Benzothiophenes entered the chemical landscape as scientists poked around coal tar and petroleum distillates back in the 19th century. Not long after, methylated derivatives like 3,5-dimethylbenzothiophene cropped up during early investigations into fuel chemistry and heterocyclic synthesis. The postwar period, with its surge in petrochemistry and organic electronics, kicked off real momentum. Researchers shifted gears toward exploring sulfur compounds not just as impurities, but as valuable building blocks and environmental markers. The compound didn’t have its own headline, but it showed up backing important studies on petroleum desulfurization, marker analysis, and new material design. As refining science improved, methylated benzothiophenes moved from stubborn trace contaminants to substances with specific analytical and industrial uses.

This compound usually appears as a pale yellow oil or low-melting solid after isolation from petroleum streams or laboratory syntheses. Anyone who’s worked in an oil or chemical research lab knows the heavy, distinctive aroma and extra heft that sulfur gives these molecules. Chemists don’t grab for 3,5-dimethylbenzothiophene when reaching for a solvent or basic reagent, but its value shines in oil tracing, environmental science, and as an intermediate in advanced organic syntheses. Inside the lab, it turns up in NMR tubes, reference standards, and process streams where sulfur content matters—both for regulatory compliance and for tracing tricky catalytic transformations.

3,5-Dimethylbenzothiophene sits in the grey area between an aromatic hydrocarbon and a sulfur compound, and it behaves accordingly. At room temperature and atmospheric pressure, one sees it as a viscous, oily liquid, though it may crystallize in cooler labs. Its boiling point hovers around 270-280°C, and that higher-than-hydrocarbon range marks out sulfur’s heavy hand. Density approaches 1.1 g/cm³, which can catch you off guard if pipetting by hand. The aromatic system lends it some stability, but that sulfur atom leaves it vulnerable to oxidation, and methyl groups on the ring make selective substitutions possible under the right conditions. Solubility in water stays very low—no surprise—but it mixes easily with common organic solvents. Keep it in sealed glass, since open-air exposure brings slow color changes and possible formation of sulfoxides or sulfones with enough oxygen around.

Lab suppliers list this compound with a CAS number of 3954-89-8. Purity grades for research often hit 98% or better, though trace polycyclics and similar isomers lurk in low-quality material from industrial sources. Labels usually carry hazard warnings: health hazard symbol for possible skin and respiratory irritation, and an environment mark because of aquatic toxicity. Safety data sheets flag its moderate flammability, so take the same precautions as any aromatic oil—use chemical fume hoods, wear gloves, and store it away from open flames. Some countries lay down extra import and handling restrictions on heterocyclic sulfur compounds, and those rules often stem from concerns about environmental persistence. Bulk shipments, when they appear, need clear UN or DOT numbers, tightly capped drums, and clear record-keeping.

In research settings, synthetic access starts with methylated benzenes—m-xylene in particular—paired with sulfurizing agents. Chemists might use elemental sulfur and acid catalysts, coaxing aromatic cyclization to close the thiophene ring. Friedel-Crafts alkylation or acylation steps set up substitution at the 3 and 5 positions, though controlling regioselectivity means adjusting solvents, temperatures, and catalysts. In industry, hydrodesulfurization units extract the compound from heavier oil fractions as a consequence of attempting to reduce sulfur emissions. There’s a constant push for greener synthesis—catalyst recycling, less harsh reagents—but a lot of routes return to old standbys: aluminum chloride, phosphorus pentasulfide, and pressurized autoclaves. Purification means distillation or, sometimes, column chromatography; both methods need patience and protective equipment because of stubborn odors and the risk of sulfurous byproducts.

Aromatic substitution reigns supreme: nitration, sulfonation, halogenation—chemists draw up schemes to install function groups at open positions. Both methyl groups can serve as starting points for oxidation, turning them into carboxylic acids or alcohols with the right reagents. The sulfur atom acts as an anchor for oxidations up to sulfoxide or sulfone, creating derivatives with very different solubility and reactivity. Metal-catalyzed couplings, including Suzuki and Heck reactions, let synthetic workers extend the skeleton for building advanced electronic materials. On the flip side, forced hydrogenation can break the aromaticity and remove the sulfur, though not without some cost and complexity. Organic labs regularly tinker with the molecule to design markers, test catalysis, or chase new ligands for applied chemistry.

Beyond its IUPAC name, you might spot labels like “3,5-DMBT,” “3,5-Dimethylthianaphthene,” and “NSC 2669” in catalogs and technical articles. Some analysts just abbreviate it as DMBT, which leads to confusion when looking at related dimethylbenzothiophenes. Industrial reports sometimes call it by trade codes if supplied in mixtures meant for calibration standards, but most chemical suppliers stick with the full systematic name to reduce ambiguity. Any researcher or industrial user juggling multiple isomers—2,3-dimethyl, 2,7-dimethyl—should double-check bottle labels since tiny structural differences impact reactivity and toxicity.

Sulfur heterocycles demand sharp lab habits. Skin contact can cause dermatitis or irritation, especially after hours of glove work. Volatility stays low at room temperature, but heating during distillation or reactions bumps up respiratory exposure risks. Spills require inert absorbents, not water, since these oils slick and seep. Fire safety matches that for aromatic hydrocarbons—class B extinguishers, ventilation, and avoidance of ignition sources. Disposal moves through hazardous waste protocols; dumping into drains runs afoul of environmental law and risks aquatic contamination. Storage means well-labeled, dark bottles, handled with goggles and chemical-resistant gloves. Most researchers I’ve met keep sulfur aromatic stocks in a locked cabinet, with logs for inventory to avoid cross-contamination and unauthorized use.

Refineries chase this compound to monitor pollution and track crude origins through “fingerprinting.” Its presence signals refining efficiency and environmental compliance, so labs use standards to calibrate sulfur analyzers. Academic work probes the mechanism of deep desulfurization, using 3,5-dimethylbenzothiophene as a surrogate for persistent impurities in fuels. Beyond petroleum, synthetic chemists use it to construct advanced ligands, photosensitive materials, and molecules for organic electronics. Due to its sturdy aromatic system, it can act as a test molecule for exploring the reactivity of novel catalysts, especially those targeting sulfur removal. It doesn’t usually headline pharmaceutical or consumer products, but pops up in specialty reagents and advanced material platforms.

Most R&D teams studying this molecule chase better ways to break it down: catalysis research dives into transition metal complexes, solid acid catalysts, and photocatalytic systems that promise cleaner, more complete conversion. Analytical chemists develop improved GC and HPLC methods to spot sub-ppm levels in complex oil matrices. There’s also a steady wave of green chemistry projects focused on turning methylated benzothiophenes into less toxic, more manageable products, with the long-term goal of shrinking sulfur emissions. As more industries reel under environmental regulations, researchers build libraries of 3,5-dimethylbenzothiophene derivatives to serve as reference points and process markers. These labs often collaborate across academia and industry, sharing techniques and updating protocols across publications and conferences.

Toxicologists approach 3,5-dimethylbenzothiophene cautiously. Animal studies show that inhalation or ingestion at high doses leads to liver and kidney stress, with some concerns about skin and eye irritation at lower exposures. Its persistence in the environment worries ecologists, as sulfur aromatics accumulate in waterways and sediments after spills. Chronic exposure in refinery and chemical plant workers motivates ongoing monitoring programs. Biomonitoring usually targets thiophene derivatives as part of a suite of volatile organic compounds in occupational health studies. Some data suggest mild mutagenicity, particularly after metabolic activation, but the evidence remains limited and the risk hinges on exposure duration and concentration. Regulatory agencies urge handling as a hazardous material, erring on the side of caution despite relatively scant epidemiological data.

Demand for cleaner fuels and tighter sulfur limits keeps the spotlight on methylated benzothiophenes. Catalysis research aims to break their resistance to hydrodesulfurization; breakthroughs here promise cleaner air and less acid rain. New product streams, like next-generation organic semiconductors, draw inspiration from sulfur-aromatic hybrids, suggesting a run of new applications if designers crack the right functionalization tricks. Continued advances hinge on collaboration—industry labs hungry for practical results, academic teams digging into deep mechanism, environmental scientists monitoring impacts down the chain. The story of 3,5-dimethylbenzothiophene—once just another stubborn sulfur pollutant—now ties into efforts to green the energy sector, tighten analytical science, and push the frontiers of organic chemistry.

Look close at the things that shape the world quietly — in labs, refineries, even in new tech ventures. 3,5-Dimethylbenzothiophene sits among those behind-the-scenes chemical compounds. Most folks won’t stumble across it in daily life, but the impact filters out in a big way. I learned this truth while consulting on technology projects in the petrochemical field, watching what happens even far upstream changes the final product within everyone’s reach.

3,5-Dimethylbenzothiophene, a sulfur compound found in crude oil, crops up in the story of fuel refinement. Refineries run into it often as they aim to clean up gasoline and diesel. It brings stubborn sulfur that doesn’t let go easily. Over my career, I sat at meetings where engineers swapped stories about their struggle to cut sulfur emissions down and keep up with stricter laws. Every time they circled back, this compound showed up on the whiteboard.

Sulfur in fuels puts soot and sulfur dioxide into our air, leading to acid rain and health problems. Everyone, whether city dweller or farmer, ends up breathing those results. The challenge with 3,5-Dimethylbenzothiophene lies in its structure. Standard hydrotreating knocks out simpler sulfur molecules, but this one holds tight. That means higher temperatures, more hydrogen, and more money spent removing it. It’s not just a technical problem. People want cleaner fuel without paying extra at the pump.

Labs use 3,5-Dimethylbenzothiophene as a test case for new catalysts. In real-life refinery settings and experimental work, chemists track how quickly and completely they can convert this compound into something less harmful. The results point to which catalyst systems hold real promise. Back in grad school, I remember groups working deep into the night, measuring sulfur left after each run — searching for cleaner, cheaper ways forward.

If a new process cracks this tough molecule open, it likely handles easier ones with no sweat. That’s part of why research money lands on this compound. It sets the bar.

Sulfur compounds like this pop up outside oil, too. Pharmaceutically, benzothiophene rings have value. Tweaks to their structure lead to drug discoveries, sometimes for cancer, other times for infections. Synthetic chemists pull starting materials from petrochemical streams, reshaping molecules like 3,5-Dimethylbenzothiophene for the next round of drug research. Out of industrial leftovers, new treatments sometimes come to life.

Environmental testing also lists it. Water and soil near old industrial sites may contain stubborn organic sulfur. Monitoring for 3,5-Dimethylbenzothiophene offers clues into contamination and helps shape cleanup plans. Law and regulation step in. Testing standards rely on consistent, well-defined chemical markers — this one stays on that list.

Cleaner fuels require better answers for tough compounds like 3,5-Dimethylbenzothiophene. The world has seen lower-sulfur diesel roll out, but prices and technical limits follow closely. Big research still aims at new catalysts, some borrowing ideas from biology, others from nanotechnology. Incentives from governments can speed up commercial adoption. From my own experience, cross-industry partnerships — researchers talking with refinery operators and regulators — usually bring real change faster.

While it rarely gets named in public, this compound shapes how the world handles fuel, health, and environment. Progress in dealing with it touches far more than one industrial pipeline.

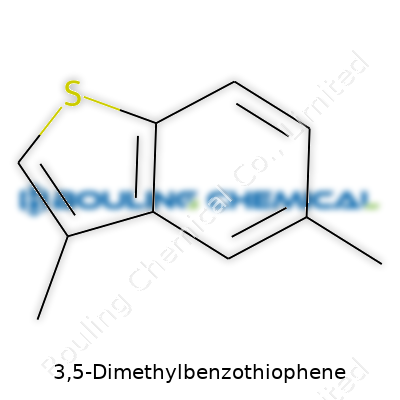

3,5-Dimethylbenzothiophene stands out as a sulfur-containing aromatic compound. In plain language, this molecule forms part of a group of chemicals that you find in crude oil and some fossil fuels. The structure catches the eye right away: a benzene ring, which forms the base, then two methyl groups stick out at the 3 and 5 positions, and the sulfur atom slides neatly into the five-membered ring. Over the years of poking around in organic synthesis labs, I’ve always recognized such sulfur aromatic rings by their faint, pungent smell.

To break it down, the chemical formula of 3,5-Dimethylbenzothiophene is C10H10S. Each molecule carries ten carbon atoms bonded to ten hydrogens, and one sulfur crowns the ring. This isn’t just a random arrangement—each atom’s position changes the chemical’s behavior and how it interacts with catalysts or biological systems. In a lab, just glancing at this formula gives clues about its solubility, how it reacts under heat, and even the way it lights up under a UV lamp.

If you add up all those atoms—10 carbons, 10 hydrogens, and a sulfur—you get a molecular weight of 162.25 g/mol. This number sits in the mid-range for small organic molecules. That matters more than it sounds: a chemist needs this value on hand for accurate calculations in synthesis, chromatography, and spectroscopy. I’ve reached for this number time and again when figuring out yields or setting up a mass spectrometer. Even a small error in weight, and you throw off your whole experiment.

Anyone spending time in energy or chemical processing recognizes 3,5-Dimethylbenzothiophene from refinery streams. It’s not just an obscure molecule—industrial plants deal with it all the time. Sulfur compounds in fuels cause air pollution; they come out the tailpipe as sulfur oxides. These oxides lead straight to acid rain and smog. More strict sulfur limits in fuels have forced refineries to invent better desulfurization processes, often bumping up against stubborn sulfurs like those in benzothiophenes. Traditional methods like hydrodesulfurization can struggle to strip away methylated benzothiophenes. Their extra methyl groups make them hang onto the fuel tighter.

So what do we do about stubborn compounds like 3,5-Dimethylbenzothiophene? In the lab, researchers keep searching for catalysts that target these molecules and break them down more efficiently. Some folks have explored oxidative or biocatalytic techniques, using microbes or advanced materials to break apart these bonds. Success comes slowly, but every improvement means cleaner air and less impact on public health. The next big jump in fuel refining could come from someone cracking the code on these types of sulfur compounds.

Having the formula and molecular weight isn’t just academic trivia. It’s a foundation for any work—environmental sampling, industrial processing, or academic research. Years working with analytical instruments taught me: if you know the formula, you know what to look for. If you know the molecular weight, you set the right filters. That’s real chemistry, turning formula sheets into cleaner technology and healthier communities.

Every time I walk into a chemistry stockroom, I think about all the times someone got careless with ordinary solvents—stories usually ending with a cleanup, occasionally worse. Now, if we’re talking about chemicals like 3,5-Dimethylbenzothiophene, most people outside specialty labs have probably never heard of it, but those who work with organosulfur compounds know there’s no excuse for lax safety. This isn’t sugar or salt; even small spills can cause headaches later.

Here’s the deal with 3,5-Dimethylbenzothiophene. It does fine in a standard chemical cabinet—as long as you’re paying attention. Forget leaving it on a benchtop or throwing it on just any shelf. Moisture plays tricks with sulfur compounds. I learned this the tough way, finding sticky residue where a bottle leaked because someone left the cap loose. Water and organic chemicals rarely mix for the better, especially if you’re prepping reactions or expecting known results.

The point? Air-tight containers don’t just sound good—they work. Store this stuff with a solid gasketed cap, inside a dedicated, clearly marked cabinet. Sulfur compounds can stink, even in low concentrations. Good ventilation stops that rotten-egg smell from becoming everyone’s problem. And there’s another reason: fumes may cause eye or throat irritation over time.

Heat is a quiet troublemaker. 3,5-Dimethylbenzothiophene isn’t as flammable as diethyl ether or acetone, but elevated temperatures can change how it reacts in storage. Chemical stability suffers if things get too warm. I’ve worked in labs where poorly insulated cabinets made summer days feel like test chambers. A quick check with a $20 thermometer can catch storage spots getting too hot. Nobody should learn about decomposition products the hard way.

Mixing incompatible reagents means risking more than ruined experiments. Keep all oxidizers, acids, and bases somewhere else. One splash or a broken container stacking error could trigger dangerous reactions. Even one cart-overloading accident showed why spacing matters. Labels help, but a separate shelf or cabinet avoids mistakes during rushed refills or inventory checks.

Maybe paperwork isn’t exciting, but I’ve seen how missing or ignored safety data sheets can lead to big problems. Most suppliers spell out rules for each chemical, not because they want more paperwork—these guidelines come from real-world disasters and trial-and-error. Store printed copies nearby and make sure everybody in the lab reads them. It’s better than scrambling during surprise inspections or emergency drills.

Safeguards work if people use them every day. Training isn’t just for new hires; even seasoned chemists forget steps once in a while. Encourage questions; share stories about close calls. My own mistakes have taught me more than a shelf full of manuals. If someone spots a damaged lid or sees liquid pooling under a bottle, the fix should happen now, not “next week.”

I do routine walk-throughs and encourage colleagues to do the same, checking seals, reviewing labeling, and looking for leaks. Catching small problems early can prevent ruined research or bigger incidents down the line. The right routine turns safe storage into habit, not afterthought.

In the world of chemistry, some names stick in the mind just because they sound complex—3,5-Dimethylbenzothiophene easily tops that list. The stuff often pops up during oil refining or when researchers play with organic sulfur compounds. I’ve watched folks mistake its oily, colorless look for something pretty harmless. That kind of thinking tends to end badly.

This compound doesn’t belong in anyone’s salad dressing. Even minor skin or eye contact can cause irritation, sometimes worse. Inhalation of fumes over time nudges up the risk of respiratory trouble. On top of that, poorly ventilated workspaces turn what seems harmless into a long-term health gamble. Nothing dramatic like a flamethrower incident, but long exposures stack up and people feel the results later.

Any person handling 3,5-Dimethylbenzothiophene should start with the basics: gloves, safety goggles, a proper lab coat. No everyday clothing will cut it. Neoprene or nitrile gloves block most contact, especially if you’re pouring or mixing. Goggles keep accidental splashes out of your eyes. An apron adds one more barrier for people especially concerned about staining their regular work clothes or skin.

If the job throws dust or vapors into the air—common in industrial setups—an N95 mask or half-mask respirator works better than wishful thinking. Open windows won’t remove all the danger. A good fume hood or proper extraction fans make a real difference and keep workplaces healthier in the long run.

Storage gets overlooked until the day a leak hits. I’ve seen folks using anything from soda bottles to open trays. A tight-sealed glass or high-density polyethylene container handles this chemical best; metal containers and cheap plastics break down or corrode. Labels must stand out, especially in shared fridges or cabinets, where cross-contamination can cause genuine harm. Never drop the stuff near heat or flames—3,5-Dimethylbenzothiophene has a flash point high enough not to panic but low enough to respect.

Loading larger quantities always needs two people and a spill kit within reach. Granular absorbents or even old cat litter mop up small spills, but everything gets collected and sent to hazardous waste—no rinsing down the sink. A few moments spent setting up makes for far fewer stories about ruined floors or trips to the hospital.

Disposing of 3,5-Dimethylbenzothiophene isn’t as simple as tossing it out with used paper towels. Most communities ban pouring organic sulfur compounds into drains or regular trash cans. Contact local hazardous waste services—these folks have seen it all before, and follow up with certificate paperwork. Aside from the law, neighbors stay happier when their plumbing doesn’t smell like weird chemistry. Leftover chemicals pile up quickly, so plan regular disposal days rather than putting it off for weeks. Every chemist I’ve worked with who ignored this advice has dealt with bigger headaches later on.

No one sticks with every rule 100% of the time. I’ve watched careful teams turn sloppy under time pressure. Regular safety drills, honest accident reporting, and keeping a clear list of do’s and don’ts make things smoother for everyone. Sometimes, the safest workplaces grow out of small reminders and the willingness to ask dumb-sounding questions.

Science doesn’t have to run on luck. Respect for these chemicals—stored the right way, handled with decent gloves, and cleaned up without shortcuts—keeps people healthy and jobs running smooth. Respect isn’t just some sticky label. It’s what you do every day, down to the details.

3,5-Dimethylbenzothiophene looks like one clear-cut thing on paper. In reality, sourcing it never feels that simple; suppliers list it across a range of purities, each with its own pros and cons. Over years spent handling specialty chemicals, I’ve seen how purity levels shape what’s possible in research labs, industry plants, and even in regulatory paperwork. Someone new to this compound might think, ‘Why fuss over a few percent difference?’ Experience says otherwise.

When you need this compound for organic synthesis or high-sensitivity testing, lower purity can introduce more headaches than it’s worth. Imagine running months of experiments only to find that impurities have skewed your results or made your data unreliable. I remember a colleague struggling with this while chasing trace sulfur compounds in fuel samples. A tiny amount of contaminant meant repeating dozens of runs.

On the flip side, not every process demands near-perfect purity. In bulk applications, like those found in petroleum analysis or large-scale manufacturing, minor impurities sometimes won’t ruin the day. Buying the highest purity usually means paying a premium. Companies with tight budgets—and common sense—often weigh the risks of contaminants against the cost savings.

Global suppliers advertise grades ranging from ‘technical’ (often as low as 90%) to ‘analytical’ or ‘high purity’ (above 98%). Specialty distributors push even higher grades for sensitive research. Each batch ends up certified with its own specs and supporting data sheets, but labs and factories can’t just take numbers at face value. Subtraction matters—if a shipment comes in at 97% instead of 99%, that missing piece might come from substances that trash sensitive equipment or push reactions in strange directions.

I've learned that trusting purity claims without third-party testing turns out to be risky. NMR, GC-MS, and HPLC assays end up playing a vital role, especially in regulated industries. Environmental labs, for instance, can’t stake their compliance on a salesman’s word. I’ve seen entire investigations stall for weeks over a bad batch, and it’s not unusual for a team to set aside part of the budget just for double-checking suppliers.

For anyone involved in purchasing or handling 3,5-Dimethylbenzothiophene, getting the right grade starts with clear communication. Buying cheap and discovering quality issues later usually means lengthy troubleshooting. It pays to ask direct questions: What’s the current purity, and how has it changed between lots? What’s the main impurity, and at what level? Clear, testable answers prevent most confusion.

In some cases, purifying the material in-house brings benefits, but not every lab or plant has that kind of setup. Building strong relationships with suppliers, insisting on batch records, and periodically validating samples are time-tested strategies for sidestepping nasty surprises.

Purity grades for 3,5-Dimethylbenzothiophene matter a lot more than most product catalogs let on. Experience tells me it pays to go beyond the label, understand what a given application can tolerate, and back up every purchase with good data.

| Names | |

| Preferred IUPAC name | 3,5-dimethyl-1-benzothiophene |

| Other names |

3,5-Dimethyldibenzothiophene 3,5-Dimethyl-1-benzothiophene |

| Pronunciation | /ˌθriːˌfaɪv daɪˈmɛθɪl bɛnˈzoʊˌθaɪ.oʊˌfiːn/ |

| Identifiers | |

| CAS Number | 1200-12-2 |

| 3D model (JSmol) | `3D64I` |

| Beilstein Reference | 344134 |

| ChEBI | CHEBI:76254 |

| ChEMBL | CHEMBL164223 |

| ChemSpider | 13864297 |

| DrugBank | DB02573 |

| ECHA InfoCard | 03c959f6-6c53-4e88-830f-6661be381adf |

| EC Number | 205-700-8 |

| Gmelin Reference | 82807 |

| KEGG | C09889 |

| MeSH | D015434 |

| PubChem CID | 92248 |

| RTECS number | DC3975000 |

| UNII | W3M69XJ4GJ |

| UN number | NA9166 |

| Properties | |

| Chemical formula | C8H10S |

| Molar mass | 162.26 g/mol |

| Appearance | Light yellow to brown liquid |

| Odor | aromatic |

| Density | 1.04 g/cm³ |

| Solubility in water | Insoluble |

| log P | 3.80 |

| Vapor pressure | 0.038 mmHg (25°C) |

| Acidity (pKa) | 32.46 |

| Basicity (pKb) | pKb = 15.20 |

| Magnetic susceptibility (χ) | -40.74e-6 cm³/mol |

| Refractive index (nD) | 1.582 |

| Viscosity | 3.37 mPa·s (at 25 °C) |

| Dipole moment | 2.07 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 332.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | 89.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -5607.4 kJ/mol |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. May cause respiratory irritation. Toxic to aquatic life with long lasting effects. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H315, H319, H335 |

| Precautionary statements | P261, P264, P271, P273, P301+P312, P304+P340, P312, P337+P313, P405, P501 |

| NFPA 704 (fire diamond) | 2-2-0 |

| Flash point | Flash point: 102°C |

| Autoignition temperature | Autoignition temperature: 510 °C |

| Lethal dose or concentration | LD50 (oral, rat): >2000 mg/kg |

| LD50 (median dose) | LD50 (median dose) = 3000 mg/kg (rat, oral) |

| NIOSH | GV5950000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 10 mg/m³ |

| Related compounds | |

| Related compounds |

Benzothiophene 2-Methylbenzothiophene 3-Methylbenzothiophene Dibenzothiophene |