Chemistry textbooks often pay little attention to the smaller players like 3.5-Dimethoxybenzoic acid, but its story stretches back more than 100 years. The benzoic acid backbone, a rugged survivor in industrial and academic labs, picked up new relevance when methoxy groups came into play in the early 20th century. Researchers hoped these little side-groups would push the boundaries of pharmaceuticals and dyes. During those early years, chemists relied on lengthy extraction and crystallization. Yields could be frustrating and batches uneven, but over time, improvements like methylation with dimethyl sulfate or diazotization made production less of a gamble.

3.5-Dimethoxybenzoic acid usually shows up as a white to off-white crystalline powder, visually no different from half a dozen organic acids on a lab shelf. Even though it's not a household name, anyone working with organic synthesis, especially in drug development or pigment chemistry, knows its value. Keep the lid tight: it can absorb moisture, making future weighing or solution prep a headache.

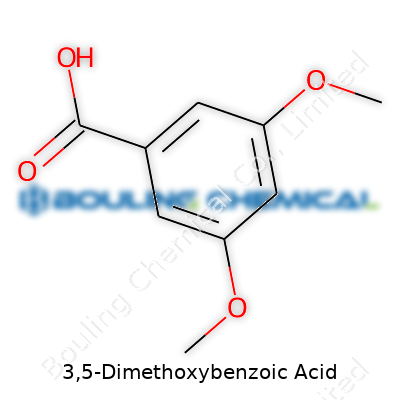

Looking at this compound, its formula C9H10O4 adds up to a molar mass of about 182.18 g/mol. It boasts a melting point range between 184 and 187 °C. In practice, this means all but the hottest storerooms can't hurt it, but autoclaving or high-temp reactions break it down and release pungent byproducts. It's only slightly soluble in water, yet it takes to ethanol, ether, and chloroform with little complaint, so labs often use those when purifying or reacting. The sum of those two methoxy groups lowers its acidity compared to plain benzoic acid—worth remembering when planning multi-step syntheses.

Grades of 3.5-Dimethoxybenzoic acid depend on what you're planning to do. Reagent grades promise purity above 98%, with most suppliers printing CAS number 1663-76-9 on labels so orders don't go sideways. Impurity levels, moisture content, residual solvents—every serious datasheet spells these out line by line. Shipping this compound means UN codes and hazard pictograms, like “Irritant,” and traceability for batch numbers. Safety data sheets emphasize closed containers, cool storage, and clear labeling. Product synonyms sometimes mess with new buyers: some bottles may say “m-anisic acid,” “Benzoic acid, 3,5-dimethoxy-," or even “3,5-DMA.”

Making 3.5-Dimethoxybenzoic acid in a decent yield means thinking ahead. One route kicks off from 3,5-dihydroxybenzoic acid—available but pricier—using methylating agents like dimethyl sulfate under basic conditions. Sodium hydroxide keeps everything deprotonated and soluble, but vigilance is needed; poor control brings side-products and sometimes dangerous fumes. Neutralization and slow acidification pull the product from solution, then recrystallization from ethanol cleans it up.

Building off the stability of its benzoic core, this compound serves as a handy starting point for substitutions and coupling reactions. Those methoxy groups resist a lot, but nucleophilic attack or oxidative processes can take them off or transform them further when pushed with metal catalysts. The carboxyl end forms esters easily, whether for new flavors in fragrance chemistry or as intermediates in drug synthesis. It connects with amines to make amides—another door for tuning biological activity in medicinal chemistry. Grignard reagent additions, catalytic hydrogenation, and halogenations show up in the smarter organic labs, sometimes building complexity or stripping groups away for custom synthesis.

Anyone surfing catalogs or chemical inventories runs into a list of aliases for the same molecule. "m-Anisic acid" shows up most often, a nod to the methoxy groups at the meta positions. IUPAC strictness calls it 3,5-dimethoxybenzoic acid, while older German or French literature might shorten or Latinize the label. Suppliers typically stick to the CAS listing, 1663-76-9, to dodge confusion, but seasoned researchers always check synonyms to make sure orders hit the right target.

Working with 3.5-Dimethoxybenzoic acid feels like handling most substituted benzoic acids, but methoxy groups don’t make a substance entirely benign. Even without dramatic toxicity, gloves, eye protection, and dust masks ward off skin and eye irritation. Spills spread blinding white dust beyond the bench, so ventilation helps. Waste disposal rules call for non-halogenated organic collection, with downstream incineration. Some older procedures still use methyl bromide or dimethyl sulfate in synthesis; these reagents demand fume hoods and proper training, as their hazards far outstrip the end product.

Folks most likely to order this acid include organic chemists intent on building larger molecules, and in the past five years, its use in synthesizing advanced pharmaceuticals picked up again. 3.5-Dimethoxybenzoic acid’s stability and substitution pattern suit intermediate roles in anti-inflammatory drug design, antibacterial research, and pigment manufacturing. Dye chemists once relied on it for color tuning, especially in textiles and food-safe products, long before stricter regulations narrowed the permittable palette. You’ll find it in agrochemical research too, often as a parent or breakdown product in metabolic pathway mapping.

Labs keep pushing 3.5-Dimethoxybenzoic acid into new directions: medicinal chemistry uses it for structure-activity relationships in search of safer anti-inflammatory agents, given its chemical closeness to salicylate standards. Pharmaceutical groups test it for synergy with heterocycles and as a scaffold for antifungal or antiviral drugs. Material science programs see patchy but persistent work with its esters for biodegradable plastics and responsive coatings. Each change in functional group—sometimes just a methyl or chlorine—sparks follow-up studies in crystalline structure, solubility, and effect on living tissue. Pure curiosity leads to new derivatives; some never leave the bench, others make it into patent filings or clinical trials.

The safety file on 3.5-Dimethoxybenzoic acid isn’t as thick as with bigger players like aspirin, but core studies say low acute toxicity in rodents, with skin and eye irritation the only likely complaint at lab-scale exposures. Chronic effects haven’t been flagged at current levels of use. Researchers run breakdown and metabolism studies to see if the methoxy groups add risk, but results suggest fast passage through the body’s usual catabolic paths. Environmental impact still needs regular checks, since aromatic acids don’t always break down fast in water or soil. Animal studies on parent benzoic acid compounds help give context, yet direct data for each variant remains sparse.

Interest in 3.5-Dimethoxybenzoic acid picks up each time synthetic hurdles ease or new drug targets appear. With better methylation methods and less toxic reagents, labs get safer, purer product. The ongoing hunt for unique anti-inflammatory compounds provides fresh reason to tweak this molecule’s structure—even a minor shift can pay off in activity or safety. Materials scientists looking for sustainable, high-performance polymers continue to probe its ester and amide derivatives. Regulatory changes always shape research, forcing some applications to fade as others get a green light. If chemistry curricula and toolkits continue adapting, the story of 3.5-Dimethoxybenzoic acid will add more surprising chapters over the next decade.

A chemist grabs a bottle, studies the label: 3.5-Dimethoxybenzoic Acid, purity 98%. To some, that looks close enough to perfect; in the lab, one or two percent off can mean the difference between a failed experiment and data you trust. Every researcher knows what non-pure chemicals do. They mess with results, introducing doubts or even full-on errors.

Lab work and manufacturing both demand accuracy. The purity of 3.5-Dimethoxybenzoic Acid often falls around 97–99%, depending on the supplier. That range tells its own story. Something at 98% purity comes from careful synthesis and proper storage. Impurities might include unreacted starting material or leftover solvents. It isn’t some mysterious measure; it’s quality control you can usually trace to a chromatography test or a melting point you can verify.

Early in grad school, I tried to push an aromatic substitution using a batch labeled “97%.” The reaction barely moved. The next trial, with freshly purchased “99+%” material, finished fast, clean, and with solid yield. These numbers aren’t just advert fluff — they shape how well research unfolds. Fields like drug development, dyes, or specialty coatings stake their advances on this reliability. Researchers can’t afford to treat a two percent impurity as a tiny afterthought since some trace contaminants can foul up a sensitive catalyst or block a synthetic step.

Nobody wakes up thinking about residual solvents or spectral peaks, but every lot comes with a certificate of analysis for a reason. Most producers measure purity with high-performance liquid chromatography (HPLC) or nuclear magnetic resonance (NMR). Sometimes, a sharp melting point means clean crystals. Sometimes, a slightly muddy spectrum means trouble’s around the corner. That two percent impurity can be the difference between stable storage and a slow, invisible breakdown.

Researchers sometimes re-purify 3.5-Dimethoxybenzoic Acid themselves, especially in sensitive setups. Recrystallization, column chromatography, these old standbys often raise the purity another notch. Chemistry gets hands-on in this way, which anyone who’s ever puzzled at inconsistent yields will appreciate.

Some make the mistake of trusting every off-the-shelf chemical as “good enough.” Then a batch goes sideways, wasting time and money. Why? Because a manufacturer’s 97% batch could include traces of byproducts that sneak through less rigorous syntheses. A city’s water supply might handle that kind of margin, but a high-precision pharmaceutical process cannot.

One fix involves picking a supplier with regular batch testing, transparent reporting, and a willingness to tweak their processes. Another strategy means running your own purity checks, even if that feels redundant. At least then, results won’t blindside your project. Sometimes pooling resources between labs brings better analytical capability within reach, letting all partners work with purer materials.

A synthetic route for a basic classroom demo might do fine with a lower purity, just to show a reaction happens. For analytical work, the tightest tolerances matter — 99% or above isn’t luxury, it’s necessity. A chemist ignores this truth at their peril. Researchers know the pain of re-running controls because a reagent cut a corner.

So, whether you see 97% or 99.5% on the label, that percentage writes more than a number. It marks the difference between “good enough” and breakthrough. In chemistry, that puts purity front and center, every single time.

Storing chemicals like 3.5-Dimethoxybenzoic acid isn’t just about stacking bottles on a shelf. Carelessness can eat away at a research budget, degrade the quality of experiments, and pose safety risks that no one wants to face. This substance is no exception. It tends to look harmless—a fine white powder, a little like baking soda—but it responds strongly to its surroundings.

This compound draws trouble if exposed to damp air. Even small traces of moisture in the atmosphere can start to clump it up and nudge it towards degradation. It makes sense to work fast and seal it shut after every use. I’ve seen what happens when caps aren’t screwed on properly: sudden mystery peaks in an NMR, or failed reactions that would make any research advisor sigh. A tightly sealed, air-tight container keeps these issues away, for the most part.

Heat speeds up unwanted reactions—sometimes faster than people realize. Storing 3.5-Dimethoxybenzoic acid at room temperature is alright in many labs, as long as direct sunlight isn’t a factor. Back in college, I watched someone store sensitive chemicals too close to windows and watched batches turn yellow over time. Direct light, especially UV, slowly chips away at the compound’s integrity. A cool and dry cabinet, far from light sources, has always seemed the safest bet. Some synthetic chemists prefer the fridge for long-term storage, though not the freezer, as repeated thawing and condensation can introduce water where it isn’t wanted.

Even a sliver of skin oil can cause trouble over time. No need for anything fancy, just a standard pair of gloves and clean spatulas will do the job. Avoiding cross-contamination pays off—adding trace acid to another sample or vice versa can throw results off balance. Anyone who’s shared a communal lab knows the scramble when white powders start looking a little off-color or clumpy, traceable back most often to careless handling.

Proper storage isn’t just about a physical bottle; clear labeling matters. Anyone picking up the vial weeks later needs to know exactly what’s inside, who weighed it out, and the date of storage. Leaving it up to memory or generic ‘white powder’ bags stacks up confusion. Many labs make a habit of recording batch numbers and dates on a visible label, so expired or questionable stock gets weeded out early.

Every lab faces its own storage headaches—small spaces, too much stock, limited resources. Even so, some solutions really help. Silica gel packets in the cabinets keep humidity in check. Regular shelf checks help spot old material before it causes trouble. Simple things like keeping a running inventory make it easier to avoid the drama of expired or degraded chemicals mid-project.

Storage isn’t glamorous, but it lays the groundwork for every project. Every time I walk into a well-organized lab, with powders tucked away from sun, moisture, and stray hands, the work just flows better. Small steps like these let scientists focus on results, not on headaches from unexpected contamination or breakdown.

Summary: 3.5-Dimethoxybenzoic acid stays stable and ready for action when it’s sealed tightly, kept cool and dry, away from sunlight, and handled with clean utensils and labeling. Skipping these steps builds frustration and wastes valuable research time. Good storage isn’t about red tape—it’s about keeping the science strong.3.5-Dimethoxybenzoic acid doesn’t make headlines, but if you spend any time around synthetic chemistry, you notice its steady presence. In the lab, people rely on it for more than its mouthful of a name. This compound, with its two methoxy groups and a carboxylic acid, plays a subtle yet steady part across both research and industry.

Let’s cut to the chase: research teams use 3.5-dimethoxybenzoic acid as a building block. It anchors organic synthesis, especially when making active ingredients for medicines. Medicinal chemists see value in these aromatic acids when designing and producing drug candidates, since that methoxy and carboxyl combo offers just the right balance of reactivity and stability. If you’ve worked with non-steroidal anti-inflammatory drugs or certain antihistamines, you’ve probably flipped through synthesis routes featuring benzoic acid derivatives as intermediates.

The molecule's relatively simple structure means researchers can easily modify it, tacking on other groups to create compounds with new pharmaceutical properties. This adaptability helps drive the constant search for more effective, less toxic therapies.

Outside medicine, this benzoic acid derivative lands in specialty chemicals and materials. People making dyes, pigments, and optical brighteners reach for 3.5-dimethoxybenzoic acid, because it kickstarts reactions that lead to clear or vivid coloration and enhances stability in sunlight. Textile and paper manufacturers banks on this stability to keep products looking fresh after exposure to light and heat—a small addition with big downstream impact.

Applications stretch into polymers, too. Chemists use it to make specialty plastics or coatings, where small tweaks to a molecule’s shape or electronic properties ripple out and change how a final product performs. Personally, I’ve seen this at play in coatings for electronics, where a tweak to an acid group made the difference between a flexible screen and a brittle failure.

In teaching labs, faculty deploy 3.5-dimethoxybenzoic acid for classic experiments in organic synthesis and crystallization. Students grasp the real world of chemistry by seeing how such a molecule behaves in both reaction and purification. The compound's predictability means it's been a go-to for techniques like recrystallization or thin-layer chromatography, offering a training tool as reliable as any beaker or pipette.

Chemical research’s future leans hard on the ability to invent new molecules. 3.5-Dimethoxybenzoic acid stands out for its usefulness in combinatorial chemistry, where researchers build vast libraries of potential drug or material candidates by tweaking existing molecules. Its straightforward reactivity lets scientists generate dozens or even hundreds of new compounds in a single campaign, fueling both academic papers and industrial patents.

Handling and sourcing chemicals always brings up the matter of safety and environmental impact. 3.5-Dimethoxybenzoic acid holds up well in standard storage, and traditional safety precautions—gloves, goggles, good ventilation—suffice for most settings. Green chemistry principles push researchers to consider alternatives, but so far, this compound’s role as a reliable intermediate keeps it on benches around the world. People keep seeking out eco-friendlier processes and solvents, yet as of now, the utility of this chemical holds strong.

If you work in a chemistry-adjacent field, you probably come across 3.5-dimethoxybenzoic acid more often than you realize. Its uses spread across medicine, industry, education, and pure research, making it one of those quietly essential compounds that power progress behind the scenes.

A Certificate of Analysis (COA) feels like one of those pieces of paper no one cares about till something goes sideways. For anyone working in chemistry, food science, or pharmaceuticals, a COA isn’t a fancy extra—it’s the backbone of trust between buyer and seller. Now, for something like 3.5-Dimethoxybenzoic Acid, it isn’t just about a handful of numbers or a stamp from a company lab. It means that what’s in the bottle actually matches the label, and if you ask around, you’ll hear stories of the headaches that come when no COA is available.

Back in the day, a colleague ordered a “pure” reagent from a lesser-known supplier. It arrived fast, the price looked good, but the results in the flask never quite lined up with published reactions. After rounds of troubleshooting, it turned out impurities in the compound tossed everything off—no COA was provided. Ever since, most labs I’ve worked with order only from places that supply a real COA, and few forget that lesson.

With 3.5-Dimethoxybenzoic Acid used in synthesis, process controls, or as a reference standard, nobody wants to fly blind on purity. Contaminants, trace metals, or incorrect melting points lead to delays, extra costs, lost reputation. A COA makes it clear—every lot has been checked for identity, purity, and safety.

Today, many reputable suppliers post COAs online for each batch. That means you can check the certificate before a bottle even shows up, and if the numbers don’t stack up, you can walk away. Labs working under strict quality standards, like ISO or GMP, won’t even accept a shipment without one. Regulators demand it, customers expect it, and researchers rely on it.

In my own projects, missing or questionable COAs slow everything down. I’ve lost whole weeks chasing missing data on reagents, then had to reschedule multiple runs. Time wasted on unnecessary troubleshooting comes straight out of someone’s budget. A transparent supply chain, supported by straightforward COAs, saves real money and keeps everyone honest.

Not all suppliers handle certificates the same way. You run into places, often outside major markets, that play fast and loose with documentation. Some small chemical distributors skip the COA or only give a vague, half-complete printout—hardly enough when your work or a client’s safety rides on the details. Retrospectively verifying a batch becomes a guessing game, especially if samples are long gone.

Serious buyers need to treat this upfront. One solution means always requesting the COA before placing any order, not just after delivery. I’ve had to push back on purchasing teams that didn’t see the difference. Sharing these stories with new labs helps everyone understand: a cheap bottle costs more if you burn a week cleaning up problems from someone else’s shortcut.

It helps to build ongoing relationships with suppliers known for their documentation. Direct phone calls and clear terms in the purchase order—ask for batch-specific COAs, not generic templates—avoid 90% of future headaches. If a company can’t provide a proper COA quickly, that’s a bright red flag.

No one wants paperwork for paperwork’s sake. In fields using specialty reagents like 3.5-Dimethoxybenzoic Acid, a solid Certificate of Analysis forms a baseline for quality and trust. By insisting on this document and holding suppliers accountable, everyone in the supply chain protects time, budgets, and reputations.

Many folks glaze over when scientists start rattling off chemical formulas and molecular weights. Chemistry class can feel like a slog, full of symbols and numbers that don’t seem to touch everyday life. But these details help us understand how things work and what we’re actually using, eating, or dealing with.

Let’s dig right into it. 3,5-Dimethoxybenzoic acid goes by the formula C9H10O4. Its molecular weight clocks in at 182.17 g/mol. Both numbers say a lot in just a few symbols. Here, C stands for carbon, H for hydrogen, O for oxygen. Count those up: 9 carbons, 10 hydrogens, and 4 oxygens. These numbers don’t just serve chemists working in a lab; they come up in manufacturing, pharmaceuticals, and even environmental work.

Years ago, I worked with a team analyzing new dyes for textiles. We needed to check if they broke down safely and whether people might get exposed to harmful byproducts. Getting the formula right told us what to expect. A tiny change—a single atom here or there—can mean the difference between a harmless ingredient and something with pretty harsh side effects.

3,5-Dimethoxybenzoic acid’s methoxy groups at positions three and five on the benzene ring make it very specific. The arrangement tips you off to how it might react. Tweaking the structure changes the way it dissolves in water or oil, how it behaves at different pH levels, and even how it smells.

The importance of reliable chemical data shows up in medicine too. For anybody making pharmaceuticals, even a tiny slip in the molecular weight can mean using the wrong dose. Chemists need this info before any mixing, measuring, or shipping starts. Errors mean waste, recalls, and sometimes worse.

Another place these numbers come up is in green chemistry. Companies trying to replace toxic chemicals check formulas like C9H10O4 to see if newer ingredients really do break down faster or produce less pollution. If the numbers don’t add up, the end product probably won’t work as advertised, or it might leave more mess behind.

I’ve seen projects waste days tracing problems back to a missed decimal or a botched calculation of the molecular weight. If a chemist mistakenly uses C8H8O2 instead of C9H10O4, they end up making a different compound. The molecular weight difference means every measurement gets thrown off. Down the line, mixing, packing, and labeling all take a hit. This isn’t just an exam mistake—it shapes safety on factory floors and in hospitals.

Every time you glance at an ingredient list or see a batch number on a medication bottle, you’re seeing the fingerprints of chemical precision. Details like the molecular weight and chemical formula of 3,5-dimethoxybenzoic acid keep everything moving smoothly at every step, from the lab bench through to your house or hospital room. Getting these details locked down puts trust and safety into hands-on science.

| Names | |

| Preferred IUPAC name | 3,5-Dimethoxybenzoic acid |

| Other names |

m-Xylenic acid 3,5-Dimethoxybenzoic acid 3,5-Dimethoxybenzoesäure |

| Pronunciation | /ˌθriː.pɔɪnt.faɪv daɪˌmɛθ.ɒk.si bɛnˈzoʊ.ɪk ˈæs.ɪd/ |

| Identifiers | |

| CAS Number | 99-51-4 |

| Beilstein Reference | 1208732 |

| ChEBI | CHEBI:85270 |

| ChEMBL | CHEMBL254353 |

| ChemSpider | 8675 |

| DrugBank | DB04248 |

| ECHA InfoCard | 100.022.013 |

| EC Number | 214-033-5 |

| Gmelin Reference | 8948 |

| KEGG | C06981 |

| MeSH | D008398 |

| PubChem CID | 97754 |

| RTECS number | DG9275000 |

| UNII | Y8Z84T8K4E |

| UN number | UN2811 |

| Properties | |

| Chemical formula | C9H10O4 |

| Molar mass | 182.17 g/mol |

| Appearance | White to off-white crystalline powder |

| Odor | Odorless |

| Density | 1.34 g/cm³ |

| Solubility in water | Slightly soluble in water |

| log P | 1.85 |

| Vapor pressure | 0.0000137 mmHg at 25°C |

| Acidity (pKa) | 4.09 |

| Basicity (pKb) | 11.2 |

| Magnetic susceptibility (χ) | -54.7·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.567 |

| Viscosity | 953.5±159.6 mm^2/s at 25 °C |

| Dipole moment | 2.70 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 160.8 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -362.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1604 kJ/mol |

| Hazards | |

| Main hazards | Irritating to eyes, respiratory system and skin. |

| GHS labelling | GHS07, Exclamation Mark |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H315, H319, H335 |

| Precautionary statements | Precautionary statements: P261, P264, P271, P301+P312, P305+P351+P338, P304+P340, P330, P405, P501 |

| Flash point | 137°C |

| Lethal dose or concentration | LD50 (rat, oral): > 2000 mg/kg |

| LD50 (median dose) | LD50 (median dose): Mouse oral 890 mg/kg |

| NIOSH | DJ9635000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 10 grams |

| Related compounds | |

| Related compounds |

Benzoic acid 3,5-Dimethoxybenzaldehyde 3-Methoxybenzoic acid 4-Methoxybenzoic acid 3,4-Dimethoxybenzoic acid 2,4-Dimethoxybenzoic acid |