Decades back, the chemical industry saw a shift toward advanced organic fluorine compounds, mainly because scientists grew more aware of the unique stability and reactivity that fluorinated structures offer. When research teams looked for new morpholine derivatives to improve properties for pharmaceutical intermediates, specialty solvents, and surface modifiers, they kept running into the same limitations with traditional alkyl substitutions. Around the turn of the 21st century, 4-(2,2,3,3-Tetrafluoropropyl)Morpholine started gaining attention as engineers began tapping into the compound’s particular substitution pattern for better chemical resistance, volatility profiles, and bioactive potential. The development of precision fluorination techniques, especially with reagents like Selectfluor and advanced perfluoroalkylation methods, finally made this compound accessible for both lab-scale curiosity and commercial exploration. Conversations with chemists at the time show that the leap from theory to practice meant overcoming both the challenge of selective fluorine incorporation and the hazards linked to handling such reactive compounds.

At a glance, 4-(2,2,3,3-Tetrafluoropropyl)Morpholine—sometimes abbreviated as TFPM or identified by its CAS number in technical circles—delivers a mix of chemical stability and reactivity that seems rare among morpholine derivatives. The presence of the tetrafluoropropyl group boosts both lipophilicity and resistance to oxidative breakdown, setting it apart as an attractive backbone for building block libraries. This compound draws attention from scientists interested in drug development and materials engineering, since it serves as both an end-use specialty chemical and a valuable intermediate. While the world of specialty fluorochemicals can seem esoteric for non-chemists, the interest in TFPM is rooted in everyday product innovations: coatings that last longer, fuels that run cleaner, and medicines with more favorable safety profiles.

Anyone working in a lab quickly notices that TFPM looks like a clear, low-viscosity liquid under typical ambient conditions. With a boiling point near 180–190°C and a density slightly higher than water, the compound stands out for both thermal stability and easy handling during synthesis or formulation. The tetrafluoropropyl group not only sharpens the NMR signals for chemists tracking reactions, but also gives TFPM non-polar character without losing the morpholine ring’s basicity. Chemical resistance extends against acids, bases, and oxidizers, and the compound shows low levels of water solubility compared to non-fluorinated morpholines. All these facts matter to formulators and QC analysts who face the daily grind of making product specs without surprises.

Suppliers provide TFPM under strict specifications, tracking not only purity (often >98% by GC or NMR) but also residual solvents, trace metal content, and sometimes chiral excess if the synthesis allowed for it. Drums and bottles usually come marked with hazard pictograms for chemical burns and environmental hazard, along with batch traceability and recommended storage (ambient temperature, moisture-proof containers). My experience with technical data sheets usually reveals a full page of stability information—customers want reassurance on shelf life, compatibility with packaging, and correct handling instructions for both bulk and high-purity R&D grades.

Making TFPM on a practical scale isn’t trivial. Most routes start from either morpholine or a suitably protected morpholine derivative, with the key step involving alkylation with 2,2,3,3-tetrafluoropropyl halide under strong base conditions. Older procedures relied on sodium hydride or potassium carbonate in polar aprotic solvents, while recent advancements use phase-transfer catalysts or microflow reactors for better yields and less hazardous waste. Selectfluor-based approaches often help in minimizing side products, reducing both cost and environmental risk. Large-scale production demands robust venting for hydrogen fluoride, scrupulous temperature control, and constant monitoring for runaway exotherms. Operators in the plant often say the prep is as much about logistics as chemistry—raw material handling, fluorinated waste disposal, and keeping the process contained all rank as front-line challenges.

The morpholine ring tolerates a fair bit of modification post-synthesis, but the tetrafluoropropyl side chain stays impressively inert in most reaction conditions, which explains why chemists use TFPM as a scaffold in building fluorinated analogs. Standard reactions include N-acylation, N-oxidation, and cross-coupling with aryl halides, all without knocking off the fluorine atoms. Hydrogenation or reduction rarely affect the fluorine substituents, but the ring’s nitrogen remains a hotspot for substitutions or protection/deprotection cycles. Tweaking the ring or side chain—say through chain extension or the installation of additional functional groups—lets TFPM act as a springboard for dozens of more complex fluorinated chemicals.

Chemists know 4-(2,2,3,3-Tetrafluoropropyl)Morpholine by a short list of names: TFPM, tetrafluoropropyl morpholine, and sometimes shorthand like 4-TFPM. Different suppliers may register it under their own product codes, but the chemical literature generally sticks with systematic naming to avoid confusion. Regulatory agencies track it with its CAS number, which helps standardize safety data across company and national boundaries. My own practice is to double-check all synonyms on SDS documentation, since cross-referencing remains crucial with niche fluorochemicals where brand-specific names come and go.

Handling TFPM in the plant or lab means more than just wearing gloves and goggles. Operators receive extensive training in chemical handling and emergency procedures, since spill risks increase with volatile fluorinated organics. Safety data sheets flag TFPM as potentially skin and eye irritating, with special disposal instructions because of persistent fluorinated waste. Good ventilation, chemical-resistant aprons, and strict access controls reduce chances for exposure. Companies often use dedicated storage cabinets with vented enclosures, never mixing open containers with non-fluorinated solvents or acids. Tracking these standards isn’t just about legal compliance: my experience says attention to detail saves both time and money when unexpected accidents happen.

TFPM finds a home where traditional morpholine compounds fall short. Pharma researchers use it to design drug candidates with increased metabolic stability; the tetrafluoro group resists breakdown by enzymes, boosting bioavailability and sometimes improving selectivity. Specialty coatings see benefits in terms of hydro- and oleophobic surfaces, since the fluorinated tail imparts stain and solvent resistance for textiles, foams, and industrial sealants. Electronics engineers value it for its compatibility with fluoropolymer matrices, especially in antistatic or semiconducting films. In my work with industrial partners, I’ve seen niche uses even in battery electrolytes and as trace components in refrigerant blends.

Academic groups keep chasing new uses for TFPM as both an intermediate and an end product. Recent peer-reviewed articles detail routes to more complex morpholine architectures, leveraging TFPM’s unique substitution for things like improved ionic liquids or molecular probes. The promise of lower toxicity and higher chemical inertia leads researchers to adapt standard synthetic methods for fluorinated morpholines, comparing yields, purities, and reaction times. Collaboration between industrial and academic labs—often coordinated through shared analytical facilities—speeds up application testing, whether for new materials, pharma screening, or even agrochemical candidates that need specialized environmental profiles. Teams push for green chemistry alternatives, exploring catalytic fluorination and waste minimization at every step.

Toxicologists dig into both acute and chronic toxicity for fluorinated organics, and TFPM draws particular concern over potential environmental persistence. Early tests suggest low acute toxicity in mammalian systems, but long-term bioaccumulation isn’t fully mapped yet. Scientists run simulated degradation studies in soil and water, mapping how the fluorine atoms affect breakdown compared to non-fluorinated morpholines. Regulatory reviews—especially in the EU and North America—require updated data as companies push for new product registrations. Anyone working hands-on with TFPM follows strict monitoring for exposure, since even low-toxicity compounds can present cumulative risks over years of handling. That’s something I’ve taken seriously since stories of “mystery illnesses” popped up in older fluorochemical plants before today’s standards came in.

Looking ahead, TFPM stands at an intersection of regulatory pressure, green chemistry, and demand for high-performance specialty materials. Global regulations on persistent organic pollutants shape how companies design both new products and new processes involving TFPM, with life cycle impacts and end-of-life destruction now factoring into every development story. Materials science could unlock more uses in sensors, membranes, and composite films, while pharma and biotech chase formulations that balance efficacy with environmental stewardship. Academic research keeps the cycle moving, probing the limits of the morpholine ring and pushing new synthetic pathways. To realize TFPM’s potential, investment in safe scale-up, toxicity testing, and environmental compatibility matter as much as breakthroughs in chemical reactivity or product innovation.

The march of material science leans heavily on small, tailored molecules, and 4-(2,2,3,3-Tetrafluoropropyl)morpholine earns attention for a blend of chemical resilience and adaptability. Chemists put this structure to work not for the sake of novelty, but because its specific balance of morpholine’s ring and a highly fluorinated side chain offers real improvements in how things perform, from industrial lubricants to advanced coatings.

Anyone who has struggled with dissolving stubborn polymers or handling aggressive reagents knows the pain of searching for reliable solvents. The fluorinated side of this morpholine brings a desirable set of properties. It doesn’t break down easily, pulls off excellent chemical resistance, and holds up under temperature swings. Tech companies and research labs use it for specialty solvent work, especially where regular organic solvents fall short or react unpredictably.

Electronics demand reliability. A single circuit failure can turn months of effort and millions of dollars into scrap. Here, 4-(2,2,3,3-Tetrafluoropropyl)morpholine gets blended into coatings and surface treatments, driving down moisture intrusion and static buildup. It also finds roles in painting or finishing sensitive surfaces, giving precise wetting and drying behavior. Fluorine’s non-stick legacy joins morpholine’s stability, and this means fewer reworks, longer shelf life, and more consistent tech.

Drug companies keep close watch on compounds that resist breakdown, especially for targeted delivery systems or for medicines that hang around in the body long enough to take effect. By attaching a tetrafluoropropyl group to morpholine’s already popular scaffold, researchers create molecules that last longer and sometimes work better in the demanding environment of the human body. This small tweak can lead to better drugs—a claim backed up by ongoing patent filings in major pharmaceutical markets.

Fluorinated materials often show incredible slipperiness and resistance to wear, which is gold for engineers designing for extreme environments. Add this morpholine compound to lubricants, and you get better performance in aerospace components, precision bearings, or equipment that faces strong acids or bases. It tolerates rough treatment, keeps surfaces clean, and lengthens maintenance intervals, which can make the difference between costly downtime and a smooth run.

Powerful chemistry always deserves respect. With great durability comes the risk of persistence. Several fluorinated chemicals have raised concern due to environmental buildup. Companies using 4-(2,2,3,3-Tetrafluoropropyl)morpholine must take steps to manage leaks, recover waste, and keep it away from water sources. Efforts from regulatory agencies and industrial leaders focus on safer processing and better cleanup technologies. These steps aren’t just red tape—they set a baseline for responsible use and help maintain public trust in materials that quietly make so much modern progress possible.

Chemists and engineers continue to rely on finely tuned molecules like 4-(2,2,3,3-Tetrafluoropropyl)morpholine to bridge the gap between what nature provides and what technology demands. Every new use adds a layer of knowledge, showing how the right structure can unlock new possibilities in the lab, in industry, and in daily life. Attention to sustainability and safety will shape where and how such chemicals find new homes in tomorrow’s products.

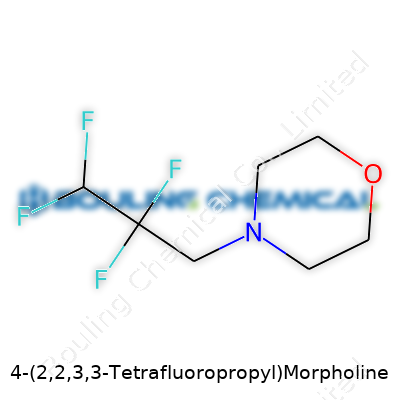

Anyone who’s spent time around a chemistry lab knows that the structure of a molecule really decides much about its use and behavior. Take 4-(2,2,3,3-Tetrafluoropropyl)morpholine as an example. Breaking down the name clues us in on its build and characteristics.

Morpholine forms a six-membered ring that contains four carbons, one oxygen, and one nitrogen. It’s a backbone for many industrial chemicals, easily recognized by its slightly fishy odor and its ability to dissolve in water. Slap a 2,2,3,3-tetrafluoropropyl group onto the fourth position of that ring, and things start to get interesting. This side chain includes a three-carbon propyl group decked out with four fluorine atoms, giving it the “tetrafluoro” name.

Lay it out on paper like this: the morpholine ring sits center stage, and the 2,2,3,3-tetrafluoropropyl group attaches to the nitrogen on position four. The full chemical formula comes out to C7H11F4NO.

Walking through chemical plants and research spaces, you see how a tweak like swapping out hydrogens for fluorines can shift everything. Fluorine pulls electrons, resists reactivity, and shrugs off water, acids, and bases. In 4-(2,2,3,3-Tetrafluoropropyl)morpholine, these changes aren’t just academic. Fluorinated chains help this compound stay stable where others break down.

Adding these fluorines isn’t cheap or easy. Making any fluorinated organic molecule stretches a chemist’s patience and wallet. The synthetic path usually means ugly reagents, careful exotherms, and specialized equipment to handle aggressive fluorinating agents.

But stability wins out in many industries. Pharmaceuticals lean on tough, stable building blocks like this to anchor active molecules. Agrochemicals follow suit, hunting for persistent, rainproof additives. Materials science teams chase fluorinated compounds to toughen polymers or impart nonstick properties.

The more fluorine lands in a chemical, the more heads turn. People should stay aware of the way these compounds linger in soil, water, and even bloodstreams. Companies can’t just look at what a compound can do today. They should ask what happens once it leaves their hands. The world learned this the hard way with older fluorinated chemicals showing up across the globe decades after they left factory walls.

It’s good practice to rethink recycling routes and disposal routines for these complex molecules. Instead of sending waste down the drain, companies could pursue advanced destruction strategies using heat or plasma. Environmental health teams already track trace amounts of similar compounds in water and food chains. Strong policy, more open reporting, and community engagement matter just as much as hard science in meeting these challenges.

There’s excitement in working with molecules like 4-(2,2,3,3-Tetrafluoropropyl)morpholine. Chemistry advances every day, but society earns more by weighing long-term consequences alongside innovation. Responsible research, steady regulation, and honest discussion make all the difference.

The name 4-(2,2,3,3-Tetrafluoropropyl)Morpholine does not roll off the tongue, but chemicals with long labels often turn up in less obvious spots—near lab benches, inside industrial cleaning agents, or as specialty intermediates in plastics and coatings. Whenever something with as many fluorines as this molecule shows up, I start checking for its record with people and nature alike. Many fluorinated compounds, like PFAS, teach us to stay alert. They’re tough to break down and can travel great distances, showing up in places we never meant them to go.

Getting a clear health or environmental profile for 4-(2,2,3,3-Tetrafluoropropyl)Morpholine isn’t easy. Open-access databases, including PubChem and the European Chemicals Agency (ECHA), report scant toxicology data on this chemical. While that means the worst-case scenarios aren’t confirmed yet, experience tells me that the unknown can carry just as much risk as the proven harmful.

Fluorinated structures tend to resist the normal ways microbes break things down, so I’d expect this chemical to stick around if spilled or dumped. Compounds like this can build up in the soil, seep into waterways, or drift in the air, especially around facilities making or using them. Some morpholines can affect the central nervous system or irritate eyes and lungs. Without solid long-term studies for this exact molecule, the most prudent approach borrows lessons from similar chemicals—handle with gloves, mind the ventilation, and keep it out of the water.

Our history with highly stable compounds that include fluorine isn’t reassuring. Per- and polyfluorinated substances (PFAS) hang around for decades, blending into streams, fish, and farm soil. Researchers see links between some of these chemicals and problems like thyroid disease, immune suppression, or cancer. While this morpholine hasn’t drawn the spotlight on its own, any new entrant from the same family should be treated as if trouble could follow unless research proves otherwise.

Most people never need to handle substances like this directly. Workers at chemical plants, or those in companies that use specialty solvents, get exposed first and hardest. These folks deserve the safety data sheets in plain language, not just a QR code or a stack of printouts no one actually reads. Looks like this specific molecule may not have a deep public data sheet yet. Industry leaders and regulators have a responsibility to push for testing, share early findings, and step in with restrictions if the evidence stacks up against its safety.

Better transparency and independent toxicology studies shape smarter decisions. Lawmakers and community groups should press for public registry listings, calling out not just the risks but also the gaps in what we know. Alternatives to persistent fluorinated compounds are starting to appear, especially in coatings and intermediates. Plant operators and formulators can start switching out legacy chemicals for greener options—sometimes a test batch and some real-world feedback reveal safer, cheaper paths forward.

Experience says not to wait for disaster or discovery. Build in better safety up front, ask for more data, and never assume a new molecule is harmless just because it isn’t a household name yet.

Working with chemicals like 4-(2,2,3,3-Tetrafluoropropyl)morpholine pushes you to keep safety top of mind. This substance finds use in specialized research labs and industrial settings. The thing is, fluorinated chemicals pose challenges—unexpected spills or contact add risks for the whole team. My time in shared university labs taught me that it takes only a single overlooked bottle or missing label for small mistakes to become major issues. Planning goes a long way, and clear steps for each procedure keep people and property safer.

A dry, cool environment helps maintain the compound’s chemical structure. Direct sunlight or intense heat accelerates breakdown, which chews up shelf life and introduces new hazards. A dedicated chemical storage fridge—locked, well-ventilated, and equipped with temperature monitoring—brings peace of mind. Chemicals like this one often need separation from acids, bases, and oxidizers, since incompatible substances spark dangerous reactions. Storing them in isolated, clearly labeled containers on shatter-proof shelving beats dealing with broken glass every time.

One recurring lesson from lab life: don’t treat chemical containers like any other piece of equipment. Lids get loose once or twice, and it’s easy to overlook slow leaks or crusted residue. A spill mat underneath each bottle catches the drips and keeps most surprises off the floor. Store original packaging whenever possible; manufacturer containers resist corrosion and keep the label’s details intact. If you transfer to a smaller bottle, use a robust label with both the substance name and hazard pictograms. Sketching out emergency contacts for the chemical cabinet—posted inside the door—speeds up response if things go sideways.

The unpredictability of fluorinated compounds shapes how I handle them. Proper gloves—nitrile does the trick—form a barrier if splashing gets out of hand. Full goggles, not just safety glasses, protect against accidental sprays. Working in a chemical fume hood means inhalation risks stay low, and local exhaust extraction stops vapors from drifting through the workspace. Grab a buddy for high-risk work; a second pair of eyes helps spot small slips before they grow.

Importantly, only use equipment rated for fluorinated chemicals. Some plastics degrade on contact, while glass and fluoropolymer-coated tools stand up better to repeated exposure. Double-checking the seal on bottles, taps, and tubing means fewer unexpected messes. Routine checks for corrosion, strange odors, or discoloration can signal storage failure before anyone’s health takes a hit. If you see anything off, report—don’t try to handle it solo.

Even the most careful work produces waste. Following established hazardous chemical waste procedures matters—a lot. Solvents and wipes soak up residue, and those materials go in puncture-resistant, labeled bags. Transporting waste in closed, secondary containers prevents leaks between the bench and disposal site. Local regulations set the final steps; connecting with your facility’s hazardous waste officer avoids legal trouble or environmental slip-ups.

Facilities shy on updated safety showers, eyewash stations, or spill kits set up staff for a world of hurt. Quick access to first aid beats regret each time, so double-check placement and make sure everyone stays trained. Reporting minor incidents builds better protocols, and nothing protects the team like keeping communication wide open.

Hands-on experience with chemicals shows me that respect shapes good outcomes. Each safety habit—however small—protects health, equipment, and science itself. By sticking to proven storage and handling strategies, people working with 4-(2,2,3,3-Tetrafluoropropyl)morpholine can keep labs productive and everyone headed home in one piece.

A little-known compound like 4-(2,2,3,3-Tetrafluoropropyl)Morpholine stirs up real questions for chemists and manufacturers. I’ve tried hunting for reliable Safety Data Sheets (SDS) or clear regulatory guidance for substances that slip beneath the radar. Regulatory agencies make efforts to keep pace, but smaller, niche chemicals don’t always land on their lists right away. This one in particular highlights a gap that matters for anyone on the front line of industrial labs, chemical distribution, or environmental health.

Relying on proven data and accepted protocols forms the backbone of lab safety. Without an SDS, users have no clear map for proper handling, incident response, or disposal. I've found that even seasoned chemists pause before opening a bottle lacking trustworthy information. If we can't spot clear toxicity profiles, reactivity hazards, or eco-impact, every step turns into a gamble. You want to know if gloves or goggles are enough, or if you’re risking an exothermic accident just by transferring the stuff between containers.

Europe, the United States, and several Asian countries each keep huge chemical inventories—REACH in the EU, TSCA for the US, and similar systems elsewhere. When a newer molecule slips onto the market, these lists might not reflect its risks yet. Authorities require solid, peer-reviewed data before stamping approval or warning labels. Vendors sometimes pass along patchwork documents, pulling pieces from related chemicals if nothing else exists. Some techs end up using a blend of common sense and old habits, but that can’t substitute for hard data.

Regulatory silence presents trouble for more than just chemists. Waste management teams, environmental protection officers, and public health experts all rely on SDS information. If a spill happens, local authorities scramble for cleanup guidelines. If the compound reaches groundwater, downstream communities deal with the fallout—often in the dark about what chemicals contaminated their water.

For reference, the European Chemicals Agency keeps a searchable database, though a check for this morpholine derivative doesn’t yield much. The US Environmental Protection Agency’s TSCA list also skips over it. If we go by history, no published toxicology reports points to a true information gap, not a known track record of safety. This situation pops up with other specialty chemicals, too.

Consulting expert panels can help develop a provisional SDS. Outreach to original manufacturers often shakes loose more detailed information. Pressing suppliers to disclose or sponsor independent toxicological assessments would close some gaps. Investing effort in third-party testing, or joining with regional chemical safety groups, improves collective knowledge. Until a full SDS appears, strict control measures should mirror those for structurally similar but well-studied compounds. Sticking with the highest level of caution buys time while researchers do the slow work of catching up.

Acting on incomplete data feels risky, but inertia allows gaps to linger. Chemical firms and research institutions should push for transparency, sharing what data they gather and leaning on industry groups to standardize best practices. A little more transparency and cross-border cooperation means rare chemicals like this morpholine derivative can’t fly under the radar much longer.

| Names | |

| Preferred IUPAC name | 4-(2,2,3,3-Tetrafluoropropyl)morpholine |

| Other names |

1-(2,2,3,3-Tetrafluoropropyl)morpholine Morpholine, 4-(2,2,3,3-tetrafluoropropyl)- Perfluoropropylmorpholine |

| Pronunciation | /ˈfɔːr tuː tuː θriː θriː ˈtɛtrəˌflʊə.rəˈprəʊpɪl ˈmɔː.fəˌliːn/ |

| Identifiers | |

| CAS Number | 1374191-78-4 |

| 3D model (JSmol) | `3Dmol.php?cid=132779260` |

| Beilstein Reference | 4158734 |

| ChEBI | CHEBI:139646 |

| ChEMBL | CHEMBL3702061 |

| ChemSpider | 30922678 |

| DrugBank | DB08357 |

| ECHA InfoCard | 03b07d49-ee23-4842-8633-f5f3703fa749 |

| EC Number | EC 813-198-4 |

| Gmelin Reference | 107555 |

| KEGG | C18905 |

| MeSH | D064370 |

| PubChem CID | 136877350 |

| RTECS number | KL9360000 |

| UNII | NE6B7W6H8D |

| UN number | UN3272 |

| CompTox Dashboard (EPA) | DTXSID3037865 |

| Properties | |

| Chemical formula | C7H13F4NO |

| Molar mass | 207.17 g/mol |

| Appearance | Colorless liquid |

| Odor | odorless |

| Density | 1.39 g/cm³ |

| Solubility in water | Slightly soluble |

| log P | 1.2 |

| Vapor pressure | 0.48 mmHg at 25°C |

| Acidity (pKa) | pKa ≈ 8.4 |

| Basicity (pKb) | 5.51 |

| Magnetic susceptibility (χ) | -70.94 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.389 |

| Viscosity | 85 cP (25°C) |

| Dipole moment | 2.85 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 380.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1104.8 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1766.2 kJ/mol |

| Pharmacology | |

| ATC code | N05CM21 |

| Hazards | |

| Main hazards | Causes skin irritation. Causes serious eye irritation. May cause respiratory irritation. |

| GHS labelling | GHS07; GHS09 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H315, H319, H335 |

| Precautionary statements | P261, P271, P273, P280, P302+P352, P305+P351+P338, P362+P364, P501 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | 70°C (closed cup) |

| Autoignition temperature | 260 °C |

| Lethal dose or concentration | LD₅₀ Oral Rat: >2000 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 >2000 mg/kg |

| PEL (Permissible) | Not established |

| REL (Recommended) | Not established |

| Related compounds | |

| Related compounds |

4-(2,2,2-Trifluoroethyl)morpholine 4-(2,2,3,3,3-Pentafluoropropyl)morpholine |