Chemists first synthesized 2-Piperazin-1-ylethylamine during the mid-20th century, at a time when exploration of heterocyclic amines led to a wave of useful intermediates. Early on, this compound attracted attention for its simple but versatile structure, which offered routes into pharmaceutical development, polymer production, and organic synthesis. Decades of experimentation reflected a broader trend through which researchers prototyped new drugs and specialty chemicals by tweaking basic amines, looking for improved performance and safety. Experiences in a university lab, working under the yellow glow of bench lamps, taught me how small structural differences could decide whether an amine became a promising candidate or got pushed aside for something more reactive or less toxic. The methodical approaches used to chart out the reactivity of piperazine derivatives highlighted a commitment to scientific rigor and the willingness to iterate even tiny modifications. This spirit lives on as new chemical entities build on these old foundations.

2-Piperazin-1-ylethylamine shows up as a colorless to pale yellow liquid, with a pronounced amine odor. It often comes in tightly sealed bottles, labeled with hazard warnings due to its potential health risks. Chemically, the molecule brings together a flexible ethylamine chain linked to a piperazine ring structure, offering two distinct pockets of reactivity. The demand for this compound in my own experience mirrors broader industry trends: requests often start with a phone call from a pilot-scale facility or a pharmaceutical startup looking for reliable supply. While big-volume markets like commodity chemicals focus on efficiency and cost, smaller labs value traceability and purity, concerns addressed by producers driven to improve analytical methods. As chemists saw new possibilities in drug design and functionalized polymers, interest in the compound broadened even more.

The boiling point tends to cluster around 240–250°C, underscoring both its volatility and need for careful temperature control. Solubility experiments I ran confirmed easy mixing with water and common polar solvents such as methanol or ethanol, a convenience that smooths out many workflow challenges during synthesis and purification. The free-flowing liquid form stands up well in storage provided there’s minimal exposure to open air, since the strong amine base can absorb carbon dioxide or water vapor and eventually degrade. Handling this amine gave me firsthand appreciation for personal protective gear; the sharp odor and potential for skin absorption reinforce why labs emphasize safe handling. Its reactivity emerges when it gets involved in nucleophilic substitution and cyclization, properties that make it attractive as both a raw material and intermediate step toward something bigger.

Manufacturers list high purity grades of 2-Piperazin-1-ylethylamine at or above 98%, specifying moisture content, residue on evaporation, and trace-metal percentages. Global standards, such as those harmonized by ISO and reached through years of cross-border chemical trade, inform labeling practices. Packaging always reflects strict labeling rules: prominent hazard pictograms, detailed safety instructions, lot numbers for traceability, and exact net and gross weights. Even at small scale, routine batch testing ensures each shipment matches specification sheets. I remember tracking shipments using those lot numbers to solve discrepancies and realize just how much traceability matters. Many facilities now incorporate QR codes to help downstream users access real-time safety and compliance information, a nod to both digitalization and rising regulatory pressure.

Standard synthetic routes to 2-Piperazin-1-ylethylamine rely on alkylation or reductive amination. One widely adopted method couples ethylene diamine with piperazine under controlled conditions, usually in the presence of catalysts and with carefully staged reagent additions to reduce unwanted byproducts. Scaling up demands smart engineering and safety controls, since pressure and heat fluctuations can create hazardous situations. My exposure to pilot plant operations revealed the need for redundant temperature monitoring and automatic shutdown features — it’s not enough to trust one layer of instrumentation. In academic settings, the process sometimes doubles as an educational exercise, underscoring foundational organic techniques from distillation to chromatographic purification. Recent innovations focus on “greener” alternatives: flow synthesis, less hazardous solvents, and catalyst recycling, part of a broader sustainability trend across the fine chemical sector.

Few compounds match the versatility of 2-Piperazin-1-ylethylamine in multi-step synthesis. The amine groups invite acylation, alkylation, and reductive transformations, laying the groundwork for novel heterocycles or tailored polymers. Its bifunctional character lets chemists build complex molecular scaffolds, often as part of drug discovery pipelines where slight changes at this position shift biological activity. My stints working in medicinal chemistry showed just how often a project circled back to these small amines, revisiting them to enhance solubility or tweak potency. Polymer chemists also look to this molecule for creating crosslinked networks or as a flexible softening agent. Each modification, whether a simple N-alkylation or elaborate cyclization, unlocks a different class of products, driving demand up and down the supply chain.

Chemists’ habit of using multiple names for the same compound crops up again here. Other naming conventions include N-(2-Aminoethyl)piperazine, 2-(Piperazin-1-yl)ethanamine, and AEPP. Catalog vendors list these alongside unique identifiers such as CAS number 140-31-8 or EINECS 205-411-0, letting researchers match local and international records. My own ordering experience hammered home how crucial these cross-references are; a simple typo between synonyms risks mixing up compounds or missing regulatory requirements. Consistent naming practices help procurement teams, customs authorities, and downstream labs keep shipments and paperwork in line.

Strict safety protocols apply from loading dock to bench scale. 2-Piperazin-1-ylethylamine can cause skin irritation, eye damage, and respiratory distress if handled without proper equipment. My own hands-on work taught respect for double-gloving and the use of fume hoods during transfers or weighing. Material Safety Data Sheets (MSDS) detail appropriate first aid, spill containment, and storage temperature ranges. Emergency planning often extends beyond the lab; chemical producers invest in training for first responders and in community right-to-know programs. Across the sector, near-miss reporting and root cause analysis shape ongoing improvements, while international standards like GHS labeling and REACH compliance shape product packaging and distribution. Continuous improvement in hazard communication and PPE options reflects both industry priorities and regulatory evolution.

Pharmaceutical manufacturing leans heavily on 2-Piperazin-1-ylethylamine for building blocks in antihistamines, psychotropics, and many experimental drug candidates. Contract manufacturers rely on timely, quality-assured supplies to meet tight development and production timelines. The story repeats in polymer science, where the compound shows value as a chain extender, crosslinking agent, or surface modifier. I saw labs use it to tweak resin performance or impart specific adhesive properties. Agrochemicals and dyes round out major application fields, leveraging the molecule’s robust structure for durability and biological effects. R&D teams often order smaller bottles to screen new functionalizations on prototype devices or potential therapeutic scaffolds.

Active research circles around more selective derivatization, enhanced catalyst efficiency, and greener process chemistry. Some of the R&D work I followed highlights the challenges of finding safer alternatives without losing the reactivity and cost advantages of amine-bearing molecules. Universities and contract research organizations join a feedback loop with industry, using real-world process bottlenecks to pose new academic questions. A growing focus on computational chemistry aids rational design, helping some groups avoid time-consuming bench synthesis and move quickly to the most promising molecular modifications. Stakeholders now push for lifecycle assessments and environmental toxicity profiling alongside yield and throughput data, aligning technical progress with sustainability benchmarks.

Toxicologists report a mixed profile: 2-Piperazin-1-ylethylamine can trigger acute irritation and longer-term organ damage if exposures cross occupational safety thresholds. Experience handling unlabeled or poorly documented stocks in legacy storage drives home the practicality of detailed recordkeeping and routine training. Rodent studies and in vitro toxicity screens continue to generate fresh data on both the parent amine and its downstream metabolites, shaping worker safety guidelines and permissible exposure limits. Often, the push for greater transparency from manufacturers — regular publication of updated toxicity and environmental fate studies — meets demands from both regulators and downstream users. In industry, the consensus now expects ongoing investment in exposure monitoring and health surveillance for employees.

Industry watchers anticipate rising demand for 2-Piperazin-1-ylethylamine based on its role in next-generation pharmaceuticals and specialty polymers. The shift toward digitalization and more data-driven process control could boost efficiency and reduce waste, while innovators hunt for lower-toxicity derivatives that keep all the desired reactivity. My meetings with synthetic chemistry teams often veer into how automation and continuous flow can bring lab-scale ideas to full-scale manufacture much faster. A move toward circular practices — recycling or reusing spent reagents — blends business needs with environmental stewardship. Academic and industrial partnerships play out in regular conferences and open-access journals, sustaining a collaborative effort that ensures this humble molecule keeps evolving in sync with the industry’s larger challenges and opportunities.

2-Piperazin-1-ylethylamine sounds like a mouthful, but it’s a small organic molecule that’s pretty useful behind the scenes in labs and factories. This compound belongs to the piperazine chemical family, which means it features a six-membered ring with two nitrogen atoms tucked inside. Chemistry lessons aside, what gets folks talking about this compound aren’t its technical diagrams, but how it shows up in business and medicine.

People working on new medicines make a big deal about 2-Piperazin-1-ylethylamine. The molecule serves as a building block. Basically, scientists stitch it onto other chemical structures to make drugs with new properties. You see it in early-stage research when teams hunt for promising molecules to fight disease. A quick check of recent scientific papers turns up research into anti-cancer, anti-malarial, and anti-psychotic compounds made from piperazine derivatives like this one.

The pharmaceutical industry leans on compounds with piperazine cores because these rings bring flexibility and stability to the new drug designs. Those nitrogen atoms in the ring aren't just decorative—they can grab onto parts of biological targets like proteins and help drugs do their job inside the body. Choosing the right building blocks early on can put researchers miles ahead in the chase for better treatments.

Pharma gets a lot of the spotlight, but 2-Piperazin-1-ylethylamine has jobs outside the clinic. Chemical manufacturers use it in the production of specialty coatings, resins, and even water treatment chemicals. Some of the compounds derived from it step up as corrosion inhibitors or stabilizers in industrial processes. It might seem like a small detail, yet these contributions add up to stronger, longer-lasting materials in factories, pipelines, and storage tanks.

In research and development labs, chemists reach for this molecule as an intermediate. Intermediates act like pit stops on the way to a finished product. Each reaction uses chemical bits like 2-Piperazin-1-ylethylamine to pile on, trim off, or rearrange atoms. The availability and reactivity of this building block let scientists explore new ideas efficiently. Coming from my own work in lab research, having reliable intermediates on the shelf helps speed up tough projects that demand both creativity and accuracy.

Not every specialty chemical sails through regulation without scrutiny. Regulatory agencies demand clear records of how intermediates and their final products behave in the environment and the human body. 2-Piperazin-1-ylethylamine doesn’t get a free pass. Anyone working with it needs solid safety training. Gloves, goggles, and ventilation become standard, along with detailed logs of handling and disposal. Plant managers or lab supervisors keep a close eye on these rules to protect both workers and the company from potential hazards or fines.

Many specialty chemicals face public pressure to prove their value and safety. As a chemist, I see the balance teams try to strike—innovating with new molecular tools like 2-Piperazin-1-ylethylamine while keeping a close watch on environmental and health impacts. Some solutions show promise, like moving towards greener chemistry or improving training for anyone who handles these molecules. It pays to keep the conversation going about which chemicals pull their weight and which can be replaced by safer, more sustainable options.

I’ve spent years in labs that rely on all kinds of amine compounds. 2-Piperazin-1-Ylethylamine pops up more often than most folks might guess. With a molecular structure that makes it both reactive and a bit sneaky, this chemical doesn’t just warrant respect — it demands it.

No matter how many training sessions you sit through, nothing compares to that first whiff of an amine in person. The smell is enough to stick in your nose and your memory. Forgetting gloves or goggles only happens once. I always put on nitrile gloves, goggles that actually seal, and a decent lab coat before opening any container with 2-Piperazin-1-Ylethylamine. Regular latex gloves can fail without warning — the compound chews right through. Getting it on your skin stings, but long-term, it’s exposure that bites back. Skin, eyes, even a quick inhale — every route matters.

Chemical fume hoods have saved my skin more than once. These aren’t just for looks or lab protocols. A poorly-ventilated space turns even careful work into Russian roulette. 2-Piperazin-1-Ylethylamine vapors rise up fast, so a well-running hood makes the job less nerve-racking. Some colleagues used to assume opening a window helped. It doesn’t. Controlled ventilation is the game-changer.

A good label, tight cap, and right container make life easier. I grab brown bottles and stash them away from acids or oxidizers. A sealed desiccator gives peace of mind, especially in a room where humidity loves to sabotage chemicals. Spills can get ugly in a hurry, too. I’ve seen someone wipe up 2-Piperazin-1-Ylethylamine with a towel and end up with a rash that wouldn’t quit. Absorbent pads and an emergency eye wash station nearby mean accidents turn into stories — not permanent problems.

Before picking up any unfamiliar bottle, I pore over the SDS (Safety Data Sheet). There’s always a detail that surprises even the veterans. The document covers everything from flammability to what happens in case of accidental contact. After seeing a co-worker struggle with dizziness after a poorly contained spill, I learned to keep emergency numbers tacked right above the benchtop.

In my experience, the best labs run drills for chemical exposure just as seriously as fire alarms. Shortcuts or skipping those tutorials shows up in the worst way on days when something splashes or spills. Buddy systems, consistent reminders, and quick refresher courses help cement habits. Anything less opens the door to avoidable injuries.

The nastiest incidents I’ve heard about usually trace back to simple steps ignored or rushed. A missing warning label, skipping handwashing, or forgetting to close a cap before leaving for lunch. None of this stuff happens in isolation. Open communication and regular checks make it easier to spot trouble early. Sharing stories of close calls, instead of covering them up, actually roots good habits.

Labs never stagnate. Handling 2-Piperazin-1-Ylethylamine, like any reactive substance, evolves with each new detail and shared experience. PPE, air controls, solid protocols, and real communication — they’re not just boxes to tick. They’re why lab teams end days safe and ready to work again tomorrow.

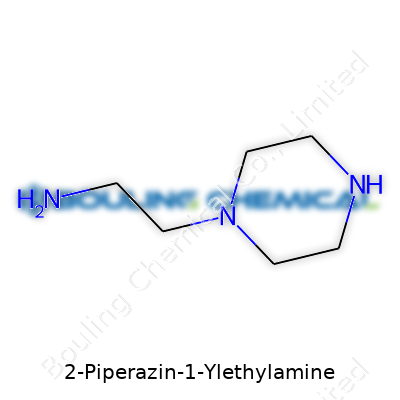

2-Piperazin-1-ylethylamine sounds intimidating but breaks down into two familiar parts. One end has a piperazine ring, the other carries an ethylamine group. In simpler terms, you’re looking at a six-membered ring made from four carbons and two nitrogens, which gives the molecule some unusual characteristics right out of the gate. Attached to this ring is a two-carbon chain, and on the far end, a free amine group sticks out.

This molecule's backbone shapes its chemical personality. I’ve seen how the piperazine ring crops up in medications, adhesives, lab reagents—you name it. Those nitrogen atoms tucked inside the ring change the way it interacts with other molecules and with water; they offer sites for bonding, making the substance valuable in pharmaceutical design. The ethylamine chain doesn’t just hang on as decoration. Its free amine group helps it slot into receptors in the body or serve as a building block for more complex compounds. That’s what makes molecules like this one show up in so many research discoveries and trials.

Chemists and drug designers use 2-piperazin-1-ylethylamine as a stepping stone. It helps them create antihistamines, antipsychotics, and other drugs that rely on nitrogen-rich frameworks. I remember reading papers that describe how minor tweaks to this basic structure changed the way a molecule worked in the brain or the immune system. The free amine group is a hot spot for chemical reactions, so with a little work, folks in a lab can hook up new side chains, rings, and pharmacophores.

This molecule isn’t always easy to work with. The same reactive parts that interest chemists also lead to side reactions in the lab. Impurities show up if the right controls aren’t in place. I’ve heard stories where research teams needed several extra purification steps and occasionally had to scrap a batch because the final product wouldn't pass a purity test. Investing in better purification techniques, or choosing safer solvents and reagents, gives better results. Lab safety also gets tricky because amines can trigger headaches, and piperazine-based substances share some toxicity risks. Good ventilation, gloves, and safe-handling routines always reduce these risks.

2-Piperazin-1-ylethylamine brings flexibility to drug development and industrial chemistry. Its straightforward design hides a lot of potential for building new treatments and tools. The real story lies in its usefulness as a foundation—a base that can turn into something much more valuable with the right chemical craftsmanship. Its structure, functional groups, and reactivity all combine to make it a go-to choice in labs that need reliability, adaptability, and a path forward when facing novel chemical challenges. For anyone invested in synthesis, the molecule isn't just a line on a supply sheet. It’s a resource worth understanding for the road ahead.

Anyone who browses chemical supplier catalogs or scours online vendor listings has come across 2-Piperazin-1-Ylethylamine at some point. This chemical pops up in research environments, pharmaceutical development rooms, and industrial labs. You’ll find it listed on platforms specializing in laboratory and specialty chemicals, but the road doesn’t always point straight to checkout. Many suppliers flag this compound as “for research use only,” which hints at its specialized applications. Ordering a bottle is not as easy as grabbing it off a drugstore shelf.

My own experience navigating these supplier portals reminds me how quickly chemical interest can grow complicated. Legitimate sellers expect more than a shopping cart. They usually ask for documentation that proves your lab or institution is equipped to handle chemicals safely. Companies, research groups, or universities can usually furnish those credentials, but private buyers and hobbyists hit a wall. These requirements draw a clear line—everybody’s safety comes first, and chemicals with potential risks or regulatory issues won’t just ship out to unknown addresses.

Regulatory rules don’t treat every chemical the same way. In the United States, 2-Piperazin-1-Ylethylamine does not land on federal controlled substance schedules or DEA watchlists. This means the government doesn’t see it as a drug precursor or a hazardous chemical needing nationwide special tracking. Still, this isn’t a wild west—industrial chemicals fall under local laws and policies that demand proper documentation and safe storage. Suppliers can refuse orders from parties without proper research institutional ties or a documented track record.

Countries in the European Union, and throughout Asia, classify chemicals in their own ways as well. Sometimes, local customs snag a package or ask for proof that you know how to handle, store, and dispose of chemicals responsibly. Lack of compliance turns a routine order into a bureaucratic headache or confiscation risk. Legitimate labs, manufacturers, or educational institutions keep their paperwork in order because this isn’t just a regulatory hoop—it keeps accidents off the front page of the news.

In my time supporting university labs, compliance folks showed genuine worry when they saw ambiguous chemical requests come through. Raw chemicals, even ones not strictly regulated, often act as starting material for more sensitive or dangerous compounds. Unchecked distribution can fuel unsavory enterprises or put vulnerable people in danger. That’s one reason suppliers verify institutional use, train staff on chemical handling, and steer clear of dodgy buyers.

Smart research does not start with shortcuts. A corner-cutting approach puts communities, reputations, and careers at risk. The best vendors offer safety sheets, technical support, and guidelines for clean disposal—all part of a culture that values lives as much as data. Anyone sourcing chemicals in bulk, or hoping to try out new reagents, should double-check regulations at every step and work with suppliers that act as partners, not just sellers.

Rogue markets and back-alley sellers pitch convenience, but they cut out accountability. Big industry players and responsible researchers lean on transparency and proper record-keeping. These habits help root out foul play and set the whole industry on firmer ground.

A public record of supply, safe disposal, and ongoing training beats any shortcut. Every time someone chooses to follow the rules, they strengthen a supply chain that respects regulations, health, and the environment. Even if a particular chemical does not demand a federal license, a reputation for careful sourcing matters more in the long run.

Working in a university lab opened my eyes to just how quickly mistakes with storage can snowball. 2-Piperazin-1-Ylethylamine, with its low flash point and reactivity with acids and oxidizers, belongs on a short list of chemicals where care beats convenience every time. Leaving it on a cluttered bench with organics and glassware doesn’t cut it. This is not a casual bottle of solvent—bring out the sturdy, airtight containers. Labels need more than just “handle with care”; include concentration and initials, so everyone knows who to ask if a question comes up.

A good habit: keep it out of sunlight, away from heat sources, and inside a locked, well-ventilated chemical cabinet. Some schools and research spaces use chemical-proof refrigerators for amines like this, since low temperatures make unwanted reactions much less likely. Humidity ramps up the risk, so squeeze the cap tight every time you open it. Too much complacency leads to yellowed, degraded chemicals. Nobody wants the panic of a leak discovered weeks late.

The real trouble starts at the end of the bottle. Pouring anything like 2-Piperazin-1-Ylethylamine down a sink drains more than just wastewater systems—it chips away at environmental protections that communities rely on. This kind of amine interacts with chlorine in municipal water, forming compounds that don’t get removed in standard water treatment. Very little research tracks the health effects of byproducts from improper disposal, but what we know doesn’t look promising.

Regulations like the Resource Conservation and Recovery Act treat this compound as hazardous waste. From what I’ve seen, mixing it with regular trash or diluting it in cleaning buckets risks legal headaches and real harm. I've watched people try shortcuts, and cleanup crews always pay the price later. Segregate spent material in compatible, labeled containers—no rusty cans, no glass jars with mystery stains. Good labs send full containers to licensed waste handlers who understand how to neutralize and process them.

If you work with chemicals often, a recurring training schedule means fewer lapses over time. Staff who shy away from asking “Is this the right waste bin?” sometimes wind up making big mistakes. A simple visual checklist posted near storage cabinets keeps everyone honest. If signs fade or labels peel, replace them fast.

In my own lab, swapping stories and learning from small mistakes helped us dodge bigger disasters. One researcher’s fluke—storing incompatible chemicals side by side—sparked a conversation that changed how everyone labeled and segregated their reagents. Keeping a running log of purchases and disposals flagged unusual stockpiles before they became a liability.

Switching to online training platforms and building relationships with reputable hazardous waste companies cuts through confusion. Encouraging a no-blame approach to questions and near-misses keeps the safety culture strong. All it takes is one slip to remind everyone why diligent storage and respectful disposal of 2-Piperazin-1-Ylethylamine matters. The habits pay off for more than the paperwork; they protect coworkers, the neighborhood, and the water we all share.

| Names | |

| Preferred IUPAC name | 2-(Piperazin-1-yl)ethan-1-amine |

| Other names |

N-(2-Aminoethyl)piperazine 1-(2-Aminoethyl)piperazine AEP N-Aminoethylpiperazine 2-(1-Piperazinyl)ethylamine |

| Pronunciation | /tuː paɪˌpɛrəˈziːn wʌn ˌɪl ˈɛθɪl əˈmiːn/ |

| Identifiers | |

| CAS Number | [6946-34-9] |

| 3D model (JSmol) | `3D Model (JSmol) String for 2-Piperazin-1-ylethylamine: CNCN1CCNCC1` |

| Beilstein Reference | 1698739 |

| ChEBI | CHEBI:38899 |

| ChEMBL | CHEMBL140213 |

| ChemSpider | 23211159 |

| DrugBank | DB08375 |

| ECHA InfoCard | ECHA InfoCard: 100.119.226 |

| EC Number | 214-077-3 |

| Gmelin Reference | 108137 |

| KEGG | C14485 |

| MeSH | D08.811.913.696.465 |

| PubChem CID | 2059 |

| RTECS number | KV7175000 |

| UNII | 6D33P6RLL1 |

| UN number | UN2734 |

| CompTox Dashboard (EPA) | DTXSID9058363 |

| Properties | |

| Chemical formula | C6H16N4 |

| Molar mass | 157.25 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | Amine-like |

| Density | 0.994 g/mL at 25 °C (lit.) |

| Solubility in water | soluble |

| log P | -1.2 |

| Vapor pressure | 0.0286 mmHg at 25 °C |

| Acidity (pKa) | 9.75 |

| Basicity (pKb) | 9.08 |

| Magnetic susceptibility (χ) | -7.6e-6 |

| Refractive index (nD) | 1.527 |

| Viscosity | 15 cP |

| Dipole moment | 2.32 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 276.5 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -68.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3557.9 kJ/mol |

| Pharmacology | |

| ATC code | N04BC09 |

| Hazards | |

| Main hazards | Harmful if swallowed, causes severe skin burns and eye damage. |

| GHS labelling | GHS02, GHS05, GHS07 |

| Pictograms | GHS06,GHS05 |

| Signal word | Warning |

| Hazard statements | H302, H314, H373 |

| Precautionary statements | P264, P280, P302+P352, P305+P351+P338, P310 |

| NFPA 704 (fire diamond) | 1-3-0 |

| Flash point | 74°C |

| Autoignition temperature | 385 °C |

| Lethal dose or concentration | LD₅₀ Oral rat: 2,740 mg/kg |

| LD50 (median dose) | LD50 (median dose) of 2-Piperazin-1-Ylethylamine: "500 mg/kg (Rat, oral) |

| NIOSH | SNJ14 |

| PEL (Permissible) | Not Established |

| REL (Recommended) | 5 mg/m³ |

| Related compounds | |

| Related compounds |

Piperazine N-Methylpiperazine 1-(2-Aminoethyl)piperazine N-Ethylpiperazine Homopiperazine Morpholine 1,2-Diaminoethane (Ethylenediamine) 1-(2-Hydroxyethyl)piperazine |