Industry never stops shifting, and some chemicals that seemed unremarkable a few decades ago have become essential today. 4-(3-Chloropropyl)morpholine stepped onto the scene after researchers in the late 20th century dove deep into morpholine derivatives, most of which aimed to address tough challenges in organic synthesis and pharmaceuticals. Before it made a name for itself, chemists tinkered in labs, stacking new side chains onto the morpholine ring. The appearance of the 3-chloropropyl group, a modest but potent tweak, opened new doors. It became a workhorse for custom-tailored molecules, thanks to its combination of stability and reactivity. Professional journals from the late 1970s mention its uses in developing agrochemicals and as a flexible building block, but the momentum picked up pace in the 1990s as more industries realized what this little molecule could offer.

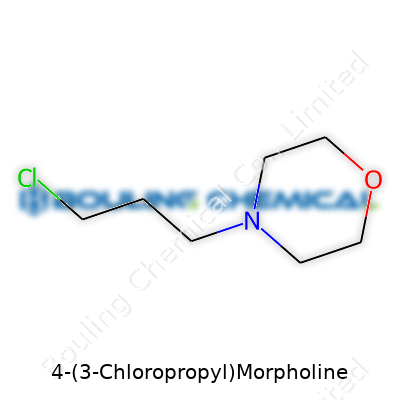

What’s in a name? In the case of 4-(3-Chloropropyl)morpholine—often called 4-CPM, N-(3-chloropropyl)morpholine, or sometimes just “chloropropylmorpholine”—the answer is a morpholine ring fitted with a three-carbon chain capped by a chlorine atom. That setup gives the molecule both an amine and an alkyl halide handle. Its utility goes way beyond surface-level; chemists respect 4-CPM for its adaptability in synthesis and compatibility with common solvents and reagents. Whether you’re running a pilot lab or a full industrial reactor, you’ll find 4-CPM available in grades suited to both research and production, often packaged with detailed documentation for compliance.

Hold a sample of 4-(3-chloropropyl)morpholine up to the light, and you’ll notice a clear to slightly yellowish liquid, easy to measure and pour. It brings a faint amine odor to the bench—hard to ignore in an enclosed space. Its melting point sits below room temperature, and it refuses to solidify under typical storage conditions. Boiling points tend to land above 230°C, which lets it survive most lab heating methods. Water solubility is moderate; it mixes readily with organics like ethanol, acetone, and chloroform. On the chemical side, the morpholine ring shrugs off mild acids and bases, but the 3-chloropropyl chain opens up a world of alkylation and nucleophilic substitution reactions. You’ve got a molecule that’s easy to handle in reactions and stubborn against many forms of degradation, so long as you keep it away from strong oxidizers or intense heat.

Ordering a bottle from a major supplier, you’ll spot the lot number, purity (often 98% or higher), expiration date, and exact volume or weight. Documentation includes a certificate of analysis with gas chromatography and NMR verification. Labeling requirements set by regulatory authorities spell out hazard classifications: flammable, toxic if swallowed or inhaled, potential irritant. At shipping, you’ll see compliance with UN transport codes, and material safety data sheets that leave no room for uncertainty. Strict labeling under GHS matches the reality—this is a chemical deserving respect and handling by professionals equipped with full PPE.

Synthesizing 4-(3-chloropropyl)morpholine doesn’t call for custom reactors, but experience pays off in preventing unwanted side products. Most routes begin with morpholine, a simple heterocycle, and 1,3-dichloropropane as a key alkylating agent. The reaction settles in a polar aprotic solvent, often DMF, with a base like potassium carbonate to pull the right protons at the right moment. Under mild heating, the morpholine nitrogen attacks the chlorinated carbon, kicking off a nucleophilic substitution and linking the three-carbon chain onto the ring. Excess starting materials and byproducts clear out through distillation and washing, leaving a product pure enough for even the pickiest requirements. Industrial processes scale easily, with careful controls for vapors and stir efficiency. In academic labs, some prefer using a two-step method—first alkylating morpholine with an epoxide, then treating the intermediate with hydrogen chloride. Both techniques have their champions, but the end goal stays the same: a pure, well-characterized, and properly handled chemical.

Watch 4-CPM under the microscope of a seasoned synthetic chemist, and you’ll see why it draws repeat customers. The chlorine functions as an invitation for nucleophilic substitution—near-perfect for making quaternary ammonium salts, extending carbon chains, or latching onto aromatic rings. It anchors in multistep syntheses where robustness matters, and reacts smoothly with both hard and soft nucleophiles. The morpholine segment holds its own in reducing environments or mild acid/base conditions, serving as a backbone for pharmaceuticals, catalysts, or even surfactants. Modification possibilities include oxidative cleavage for new functionalities, reductive amination, or coupling in click chemistry. Labs have taken 4-CPM further by swapping the halide for other leaving groups, or using it as a stepping stone for even stranger side chains. Chemical creativity finds strong footing here.

Chemists never settle for a single name. The bottle might say 4-(3-chloropropyl)morpholine, but catalogs may list N-(3-chloropropyl)morpholine, or just 4-CPM. Beyond these, researchers sometimes refer back to CAS Number 7527-95-5, making sure they’re all talking about the same thing during procurement or cross-disciplinary projects. Nobody wants to order the wrong product or stumble over paperwork, so these alternative names form the language of routine and compliance.

Handling comes with responsibility. The chlorinated chain and morpholine core send clear warning signs to safety professionals. Standard lab best practices recommend chemical goggles, butyl gloves, and long sleeves every time you crack open a bottle. Fume hoods become non-negotiable, thanks to the risk of vapor inhalation. Direct skin exposure leads to stubborn burns or rashes, and accidental ingestion can trigger central nervous system symptoms—dizziness, nausea, or worse. Industrial settings adopt closed-transfer systems and chemical spill procedures, with neutralizing agents ready at hand. Storage guidelines dictate a cool, dry place, tightly sealed containers, and frequent inspections for corrosion or leaks. Disposal meets strict regional rules, usually involving high-temperature incineration via licensed contractors. Regular training and periodic safety audits keep risks controllable, not just for compliance but for peace of mind.

Ask a dozen chemists about 4-CPM’s application, and you’ll get a dozen answers. Any industry pushing the envelope in medicinal chemistry, material sciences, or agrochemistry probably leans on this molecule at some point. In drug development pipelines, 4-CPM finds a role both as an intermediate and as a tailoring group for side-chain engineering. Crop protection companies slot it into new pesticide backbones, using the chloropropyl chain to fine-tune biological activity. In the polymer field, the morpholine piece serves as a handy linking unit, anchoring chains or changing solubility properties. Beyond the laboratory, several suppliers have explored its utility in epoxy curing agents and anti-corrosion additives, banking on its chemical resistance and flexibility. Custom manufacturers keep 4-CPM in steady production cycles, often tailoring batch sizes and purity to each buyer’s workflow.

Chemistry keeps evolving, and 4-CPM finds its spot in the middle of ongoing R&D projects. Research teams experiment with new derivatives to hunt for higher selectivity or increased potency, branching out into fields like green chemistry and sustainable synthesis. Structural tweaks, often led by AI-guided compound selection, employ 4-CPM as a scaffold in virtual screening libraries. In academic settings, research groups publish reports on converting 4-CPM to a host of N-heterocyclic compounds and alkylated amines with therapeutic prospects. Analytical chemists dive in, optimizing GC-MS and HPLC methods for trace-level detection in complex mixtures, spurred by the need for precise impurity control. Collaborative work between universities and manufacturers yields patents on novel applications every year, each new use tied to real-world problems.

No one should underestimate toxicity, especially with organochlorine compounds. Early animal studies flagged 4-CPM for moderate acute toxicity when mishandled, with LD50 values signaling the need for proper care. Research teams track its metabolic breakdown, noting liver and kidney as major processing sites. Evidence of central nervous system effects surfaced in high-dose exposure studies, with symptoms ranging from drowsiness to more serious neurological reactions. Chronic low-dose studies remain rare, though manufacturers and regulatory groups regularly test for mutagenicity, reproductive effects, and bioaccumulation. Industry guidelines treat 4-CPM as a hazardous substance, not because it’s the most dangerous molecule in the lab, but because repeated exposure packs cumulative risk. Safety data focus on minimizing inhalation and direct contact, leading to higher investments in ventilation, PPE, and emergency response drills. Ongoing investigations look at environmental breakdown and safe bioremediation strategies.

Chemistry as a field keeps adapting, and the spotlight on 4-CPM only grows brighter. As regulations on solvents and reagents tighten, companies search for versatile intermediates that deliver both reactivity and manageable safety profiles. The morpholine ring’s reputation for pharmaceutical compatibility makes 4-CPM a regular subject in drug discovery programs. Synthetic routes gain ground in terms of yield and environmental impact, with more teams exploring catalytic, solvent-free, or recyclable systems. Alongside traditional fields, a new wave of researchers tests its adaptations for advanced polymers and specialty coatings. As demand for renewable resources rises, the pressure mounts to extract every bit of utility from established chemicals. Collaboration between industry, academia, and government helps to map out the most responsible application strategies, keeping safety—and innovation—front and center.

Most people rarely come across the name 4-(3-Chloropropyl)Morpholine unless deep in the world of chemicals. In chemical labs and factories, this substance pops up during different stages of making drugs, agricultural products, and specialty materials. Chemists value the structure for its flexibility when making more complex molecules. This compound supplies a backbone that lets drug makers build new medicines or tweak older ones to reduce side effects.

Research teams often work with morpholine derivatives for the sake of developing new therapies. The morpholine ring appears in plenty of antiviral and antifungal drugs, and the 3-chloropropyl group turns out to help molecules link together in ways that boost their performance inside the body. Synthetic chemists use 4-(3-Chloropropyl)Morpholine as a shortcut for making certain antibiotics and central nervous system drugs. By keeping this substance on hand, labs speed up the process. That means less waiting for critical treatments to hit hospital shelves.

The jobs don’t stop at human health. In agriculture, manufacturers reach for this compound as a building block in plant fungicides. By starting with 4-(3-Chloropropyl)Morpholine, they produce chemicals that stop deadly molds from wiping out harvests. More food reaches tables with the help of this invisible ingredient. Factories also use it when they make coatings and dyes. I remember touring a textile plant where the operator described how this chemical helps dyes bond to fabrics better, preventing colors from washing out. Small changes in chemical structure, made possible by ingredients like this, drive improvements you can see in everyday life—from brighter clothing to less food waste.

Despite all these benefits, production comes with risks. I’ve seen firsthand how workers in chemical plants monitor exposure limits and suit up with protective gear. 4-(3-Chloropropyl)Morpholine can irritate skin and lungs. Countries with strong chemical regulations require companies to label and store these kinds of chemicals securely.

Regulatory agencies in Europe and North America track who buys and sells certain industrial chemicals. Unregulated, intermediates like this one draw interest from traffickers looking for shortcuts in making illegal drugs. Law enforcement and chemical suppliers work together to prevent diversion. It’s frustrating to see resources meant for medicine misused in crime, but robust tracking and staff training cut down on these incidents.

Balancing access and safety takes coordination. Regular audits, background checks, and digital tracking systems exist for a reason. No system is perfect, but tightening one link—extra safety data sheets, better education for workers, improved air handling—pays off. I’ve seen safe practices turn what looks like a risky business into a hub of innovation. The public rarely notices the pieces behind everyday protection and health until something goes wrong. By supporting stronger safety policies, we create space for medical, agricultural, and material innovation without ignoring the hazards.

Relying on 4-(3-Chloropropyl)Morpholine delivers life-saving treatments, safer crops, and more reliable goods. Responsibility for handling it safely must sit with everyone who manufactures, sells, or researches with it. Vigilance in the lab and factory keeps the benefits flowing and the risks contained.

Nothing quite helps like breaking down a compound to its bones. 4-(3-Chloropropyl)morpholine shows up in plenty of research because it brings together a morpholine ring and a chlorinated side chain. The morpholine ring has four carbons, one nitrogen, and one oxygen—simple enough. Picture morpholine as a six-membered ring, with atoms lined up like a dance, hand-in-hand: O-C-C-N-C-C. Attach a three-carbon chain carrying a chlorine atom on the fourth carbon position of the morpholine, and the real personality of this molecule comes out.

Count the atoms: Morpholine by itself is C4H9NO. That chloropropyl tail adds three carbons, six hydrogens, and a chlorine. Swap a hydrogen for the tail, and you end up at C7H14ClNO.

Many online sources point to the same formula: C7H14ClNO. Solid, trustworthy chemical catalogs like Sigma-Aldrich or PubChem confirm this. Overlooking a single atom—or even a hydrogen—can derail a synthesis, waste time, and lead to frustrating nights in the lab.

Get this wrong, and every calculation that hangs on it goes down the tubes. Divide it up: Carbon comes in at 12.01 g/mol, hydrogen at 1.008 g/mol, nitrogen at 14.01 g/mol, oxygen at 16.00 g/mol, and finally, chlorine at 35.45 g/mol.

Add them: 84.07 + 14.112 + 35.45 + 14.01 + 16.00 = 163.64 g/mol.

Chemical syntheses hinge on precise mass measurements. If anyone has tried to scale up work from milligrams to kilograms based on bad math, they know the agony of seeing an expected reaction fail miserably. Even in high school, a botched stoichiometry calculation ruined my experiment—too much of a reactant, not enough of another, and nothing went right. Professional labs don’t tolerate that.

Pharmaceuticals, specialty polymers, or agrochemicals based on morpholine derivatives have no room for slip-ups. Mistakes carry heavy costs, including potentially dangerous by-products or lost intellectual property battles. Regulatory filings—especially with agencies like the US FDA—leave no space for fuzzy chemistry.

Today, digital chemistry databases and reliable supplier catalogs make double-checking a formula faster than ordering morning coffee. I trust ChemSpider and the PubChem project, which crowdsource validation through academic and industry users. These crowdsourced platforms help researchers avoid classic wrong-turns. Mistyped formulas or misplaced halogens can still slip past, but the checks and balances work most days if you know what you’re looking for.

It pays to cross-check every number. The humble calculator and a sharp pencil often save the day when digital tools get cluttered or databases get out-of-sync. Saving a retraction, a missed deadline, or customer complaint often hangs on habits like this. The stakes for a mistake, especially in scale-up, sting more than the minor hassle of doing it right the first time.

A small tip: keep a habit of jotting the molecular breakdown every time, no matter how routine. Training new staff on this basic muscle memory has saved my workplaces from costly errors. It’s simple, honest work—just the bread and butter of chemical research, and worth every second spent.

Working in labs and handling a slew of chemical substances, I’ve learned to take every compound seriously—even those that sound harmless by name. 4-(3-Chloropropyl)morpholine is a clear example of a specialty chemical that often crops up in niche industrial applications. Its use might not make headlines, but that doesn’t mean it’s risk-free. Many industrial chemicals carry nasty surprises because manufacturers, researchers, and regular workers may only see them in small doses or controlled spaces. Once a chemical enters broader use, its risks become everyone’s problem.

The general rule with organic compounds containing chlorine rings true here: they deserve respect. Chlorinated compounds often spell trouble for human tissue. 4-(3-Chloropropyl)morpholine is no exception. Based on its makeup, eye, skin, and breathing irritation can hit anyone exposed, sometimes even after brief contact. Related compounds trigger headaches, dizziness, or worse if inhaled, absorbed, or swallowed. Safety data sheets from credible chemical suppliers mark this one with hazard warnings—corrosive to skin and eyes, harmful if inhaled, toxic if swallowed.

Some people brush off calls for gloves or goggles in the lab, thinking only concentrated acids require that level of protection. That thinking can land you in the emergency room, especially with compounds like this. The National Library of Medicine lists chloropropyl-containing chemicals as potential sources of severe burns or pulmonary distress. Chemical burns don’t just hurt—they can mean life-changing nerve or tissue damage.

Years ago, I witnessed a friend suffer chemical burns after a splash with another morpholine derivative. The incident hammered home how fast mistakes unfold. Chemical toxicity often hides behind inconsistent labeling and the illusion of safety built by repetition. Placing blind trust in fume hoods or lab coats isn’t enough. Once these chemicals enter waterways or air through spills or poor storage, communities and the wider environment pay the price.

The United States Environmental Protection Agency and European regulators label many chloropropyl substances as environmentally hazardous, citing their ability to persist in water and soil. That kind of information rarely makes its way into high school or even undergraduate chemistry lessons, contributing to a false sense of security. Systematic studies on 4-(3-Chloropropyl)morpholine remain limited, but its chemical cousins bear out the same story: toxicity on both personal and ecological fronts.

Knowledge gaps make hazard management even more urgent. If you work near this chemical or handle it yourself, personal protective equipment isn’t optional—face shield, gloves made for organics, and a solid lab coat keep you ahead of accidental exposure. Fume hoods pull vapors away, but only proper training ensures no one cuts corners under time pressure. In workplaces, safety audits and transparent communication about exposure risks keep everyone accountable. Mats, spill kits, and chemical-resistant storage matter just as much as safety signage.

Better labeling, stricter regulation, and easier access to Material Safety Data Sheets—those steps would protect both seasoned chemists and anyone who finds themselves near a spill or mishandled shipment. Community awareness campaigns bridge the gap, so health workers and first responders know what to expect when exposure cases crop up. Finally, companies must invest in research to fill toxicity data gaps instead of waiting for accidents to force their hand.

There’s real harm possible if 4-(3-Chloropropyl)morpholine gets underestimated. Treat it with the same vigilance reserved for any chemical with a corrosive or toxic label. Experience has shown me that careful attention, honest risk assessment, and collaborative prevention efforts don’t just keep the workplace safe—they protect families and neighborhoods long after the lab doors close.

I’ve spent plenty of time working around chemicals just like 4-(3-Chloropropyl)Morpholine. It doesn’t take long to learn that safety in a lab or warehouse hinges on respect for what the material can do. Health experts and chemical safety authorities have documented that this substance can irritate the eyes, skin, and respiratory system. Some morpholine compounds also get flagged for more serious long-term effects if mishandled. The lesson: even if a spill seems like “just another bottle,” burns or worse can follow if you get careless.

With any chemical that contains chloro groups, unwanted reactions stay a real worry, especially around strong acids, bases, or oxidizers. Industry guidelines — and real-world accidents — show that ignoring this reality damages equipment, sets up fires, or even exposes workers to harmful vapors. I remember a case where improper segregation in storage led to a reaction that triggered an evacuation. Local firefighters didn’t appreciate it, and neither did the maintenance crew fixing the fallout.

Keeping 4-(3-Chloropropyl)Morpholine in a well-ventilated, dry, and secure spot goes a long way. I’ve seen solid results storing sealed containers in cabinets marked for hazardous organics — always kept cool, usually below 25°C. Moisture-proof surroundings help, since water can sometimes corrode containers or set off slow chemical changes. Clear labeling prevents someone from grabbing the wrong bottle, and records help in case anything unusual turns up later. From personal experience, nothing beats double-checking that shelves can handle leaks, since liquids love to find their way downhill.

Lab practice, research libraries, and company policies all push the same point: gloves, goggles, and lab coats aren’t up for debate. In one plant I worked, a splash got past someone’s basic gloves and caused a nasty rash. A better choice — thicker chemical-resistant gloves and face protection — would have spared them a trip to the clinic. Running an eyewash station and a safety shower nearby just makes sense. Simple steps protect skin, eyes, and airways much better than promises to “be careful.”

Even well-run sites see the odd accident. Being ready pays off. Granular absorbents, neutralizing agents, and proper waste bins should stay close. Quick response keeps small spills from turning into serious risks. Checking the area for ventilation and fire hazards makes a huge difference. I’ve watched experienced crews shut down spill zones in minutes, while unprepared groups turned a little mess into a cleanup marathon.

Solid training beats shortcuts every day. People who know the risks and the right precautions work with steady hands and fewer mistakes. I try to make safety briefings practical by sharing real stories, not just procedures. It sticks better when someone pictures what could happen instead of just reciting a rulebook. If something changes — new containers, new staff, or a different ventilation setup — updates go out right away.

Regulators and safety organizations keep adjusting rules as studies reveal more about chemical health effects. Staying current gives workers and communities better odds. Audits, up-to-date safety data sheets, and honest communication shape safer workspaces for everyone. Experience tells me that “good enough” can turn dangerous in a blink. Treating every detail as essential helps make sure nothing gets missed.

Those working in laboratories or industrial spaces will quickly notice how packaging influences chemical safety and workflow. 4-(3-Chloropropyl)Morpholine, a specialty chemical often used in synthesis for pharma intermediates or specialty materials, doesn’t get the glamour treatment of big-name compounds. Yet how it arrives at your loading dock matters a great deal. No one in the lab wants leaky bottles or cross-contamination—and in chemical production, a cracked drum can turn a good day sideways.

Vendors commonly offer this compound in UN-rated HDPE bottles, aluminum containers, or steel drums. I’ve seen 500-gram and 1-kilogram plastic bottles for research batches or pilot runs. Larger orders, say 25- to 200-liter steel drums, get used for routine bulk production. These drums carry proper seals and tamper-evident closures, avoiding surprises that can derail a QC audit or draw attention from regulators. Aluminum options often show up for air-sensitive or light-sensitive chemicals, but morpholine derivatives usually stay happy in black HDPE or steel.

Quality warehouses rarely ship 4-(3-Chloropropyl)Morpholine loose or in makeshift bags. Cracking open a dented steel vessel can bring flashbacks of past spills and cost overruns. Stabilized, lined drums or bottles cut down on the risk. In smaller syntheses, I’ve reached for material packed under nitrogen for extra peace of mind—sometimes the minor upcharge saves hours cleaning up disappointment.

Few subjects spark as much debate as purity grades. Some researchers demand 98%+ for their experiments to run smoothly, otherwise end up chasing mystery byproducts. Industrial buyers weighing the balance of yield and cost might select 95% or “technical grade” for less critical production steps. I’ve found that for downstream pharma intermediates, even a single percentage point can alter product quality or regulatory compliance. Labs pushing boundaries lean on analytical grade, where purity sits above 99% by gas chromatography—anything less creates guesswork, especially where reproducibility counts.

Certificates of Analysis (CoA) form a non-negotiable part of any shipment. Trusting a drum without solid paperwork usually backfires. I’ve had batches get rejected after a single GC-MS run revealed discrepancies between label and reality. I always urge teams to review impurity profiles, particularly residual solvents or chlorinated byproducts, since those traces invite scrutiny from end users and watchdogs alike. Supplier transparency about test methods encourages peace of mind; weak documentation usually raises a red flag long before a drop is poured out.

Companies juggling regulatory hurdles watch for suppliers who take traceability seriously. Hazard class labeling, batch numbers, and shelf life get more attention now, especially from clients in Europe, the US, and Japan. A supplier’s reputation rests on those details, and I’ve seen buyers blacklist firms after a single bad episode. Packing integrity and accurate grade claims form the line between successful scale-ups and paperwork headaches with customs or local authorities.

Fixing packaging or purity mistakes takes time that researchers, QA managers, and procurement teams rarely have. Open communication with suppliers keeps expectations straight—ask clear questions about closures, liners, and lot-to-lot consistency before placing an order. During delivery, venturing beyond a simple visual inspection to an in-house identity check goes a long way. In my experience, those extra minutes early in the process save significant trouble down the line and build trust between buyers, suppliers, and end users alike. For anyone handling 4-(3-Chloropropyl)Morpholine, these decisions shape everything that follows in the lab or on the factory floor.

| Names | |

| Preferred IUPAC name | 4-(3-chloropropyl)morpholine |

| Other names |

1-(3-Chloropropyl)morpholine Morpholine, 4-(3-chloropropyl)- 3-Chloropropylmorpholine |

| Pronunciation | /ˈfɔːr θri ˈklɔːrəˌproʊpɪl ˈmɔːrfəˌliːn/ |

| Identifiers | |

| CAS Number | 24449-22-1 |

| 3D model (JSmol) | `3D model (JSmol)` string for **4-(3-Chloropropyl)Morpholine**: ``` CCCCN1CCOCC1Cl ``` |

| Beilstein Reference | 1720735 |

| ChEBI | CHEBI:189491 |

| ChEMBL | CHEMBL492332 |

| ChemSpider | 21405160 |

| DrugBank | DB02138 |

| ECHA InfoCard | 25-211-875-1 |

| EC Number | “4179-29-3” |

| Gmelin Reference | 1109192 |

| KEGG | C18633 |

| MeSH | D017245 |

| PubChem CID | 107798 |

| RTECS number | UB3155000 |

| UNII | 3JYG1O439F |

| UN number | UN2735 |

| Properties | |

| Chemical formula | C7H14ClNO |

| Molar mass | 177.66 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | Amine-like |

| Density | 1.10 g/mL at 25 °C |

| Solubility in water | Slightly soluble |

| log P | 0.6 |

| Vapor pressure | 0.2 mmHg (25°C) |

| Acidity (pKa) | 10.3 |

| Basicity (pKb) | 6.27 |

| Magnetic susceptibility (χ) | -7.42e-6 |

| Refractive index (nD) | 1.486 |

| Viscosity | 1.157 cP (20°C) |

| Dipole moment | 3.61 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 359.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -5292.7 kJ/mol |

| Hazards | |

| Main hazards | Harmful if swallowed, causes skin and serious eye irritation, may cause respiratory irritation |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | H302 + H312 + H332: Harmful if swallowed, in contact with skin or if inhaled. |

| Precautionary statements | P261, P264, P271, P272, P280, P302+P352, P321, P362+P364, P405, P501 |

| NFPA 704 (fire diamond) | Health: 2, Flammability: 1, Instability: 0, Specific: - |

| Flash point | 78 °C |

| Autoignition temperature | 230 °C |

| Lethal dose or concentration | LD50 (oral, rat): 1890 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50: 1800 mg/kg |

| NIOSH | Not established |

| PEL (Permissible) | No PEL established. |

| REL (Recommended) | REL: NIOSH TWA 5 mg/m3 |

| Related compounds | |

| Related compounds |

4-(2-Chloroethyl)morpholine N-(3-Chloropropyl)morpholine 4-(3-Bromopropyl)morpholine 4-(3-Iodopropyl)morpholine 4-(3-Chloropropyl)piperidine |