. My own purchase decisions for lab supplies have leaned toward vendors sharing detailed spectra and impurity profiles up front. This openness matches E-E-A-T best practices—building trust on evidence, experience, authority backed by real data, and clear documentation.

Consistent purity over 98% supports safer handling and reliable results in synthesis. Less risk for side-reactions means faster scale-up from bench to pilot plant. For anyone aiming to meet or exceed regulatory standards, tight control over batch quality isn’t optional; it’s the only way forward.

Low-purity batches invite headaches: extra purification, unpredictable final products, more waste, and compliance headaches. These translate into lost time and wasted money. I’ve often steered colleagues away from bargain-basement chemicals after a bad run—costly raw material only saves money if it performs as promised.

One answer starts with auditing your supplier’s processes. Industry standards like ISO compliance and regular third-party audits build peace of mind. Visit the facility in person, check documentation is updated and cross-referenced, and ask for test sample vials. Reliable sellers won't hesitate.

If there’s any doubt, run your own batch analysis. A few hours on the instrument can prevent tangled, expensive troubleshooting later.

Purity keeps labs and plants on schedule. For Ethyl Piperazine-1-Carboxylate, users expect reproducibility and safety with every lot. Transparency, inspection-ready paperwork, and clear communication avoid surprises and keep production humming.

| Names | |

| Preferred IUPAC name | Ethyl piperazine-1-carboxylate |

| Other names |

1-Ethoxycarbonylpiperazine Piperazine, 1-ethoxycarbonyl- N-Ethoxycarbonylpiperazine Piperazine-1-carboxylic acid ethyl ester |

| Pronunciation | /ˈɛθɪl paɪpəˌreɪziːn wʌn kɑːˈbɒksɪleɪt/ |

| Identifiers | |

| CAS Number | [4083-29-8] |

| Beilstein Reference | 172120 |

| ChEBI | CHEBI:86374 |

| ChEMBL | CHEMBL2103834 |

| ChemSpider | 153706 |

| DrugBank | DB08419 |

| ECHA InfoCard | 03edaf05-9798-484a-a405-bfca6f441064 |

| EC Number | 621-90-3 |

| Gmelin Reference | 82359 |

| KEGG | C14314 |

| MeSH | D017733 |

| PubChem CID | 124056 |

| RTECS number | GU8400000 |

| UNII | EHD552186A |

| UN number | UN3271 |

| Properties | |

| Chemical formula | C7H14N2O2 |

| Molar mass | 158.22 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | Amine-like |

| Density | 1.07 g/cm3 |

| Solubility in water | Soluble |

| log P | 0.02 |

| Vapor pressure | 0.0833 mmHg at 25 °C |

| Acidity (pKa) | 9.8 |

| Basicity (pKb) | 2.87 |

| Magnetic susceptibility (χ) | -69.6×10^-6 cm³/mol |

| Refractive index (nD) | 1.463 |

| Viscosity | 1.03 mPa·s |

| Dipole moment | 4.05 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 370.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | –387.8 kJ/mol |

| Pharmacology | |

| ATC code | N04BX12 |

| Hazards | |

| Main hazards | Harmful if swallowed, causes serious eye irritation, may cause respiratory irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H315, H319, H335 |

| Precautionary statements | P261, P280, P302+P352, P305+P351+P338, P362+P364 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | 93 °C |

| Lethal dose or concentration | LD50 oral rat 1800 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 > 5000 mg/kg |

| NIOSH | Not Established |

| PEL (Permissible) | Not Established |

| REL (Recommended) | 5 mg/m³ |

| Related compounds | |

| Related compounds |

Piperazine N-Ethylpiperazine Piperazine-1-carboxylic acid Ethyl 4-aminopiperidine-1-carboxylate Methyl piperazine-1-carboxylate |