2-Heptadecyl-1H-Imidazole came about from decades of research into improving corrosion inhibition and surfactant behavior in both industrial and academic settings. Chemists searching for ways to deliver more robust protection in metalworking fluids and lubricants discovered that imidazole derivatives featuring long alkyl chains could punch above their weight in stabilizing diverse systems. By the late 20th century, advances in organic synthesis opened doors to making a variety of substituted imidazoles. Scientists took the 1H-imidazole ring and attached a straight seventeen-carbon chain, responding to known trends that linked longer alkyl substituents to stronger surface activity and metal affinity. Patents from research arms of oil and chemical giants in Europe and North America pop up throughout the 1970s and 80s, referencing various uses for heptadecyl-imidazoles as corrosion inhibitors, emulsifiers, and agents for treating textiles or surfaces. By now, the compound walked from the lab into commercial reality, especially as changes in manufacturing standards forced industry to upgrade the rust and corrosion protection in their fluids and coatings.

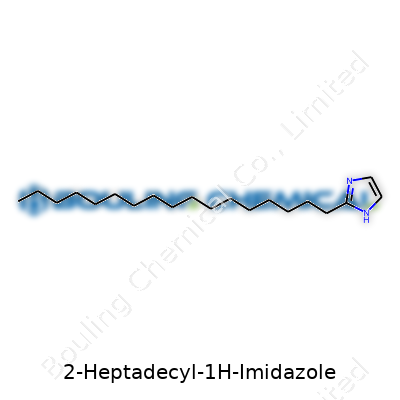

2-Heptadecyl-1H-imidazole stands out as a specialty chemical. Structurally, the molecule brings together a 1H-imidazole ring and a heptadecyl tail. This pairing allows the molecule to act as both a mild base and an efficient surfactant. The chemical enjoys popularity in settings that require tailored surface activity and selective corrosion protection, often in harsh or saline environments. Though not produced in commodity amounts, it claims a foothold in specialty lubricants, detergents, and even research aimed at crafting advanced nanomaterials. In my experience, niche compounds like this get ordered in kilograms, not tons, and buyers often want data on purity, melting point ranges, and detailed safety sheets ready to go for compliance audits.

2-Heptadecyl-1H-imidazole comes as a white to off-white crystalline solid, though some batches appear waxy under ambient conditions thanks to the long carbon chain. The melting point typically hovers around 70-75°C, depending on purity and storage. Its molecular weight sits at 346.6 g/mol. Given its structure, the compound resists dissolution in water, prefers organic solvents, and demonstrates amphiphilic tendencies. This means it lines up at interfaces, much like classic surfactants. On the chemical side, the imidazole ring can coordinate with metal ions, a property that draws attention for corrosion applications or designing functional coatings. The basic nitrogen atom can pick up a proton, though this rarely happens under neutral conditions due to the electron-donating nature of the attached group. In my view, these dual properties—hydrophobic tail and reactive head—help it stand out against simpler inhibitors or emulsifiers.

Sourcing this compound brings a cascade of technical checks. Buyers need an assay, usually offered by suppliers at or above 98% purity, analyzed by HPLC or GC-MS. Important specs include melting point, residue on ignition, moisture content (Karl Fischer titration often suffices), and verification of chain length by NMR. Most packaging comes in tightly sealed amber glass or HDPE containers, emphasizing exclusion of moisture and oxygen. Labelling follows GHS guidelines—hazard pictograms, signal words like ‘Warning’, and detailed statements on health effects and preventive measures. In my practice, a good COA not only lists these specs but also the synthetic method used, to help replicate or troubleshoot batch inconsistencies.

Manufacturers usually synthesize 2-heptadecyl-1H-imidazole using a condensation process. This starts with 1-heptadecylamine and glyoxal, reacting under controlled temperature with ammonia or ammonium acetate as a catalyst. Proper stoichiometry matters, since the lengthy alkylamine may cause emulsions or slow down the reaction if mixed too quickly. Post-reaction workup involves extraction into non-polar solvents, washing, drying, and slow crystallization. Final purification involves recrystallization from hexane or ethyl acetate. At scale, equipment like jacketed reactors and centrifuges handle the challenge of separating waxy solids without significant yield loss. Sometimes, additional purification through column chromatography sharpens the product profile for high-value applications. Chemists working at the bench need patience here: the waxy product can gum up glassware, and even after months of practice, getting a clean, repeatable yield often takes trial and error.

The core imidazole ring opens up diverse modification paths. The alkyl tail can undergo selective oxidation, α-bromination, or conversion to quaternary salts with alkylating agents, which enhances antimicrobial activity. The ring itself tolerates N-alkylation, acylation, or metal coordination. The nitrogen at position one stands alone for further substitution, but its reaction rates slow substantially once the fatty chain goes on. In research, scientists often exploit the metal-binding ability to anchor the molecule onto nanoparticles or as a chelating agent in coordination polymers. I remember colleagues trying to attach new functional groups at the C4 or C5 positions, aiming to tune hydrophilicity or cross-linking capacity for targeted industrial coatings.

Catalogues and technical literature often refer to this compound as N-heptadecylimidazole or 1-heptadecylimidazole, reflecting which nitrogen hosts the alkyl group. Other synonyms include 2-heptadecylimidazole and heptadecyl-1H-imidazole, with minor tweaks in naming across regulatory filings. CAS numbers and unique supplier codes help keep confusion at bay, but in practice, people scan for the heptadecyl tail and imidazole ring as clues. Product listings in China and India sometimes highlight ‘long-chain imidazole’ amid broader corrosion inhibitor blends. Knowing the right synonym often determines whether you’ll actually get the correct material from a supplier.

Handling 2-heptadecyl-1H-imidazole requires care, even for experienced chemists. The powder can cause mild irritation to skin or eyes, and inhaling dust poses respiratory risks. Most labs enforce use of gloves, safety glasses, and dust masks. Material safety data emphasize avoiding sources of heat, since decomposition can release fumes like nitrogen oxides. Spills turn slippery on smooth surfaces, so anti-slip mats and spill kits stay close at hand in production areas. GHS labeling puts it as 'Hazardous', demanding waste disposal according to environmental standards for amine-containing organics. Supervisors check storage conditions regularly; dry, cool rooms and clear separation from acids or oxidizers form part of any inspection checklist. I’ve found that clear training and frequent refresher drills make the biggest difference, especially for new lab techs who might overlook the risks of handling even “mild” irritants.

This specialty imidazole pops up wherever surfactant qualities and metal surface protection intersect. Its main calling card is corrosion inhibition in oilfield brines, industrial water circuits, and metalwork fluids. It helps form a tenacious barrier on steel surfaces, especially in saline or mildly acidic settings. In detergents and cleaning products, it acts as a mild surfactant and anti-static agent. Some textile mills use it to coat fibers, boosting wash durability and resistance to breakdown by harsh washing agents. More recently, research groups turn to this molecule when building advanced nanomaterials, using the imidazole ring to anchor nanoparticles or catalyze surface assembly. I’ve seen creative chemists use heptadecyl-imidazoles as templating agents in mesoporous silica synthesis or attach them to biologically active motifs for antimicrobial coatings. In most cases, buyers look for targeted function and documented safety, trusting this molecule to deliver results not easily achieved with bulk commodity surfactants.

Scientists keep prodding at the boundaries of what 2-heptadecyl-1H-imidazole can do. One current research hotspot explores how its structure tunes the self-assembly of monolayers on metals or oxides. By adjusting the chain length or adding other substituents, developers aim to create new barriers protecting metals against extreme chemical or marine exposures. In the nanotech world, the molecule acts as a stabilizer and ligand for metal nanoparticles, sometimes improving their catalytic or magnetic properties. Polymer chemists find its robust structure useful for crafting copolymers with anti-static properties or advanced membranes. There’s growing interest in sustainable chemistry circles: some groups test recyclable catalysts based on imidazole ligands, using heptadecyl chains to encourage recycling or easy separation after reactions. Having talked with a few PhD students in surface science labs, I know they value the compound’s dual reactivity and hydrophobicity when designing new experiments around surface functionalization and even controlled drug delivery systems.

Even specialty compounds need a close look at long-term health effects, and 2-heptadecyl-1H-imidazole is no exception. Acute studies suggest that it poses relatively low toxicity by oral or dermal exposure, well below the cutoffs for more reactive amines. Eye and skin contact remains a concern for irritation and sensitization — a common trait among imidazole derivatives. No significant mutagenic activity turns up in standard Ames assays, but data on chronic exposure in humans still remains thin. Environmental studies show the molecule tends to partition into sediments due to its hydrophobic structure, with slow breakdown times under ambient conditions. Regulatory agencies track usage levels in effluents and set disposal guidelines that cover not just discharge, but also accidental releases into soil or water. It’s clear that more work needs to happen on tracking environmental fate, especially as companies scale up use in oilfield and industrial applications where accidental release can affect aquatic organisms and soil health. As a lab manager, I also flag the need for improved longitudinal studies, tracking trace exposure in repetitive workplace settings. Most users mitigate these issues with simple PPE and solid engineering controls, but vigilance remains crucial as new use cases emerge.

The push toward high-performance, environmentally conscious chemicals gives 2-heptadecyl-1H-imidazole a path for future relevance. Advances in surface chemistry demand inhibitors and surfactants that offer both strong binding and minimal environmental persistence, a tough challenge. Researchers work to modify the imidazole ring or swap the alkyl tail for biodegradable options, chasing the right mix of stability and break-down potential. Industries that once relied on phosphate or chromate-based protectants turn more and more to organic molecules for compliance and sustainability targets. Applications in green nanotechnology and smart coatings may open new routes—improving the shelf life of catalysts, giving textiles or plastics inherent resistance to microbes, or building ultra-thin protective layers on vital infrastructure. As governments and end-users ask tougher questions about chemical persistence, bioaccumulation, and long-term toxicity, the pressure builds for thorough, transparent studies. I believe that by focusing on innovation and responsible stewardship, producers and researchers can guide this compound through the regulatory maze, ensuring its best features get used in safer, cleaner ways for decades to come.

2-Heptadecyl-1H-imidazole usually finds its name buried deep in the ingredients list of technical products, far from the spotlight. In everyday industry, this compound plays a crucial supporting role, making things run smoother without grabbing too much attention. I’ve seen firsthand how the details hidden on a label can drive the performance of a material, especially on the factory floor or in the research lab.

One of the most valuable tricks up this molecule’s sleeve is its strength as a corrosion inhibitor. From pipelines buried under the ground to industrial boilers working around the clock, steel and other metals run up against water, salt, and acids every single day. Corrosion doesn’t simply raise maintenance costs; it directly affects safety, equipment longevity, and operational downtime. Adding 2-heptadecyl-1H-imidazole creates a protective layer on metal surfaces, slowing or stopping rust before it begins. In oil and gas or manufacturing plants, this simple preventive measure can stop a minor repair from snowballing into a disaster. According to industry data, strong corrosion inhibitors can boost the average service life of machinery by several years, which saves a considerable amount of money and resources.

People who work with engines and machinery recognize the struggle to maintain smooth, efficient movement, often in the most punishing conditions. Lubricants laced with 2-heptadecyl-1H-imidazole resist breaking down under pressure and heat. Car owners may never spot this molecule in their motor oil, but it contributes to fewer breakdowns and a longer engine life. Experience in automotive workshops often lines up with the research: good anti-wear additives extend intervals between maintenance and halt the cycle of endless part replacements.

Certain plastics and paints just won’t stick well unless a surface treatment steps in. 2-Heptadecyl-1H-imidazole offers a solution for manufacturers who want coatings that bite down and don’t peel off. In the construction industry or assembly lines, poor adhesion leads to wasted product and expensive callbacks. Using additives that improve wetting and anchoring brings better coverage in fewer coats, slashing costs and reducing rework.

Modern electronics demand materials that stay stable through heat, moisture, and repeated handling. This compound has gained a foothold in specialized resins and conductive polymers, adding durability without harming performance. I’ve seen electronics fail from poor material choices—plastic parts shatter, circuit boards corrode, solder joints let go. Ingredients like 2-heptadecyl-1H-imidazole support reliability as devices get more compact and powerful, supporting a longer product lifespan and less electronic waste.

Chemical safety has become a bigger focus across all industries. Some corrosion inhibitors contain heavy metals or toxic elements, but this compound offers a cleaner alternative for both workers and the environment. Companies now face stricter environmental standards, and using safer chemical additives can prevent costly fines and reputation loss. For folks who value sustainability, the shift to less toxic substances provides peace of mind when choosing which products to support.

2-Heptadecyl-1H-imidazole shows plenty of untapped potential across manufacturing, automotive, and advanced electronics. By investing in greener production and reaching for higher purity grades, suppliers could bring improved versions to market. On the consumer side, backing trusted companies and paying attention to certifications helps drive change across supply chains. A simple ingredient, used wisely, can pave the way toward safer products, less waste, and fewer headaches for everyone who depends on well-made tools and machines.

Anyone who’s spent time working in labs or on the production floor knows chemical purity isn’t just a checkbox on a datasheet. Purity tells us if a compound like 2-Heptadecyl-1H-Imidazole will perform the role it’s hired to do—or leave us cleaning up unexpected side effects. I've handled plenty of batches where a couple of percent difference in purity spelled the difference between solid results and frustrating dead-ends.

For 2-Heptadecyl-1H-Imidazole, purity standards usually hover at 97% or higher in commercial offerings, especially if the compound is headed into specialty coatings, lubricants, or research projects. Impurity levels push far beyond paperwork: they sometimes interfere with surface activity or blacken otherwise transparent results in analytical methods. During one synthesis project, contaminants twisted up the melting point and brought inconsistent readings. Chasing those ghosts eats hours, sometimes days, so accuracy on purity isn’t just a formality.

Reliable suppliers use a mix of methods when verifying purity. NMR (Nuclear Magnetic Resonance) offers a strong look at the structure and can pick up on both tiny and chunky impurities. GC (Gas Chromatography) or HPLC (High Performance Liquid Chromatography) help with quantifying trace contaminants, especially those the naked eye misses. Purity numbers on a certificate of analysis rest on actual data collected by these tools.

Still, not every lot coming off a production line tells the same story—batch-to-batch differences creep in. Asking for recent certificates goes beyond best practice; it’s plain common sense. Sometimes, I’ve checked samples myself because paperwork alone can’t guarantee confidence in a high-stakes experiment or production run.

Most of us judge purity by what’s riding along with the main content. Fatty acids and other imidazole cousins can tag along in trace amounts. These "hitchhikers" often look minor on a report but can throw off properties like chemical reactivity or surfactant action. One synthesis went sideways in our lab because an overlooked contaminant led to cloudiness when clarity mattered. That single misstep forced us to re-run the lot and delayed downstream work for days.

Lower purity sometimes means tangled results: stubborn odors, unexpected tints, variance in thermal behavior. In industrial coatings, these show up as uneven finish or a sudden slip in durability tests. For anyone working under tight timelines, troubleshooting those variables stacks up costs and undermines confidence in the supply chain.

It helps when suppliers push beyond minimal standards and clearly annotate every impurity down to trace levels. Laboratories can encourage this by refusing low-detail documentation or by sending a sample out for third-party analysis. Sometimes it's worth paying more for a rock-solid batch than saving a few dollars up front and gambling with downstream consistency.

In my work, investing in direct conversation with suppliers shortens the feedback loop. Asking about process changes, new purification steps, and batch-specific quirks creates a better partnership than just scanning PDF certificates. More transparency keeps surprises at bay and helps teams focus on results, not crisis management.

For buyers and end-users, choosing 2-Heptadecyl-1H-Imidazole at 99% or higher purity often cuts trouble at the root. It keeps synthesis predictable, delivers true-to-label performance, and lets R&D hit its stride without unnecessary detours. In a business that trades on trust and outcomes, that level of confidence pays off every time.

2-Heptadecyl-1H-Imidazole isn’t a chemical you encounter in everyday life, unless you work in a lab or chemical manufacturing plant. I’ve spent years in research environments, and chemicals with long carbon chains and an imidazole ring often draw two types of attention: curiosity from newcomers, and respect from those who’ve seen mishandling go sideways. When storing compounds like this, ignoring the basics never ends well. In my own lab days, skipping the fundamentals always led to mistakes down the line, from ruined samples to health scares.

This compound stands up to regular room temperature, but heat shortens its shelf life and invites instability. I once watched a colleague leave a sensitive sample near a heating vent “just for a minute.” After a few weeks, the sample broke down, showing discoloration and strange odors. For long-term storage, a cool, dry cabinet away from any heat source works best. Consistent room temperature around 20–25°C keeps things calm. Avoiding sunlight does more than preserve potency—it also helps keep the compound from degrading or forming harmful byproducts.

Moisture can sneak into containers, especially if you’re in a humid area. During a particularly muggy summer, I saw a container sweat up overnight and crystals started clumping from moisture. Sealed, airtight containers—preferably glass with a good screw cap or septum—stop water from getting inside. Some older labs still use plastic, but glass stays inert, so there’s no risk of the container breaking down or letting the chemical absorb leached plasticizers. Silica gel packets help pull excess humidity out of the air inside the storage box.

2-Heptadecyl-1H-Imidazole won’t explode if stored near other organics, but letting fumes mix or solutions spill creates confusion and real hazards. I saw a situation where an unlabeled bottle caused a headache for weeks—nobody knew what was inside, and clean-up took three calls to the safety team. Keep each chemical separate and label every bottle with the compound name and date received. Labels fall off if surfaces are oily or wet, so wipe bottles clean before writing.

Long-chain imidazoles aren’t the kind of chemicals you toss in a desk drawer or leave open on a counter. Skin contact or inhaling powder isn’t safe. Always store in a well-ventilated, designated chemical cupboard, away from food, coffee cups, or electronics. My experience shows that accidents happen most often when people forget this, or think, “It’ll only be here for a day or two.”

If 2-Heptadecyl-1H-Imidazole leaks, ventilate the area, carefully collect the spill with disposable towels, and use gloves and goggles. Place cleanup waste in a labeled hazardous collection bin. I remember the relief of having proper spill kits available just a reach away, instead of improvising with whatever was on hand. Waiting to fix a small storage mistake just risks bigger problems—damage to equipment, or long-term health effects from repeated exposure.

In practice, storing 2-Heptadecyl-1H-Imidazole boils down to this: dry, cool, dark, and sealed. This takes a bit of setup at first, but once the habits are in place, it makes daily handling easier and safer. Record-keeping helps trace problems back to their source, so keep logs updated. Respecting both the chemical and the people around it forms the real foundation of chemical safety, and in my experience, good storage pays back in fewer headaches and safer work for everyone.

Working with chemicals like 2-Heptadecyl-1H-Imidazole turns up plenty of safety questions. Sometimes folks forget, but exposure to lesser-known industrial chemicals packs unpredictable risks, even if they don’t grab headlines. Just because something’s rarely talked about doesn’t mean it won’t cause problems. Workers handling imidazole derivatives can deal with skin irritation, breathing issues, or even more serious internal effects. Knowing these risks pushes everyone—lab staff, manufacturers, even warehouse teams—to look out for one another.

A lot of chemical incidents begin with the small stuff—skipping gloves, forgetting goggles, or not checking sleeves. Ever tried cleaning up an unexpected spill with nothing more than a paper towel? It turns out, even low-key chemicals act up when least expected. For a substance like this one, gloves made from nitrile or neoprene stop the liquid from seeping through. Splash-resistant goggles put a quick end to accidental contact. Lab coats and aprons cover what gloves and goggles don’t. Respiratory protection, like N95 masks or even half-masks with the right cartridges, makes sense if there’s even a whiff of vapors or dust.

Many headaches disappear with decent storage. Sure, it seems simple, but experience says otherwise. Many chemicals lose stability or react with air, humidity, or nearby materials. This one really shouldn’t be near strong acids, oxidizers, or moisture. Containers sealed tight and labeled well cut the risk of confusion. Storing in a cool, dry corner—never near heat, direct sun, or busy walkways—helps avoid accidents. If you’ve ever spent hours tracking down the cause of a strange smell or sticky mess, you know the value of labeling every jar and bottle.

Spills don’t ask for permission. Quick action, not panic, turns a near-miss into a non-event. Absorb spills with clay or commercial pads, and never grab sawdust or ordinary rags—some absorbents might make things worse. Double-bag the waste and mark it clearly. Ventilate the area fast and keep people without protective gear away from the scene until cleanup wraps up.

People make mistakes if they don’t know what they’re handling or just see no reason to care. Early in my career, I watched a coworker stir a beaker bare-handed. He spent his lunch break in a med bay with a nasty rash. Regular training, not just dry manuals, creates a crew that spots hazards before they blow up. Discussions, hands-on demos, and Q&A sessions make rules stick. Short quizzes and informal walkthroughs with new hires close knowledge gaps.

Ignoring those headaches or bouts of nausea after working with new chemicals rarely pays off. Everyone leaves a little tougher after talking about symptoms early. Documenting near-misses helps identify workarounds and sparks genuine changes—better ventilation, newer gloves, revised protocols.

Anyone handling chemicals, new or old, stays safer when they lean on habits formed from others’ mishaps. The right protective gear, smart storage, and honesty about mistakes save limbs, health, and sometimes lives. The best cultures in science and industry welcome tough conversations, reward careful work, and thrive on practical training. Progress doesn’t have to trade safety for convenience or cost.

2-Heptadecyl-1H-imidazole rarely makes headlines, but chemists and manufacturers familiar with specialty surfactants or corrosion inhibitors know its potential. Anyone searching for this compound in 25-kilo drums or pallet quantities finds a surprisingly tough road. Online catalogs and big chemical suppliers do not keep 2-heptadecyl-1H-imidazole ready for shipment. Orders typically require custom synthesis, which is both time-consuming and expensive. It’s not like shopping for sodium chloride or acetone. Smaller research quantities can sometimes be sourced from niche catalog houses, but these lots rarely exceed a few grams.

I spent several years working in a specialty chemicals lab and encountered the same situation with dozens of rare imidazoles. Large-scale suppliers focus on chemicals with broad, stable demand. Without steady orders from oilfield service companies, plastics producers, or coating formulators, stockpiling specialty molecules just doesn’t make sense for them. Producing 2-heptadecyl-1H-imidazole also involves tricky synthesis: attaching a long alkyl chain to an imidazole ring isn’t a standard process. Yields often drop, impurities rise, and finding raw materials can quickly drive up costs. Many plants won’t devote reactors or storage to an oddball like this unless someone is willing to pay up front.

Some innovations never leave the bench because key building blocks are unavailable in bulk. 2-Heptadecyl-1H-imidazole might prove valuable for new corrosion-resistant coatings or green surfactants, but if nobody can buy it by the barrel, the work stops cold. I remember a project where our team proved a new quaternary imidazole stopped rust in marine steel better than leading products—only to find we couldn’t source the main ingredient affordably for our pilot batch. Months of development shelved, all because a key molecule wasn’t commercially supported at scale.

Direct requests to reputable synthesis houses sometimes open doors. Custom manufacturers, especially in Europe, the US, and South Asia, will scale up to hundreds of kilos if minimum orders and longer lead times are acceptable. These partners often ask about purity, packing, and end use before quoting. Strong demand or a consortium of interested customers brings prices down. It’s worth investing months to build actual demand forecasts supported by potential buyers, rather than hoping a distributor will suddenly expand their catalog. Industry alliances—especially in oilfield chemistry and advanced materials—have succeeded in pooling needs for rare intermediates. A steady purchasing agreement, even for a few hundred kilos per year, changes the conversation with producers.

Transparency on synthesis route, regulatory status, and regional compliance also matters. Many Western countries ask for REACH or TSCA registrations before clearing industrial scale imports, which adds hurdles for both buyer and maker. Navigating these hurdles often requires hands-on collaboration instead of web forms or email blasts. Researchers, procurement teams, and business development often get farther by picking up the phone and establishing real relationships with specialty chemical producers and brokers.

Bulk access to 2-heptadecyl-1H-imidazole stands as a test of how niche chemistry advances—or stalls. Without proven demand, major suppliers steer clear, leaving innovators to source or synthesize their own. Expanding availability depends on creating strong commercial pull, sharing resources, and working with trusted partners willing to tackle rare synthesis challenges head-on.

| Names | |

| Preferred IUPAC name | 1-heptadecyl-1H-imidazole |

| Other names |

2-Heptadecylimidazole 1H-Imidazole, 2-heptadecyl- 2-n-Heptadecylimidazole |

| Pronunciation | /tuː hɛp.təˈdiː.sɪl ˈwʌn eɪtʃ ɪˈmɪd.ə.zɔːl/ |

| Identifiers | |

| CAS Number | 6965-10-6 |

| 3D model (JSmol) | `C1CCCCCCCCCCCCCCCN2=CN=CN2` |

| Beilstein Reference | 1865407 |

| ChEBI | CHEBI:166127 |

| ChEMBL | CHEMBL4270629 |

| ChemSpider | 24276256 |

| DrugBank | DB08495 |

| ECHA InfoCard | 17e0ec3f-6b56-480f-851f-0e23a5369c9d |

| EC Number | 620-537-2 |

| Gmelin Reference | 136273 |

| KEGG | C19113 |

| MeSH | D017890 |

| PubChem CID | 10467754 |

| RTECS number | UP2275000 |

| UNII | 46C495C8WK |

| UN number | UN3272 |

| Properties | |

| Chemical formula | C20H40N2 |

| Molar mass | 322.34 g/mol |

| Appearance | White to off-white solid |

| Odor | Odorless |

| Density | 0.88 g/cm3 |

| Solubility in water | Insoluble |

| log P | 5.8 |

| Vapor pressure | 6.04E-6 mmHg at 25°C |

| Acidity (pKa) | 13.9 |

| Basicity (pKb) | pKb = 3.56 |

| Magnetic susceptibility (χ) | -88.14 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.4920 |

| Viscosity | 46.3 mPa·s |

| Dipole moment | 3.67 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 640.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -10770.2 kJ/mol |

| Pharmacology | |

| ATC code | D01AE24 |

| Hazards | |

| Main hazards | Causes skin irritation. Causes serious eye irritation. May cause respiratory irritation. |

| GHS labelling | GHS05, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. Toxic to aquatic life with long lasting effects. |

| Precautionary statements | P261, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-1-0-ALK |

| Flash point | > 204°C |

| LD50 (median dose) | LD50: >2 g/kg (rat, oral) |

| NIOSH | DJ2275000 |

| PEL (Permissible) | PEL (Permissible) of 2-Heptadecyl-1H-Imidazole: Not established |

| REL (Recommended) | 0.5 mg/m³ |

| Related compounds | |

| Related compounds |

1-Heptadecylimidazole 2-Octadecyl-1H-imidazole 2-Hexadecyl-1H-imidazole 1-Methylimidazole 1-Butylimidazole |