Benzimidazole didn't just spring up from nowhere; it has a story that stretches over a century. Chemists first introduced it to the world in the late 19th century, as a curiosity from experiments involving o-phenylenediamine and formic acid. Slowly, as organic chemistry blossomed, researchers realized this compound deserved more attention. Sulfanilamide-based drugs opened new doors in medicine—including antibiotics and antifungals—which pushed benzimidazole into the spotlight. This basic structural unit now shows up everywhere: from crop protection chemicals to essential pharmaceuticals. Its journey mirrors the growth of scientific curiosity fueling real-life solutions. Every time I’ve dug up historical timelines in chemical textbooks or spoken with synthetic chemists, one theme stands out—benzimidazole marked turning points in both chemical theory and manufacturing.

Pick up a bottle marked with “benzimidazole” at a chemical supplier, and you’re holding a building block behind some of the biggest pharmaceutical breakthroughs. It’s not flashy. Usually, you’ll find it as a white to off-white crystalline solid, with a slightly bitter taste (many lab folks can attest to that, purposely or accidentally). What sets benzimidazole apart comes down to its versatility. Its chemistry supports the structure of antifungal, antiviral, and anticancer medicines. On the shelf or in a spreadsheet, benzimidazole stands as a keystone for active pharmaceutical ingredients (APIs) and advanced materials.

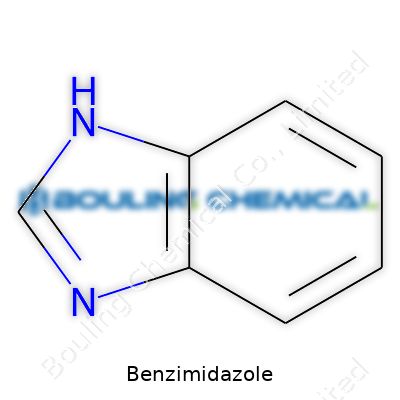

With benzimidazole, analysis in the lab reveals a molecule with clear traits that chemists latch onto. Its melting point, usually found in the range of 170-174°C, stands consistent enough for clear identification. Solubility doesn’t impress in water—it barely dissolves—but throw it in organic solvents like DMSO or ethanol, and it opens up. The structure—a fused benzene and imidazole ring—drives its chemical stability. This means the molecule resists acids, holds up in basic conditions, and tolerates heat fairly well. The planar form also invites stacking interactions, making it a surprising guest in supramolecular chemistry. From my experience in the laboratory, molecular stability grants researchers the freedom to play around with new derivatives, expanding the lineup for drug discovery and chemical synthesis.

In the real world, chemists want hard data before buying or working with chemicals. For benzimidazole, the label needs to spell out the minimum purity percentage—often above 98% for research. Manufacturers include batch numbers, lot codes, and often spectral data. You might spot IR, NMR, and mass spectrometry peaks listed on a technical data sheet. This information becomes vital for reproducibility—a tenet of Good Manufacturing Practice (GMP) embraced not just by regulators but by anyone who’s ever needed to backtrack a failed experiment. Proper labeling matters for safety too: hazard pictograms, risk phrases, and recommended storage conditions keep everyone up to date on best practices.

Factories and labs don’t just find benzimidazole lying around. Most preparation involves condensing o-phenylenediamine with carboxylic acids, aldehydes, or related carbonyl sources. Classic procedures rely on controlled heating—sometimes in strong acid—to coax the rings together. In my professional experience, improvements have trimmed down reaction times and cut waste. Microwave-assisted techniques, for example, shorten what used to be overnight runs to less than an hour. The push for green chemistry now steers more labs toward solvent-free or water-based syntheses. It’s hard not to be impressed when one synthetic tweak slices both cost and environmental burden.

What makes benzimidazole so useful comes down to all the ways chemists can modify its structure. Adding different side groups to the nitrogen atoms opens up a shopping list of analogs. Halogenation, alkylation, or acylation of the benzene or imidazole ring creates compounds with new properties. In drug development, chemists often tweak benzimidazole cores to improve absorption, reduce toxicity, or target specific enzymes. The sturdy backbone holds up under a range of reaction conditions, giving creative minds plenty of room for exploration. Ask anyone working in medicinal chemistry—finding new ways to decorate this molecule remains a mainstay in the hunt for next-generation therapies.

Depending on the catalog or context, benzimidazole goes by a few other names. Some call it 1,3-benzodiazole, reflecting its structure: a benzene fused to an imidazole. Suppliers in pharma and agrochemical markets might list it among a landscape of proprietary trade names, especially for modified derivatives. Its derivatives, like albendazole and thiabendazole, pack more recognition due to their use as medicines or pesticides. Through years of reading journals and purchasing chemicals, I’ve learned that keeping up with synonyms matters—miss a name, and you risk overlooking important research or missing out on stock in the warehouse.

Labs and production plants treat benzimidazole with respect, not out of fear but out of professionalism. Most pure benzimidazoles aren’t classified as particularly hazardous, but as with most fine chemicals, dust inhalation and accidental skin contact are best avoided. Chemical Safety Data Sheets, or SDS paperwork, spell out details: wear gloves, use fume hoods, prevent spills, label waste for hazardous disposal. European regulators under REACH and US authorities through OSHA set high expectations, and most manufacturing floors rise to them—protecting both workers and the environment. Years spent in industry drilled into me that routine training and a clear chain of communication make all the difference between safe handling and close calls.

Few molecules compare to benzimidazole for sheer impact in daily life, whether people realize it or not. In crop science, its derivatives protect farms from fungal invaders, translating into reliable harvests and stable food prices. In medicine, benzimidazole rings form the backbone of antifungals, anticancer agents, and even treatments for parasitic diseases that plague both developing and developed worlds. Chemical industries tie it into pigments, corrosion inhibitors, and specialty polymers. As someone who once ran biological assays on new chemical entities, the faint hope that a benzimidazole derivative might show a positive result felt tangible; whole research teams depended on it to steer projects to the finish line.

Researchers focus on benzimidazole chemistry not for tradition’s sake, but because nearly every major leap comes from relentless questioning. Teams across Europe, Asia, and North America push for compounds with stronger biological activity, lower environmental impact, or cheaper synthesis routes. High-throughput screening, computational modeling, and structure-based drug design now accelerate the pace—no longer stymied by the manual benchwork of the past. Reading current literature and talking with colleagues at conferences, the message comes through: without disciplined experimentation and investment in human expertise, innovation around benzimidazole would stall, choking off opportunities for better drugs and safer chemicals.

Deciphering the risks around benzimidazole and its derivatives demands as much scrutiny as exploiting its benefits. Animal studies, case reports, and environmental monitoring stack up over decades. Some derivatives—especially those used in high doses as anthelmintic drugs—show potential for liver or bone marrow toxicity if mishandled. Strict testing regimens for new drug candidates sort the promising from the problematic, using both in vitro assays and real-world trials. From time to time, regulators adjust acceptable daily intakes or issue new guidelines after gathering more evidence. In my own lab career, protocols for handling biologically active benzimidazoles reflected a healthy skepticism—use the minimum, dispose of it carefully, and stay up to date with the literature. Those habits don’t just protect health; they preserve research credibility.

As scientific understanding deepens, benzimidazole keeps offering more surprises. Next-generation drug candidates aim at tackling resistant microbes and hard-to-treat cancers, focusing on tuning benzimidazole’s framework to slip past cellular defenses or block tough biochemical targets. Green chemistry has inspired a wave of interest in sustainable synthesis techniques—cutting waste and energy while boosting output. In the agricultural sector, new benzimidazole-based fungicides hope to overcome rising resistance while shrinking environmental footprints. If my experiences in research settings have taught me anything, it’s that no “mature” area of chemistry ever sits still—benzimidazole’s evolving story proves that, with each new derivative and every application expanding what started out as a simple aromatic heterocycle.

Benzimidazole holds a sturdy spot across medicine, agriculture, and science. I remember seeing it crop up years ago on a prescription for a rescue dog at the animal shelter where I volunteered. Back then, I couldn't pronounce it, but now, after watching how it shifted quickly from a veterinary staple to a key part of human medicine and farm work, the reason for its popularity is hard to miss.

Doctors reach for benzimidazole-based drugs because they make short work of pesky intestinal parasites. Hookworm, roundworm, whipworm – all met their match. People keep getting infected by these worms, especially in places where clean water runs short. Children miss school, adults lose workdays. Albendazole and mebendazole, both built on the benzimidazole backbone, play a big part in health programs run by the World Health Organization. They cost pennies to make, so even the tightest public health budgets can afford them.

I once watched a public health campaign in rural Central America distribute thousands of mebendazole pills. Weight checks, dose calculations, and a lot of talk about handwashing. After a few months, school attendance shot up. Kids had more energy and fewer stomach aches. Studies back this up: Worms in the gut drag down nutrition, and deworming helps children grow and thrive.

Farmers depend on earth that produces. Benzimidazole derivatives such as carbendazim and thiabendazole protect crops from fungi and pests. Bushels of wheat, rice, and apples would look far worse at harvest without treatments like these. Fungal diseases spread fast, and in humid places I’ve seen mold destroy entire crops in a week. Spraying fields, treating seeds, and soaking fruit post-harvest with fungicides keeps food on shelves. Because of this, food supply chains stay steady from field to grocery bag.

Of course, heavy use of these chemicals brings up big questions about resistance. Fungi learn fast. Disease outbreaks grow harder to control if benzimidazoles don’t work like they used to. More farming communities combine different types of treatments and rotate fields, hoping to slow resistance and protect yields.

Beyond the clinic or the farm, benzimidazole pops up in science labs. This chemical structure gives researchers a reliable way to build new molecules. Scientists have tinkered with dozens of benzimidazole variants to design fresh cancer drugs and antifungals, searching for ways to treat diseases that current pills miss.

Benzimidazole also acts as a probe in cell studies. By disrupting tubulin in cells, it can stop cell division, which helps cancer researchers understand tumor growth and look for breaking points in disease processes.

With all these benefits, the temptation to use benzimidazoles everywhere runs high. Still, real risks build with overuse. Worms develop resistance, so treatments stop working. Fungal populations on farms can turn stubborn. Surveillance programs that track resistance in both hospitals and farms help spot trouble early, allowing a switch to alternative treatments before things spiral.

Public education matters. People who know the signs of infection, who understand why finishing a prescribed course matters, and who recognize fungal threats in their fields can keep benzimidazole’s legacy strong. As countries invest in sanitation and food safety, and as science moves toward smarter, targeted drugs, benzimidazole will keep earning its stripes across health, food, and technology.

Benzimidazole drugs have earned their place in medicine as effective treatments for worms in humans and animals. Most people who take these medications get the relief they hope for, but side effects can pop up. Some are mild and just annoying, while others deserve more caution. Doctors rely on them because they work, but patients should always know what they’re signing up for.

Nausea, stomach pain, and diarrhea show up for a good number of people after a few doses. These side effects remind me that no pill is a free ride. I’ve seen folks come in, worried after their stomachs won’t settle. For most, the discomfort fades as their bodies adjust, but the experience still sours the treatment.

Headache creeps up in the first few days sometimes. It can be hard to tell if the drug or the infection gets the blame, but there’s no denying many people notice it. The difference in how each person reacts depends on age, gender, eating habits, even mood. No two stories are exactly alike.

Drug rashes can be scary. Red, itchy bumps, sometimes hives, show up out of nowhere. Most people are not expecting this kind of trouble from a worm tablet. Some even need antihistamines to calm things down. Allergies to benzimidazoles sneak up, just like food allergies. It starts as a skin thing, but in rare situations swelling in the face or trouble breathing point to a medical emergency. If I ever see anybody with sudden swelling or rash within hours of a medicine, I tell them to call emergency help. Safety trumps everything else.

Liver enzymes go up in the blood after benzimidazole use sometimes. It rarely causes symptoms, but regular blood work finds it. Doctors check on this, especially for people with pre-existing liver problems. Most folks never feel a thing, but for those with weak livers, this is serious. I tell patients to watch for yellow eyes or skin, which signal more than just a minor side effect.

Low white blood cell counts, called leukopenia, crop up in a small slice of users. This worries cancer doctors, since people who need these drugs sometimes already face infection risks. Not everyone needs constant blood tests, but if someone feels extra tired, weak, or gets unexplained fevers, that’s a reason to talk to a practitioner fast.

Benzimidazoles cross the placenta. I would never ignore this. Expecting mothers need to talk with their provider before swallowing any pills. Research has not sorted out all the long-term risks for an unborn child. If a worm infection is causing major trouble in pregnancy, the pros and cons need careful weighing.

Reading the leaflet and having a conversation with a healthcare professional before starting any medicine makes sense. Reporting side effects right away helps. Blood tests before and during long courses lowers the risk of surprises.

Every medicine offers help but sometimes takes a toll. With benzimidazole drugs, most side effects fade, but nobody deserves to be caught off guard. Asking questions, sticking to recommended doses, and checking in with a trusted provider always steer people to safer use.

People rely on benzimidazole compounds for treating a range of parasitic infections—like whipworm, roundworm, or hookworm. Medical workers prescribe these for good reason: they stop worms from growing and multiplying, interrupting their hold on the body. Based on my own work with public health outreach, children in rural communities see huge changes in energy and focus at school after proper worm treatment. It’s not a small deal; these medications matter.

Doctors and pharmacists determine a dose by the patient's weight, age, and specific parasite. Adults receive different pills or liquids than children. A typical approach runs anywhere from a single dose to a few days’ routine. If a health worker explains how to take it, follow those instructions without tweaking the plan. Skipping or doubling up has real consequences, sometimes making the infection worse or encouraging resistance. Health teams have seen that firsthand in community clinics, where people sharing pills or guessing their dose fall ill all over again.

Some benzimidazoles do just fine on an empty stomach, while others work better after food. This isn’t always clear from the packaging, so I trust a doctor or pharmacist to explain what fits my needs. For families, setting up dosing at breakfast or dinner helps remember it. It’s common for parents in resource-limited settings to line kids up for a quick spoonful at dinnertime—not fancy, but reliable.

Combining benzimidazole with certain other medications, like anticonvulsants or antibiotics, sometimes causes unpredictable interactions. People with health conditions, or those taking medicine for something else, should mention every pill or supplement to their provider. From experience, people sometimes keep quiet about herbal mixtures or over-the-counter drugs. Full honesty goes a long way toward avoiding surprises and getting the best outcome. Pharmacists often have seen these combinations, so even a quick chat at the pharmacy window helps.

Most people experience benzimidazole with no fuss. Mild stomach upset or headaches happen, but rarely do folks stop because of these issues. Allergic reactions or signs like severe rashes, trouble breathing, or swelling need quick medical attention. One parent in my neighborhood saw a child recover from worms but had to act fast when a rash appeared—being vigilant made all the difference. Serious side effects don’t pop up often, but it’s better to know and ask for care early.

Storing the medicine right—cool, dry, away from sunlight, out of children’s reach—helps it last and work properly. In some places, benzimidazole access only comes during health campaigns, so community engagement matters. Sharing pills with neighbors, common in some regions, invites mistakes. Nobody truly benefits from a half-dose or expired batch. Support from trained health workers keeps dosing accurate and side effects monitored, building trust and accountability.

Clear, hands-on demonstrations—showing how to measure and give medicine—work wonders in places with low health literacy. Picture cards and reminders help families keep track of dosing without high-tech tools. Community leaders promoting the benefits make more people comfortable with regular deworming programs. Countries investing in these efforts see kids with fewer absences, families with fewer medical bills, and communities with renewed health. Taking benzimidazole the right way does more than clear parasites—it protects lives and futures.

Benzimidazole touches various aspects of health and agriculture. At its core, benzimidazole works as a backbone for several drugs, especially in the world of antiparasitics. Farmers, vets, and doctors have relied on benzimidazole derivatives to treat parasitic infections in animals and humans for decades. Fenbendazole, mebendazole, and albendazole might ring a bell for anyone who’s wrestled with roundworms or pinworms.

These drugs can clear out stubborn parasite infestations. When farm animals stay healthy, food safety improves for everyone. Egg and meat yields take a hit when parasites run wild. After working with farmers for years, I can vouch for this firsthand—livestock free of parasites put on weight better and experience fewer health problems. Out in rural areas, public health also looks a lot better when families use benzimidazoles to stamp out intestinal worms.

Doctors stick with established doses, and over-the-counter sales remain rare in many countries. The biggest threat comes from misuse, particularly by those looking for a quick cure or assuming more medicine equals faster results. Liver toxicity and bone marrow suppression have surfaced when folks ignore recommended guidance or use these drugs far longer than they should.

Although most people and animals handle prescribed doses well, no pill is risk-free. Some people feel mild side effects—nausea and mild stomach pain crop up from time to time. Allergic reactions happen much less often, but they do show up in clinic reports.

Once, we ran into trouble on a local farm after a rancher dosed a small herd of goats with higher-than-recommended levels in a rushed attempt to clear out a parasite outbreak. In that group, two animals became lethargic and lost their appetite for several days. They recovered, but the scare stuck with the farmer. It drove home a simple lesson: dosing accuracy matters, and expert advice saves time, money, and worry.

The story doesn’t end with treatment. Parasite drugs pass through animals into pastures, so traces of benzimidazole can slip into the ecosystem. This build-up makes some worms increasingly resistant over time, just like what happens with antibiotics. A few years ago, resistance got so bad on some sheep farms that farmers had to swap treatments or adjust grazing practices just to control outbreaks.

Beyond resistance, leftover drug residues sometimes drift into groundwater or soil. The long-term risk to wildlife hasn’t been pinned down completely yet, but it’s an area researchers take seriously. As someone who spends time with both vet teams and conservationists, I’ve witnessed how tough it can be to balance animal health and environmental responsibility.

The most responsible approach starts with getting veterinary or medical input. That means making sure animals get weighed before dosing, sticking to withdrawal times for meat and milk, and never reaching for leftovers after a new problem appears. More careful record-keeping helps spot resistance patterns early.

Better awareness among farmers, pet owners, and patients leads to smarter, safer use. Drug developers have started working on new classes of parasite medicine, and some labs are busy testing alternatives that hit parasites in novel ways. Education matters just as much as innovation; people keep animals and families safer when they understand what’s at stake.

Benzimidazole isn’t just one drug—it’s a group of medicines, mostly used to fight off parasites or certain fungal infections. Many folks know names like albendazole, mebendazole, or thiabendazole. Doctors lean on these drugs for conditions caused by roundworms, pinworms, whipworms, hookworms, and sometimes to tackle tapeworms or even some unique infections in tropical parts of the world.

I’ve talked with parents and food service workers panicking over a suspected outbreak of pinworms. Here’s what a straightforward treatment plan looks like:

In rural clinics, whipworm, roundworm, and hookworm show up more. Mebendazole 100 mg twice daily for three days usually does the trick. Albendazole, 400 mg as a single daily dose (either just once or for three days, depending on the bug), can clear these up. Kids above two and adults handle these dosages well in most cases, based on guidance from sources like the World Health Organization and CDC.

Some infections—like hydatid disease (caused by dog tapeworm) or neurocysticercosis (tapeworm eggs affecting the brain)—show up less in richer countries, but aren’t rare in rural or tropical areas. Here, longer treatment matters. Albendazole at 400 mg twice daily for 28 days is common for hydatid disease. Neurocysticercosis usually needs a similar dosing plan, but with careful supervision. Anti-parasitic drugs like these can kick off strong inflammatory responses; those treating them need experience with the condition to avoid causing more harm than good.

Out on farms and ranches, veterinarians also use benzimidazoles, but in different dosages. Sheep, cattle, and even pets like dogs get specific weight-based doses, often once every few months during high-risk seasons. Resistance is becoming more common—especially in livestock—so careful tracking and not overusing these medicines makes a difference in keeping them useful for the long haul.

Even though benzimidazoles are generally safe, misuse or overuse can set off drug resistance, just like antibiotics. That’s a problem I’ve seen in parts of the world where people buy medicine without doctor input. Some folks also miss the need for repeating doses to catch any newly hatched worms. Eating and living with better hygiene helps reduce the need for medicines in the first place. Handwashing, keeping nails short, and cutting back on contaminated food are boring, unglamorous, but proven approaches.

Getting the right diagnosis before jumping into treatment always matters. A professional can zero in on the proper drug, the right duration, and any needed follow-up testing. For tough cases—like neurocysticercosis—managing side effects and coordinating with specialists changes outcomes for the better. These drugs work best as part of an overall health and prevention plan, not just as a quick fix for symptoms.

| Names | |

| Preferred IUPAC name | 1H-benzimidazole |

| Other names |

1H-Benzimidazole Benzimidazol Benzimidazolium |

| Pronunciation | /ˌbɛn.zɪˈmɪd.əˌzoʊl/ |

| Identifiers | |

| CAS Number | 51-17-2 |

| 3D model (JSmol) | 9.2 12 C8H6N2 c1ccc2[nH]c(nc2)c1 |

| Beilstein Reference | 87319 |

| ChEBI | CHEBI:16881 |

| ChEMBL | CHEMBL1631 |

| ChemSpider | 5487 |

| DrugBank | DB11221 |

| ECHA InfoCard | 100.022.271 |

| EC Number | 1.5.3.1 |

| Gmelin Reference | 79297 |

| KEGG | C06567 |

| MeSH | D000594 |

| PubChem CID | 865 |

| RTECS number | DD6475000 |

| UNII | MA9927I6EA |

| UN number | UN2583 |

| CompTox Dashboard (EPA) | DTXSID5021816 |

| Properties | |

| Chemical formula | C7H6N2 |

| Molar mass | 118.13 g/mol |

| Appearance | White to off-white crystalline powder |

| Odor | Odorless |

| Density | 1.3 g/cm3 |

| Solubility in water | Slightly soluble |

| log P | 1.48 |

| Vapor pressure | 7.7E-6 mmHg at 25°C |

| Acidity (pKa) | 5.5 |

| Basicity (pKb) | 8.3 |

| Magnetic susceptibility (χ) | -60.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.658 |

| Dipole moment | 3.98 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 117.9 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | 59.9 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3217 kJ/mol |

| Pharmacology | |

| ATC code | P02CA01 |

| Hazards | |

| Main hazards | Harmful if swallowed, causes skin and eye irritation, may cause respiratory irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS05,GHS07 |

| Signal word | Danger |

| Hazard statements | H302, H315, H319, H335 |

| Precautionary statements | P261, P264, P270, P271, P272, P301+P312, P330, P360, P363, P370+P378, P403+P235, P501 |

| Flash point | Flash point: 230°C |

| Autoignition temperature | 470°C |

| Lethal dose or concentration | LD50 (oral, rat): 960 mg/kg |

| LD50 (median dose) | LD50: 960 mg/kg (rat, oral) |

| NIOSH | DT6475000 |

| PEL (Permissible) | PEL for Benzimidazole: Not established |

| REL (Recommended) | 0.01 mg/L |

| Related compounds | |

| Related compounds |

Imidazole Benzothiazole Benzoxazole Indole Quinoxaline Purine |