Pyrrole chemistry has always drawn the attention of researchers, but 2-acetylpyrrole’s development didn’t come with fanfare. The story often runs in the background of big discoveries, as scientists dug into heterocyclic compounds in the early 1900s. Labs in Europe pushed hard on pyrrole derivatives, noticing their aroma and interesting chemical features. By the late 1940s, reference books carried entries on 2-acetylpyrrole, flagging it as a building block worth more of a spotlight—mainly because of its flavor strengths and use in synthetic chemistry. Chemistry textbooks from the mid-century marked it for its role in creating more layered flavors and fragrances, and since then, industrial labs began producing it in bulk for flavor houses and pharma researchers.

2-Acetylpyrrole wears a few hats in both labs and factories. Chemists recognize its nutty, popcorn-like scent immediately—no surprise, it sneaks into the recipe for snacks, baked goods, and coffee aromas in all kinds of packaged food. It isn’t limited to the kitchen; it brings structure to fine fragrances and shows up in some pharmaceutical syntheses, especially as a key component in making more complex pyrrole derivatives. Laboratories find it an indispensable intermediate for medicinal chemistry, while material scientists lean on it for functionalized polymers.

This molecule usually appears as a colorless to pale yellow liquid. If you bottle it up, you’ll notice its clear, fairly low-viscosity flow. With a boiling point around 230°C and a melting point just below room temperature, it hangs right in that practical zone for lab handling. Its characteristic odor rarely goes unnoticed. 2-Acetylpyrrole brings a basic pyrrole ring, outfitted with an acetyl group at the 2-position, which influences its reactivity. Its solubility makes it comfortable in ethanol and ether but less willing to mix with water. The molecular formula clocks in at C6H7NO, and it’s got just enough polarity to handle the demands of the food and fragrance worlds, but also participate in a range of chemical transformations.

Producers usually offer 2-acetylpyrrole at a minimum purity above 98%, with trace impurities tightly controlled—something regulatory agencies and quality control labs monitor closely because trace nitrogen-based compounds can skew performance in formulations. Safety data sheets emphasize its handling limits, with basic hazard labeling reflecting both its mild irritant qualities and its combustibility. Packaging reflects industry standards: amber glass for light protection, clear labels showing CAS number 1072-83-9, UN numbers for transit, batch codes, and manufacturer information for full traceability. Factories and distributors can’t cut corners here, since both food safety laws and perfumery standards demand trace-level transparency for every batch.

Lab synthesis sticks to the classics. Acetylation of pyrrole through reaction with acetic anhydride sets the pace, often in the presence of a mild acid or a Lewis acid catalyst to encourage the 2-position on the ring. The work-up brings back familiar steps: extraction, purification, and distillation under reduced pressure to clean up the finished product. Process engineers scale up by controlling heat and solvent ratios, as over-reaction or excess reagent will poison the yield or leave byproducts behind. Debugging this process comes down to careful timing, temperature controls, and regular sampling—a developer’s patience often makes the difference between a smooth run and a costly clean-up.

The acetyl group at the 2-position opens doors for tinkering. Chemists often use 2-acetylpyrrole as a starting point for more elaborate transformations. Aldol condensations, Michael additions, and reduction reactions are routine. The aromatic ring invites electrophilic substitution, and the nitrogen brings reactivity that nudges new groups onto the scaffold. Spin off from this core, and it’s possible to make building blocks for drugs, polymers, dyes, or even specialty imaging agents. The product finds itself at the heart of countless research projects aiming for better pharmaceuticals or more stable dyes.

In catalogs and on packaging, few names get tossed around as much. N-Acetylpyrrole comes up, but it isn’t the same molecule. Chemists stick with 2-acetylpyrrole, while synonyms like 1H-pyrrole-2-yl methyl ketone, 2-pyrolyl methyl ketone, and Pyrrol-2-yl-methylketon fill trade databases. In food and fragrance circles, it picks up subtle labels like “nutty flavor enhancer” or “popcorn flavorant.” On invoices or customs forms, the CAS number 1072-83-9 settles any confusion.

No shortcuts on safety with 2-acetylpyrrole. Industry guidelines set exposure limits—vapor inhalation and direct skin contact can irritate. Chemical hygiene plans mandate gloves, splash goggles, and proper ventilation. Storage demands cool, dry, dark spots, away from strong oxidizers, since this molecule can decompose or catch fire if ignored. In a food additive context, regulatory scrutiny makes trace analysis and batch tracking a non-negotiable rule. Workers handling the product go through spill drills, with absorbent material and neutralizing agents at the ready. Waste follows local hazardous disposal codes. Companies that brush off these norms find audits and recalls waiting at the door.

Food science keeps pushing for authentic flavors, and manufacturers respond by dropping microdoses of 2-acetylpyrrole into breads, crackers, popcorn, and candies. The molecule’s roasted, bready aroma stands firm in processed foods. In the fragrance realm, perfumers chase warmth and subtle smokiness, blending it into high-end colognes and scented candles. Industrial chemists use it as a building block in pharmaceutical synthesis, while advanced material labs investigate its use in electronics or specialty polymers. Research teams working on bioactive compounds test its reactions for new lead molecules, hoping for breakthroughs in cancer treatment or antimicrobial drugs.

Universities and corporate R&D wings experiment with new derivatives to chase either better flavor notes or new medicinal properties. The effort to lower production costs and greening up the synthesis pathway runs through most projects. Alternative acetylating agents, reusable catalysts, and solventless reactions top the wish lists in process development. Some researchers work on analytical methods to trace 2-acetylpyrrole in food products, aiming for even better quality assurance programs and fraud prevention tools. It’s surprising how big a role this molecule plays in flavor and fragrance development, and researchers continuously publish studies about its sensory threshold, detection in nature, and potential as a marker compound for food authenticity.

Toxicological assessment favors transparency. Short-term studies show low acute toxicity, with no significant mutagenicity flagged so far, at least in animal models. Food-grade use comes tightly regulated, as dose and purity govern risk. Repeated exposure or high-dose ingestion hasn’t turned up severe effects in rats or mice, but long-term human studies remain limited. Occupational exposure takes center stage—factory workers check for chronic irritation or allergic responses, and safety officers stay tuned for regulatory updates. The bulk of data supports its safe use under controlled circumstances, with government agencies publishing upper limits for intake and strict labeling for consumer awareness. The chemical’s low volatility reduces inhalation risks in final consumer products, but raw handling sticks to conservative exposure limits.

New uses for 2-acetylpyrrole keep emerging as both food science and drug discovery cross boundaries. Cleaner synthesis routes, higher-yielding catalysts, and greener solvents hold the promise of better sustainability. Synthetic biology teams wonder if engineered microbes could produce it more efficiently than petrochemical processes. Analytical chemists look for sharper detection and quantification methods, especially for food quality testing. As global taste preferences evolve and demand for plant-based or vegan flavors surges, the ability to create convincing roasted notes grows in importance. Meanwhile, pharmaceutical startups tread new ground, scouring pyrrole derivatives for novel biological activity. There’s excitement in leveraging every bit of information about this small but mighty molecule—whether for gourmet snack innovation, eco-friendly manufacturing, or solving puzzles in advanced materials and medicine.

Peek behind the scenes of a kitchen, cigarette factory, or flavor house, and you might find a small, fragrant molecule making a big impact—2-acetylpyrrole. I’m always interested in what gives real chocolate its deep, toasty richness or why some baked foods seem to hug your nose with a warm, almost savory aroma. In moments like those, I often think about 2-acetylpyrrole.

Before diving in, let’s cut through the tech talk. Here’s a chemical that shapes the way things taste and smell. Chocolate, bread, roasted nuts all owe something to the magic touch of this molecule. That nutty, almost popcorn-like note comes after heating certain foods—scientists call this magic the Maillard reaction. If you’ve worked a stove, you’ve chased after those rich golden crusts and wondered what’s changing inside your pan to create such unforgettable sensations. The unsung hero is often 2-acetylpyrrole.

Walk through any bakery at sunrise. There’s a reason bread pulls people off the street. Part of that pull is thanks to compounds like this one. It doesn’t just help with taste—scent memory can bring back a whole childhood in a single whiff.

Plenty of companies want to mimic what takes hours in an oven or years in an aging barrel. They use 2-acetylpyrrole to inject a natural edge into processed foods and beverages. This is how a mass-produced chocolate bar or a cheap cup of coffee gets that hint of roasty depth. Food scientists rely on it to tweak existing recipes, right down to grams and drops. You won’t see it in bold letters, but look for “natural flavors” or “artificial flavors” and there’s a chance you’re enjoying its work.

It’s hard to ignore how this changes the playing field for makers. Budgets stretch farther if a dash of this chemical freshens up instant foods. Small operations can’t always chase down real vanilla or natural cocoa beans, especially if exports falter or crops fail. In those cases, flavor science steps in, filling the gaps that nature can’t always supply.

I’ve tested some weird fragrances over the years, and 2-acetylpyrrole pops up there too—bringing warm, woody undertones to perfumes or colognes. In the world of tobacco, particularly in “designer smoking blends” or cigarette flavorings, this chemical gives smokers that familiar toasted aroma. No one ever talks about it at the counter, but smokers’ noses remember.

There’s even talk about using 2-acetylpyrrole in pharmaceuticals. Here, it’s less about taste and more about helping labs synthesize other compounds faster. Chemists like having versatile building blocks on hand, and this molecule slips easily into those roles.

Safety questions always follow food additives. Official agencies like the FDA in the US or EFSA in Europe have checked data and given it the green light in the amounts used for flavors. Still, it’s fair for eaters to ask: Do we want a world leaning too hard on shortcuts rather than real ingredients?

Flavor chemistry answers supply problems and helps us avoid waste. But as cooks or shoppers, we can still ask for straight answers about what lands on our plates. If you want authenticity, hit up local bakeries or roast your coffee at home. And keep reading those labels—2-acetylpyrrole may work magic, but nothing beats the flavor of time and honest cooking.

Chemistry often feels like a puzzle. For folks who work in labs or just have a thing for molecules, a name like 2-Acetylpyrrole will send you straight to the periodic table and a sketchpad. This molecule has a story—one worth understanding well, even for those who never plan to mix chemicals.

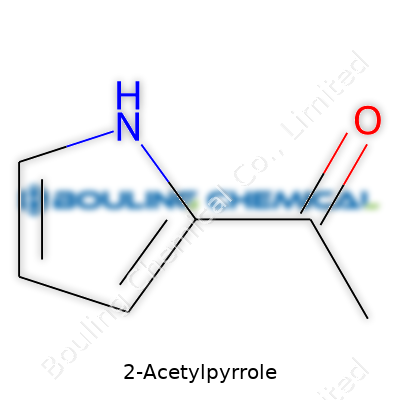

Let’s start with the basics. 2-Acetylpyrrole has a molecular formula of C6H7NO. Six carbon atoms, seven hydrogens, a nitrogen, and an oxygen get together to form this aromatic compound. Not just any arrangement will do. You’ve got a pyrrole ring—think of it as a five-membered ring with four carbons and one nitrogen making up the cycle. On the ring, at position 2, sits an acetyl group—basically, a carbonyl group (C=O) attached to a methyl (CH3).

I still remember the first time I drew out a structure for 2-Acetylpyrrole. It looks like this: the pyrrole ring makes up the main skeleton, and at the spot right next to the nitrogen (position 2), the acetyl branch sticks out. The structure connects directly to its properties—especially its scent. Anyone who enjoys the smell of fresh bread or roasted coffee can thank molecules like this. 2-Acetylpyrrole shows up in the Maillard reaction, which crafts many flavors and aromas in cooked food.

Even without a microscope, you can appreciate the importance of that structure. Chemists know: change the position of just one group, and you’ll get a different beast. Instead of rich, nutty smells, you might wind up with rubbery or even no scent.

Most people would rather not memorize formulas, but the way molecules like 2-Acetylpyrrole are built affects more than textbooks. Take food science, for example. This compound pops up in roasted snacks, whiskey, cocoa, and baked goods. Research shows it delivers not just aromatic punch but can also contribute subtle bitterness. Its formation shines a light on why toasting bread for a just-right time gets that irresistible flavor—go too far, and the scent and taste shift, sometimes becoming a little burnt.

Knowing the structure helps scientists synthesize flavors for foods, perfumes, and even pharmaceuticals. Mistaking the acetyl position or forgetting the details of the ring shifts not just the lab outcome but even safety. For example, changing the substituent’s location might land a molecule in the category of regulated or harmful substances.

Grasping the details of 2-Acetylpyrrole makes a difference in manufacturing, too. Food companies work to replicate flavor profiles that consumers crave. In my experience, companies sometimes cut corners and end up with knockoff aromas that fool no one. By understanding where each atom lands in a molecule, researchers can develop better, safer, and even more sustainable synthetic production methods. This also means potential reductions in food waste, by precisely dialing in flavors lost during processing.

Educators and regulators could drive home the importance of specifics. Teaching not just what molecules look like, but what they actually do, might motivate the next crop of chemists. Giving non-scientists some insight into why bread tastes better toasted, or why a certain perfume lingers longer, brings science out of the lab and onto the dinner table.

2-Acetylpyrrole packs a lot into a small package. Its molecular formula and structure may sound like technical trivia, but they help shape everyday experiences and guide the work of innovation teams everywhere. Chemistry doesn’t live behind high-security lab doors. Sometimes, it’s right under your nose.

2-Acetylpyrrole often crops up in food chemistry circles. Its nutty, popcorn-like scent finds use in flavors and fragrances. You see it pop up in imitation chocolate, roasted goods, and everything from tobacco to baked snacks. Still, just because it smells sweet doesn’t always mean it’s harmless. Many chemicals with pleasing scents hide health risks.

Spilling a small vial of 2-Acetylpyrrole won’t send anyone sprinting for a hazmat suit. There’s no cloud of invisible doom. But it’s not just water in the pan, either. If someone splashes it on bare skin, it can leave irritation. Breathing in concentrated vapors can stress the throat or eyes. That feeling of warning from your body — watery eyes, a sore throat — tells its own story.

Accidentally eating a product in a flavor lab, on the other hand, usually doesn’t bring disaster. In fact, the FDA lists it as “Generally Recognized As Safe” in the minute quantities found in food. Still, a big spill or careless handling in a workshop starts adding up. Just as you keep bleach away from your orange juice, you ought to show 2-Acetylpyrrole its own shelf respect.

Small kitchens and flavor technicians use this stuff in low doses, often diluted and measured with precision. A bottle forgotten open for a few hours leaves a headache and lingering smell at worst. Put this compound in a plant with vats and conveyor belts, and the risks step up. Here, spilled barrels, open drains, and faulty ventilation spell bigger trouble.

Workers filling drums for a factory batch rely on gloves and goggles for a reason. Fume hoods get their money’s worth, too. Sloppy cleanup mixes this chemical with drains and air ducts, taking it from a controlled additive to an environmental headache. Wastewater from large food factories adds up, even if each drop looks tame alone.

2-Acetylpyrrole comes with a stubborn flammability. Its low flash point means a stray flame or spark can turn a spilled beaker into a blaze. Storage doesn’t call for panic, but no one throws it next to a space heater or stacks it by the break room microwave. Safety flaps and regular checks keep things routine and avoid “learning moments” that make the local paper.

Compare it to other lab regulars — some like acetone, some like chloroform — and 2-Acetylpyrrole sits in the middle. Enough heat or carelessness raises stakes. In tight indoor spots, the right mixture of fumes and a spark ends badly. Take it outside, pace things, and keep it sealed, it fits into a safe routine like many other food-grade chemicals.

Solid gear does half the job. Gloves, goggles, clean air — these tools keep eyes, hands, and lungs untroubled. Keeping containers sealed holds in the likable odor along with any trouble. Storing it away from hot spots wins over cutting corners. Forums and lab notes show that quick cleanup and respectful storage prevent most mishaps.

Disposal matters, too. Pour this stuff down the sink and it won’t just vanish. Proper waste collection keeps it from mixing with wastewater. Even food-safe chemicals need their own end-of-life map, because city water plants aren’t built to filter every last lick of everything.

In my own stretch behind a lab bench, people figured out fast that respect — not paranoia — got us through a shift without drama. With 2-Acetylpyrrole, a dose of care punctuates each step. Use gear, clean spills, store away from heat, and treat it as you would a workplace companion with quirks. Industry and lab days both speak to a simple truth: precaution never steals too much time, but a shortcut always comes back for payment.

Walking into any chemistry lab, you can spot the veterans by their no-nonsense approach to storage. They know some compounds ask for respect, and 2-Acetylpyrrole falls right into that camp. This chemical packs a punch in flavor and fragrance work, but no one wants a ruined sample or worse, a nasty reaction caused by laziness on the shelf. I learned early on: proper storage isn’t just a suggestion—it’s protection for your work and yourself.

I’ve seen a few folks stow bottles wherever they can squeeze them in. Big mistake for 2-Acetylpyrrole. It reacts poorly to heat and light. Leaving a bottle on the bench near a sunny window is begging for trouble. Long story short, a dark, cool cupboard stands out as the easiest and best option. If you see folks treat storage like an afterthought, point out how decomposition makes a mess of purity. Spoiled samples slow down research. No one wants to run the same synthesis twice because the chemical soured in a sunny spot. Standard room temperature suits it fine, but anywhere warmer than that risks chemical changes that can throw off results.

Humidity creeps in where people least expect. If you work in a region where summers get sticky, or if your benchtop runs near a sink, think again about where you keep that bottle. Even with the cap screwed tight, regular air exposure can add just enough water to cause trouble. Moisture won’t just dilute the chemical—it spurs side reactions. A sealed container makes a world of difference, especially glass with a good gasket, not those cheap plastic lids that crack after a few months.

Organized shelves signal a healthy lab culture. Leave jars of 2-Acetylpyrrole lying around uncapped, you’re inviting cross-contamination and lost product. Labeling helps too. Ever lost a few grams because someone assumed an unlabeled bottle was something else? I have, and it’s not pretty. Labels that include received date, purity, and any observed changes in color or texture go a long way in keeping everyone honest and careful.

No one likes to talk about fire until someone sets off the alarm. 2-Acetylpyrrole, like a lot of organics, flashes off with open flames or sparks. Storing it far away from heat sources or open flames is just smart. It pairs well with other low-fire-risk organics, never with peroxides or oxidizers. Make sure your fire extinguisher works and your chemical cabinet has proper ventilation. Don’t wait for the safety officer’s reminder.

Good habits kill accidents before they start. I always use gloves and goggles, even if it’s just a dash of powder. After measuring out what I need, I reseal the bottle tight right away. Some folks use gas blankets or a nitrogen environment for long-term storage, but that usually lives in bigger industrial setups. For most people, basic steps—cool, dry, clean, and capped—cover all the bases. Combining a little caution with some organizational discipline makes day-to-day work safer and more reliable, whether you’re making flavors, fragrances, or doing bench-top synthesis.

2-Acetylpyrrole is a building block in the labs of flavor chemists and pharmaceutical companies. Folks use it to make all sorts of finished products, from baked good aromas to fine chemicals. If the material carries extra unwanted stuff—maybe byproducts from sloppy manufacturing—the results can swing wildly and cause trouble. This is why only high grades really do the trick. For commercial and research buyers, purity usually starts at 98%. I’ve seen analytical reports from reputable chemical vendors listing it at 98%, 99%, or even above. Labs go for that upper end, above 99%. Lower grades aren’t popular outside some teaching situations or low-sensitivity work, because contamination likes to muddle test results or throw off product quality. Once you’ve seen the impact of a contaminated batch—changes in smell, unexpected colors, or even failed experiments—you remember the lesson.

Organic synthesis is unforgiving. Any chemist who’s spent hours getting a reaction to go, only to realize an off-smelling bottle did them in, starts checking certificates of analysis more closely. Production-scale companies usually enforce in-house testing to back up whatever grades the supplier claims. Pure 2-Acetylpyrrole gives consistent melting points, easy reproducibility, and no headaches down the road. Regular impurities, like extra pyrrole or acetic acid, don’t just add noise—they can poison catalysts, corrode equipment, or spoil the flavor profile in food applications. Quality control is not just a technicality; it’s the only way to protect both the process and what hits the consumer’s plate or medicine cabinet.

This compound has a knack for picking up moisture and reacting with air. That makes proper packaging more than a matter of convenience. Most suppliers I’ve worked with use sealed bottles—usually amber glass for the small stuff, sometimes brown HDPE (plastic) for bigger runs. Glass keeps the smell in, but also keeps out the water vapor and light that accelerate breakdown. For 100-gram bottles or smaller, you often see plastic caps fitted with liners to keep things extra tight. Larger amounts—say, a kilogram or more—arrive in metal cans, lined drums, or sturdy high-density polyethylene. Lab shipments look like thick-walled glass vials, individually packed with a foam insert and tape sealing the cap to prevent short-term leaks during transport.

Every time I order, I notice desiccants packed alongside the bottles, or even vacuum-sealing for top-tier purity. That’s not just overkill—open a poorly sealed bottle, and the sharp, nutty odor of 2-Acetylpyrrole can fade overnight. That’s wasted money for food formulators, who need even trace notes to stay put. Some labs invest in ampoules under argon for the most delicate research, though it bumps up costs. Still, it ensures the contents stay as promised right up until the moment someone pops the seal.

A lot of the trouble comes from mishandling during shipping or storage. Good vendors put expiry dates on their bottles and batch numbers for tracing, which isn’t just paperwork. Having spent enough time in storerooms, I know that even the best-sealed bottle can go off if someone leaves it in strong sunlight or a damp cabinet. Smart operations adopt strict climatic controls—cold, dry, and away from the window. Small details like regular inventory checks and training warehouse staff to spot cracked seals make a difference.

With prices for high-purity 2-Acetylpyrrole pushing upwards for food grade, buyers need to trust that what they order holds up. In the end, strong packaging keeps quality high, and transparent sourcing helps everyone in the chain know what they’re working with. Shortcuts on purity or packaging carry more risk than they save in money.

| Names | |

| Preferred IUPAC name | 1-(1H-pyrrol-2-yl)ethan-1-one |

| Pronunciation | /tuː əˈsiːtɪl pɪˈroʊl/ |

| Identifiers | |

| CAS Number | 1072-83-9 |

| Beilstein Reference | 120922 |

| ChEBI | CHEBI:34623 |

| ChEMBL | CHEMBL161501 |

| ChemSpider | 15359 |

| DrugBank | DB03793 |

| ECHA InfoCard | 03b53b9b-7ec5-4abd-b62b-242a749088c2 |

| EC Number | EC 211-497-1 |

| Gmelin Reference | 9776 |

| KEGG | C06053 |

| MeSH | D000196 |

| PubChem CID | 7004 |

| RTECS number | UJ4375000 |

| UNII | 3D300U49T7 |

| UN number | UN2810 |

| Properties | |

| Chemical formula | C6H7NO |

| Molar mass | 109.13 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | nutty; popcorn; bread |

| Density | 1.103 g/mL at 25 °C |

| Solubility in water | slightly soluble |

| log P | 0.23 |

| Vapor pressure | 0.0447 mmHg (25 °C) |

| Acidity (pKa) | 13.7 |

| Basicity (pKb) | pKb: 9.03 |

| Magnetic susceptibility (χ) | -6.73×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.536 |

| Viscosity | 2.33 cP (20°C) |

| Dipole moment | 2.93 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 254.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -13.25 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2355.7 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302 + H312 + H332: Harmful if swallowed, in contact with skin or if inhaled. |

| Precautionary statements | P280-P305+P351+P338-P337+P313 |

| NFPA 704 (fire diamond) | 2-1-0 |

| Flash point | 88 °C |

| Autoignition temperature | 260 °C |

| Explosive limits | Explosive limits: 1.1–8.0% |

| Lethal dose or concentration | LD50 Oral Rat 1000 mg/kg |

| LD50 (median dose) | LD50 (median dose): 889 mg/kg (oral, rat) |

| NIOSH | KJ7175000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 0.5 ppm |

| Related compounds | |

| Related compounds |

2-Acetyl-1-methylpyrrole 2-Formylpyrrole 1-Acetylpyrrole 2-Acetylpyridine Pyrrole |