Science rarely unfolds in tidy chapters, and 4-Piperidinylcarboxylate reflects that. The roots of this compound stretch back to mid-twentieth-century drug development, when chemists searching for new ways to tweak heterocyclic compounds often stumbled across new building blocks by accident. 4-Piperidinylcarboxylate’s piperidine core attracted attention decades ago because it offered stability and predictability in chemical transformations. Anyone who worked in pharmaceutical or materials research during the latter part of the 1900s will remember seeing derivatives of piperidine listed in nearly every patent for central nervous system drugs. These compounds started as basic intermediates, but industry quickly saw chances to pull them into scales far beyond the academic lab.

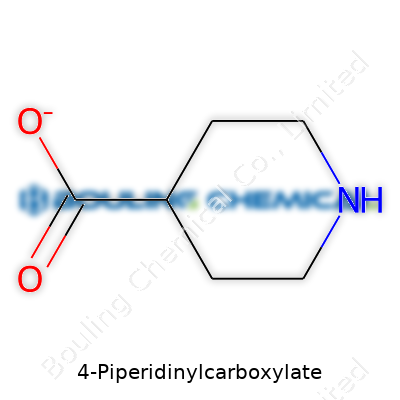

Glancing at a data sheet for 4-Piperidinylcarboxylate, you’ll see a chemical with broad aspirations. Its subtle modifications accommodate plenty of formulation needs: medicinal chemistry, polymers, even niche roles in electronics. Its direct structure, bearing a piperidine ring with a simple carboxylate group attached at the 4-position, makes it a solid foundation for both fine-tuning performance and maintaining consistency. No wonder research chemists and process engineers keep coming back to it when they encounter reactivity demands or regulatory constraints that shut off other routes.

The first thing that stands out about pure 4-Piperidinylcarboxylate is its solid form at room temperature—usually a crystalline or powdery solid, depending on its exact formulation and purity. Its melting point lands conveniently between 80 and 100°C for many derivatives, so those working with standard laboratory heating equipment rarely run into trouble. What adds even more value is that it dissolves well in most of the common polar organic solvents like methanol, ethanol, and acetonitrile, but stays stubbornly undissolved in most hydrocarbons, which helps during extraction and purification. Chemically, its carboxylate group means it can participate in both nucleophilic and electrophilic substitution reactions, acting as a versatile intermediate for building much bigger molecules.

Look on any modern spec sheet, and you’ll notice manufacturers now detail the precise purity (often above 98%), spectral characteristics, and recommended storage conditions. Proper hazard labeling remains crucial, including standard GHS pictograms for irritant or acute toxicity, since many piperidine analogs can cause irritation to the skin and mucous membranes. The best suppliers define water content by Karl Fischer titration and confirm structure by NMR and infrared spectroscopy, because anything less leaves too much uncertainty for fine chemical or drug synthesis. Quality supply demands batch analysis, and anyone who has sorted out problems arising from sloppy labeling or off-spec batches knows the cost and headaches these corners can cause.

Most commercial-scale preparation follows a pretty consistent route: cyclization of amino acids or their derivatives under carefully controlled temperatures and pH, then introduction of the carboxylate function at the 4-position using established carboxylation reactions. I’ve seen operators pipette in alkali bases and dial-in temperatures with the kind of practiced accuracy you only earn sweating through late nights in pilot plants. The process creates a product that works across research and industrial fields. As the demand for greener chemistry grows, more labs have tried biocatalytic approaches or solventless synthesis, trying to sidestep environmentally harsh reagents. While these options still need optimization, early results suggest they will move into mainstream use as regulatory environments evolve.

The real magic happens when 4-Piperidinylcarboxylate gets pushed into more complex transformations. The piperidine ring handles substitutions without losing its backbone, letting chemists swap out hydrogens for groups like methyls, aryls, or halogens. The carboxylate itself serves as a launchpad for coupling reactions, opening doors to peptide synthesis or the formation of more sophisticated scaffolds. In the right hands, this molecule transforms into dazzling arrays of analogs, acting as a workhorse in everything from drug candidate optimization to specialty material development. Those with hands-on synthesis backgrounds appreciate how predictable and tolerant it can be, minimizing those annoying dead-ends where reactions stall or side-products pop up.

Depending who you ask, you might hear chemists refer to it as 4-Piperidinecarboxylate, piperidine-4-carboxylate, or even “piperidine acid” in less formal settings. Pharmacopeias and regulatory documents also include CAS numbers and IUPAC names which can confuse younger lab staff who haven’t yet developed the knack for matching trade names to reagents on procurement portals. A quick scan through patent literature shows a patchwork of synonyms, reflecting efforts from different industries to mark territory or claim slightly modified versions. Every synthesis lab ends up with an informal spreadsheet mapping internal codes back to commercial sources, because failure to track naming stumbles can mean costly reruns and compliance headaches.

Nobody gets through a few years in chemical manufacturing or research without at least one close call. 4-Piperidinylcarboxylate demands gloves, eye protection, and ventilation because dust and trace vapors can irritate skin, eyes, and nasal membranes. Teams use sealed transfer systems and good spill kits, particularly at scales above a few hundred grams. Chemical compatibility lists warn against mixing with strong oxidizers, and storage in dedicated, labeled containers helps avoid contamination. The best labs routinely train staff to recognize symptoms of acute exposure before they escalate, prioritizing medical checkups and incident tracking. Handling standards now reflect a balance between efficiency and safety, shaped by decades of lessons from both minor mishaps and major near misses.

4-Piperidinylcarboxylate’s practical value shines in its real-world uses. Pharmaceutical chemists rely on its structural backbone to build compounds for neurological, cardiovascular, and metabolic disorders. It shows up in agrochemical discovery and helps construct specialty polymers for electronics where toughness and flexibility play a role. Analytical chemistry teams use it as an intermediate for generating custom calibration standards in method development. An old professor once pointed out you’ll spot its fingerprints all over decades of patent filings when the challenge calls for a strong, modifiable scaffold. These diverse uses grow out of its mix of chemical stability, reactivity, and practical handling.

Research into derivatives and new roles for 4-Piperidinylcarboxylate keeps accelerating, driven by advances in computational modeling and high-throughput screening. Academic-industrial collaborations have started mapping unexplored biological pathways, uncovering interactions that could lead to new drugs or imaging agents. Many R&D teams focus on tweaking side chains to increase selectivity or reduce off-target effects, using both brute-force synthesis and machine learning predictions. As someone who has spent endless hours rerunning reactions in hopes of a few extra percent yield, I value any compound that responds predictably to methodical optimization. Funding cycles and the pressure to publish make tried-and-true compounds like this especially attractive, since they shorten the ramp-up time for launching new programs.

More research has tackled potential hazards tied to both chronic exposure and acute poisoning. Animal studies suggest that while 4-Piperidinylcarboxylate generally shows lower toxicity than some piperidine analogs, risks increase if dosing exceeds reasonable thresholds. Some derivatives interact with GABAergic and nicotinic receptors, raising concerns about off-target physiological effects at higher concentrations. Occupational exposure studies led to updated workplace limits and prompted equipment upgrades across handling, waste, and personal protective equipment. Having seen the faces of colleagues benched after mild exposure incidents, I can say there is no substitute for up-to-date SDS sheets and rigorous lab culture. Modern advances like online badge monitors and closed transfer systems keep improving peace of mind in work environments.

The chemical industry never stands still, and 4-Piperidinylcarboxylate will feature in even more surprising places as new synthetic routes, regulatory demands, and product opportunities appear. Chemists are investing in greener synthesis methods, trying to cut down on hazardous by-products and energy use, responding to both environmental regulations and social pressure for cleaner technology. Early-stage work hints at roles in next-generation drug discovery, advanced electronic materials, and even as anchors for supramolecular assemblies built at the nano level. Drawing on past experience, success will rely on open data sharing, better cross-industry training, and regulatory agility—none of which come free, but each worth the investment if the goal is safer, more creative science.

I remember the first time I worked in a small university research lab, and the shelves lined with glass bottles seemed endless. Labels carried numbers and long chemical names like 4-Piperidinylcarboxylate, beneath which sat words that got too familiar too quick: “purity 98%,” “purity 95%.” Over countless syntheses, the number stamped alongside “purity” meant the difference between a sloppy experiment and one we actually wanted to repeat.

4-Piperidinylcarboxylate pulls up in organic chemistry mostly as an intermediate. Chemists check for its purity before they even think about using it. Purity might sound technical but it’s pretty simple if you think about it: the higher the purity, the cleaner the compound. Commercial labs usually ship this chemical out with a purity between 97% and 99%. Some batches hit higher, others fall short because of side reactions or not-so-ideal storage.

Here’s why this matters. Imagine spending weeks on a synthesis, then finding out a corrupted intermediate ruined your product. Extra impurities mess with everything – yields drop, data gets fuzzy, safety takes a hit. Gases, dust, or leftover solvents become a chemist’s headache. Medical research teams, especially, want as few question marks as possible in their data. Trace impurities in something used as a building block can introduce risk for everybody down the line, whether that’s a lab tech or a patient years later.

Back in the lab, analysis isn’t some black box. A simple melting point test sometimes works for solids, but chemicals like 4-Piperidinylcarboxylate usually see more advanced techniques. Most teams I know lean on high-performance liquid chromatography (HPLC) or nuclear magnetic resonance (NMR). Even gas chromatography steps in, though some forms of this chemical resist that. NMR delivers a spectral fingerprint showing whether there’s more hiding in the bottle than what you paid for.

Big companies, especially those producing pharmaceuticals, set strict in-house standards. They demand certificates of analysis for every vial, confirming the batch’s purity. For smaller outfits or academic groups, price sometimes takes priority over a near-perfect sample – but even then, if things get too messy, experiments grind to a halt.

If a fresh batch doesn’t meet the mark, tossing it might be painful, especially on a tight budget. Some labs try extra recrystallization or distillation. Sometimes it works, sometimes all you get is more wasted time. Sourcing from more trusted suppliers makes the difference. Teams contact vendors, check quality control records, or even try negotiating for better batches – especially where human safety is on the line.

Having seen the aftermath of botched purities, I know too well why labs chase that last percent. More reliable checks, clear documentation from suppliers, or even pooling resources for higher-grade chemicals help researchers sidestep headaches and keep their focus where it belongs – on answers, not on fighting contamination.

If you’re wondering if purity is just a number, it’s not. With 4-Piperidinylcarboxylate or any building block, purity shapes everything researchers can count on – accuracy in the data, the speed of progress, and the safety of everyone in the room.

4-Piperidinylcarboxylate doesn’t behave like your average household cleaner or off-the-shelf supplement. In any setting I’ve worked in, no one just leaves a compound like this out on a shelf. Practically, chemicals that have piperidine groups or similar reactive structures develop funkiness over time if they sit in open air or sunlight. Anyone who’s spilled even a tiny amount outside the bottle knows it: odors come out, discoloration follows, and pretty soon you find yourself debating which glove layer will keep it all off your skin.

I've always kept chemicals like this in shaded, dry locations. Heat can trigger slow breakdown reactions—so the usual rule is to stay below room temperature, say around 15–25°C. Higher temperatures sped up unwanted changes for us in the lab, where one forgotten vial on a sunlit counter turned gritty and darker than it should. Setting your storage in a cool dark cabinet works for a reason: less light hitting the bottle means fewer photochemical side effects, like yellowing or unpredictable degradation byproducts.

Oxygen is the usual suspect behind strange chemical changes. Even with basic organic salts like this, the risk of slow oxidation sticks around. We used tightly-capped bottles and only opened the container as needed. Vacuum-sealing or flushing the storage space with nitrogen offers even more protection; a few labs I know take this extra step for really sensitive projects or to meet long storage timelines. If you forget and leave the cap off, or use a poor-quality lid, even a dry storeroom won't stop gradual spoiling.

Humidity acts like an uninvited guest in any storage space. Just a bit of water vapor can speed up hydrolysis and trickle in over weeks. Crystals clump, cakes form, and pretty soon weighing out an accurate dose turns into a clumsy, sticky task. For us, silica gel packs and low-humidity cabinets always kept the risk in check. Opening bottles only as needed, storing samples in air-tight poly-lined containers — those steps bought us months, even years of reliable use.

In a university lab, I saw folks get lazy about separating food areas from chemical storage. You don’t have to work in a pharma facility to realize: keeping these bottles away from snacks and sips is basic common sense. Strong rules around food handling prevent accidental cross-contamination, so I never mix spaces, even at home with garden supplies.

Sharp labeling pays off in a pinch; nothing ruins your day like stumbling across an old jar and wondering what it contains because someone scribbled initials ten years ago. Clear labels with content, hazard, and date turn headaches into minor tasks. I learned this one after pitching two full bottles due to forgotten contents. Good inventory management keeps surprises to a minimum. Digital logs with expiry dates can flag old stock before it develops problems, and it saves the trouble of buying more than you need.

Anyone who’s ever spent a little time in a chemistry lab probably knows there are certain compounds that pop up again and again. 4-Piperidinylcarboxylate is one of those names you’ll bump into if you start asking where some of our most important medicines or industrial tools begin. Despite the mouthful of a name, this compound isn’t just lab-jargon; it’s more like the backstage crew that keeps the show running — quietly crucial in the background.

One of the bread-and-butter uses of 4-Piperidinylcarboxylate shows up in pharmaceuticals. Many painkillers and psychiatric drugs don’t just appear out of thin air; they start life as simple structures and get built up, step by step. The piperidine ring found in this molecule often ends up right in the bones of medicines used to treat everything from depression to chronic pain.

Once, during a research stint, I watched a medicinal chemist try out hundreds of slightly different molecules by tweaking side chains and functional groups. 4-Piperidinylcarboxylate’s structure let her add essential pieces to new candidates for anti-psychotic drugs. Its reactivity made it easy to attach other groups, which opened up a whole new category of medicine. That kind of flexibility makes chemists happy and speeds up discovery.

There’s a practical reason labs all over the world pull this compound off the shelf. Some chemical reactions need a “helper” to nudge things along; 4-Piperidinylcarboxylate often fills this role. It can act as an intermediate or protective group during the steps that turn a hunch into a scalable process.

Factories making hundreds of kilograms of active drug ingredient use this compound because it reacts predictably and cleans up easily. Less mess means fewer headaches on the cleanup side. And since manufacturing usually becomes one of the biggest costs in drug development, using well-behaved chemicals like this actually keeps important drugs within reach for more people.

4-Piperidinylcarboxylate isn’t limited to the pharmacy. Its core piperidine structure shows up in crop protection, too. Large agrochemical firms rely on similar building blocks to design molecules that fend off pests without sticking around in the soil long afterward.

I once chatted with an engineer working on polymers. He said small tweaks in their building blocks changed their toughness, taste, or even how much sunlight they could handle. By slipping in piperidine-based compounds, teams could push the boundaries for everything from plastics to special coatings. These changes mean the difference between a cracked water pipe and one that lasts twenty years longer.

The growing use of synthetic building blocks like 4-Piperidinylcarboxylate does raise some flags. Supply chain snags — like shortages from global events — can bring projects to a grinding halt. I remember our lab scrambling one year to source enough core materials when everything seemed delayed. That experience sparked a shift: more labs started looking into ways to make key intermediates closer to home or try greener synthetic methods that skip harsh solvents.

Green chemistry isn’t just trend-chasing; it means less waste, lower costs, and safer workplaces. If production moves toward more sustainable routes, the next crop of drugs, plastics, and agrochemicals should carry a smaller footprint.

Most folks outside of science circles don’t realize how many familiar products depend on these building blocks. 4-Piperidinylcarboxylate doesn’t trend on social media, but its fingerprints are everywhere from pharmacy shelves to farm fields. The ways it links up with other molecules can shape the future of health, materials, and environmental safety.

Safety information isn’t a luxury in the chemical industry. It’s non-negotiable. Whenever someone asks for a Material Safety Data Sheet (MSDS) or a Certificate of Analysis (COA) for something like 4-Piperidinylcarboxylate, it’s because the risks can be more than theoretical. These documents go beyond paperwork—they actually protect everyone in the chain from accident to litigation. I’ve seen the way corners can get cut when information isn’t clear or available. In small labs or classrooms, people have gone without proper resources, and it’s always been a gamble. Not a game anyone wins.

Having worked with obscure reagents in academic research, I know asking for an MSDS isn’t just red tape. It’s being proactive. Some specialty chemicals slip through the cracks, especially those not widely traded or sitting in regulatory gray zones. I remember tracking down documentation on rare intermediates—sometimes all you get is a photocopied catalog page or a supplier’s vague statement. That’s not good enough. Chemicals like 4-Piperidinylcarboxylate might lack broad market documentation, especially if they’re not manufactured in bulk. But even niche chemicals deserve safety documentation.

Everyday solutions start with suppliers. Most reputable chemical companies publish MSDS automatically. If it doesn’t pop up in a Google search, that’s a red flag. Anyone buying or handling the substance should expect to get an MSDS with the order, and if that’s missing, calling the supplier should be the next step. COAs come with product shipments and prove purity, origin, and batch quality.

Trade platforms or chemical marketplaces rarely fill this gap. You might find a forum thread of folks asking the same question. Regulatory agencies like OSHA or the European Chemicals Agency sometimes catalog chemicals—though for specialized substances, listings get sparse. In these cases, direct contact with the manufacturer is the only real solution. If the company won’t provide it, consider walking away from the deal.

Skipping the MSDS or pushing ahead without a COA has real-world costs. I’ve seen fume hoods emptied by alarms, all because someone discovered incompatibilities after the fact. Imagine learning about stability issues as a reaction gets out of control. Fires, spills, and poisonings aren’t rare until people start treating unknowns like they deserve respect.

Small companies sometimes roll the dice on unlisted items. Maybe they’re chasing profit or just not thinking about risk—until a regulator walks in. Fines and shutdowns follow. End users carry the risk, but so do the folks handling shipping and storage. If something goes wrong with a chemical and no documentation can be shown, there’s no legal cover.

If you run a lab or teach students, refusing to buy any chemical without full documentation isn’t just a rule—it’s a favor to your future self. Push suppliers for proper documents and make it clear you won’t compromise. Trade groups should set the standard. Regulators—especially in rapidly changing research fields—must keep pushing for better record-keeping even for highly specialized compounds.

Most accidents come down to missing information. Transparency is the shield. Push for it, even if it means a little more effort before that bottle hits your bench.

Chemistry throws a lot of tricky names out there, but 4-Piperidinylcarboxylate isn't quite as cryptic as it seems. It breaks down into two main groups: the piperidine ring—which looks like a six-sided ring with five carbons and a single nitrogen—and a carboxylate group attached to the fourth carbon. The actual chemical formula for 4-Piperidinylcarboxylate is C6H11NO2. Its molecular weight clocks in at 129.16 g/mol. Seeing those numbers in black and white brings the compound out of the fog.

Classes taught from dusty old textbooks often pound in the significance of chemical formulas and molecular weights, but those numbers grow meaningful once someone tries to mix or measure a compound in real life. Understanding molecular weight, for example, is crucial for getting the right dose in experiments. Add too much or too little, and the result turns unreliable, wasted time and materials, setting research back. When I worked in a basic college chemistry lab, nothing got emphasized more than precise measurement—relying on the accuracy of molecular weights written up on the containers.

In real-world research, a tiny change in formula—like swapping a carbon or moving an atom—can transform how a substance works in the body or interacts with other chemicals. Even seasoned researchers trip up if they make an incorrect assumption about a compound’s structure or weight. That's taught me to triple-check not just raw numbers, but the actual IUPAC names and structures too—one simple error can set off a chain reaction, especially in synthesis or pharmaceuticals work.

Mistaking the molecular weight or misidentifying the formula can spark problems ranging from failed reactions to dangerous exposures. Pharmacists and biotech workers rely on specifics like 129.16 g/mol for 4-Piperidinylcarboxylate to get accurate dosing in medicines or research chemicals. That accuracy kept the old lab manager in my department up at night—one slip on a label, one misread entry on a scale, and the whole protocol has to start from scratch.

Supply chain confusion can follow if naming conventions get mixed up. Similar compounds sometimes carry overlapping trade or slang names, so procurement mistakes aren't rare. For organizations footing big bills for rare compounds, ordering the wrong molecular weight means losing serious money and time. It frustrates everyone down the line, from warehouse techs to the scientists burning through grant money.

No one likes wasting time tracking down formula details or correcting human error. Companies should push for direct access to trusted chemical databases, with software that auto-populates key facts and cross-checks names, formulas, and molecular weights. Researchers benefit from training that dives past rote memorization, helping them visualize chemical structures and think through how a small shift in structure changes everything.

I always keep a notebook with sketches of molecules—something tangible. For those new to chemistry, drawing out the piperidine ring with its carboxylate hanger makes formulas like C6H11NO2 stick better than memorizing flashcards. Companies that support practical learning, not just digital lookups, see fewer mistakes in the lab and more confident employees.

All told, knowing the formula and weight for a compound like 4-Piperidinylcarboxylate means more than passing tests—it saves time, money, and sometimes, the integrity of research itself.

| Names | |

| Preferred IUPAC name | piperidine-4-carboxylate |

| Other names |

1-Piperidinecarboxylic acid Piperidine-4-carboxylate 4-Piperidinecarboxylate |

| Pronunciation | /ˈpɪp.əˌrɪd.ɪn.il.kɑːrˈbɒk.sɪ.leɪt/ |

| Identifiers | |

| CAS Number | 4546-87-0 |

| Beilstein Reference | 107529 |

| ChEBI | CHEBI:180557 |

| ChEMBL | CHEMBL470380 |

| ChemSpider | 163179 |

| DrugBank | DB08378 |

| ECHA InfoCard | echa.europa.eu/substance-information/-/substanceinfo/100.042.210 |

| EC Number | 87629-67-2 |

| Gmelin Reference | Gmelin Reference: "107980 |

| KEGG | C06077 |

| MeSH | D010878 |

| PubChem CID | 135393334 |

| RTECS number | TK3150000 |

| UNII | XTA9F87079 |

| UN number | UN3276 |

| Properties | |

| Chemical formula | C6H11NO2 |

| Molar mass | 201.25 g/mol |

| Appearance | White solid |

| Odor | Odorless |

| Density | 1.08 g/cm³ |

| Solubility in water | Slightly soluble in water |

| log P | 0.02 |

| Vapor pressure | 1.79E-07 mmHg at 25°C |

| Acidity (pKa) | 10.7 |

| Basicity (pKb) | 4.02 |

| Magnetic susceptibility (χ) | -61.3·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.496 |

| Dipole moment | 5.77 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 371.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | –383.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4210 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | N06AX11 |

| Hazards | |

| Main hazards | Harmful if swallowed, causes skin and eye irritation, may cause respiratory irritation |

| GHS labelling | GHS07 |

| Pictograms | GHS05, GHS07 |

| Signal word | Warning |

| Hazard statements | Harmful if swallowed. Causes serious eye irritation. May cause respiratory irritation. |

| Precautionary statements | P264, P271, P280, P301+P312, P305+P351+P338, P337+P313 |

| Lethal dose or concentration | LD50 oral (rat) 570 mg/kg |

| LD50 (median dose) | LD50 (median dose): 1800 mg/kg (rat, oral) |

| NIOSH | ST1488729 |

| PEL (Permissible) | Not established |

| REL (Recommended) | REL: NIOSH REL 5 mg/m³ |

| IDLH (Immediate danger) | Not established |

| Related compounds | |

| Related compounds |

Piperidine Piperidine-4-carboxylic acid Methyl 4-piperidinecarboxylate Ethyl 4-piperidinecarboxylate 4-Piperidone N-Boc-piperidine-4-carboxylic acid |