Long before laboratories sparkled with rows of neatly labeled glass bottles, people stumbled upon ethanolamines almost by accident. In the late 1850s, German chemist Wurtz noticed something interesting as he worked with ethylene oxide and ammonia, catching sight of a molecule with both amine and alcohol parts. Known today as 2-aminoethanol, or ethanolamine, this compound soon gained traction in both industrial chemistry and academic curiosities. As manufacturing scaled up at the turn of the twentieth century, ethanolamine emerged in everything from silk processing to the rise of detergents and textiles. My early chemistry classes always marked this compound as a workhorse, a fine example of how a simple molecule can touch so many corners of daily life and industry. Widespread commercial production started taking off around the 1930s, especially as demand grew for surfactants and corrosion inhibitors.

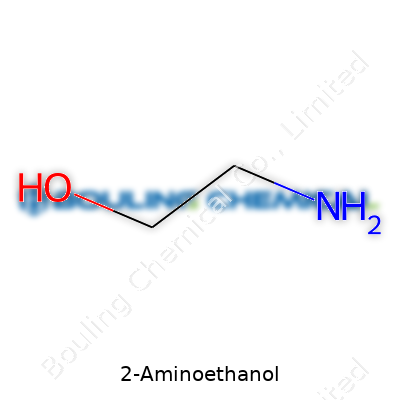

2-Aminoethanol carries a fairly straightforward structure. Its formula, C2H7NO, hints at its dual nature: an amino group and a hydroxyl group linked by two carbon atoms. The mixture of both “water-friendly” and “oil-friendly” parts makes it valuable for applications where balance between solubility and reactivity matter. Most people in facilities management know it as a colorless liquid, though it isn’t hard to recognize its characteristic ammonia-like smell. Many names float around for this molecule—monoethanolamine, MEA, or just “ethanolamine” in the industry.

At room temperature, ethanolamine exists as a viscous liquid, a bit thicker than water. With a boiling point near 170°C and a melting point hovering just over 10°C, it stays as a liquid in most process conditions. It mixes easily with water and alcohols, thanks to hydrogen bonds formed between the molecule’s “hydrophilic” ends. The amine group, ready to grab protons, makes it basic, which shows up in a pH above neutral. This is not the sort of chemical you want to work with without gloves; it’s slightly greasy and sticky to the touch, often leaving behind a faintly sharp odor on gloves and lab coats. Flammability exists but doesn’t pose a major risk unless vapors build up in enclosed spaces—good ventilation quickly drops any chance of an incident.

Product labeling stands as the first line of information for anyone receiving a fresh drum in a warehouse or laboratory. Typical labeling for 2-aminoethanol involves hazard statements on skin and eye irritation, as well as operational guidelines for ventilation and chemical handling. Purity grades can range from around 95% technical grade to high-purity options found in pharmaceutical manufacturing, with water and trace amines often being considered acceptable impurities in most industrial contexts. Manufacturers specify density (roughly 1.018 g/cm3 at 20°C), boiling and melting points, and solubility profiles right on the product documentation, with UN codes and hazard pictograms underlining the need for safe transport and storage. Guidelines follow globally recognized safety protocols, including GHS-compliant labeling.

Ethanolamine production draws on ethylene oxide, a common industrial intermediate. Reacting ethylene oxide with aqueous ammonia triggers a cascade of products, but controlling the reaction conditions—ammonia concentration, temperature, pressure—tips the scales toward producing more MEA versus its cousins (diethanolamine and triethanolamine). Continuous reactors, cooled under pressure, help maintain a steady yield. If purity ranks as a top priority, distillation and further purification steps strip out undesired byproducts. In my experience working in an organic synthesis lab, the care used during temperature ramping, ammonia feed rates, and cooling makes the difference between a high-quality product and a batch heavy with secondary amines.

2-Aminoethanol’s structure means chemists treat it as a flexible building block. Its amine group takes on acids, forming salts like ethanolammonium chloride. Through ethoxylation, it reacts further with ethylene oxide, tacking on polyether chains for use in surfactants. Alcohol group reactivity gives pathways to esters and ethers, opening another toolbox for material sciences, coatings, and specialty polymers. N-alkylation transforms the compound’s physical behavior, turning what started as a humble liquid into something that foams or disperses in water with a flick of a reaction vessel. The efforts of generations of bench chemists have shown just how versatile this simple molecule turns out to be. In the right hands, 2-aminoethanol seeds everything from herbicides to textile finishes.

Ethanolamine goes by a roster of names across different supply chains and regulatory paperwork: Monoethanolamine, 2-Hydroxyethylamine, MEA, Glycinol, and beta-Aminoethanol all point back to the same substance. It helps to know these synonyms. In procurement, confusion between MEA and DEA (diethanolamine) or TEA (triethanolamine) can cause headaches that ripple down through quality assurance and compliance checks. Global trade relies on CAS numbers—141-43-5 for 2-aminoethanol—and hazard statements specific to each jurisdiction, showing the molecule’s many business faces.

Safe work with ethanolamine asks for respect and preparation. Direct skin or eye contact leads to irritation, redness, even burns if exposure runs long enough or concentration is strong. Vapors can trouble the lungs, especially in poorly ventilated spaces. Years ago, during an undergraduate training, a simple spill showed just how fast ethanolamine can sting unprotected skin. Gloves, goggles, splash-proof aprons, and dedicated eyewash stations form the backbone of lab safety culture. Spill kits should always be close to bulk storage, and facilities keep chemical-resistant flooring and closed-system transfer gear at hand. GHS, OSHA, and EU REACH guidelines map out minimum standards, but in practice, seasoned operators know that a regular walkthrough, close supervision during transfers, and immediate clean-up go much further than any checklist.

Industry turns to 2-aminoethanol in dozens of sectors. Its main job: scrubbing acidic gases like CO2 and H2S from natural gas and refinery streams in amine gas treating units, boosting both efficiency and environmental compliance. In surfactant production, MEA adds solubility and foaming to household cleaners, shampoos, and personal care products. Textile and leather plants lean on it for wetting, dyeing, and softening. In pharmaceuticals, it serves as a pH adjuster and an intermediate for more complex molecules. Many herbicides and pesticides build their backbone with this amine. As a corrosion inhibitor in boilers and cooling systems, ethanolamine helps halt rust and extend the working life of steel pipes. This spread of uses means that everything from home cleaning to high-end manufacturing links back to this basic chemical, reflecting a global economy built on quiet, unsung molecules.

Research hops from basic synthesis to exploring new reaction routes and more sustainable methods for MEA production. Biocatalysis stands out as an active area, with scientists trying to create greener pathways using enzymes rather than traditional chemical reactors. Formulation scientists balance MEA performance in surfactants, aiming for better mildness in skin contact or higher stability under harsh process conditions. Academics investigate how minor molecular tweaks to ethanolamine analogues can open doors in pharmaceuticals and advanced materials, including ionic liquids and energy storage compounds. The level of technical complexity keeps rising, but the heart of this work ties back to decades spent learning the nuances of 2-aminoethanol chemistry in basic labs.

Toxicological studies on ethanolamine flag several concerns. Acute exposure does not usually pose a systemic toxicity threat; it mainly affects the areas it touches, causing irritation and occasional burns. Animal studies reveal that, at very high doses, ingestion or direct contact leads to more serious harm—lung effects, liver impacts, and kidney issues after long-term, repeated exposures. Regulatory agencies like NIOSH and the European Chemicals Agency set occupational limits and require clear hazard labels. The experience of environmental chemists points to low bioaccumulation, but water toxicity for aquatic species prompts careful wastewater management. Responsible handling and disposal have grown into standard practice, informed by both ongoing research and hard-won lessons from earlier eras before strict regulations.

2-Aminoethanol has no sign of slipping into obscurity. As industries grapple with carbon capture, MEA scrubbing keeps finding new relevance. Sustainable chemistry appears to be the next big chapter, with companies pushing for biotechnological production or using renewable feedstocks instead of fossil-fuel-derived ethylene oxide. This compound enjoys a central role where chemical flexibility meets industrial practicality—its ability to modify, capture, and stabilize means R&D teams across sectors return to it over and over. Anyone eyeing a career in chemical engineering or formulation science should expect this molecule to show up many times in both troubleshooting and creative problem-solving. As both challenges and regulations around safety and sustainability rise, ethanolamine’s story carries a lesson: the future often emerges from the skills honed with yesterday’s basic molecules.

2-Aminoethanol, also called ethanolamine, turns up in more places than most realize. My first introduction came from an old chemistry set, its strange scent distinct and memorable. Years later, I found out it drifts through far more grown-up products. This small molecule is a backbone in both the chemical industry and the stuff we use at home.

Every time I tackle a greasy oven or a sticky countertop, chances are some cleaning products owe a tip of the cap to 2-aminoethanol. Formulators use it to help soaps and detergents work harder, breaking down fats so a rag or sponge wipes grime away. Its ability to neutralize acids means household cleaners stay stable on the shelf and don't corrode surfaces too quickly.

On a larger scale, industrial companies use this same trait to scrub acidic gases. I once toured a power plant that captured its carbon dioxide and sulfur dioxide fumes using solutions based on ethanolamine. This helps cut down air pollution and plays a role in cleaner manufacturing—something I consider essential when thinking about our shared environment.

Scanning the back of a shampoo bottle, 2-aminoethanol often pops up among a long list of ingredients. Manufacturers add it to balance pH and ensure formulas don’t sting the skin or eyes. In pharmaceuticals, it crops up during production, acting as a building block for active ingredients found in over-the-counter and prescription meds. It’s not just what’s left out of a pill that matters—the process itself can be safer and more efficient with the right know-how.

The molecule shows up in labs as part of buffers. Back in college, preparing buffer solutions with ethanolamine kept DNA and protein samples in just the right condition. Tiny chemical tweaks can spell success or failure for hours of painstaking research. Outside the lab, farmers turn to products made from this compound for certain herbicides and pesticides. While this can boost crop yields, it also asks us to weigh the health of soil and water, remembering balance always matters in the food supply.

Demand for 2-aminoethanol continues growing. Markets predict steady expansion as new technologies rely even more on specialty chemicals. Global use brings up discussions about safety and sustainability. Workers handling concentrated ethanolamine risk burns or lung irritation, which makes proper training and protective equipment vital. Companies must follow strict guidelines so the molecule’s benefits don’t bring hidden costs to health or the planet.

As someone who finds chemistry woven into daily routines, I keep an eye on how regulators and manufacturers adapt. Some look to biosynthetic routes, aiming for greener production. Others invest in research to make every use safer, whether in your corner store or at the edge of a chemical plant’s smokestack. The journey from laboratory curiosity to kitchen staple reminds me that even small molecules, used wisely, can make a big difference.

2-Aminoethanol, often called ethanolamine, often shows up in the corners of my garage when I mess around with cleaning chemicals or work on stubborn paint stains. You’ll find it taking up shelf space in everything from industrial solvents to laundry detergents. Some folks rely on it for making soaps, softeners, and even gas sweetening. With so much of it around, getting a handle on its hazards seems like common sense, especially for those who never think about a chemical’s bite until it stings.

Cracking open a bottle of 2-aminoethanol without gloves leaves your skin tingling in seconds. It’s a skin and eye irritant that hits hard. According to the Centers for Disease Control, even low-level skin contact can spark irritation, redness, and swelling. If you splash it in your eyes, it’s not just about discomfort—it can cause real, sometimes lasting, harm. Breathing in the fumes brings on sore throats, coughing, and headaches. These aren’t just warnings made up by nervous regulators, but real-life experiences in labs, manufacturing plants, and even family homes where DIY projects get a bit too ambitious.

Chronic exposure tells a tougher story. Workers on factory floors report asthma-like symptoms, wheezing, and chest tightness after breathing in fumes year after year. Research out of the National Institute for Occupational Safety and Health points toward a possible risk of damage to the liver and kidneys if exposure sticks around over a long period. Some studies hint at reproductive risks, though the data is still a work in progress and shouldn’t set off panic. It should, at least, make anyone respect what they’re dealing with.

Animal testing paints the same rough picture. Rats and rabbits exposed to high concentrations developed respiratory irritation and, in some cases, personal injury beyond irritation. The bottom line from decades of studies—exposure in big doses does more than just annoy the senses; it can bring lasting harm.

After working at a wastewater treatment facility for a summer, I saw firsthand how certain chemicals get into streams. Ethanolamine isn’t as persistent as some industrial toxins, but it doesn't just vanish. Released into water, it can break down into smaller parts that may pose new risks to aquatic life. Fish and tiny aquatic insects sometimes suffer from the leaking leftovers of industrial runoff, and while ethanolamine isn’t as notorious as heavy metals or pesticides, its effect on water systems deserves more attention than it usually gets.

Reading up on Material Safety Data Sheets before using products with 2-aminoethanol became second nature for me after a friend got a bad chemical burn. Wearing the right gloves, working with goggles, and making sure there’s good airflow rank above all as the most reliable ways to dodge trouble. Keeping these chemicals out of kids’ reach and being honest about label warnings matters more than speed or convenience. For anyone managing industrial or lab settings, investing in proper training and spill control can stop a bad day before it starts.

A handful of companies chase after safer alternatives, focusing on less hazardous solvents and cleaners. Some progress relies on consumers demanding less toxic products, not just cheaper or more powerful ones. Regulatory agencies—OSHA, EPA, and their friends worldwide—keep tightening exposure limits, nudged along by current research and a push for transparency. As someone who’s spent time around chemicals both at work and at home, I’ve learned it isn’t always about avoiding risk entirely, but keeping awareness high, asking the right questions, and never skipping steps meant to protect health in the long run.

2-Aminoethanol, often called ethanolamine, carries the chemical formula C2H7NO. Picture a simple structure: a molecule with two carbon atoms, seven hydrogens, one nitrogen, and one oxygen. It might sound like chemistry class jargon, but this small combination powers a lot of our modern world. I’ve worked with ethanolamine in lab settings, and its character strikes you with its versatility and reliability.

A molecule shaped like that matters. Two carbons give the molecule backbone and flexibility, while the nitrogen stands out with its amino group. That’s what helps it interact with acids, metals, and biological molecules. The alcohol part, coming from the oxygen, adds solubility and reactivity. This handshake between nitrogen and oxygen in the same molecule creates countless opportunities for real-world use, like pharmaceuticals, detergents, and even gas sweetening. The combination reflects a lesson anyone in science picks up early: tiny chemical tweaks chain-react into giant changes downstream.

I once visited a water treatment plant and saw how 2-aminoethanol works quietly in the background. With its formula, it scoops up unwanted carbon dioxide and sulfur compounds out of gas streams. This helps keep industrial emissions cleaner and safer. Industries have relied on it for making soaps, dyes, and synthetic fibers. The comfort we feel washing clothes or using personal care products often traces back to chemistry like this.

Its application stretches into the medical field, too. In pharmacies, you’ll find ethanolamine as an ingredient that helps buffer pH in medicines, keeping pills and creams effective. This simple molecule stands behind smoother runs in manufacturing and health care, easing processes and improving outcomes for everyday products. Anyone who’s handled soaps or detergents benefits from the cleansing and emulsifying strengths built into ethanolamine’s chemical skeleton.

No chemical with this much reach avoids tough questions. Prolonged exposure, especially in factories, can lead to skin irritation or other health effects. Regulators have set occupational safety limits and require personal protection when people handle concentrated forms. From my own experience in safety training, the message was clear: follow protocols, use gloves, and keep ventilation running.

As ethanolamine finds its way into water systems from industrial runoff, researchers keep a close eye on its environmental footprint. Biodegradation offers some relief, since bacteria can break it down. Still, staying vigilant remains crucial. The path forward involves more robust monitoring, better waste treatment, and innovation around greener alternatives or improved synthesis routes. Groups working in environmental health keep pushing for regular reviews as new data comes in, protecting both workers and surrounding communities.

Smart handling and clear labeling go a long way. Training workers remains essential for chemical safety, and switching to closed-loop systems minimizes exposure. Investing in updated wastewater treatment technology tackles pollution before it escapes. Research teams continue to search for ways to boost breakdown rates in soil and water, aiming for even less environmental persistence. At the consumer level, supporting brands with strong environmental records encourages improvement and accountability throughout the chemical supply chain.

Sometimes called ethanolamine, 2-Aminoethanol finds its way into lots of workplaces. It slips into cleaning products, helps refine gas, and even pops up in making medicines. It isn’t as scary as some chemicals out there, but it does carry real risks. I’ll never forget watching a friend help clean up after an accidental spill. Her hands didn’t burn, but she felt a tingling that lingered all day. This stuff can irritate skin, eyes, and airways, and if it leaks out, it can create both health and fire hazards. Storing it the right way isn’t extra credit—it’s basic responsibility.

It’s tempting to treat chemical safety as a checklist for passing inspection, yet there’s more at stake. An overheated storeroom, poor ventilation, a missing label—these can spiral into real trouble. Just the vapor from 2-Aminoethanol brings about irritation or headaches, and direct contact proves worse. Tucking it away carelessly puts not only workers at risk, but also the neighborhood and even the business. In 2013, a warehouse in the Midwest learned this the hard way; a leaky barrel triggered days of cleanup and led to tighter local rules.

Over the years, best advice on 2-Aminoethanol storage hasn’t changed much. Keep it in sturdy, sealed containers, made of steel or certain plastics (like polyethylene). The room can’t be too warm—the ideal range sits below 30°C. Sunlight, heat, and flames have no business anywhere near these shelves. Even a small spill caught early can reduce harm, which highlights the need for absorbent materials and emergency showers right nearby.

Labels matter more than folks expect. Clear words—no fading or scribbles—make sure whoever grabs that drum in a hurry knows what’s inside. Too many times, mishaps happen because one can gets mistaken for another. I’ve seen small companies use hand-written stickers, only to regret it months later when water made the ink bleed. Investing in chemical-resistant labels comes across as a minor expense that pays off big when someone needs that information fast.

I once worked in an old facility where the air grew thick if chemicals sat open for long. Good airflow slices the risk of vapors gathering and keeps everyone healthier. If a drum tips or leaks, quick action prevents a bad day from turning into a disaster. Workers benefit from regular drills and having all necessary materials—like sand, pads, or proper containers—close at hand. Too often, small details like blocked exits or missing goggles show up in accident reports, so double-checking before anything gets stored only makes sense.

Without training, even fancy equipment won’t help. People need to know what 2-Aminoethanol does, how to spot trouble, and who to call in an emergency. Regular walk-throughs spot dust on vents or swelling containers before these become bigger headaches. In my experience, involving the whole team in safety discussions builds trust and catches issues early. No single person can do it all alone.

Safe storage can look simple—sealed containers, labels, clean shelves—but those everyday habits protect people’s health and keep the workplace running. Following up with checklists and learning from the past, anyone storing 2-Aminoethanol stands a better chance of avoiding costly mistakes. This isn’t just about following rules—a safe site helps everyone sleep better at night.

2-Aminoethanol shows up in laboratories, factories, and even small workshops thanks to its role in making cleaners, cutting fluids, and pharmaceuticals. It’s a clear, almost syrupy liquid, but the real concern comes from what it does to your eyes, lungs, and skin. My own experience in a small lab taught me quickly that even without a strong smell, this stuff can burn skin and eyes right away. Breathing in the vapors leads to irritation, headaches, or much worse if someone ignores it long enough.

Putting on the right gear always felt like a hassle, until the day a friend spilled a small amount on his hands. Red marks started up within seconds—no exaggeration. For 2-aminoethanol, gloves made of nitrile or neoprene make a real difference because cheap latex ones won’t hold up. Safety goggles or a full face shield block the splash that stings your eyes instantly. A lab coat and long sleeves cover up skin, acting like armor against irritation and burns.

Many old workspaces have windows painted shut or no vents at all. It’s easy to forget air matters, but letting fumes collect raises the risk of someone inhaling a respiratory irritant. Simple exhaust fans or a good fume hood cut down vapor build-up. Crack a window, use those fans, and never try to handle chemicals like this without decent airflow. It might cost a bit to set up, but it sure beats coughing fits or burning throats.

Complacency creeps in after handling the same chemical for months. People set down their coffee next to an open beaker or tap at their phone between tasks. It’s easier to get distracted than you might think. I’ve seen someone touch their sandwich with gloves they just used to measure out 2-aminoethanol—bad day for lunch, and an even worse one for the gut. Keep food, drinks, and snacks out of the work area. A clear head and good routine prevent accidents.

Spills start small then become big news for skin, air, and surfaces. Pouring slowly, over trays, cuts down on messes. If a spill happens anyway, neutralize it with sand or vermiculite—not water because it can splash. Wearing gloves, scoop up the absorbent and place it in a sealed waste bag for disposal. I learned early that waiting gives the vapors more time to spread; act right away and you’ll avoid headaches—literal and legal.

I once left a container near a heater, not thinking about volatility. Fumes built up in the storage room, setting off alarms. 2-Aminoethanol needs a cool, dry spot, away from open flames and oxidizers. Keep it closed tight, label it clearly, and double-check shelves for leaks. These habits keep things calm and safe long-term.

Accidents can catch even careful folks off guard. Eyewash stations, showers, and first aid kits need to stay close. Everyone on the team should know where to find safety gear and how to work it. Practice drills and good signage go a long way in building confidence during emergencies.

| Names | |

| Preferred IUPAC name | 2-aminoethan-1-ol |

| Other names |

Monoethanolamine Ethanolamine MEA |

| Pronunciation | /tuː əˌmiːnoʊˈɛθənɒl/ |

| Identifiers | |

| CAS Number | 141-43-5 |

| Beilstein Reference | 1718733 |

| ChEBI | CHEBI:16011 |

| ChEMBL | CHEMBL715 |

| ChemSpider | 766 |

| DrugBank | DB00160 |

| ECHA InfoCard | 03e578df-a458-4564-8ace-bd4c99b6d241 |

| EC Number | 205-483-3 |

| Gmelin Reference | 8221 |

| KEGG | C00189 |

| MeSH | D004477 |

| PubChem CID | Monoisotopic mass (g/mol): 141.13883 |

| RTECS number | KV0350000 |

| UNII | 9T8SX8Y43E |

| UN number | UN 2491 |

| Properties | |

| Chemical formula | C2H7NO |

| Molar mass | 61.08 g/mol |

| Appearance | Colorless liquid |

| Odor | Ammonia-like |

| Density | 1.012 g/mL at 25 °C |

| Solubility in water | Miscible |

| log P | -1.31 |

| Vapor pressure | 0.08 mmHg (20°C) |

| Acidity (pKa) | 9.5 |

| Basicity (pKb) | 4.75 |

| Magnetic susceptibility (χ) | -5.13 × 10⁻⁶ |

| Refractive index (nD) | 1.454 |

| Viscosity | 23.6 mPa·s (at 20 °C) |

| Dipole moment | 1.97 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 108.5 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -182.10 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1335.2 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | D08AX01 |

| Hazards | |

| Main hazards | Harmful if swallowed, causes severe skin burns and eye damage, harmful if inhaled. |

| GHS labelling | GHS02, GHS05, GHS07 |

| Pictograms | GHS02,GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H314 |

| Precautionary statements | P280, P261, P264, P305+P351+P338, P304+P340, P310, P303+P361+P353, P363, P405, P501 |

| NFPA 704 (fire diamond) | 3-1-0 |

| Flash point | 85 °C |

| Autoignition temperature | 410°C |

| Explosive limits | 3% - 23% |

| Lethal dose or concentration | LD50 oral rat 1720 mg/kg |

| LD50 (median dose) | LD50 (median dose) of 2-Aminoethanol: 1,720 mg/kg (rat, oral) |

| NIOSH | ZC0700000 |

| PEL (Permissible) | '3 ppm' |

| REL (Recommended) | 100 ppm |

| IDLH (Immediate danger) | 1000 ppm |

| Related compounds | |

| Related compounds |

Diethanolamine Triethanolamine Methyldiethanolamine Aminoacetaldehyde Ethylene glycol Choline |