2-Acetyl-3-Ethyl Pyrazine didn’t catch attention overnight. It took decades of curiosity about why food tasted good before chemists and flavorists zeroed in on pyrazines. In the middle of the twentieth century, food scientists wanted to know just what set the addictive crunch of toasted cereals or the nutty aroma of roasted peanuts apart. Tracing these smells back to the molecules responsible, pyrazines kept appearing. Among them, 2-Acetyl-3-Ethyl Pyrazine stood out, thanks to its strong, almost universal appeal in savory snacks. Researchers isolated, identified, and began to synthesize it for commercial use, forever changing how food manufacturers thought about “natural flavors.”

2-Acetyl-3-Ethyl Pyrazine walks into a room loaded with character. You find it in products that aim for the golden standard of roasted, nutty, and baked notes. Most often you’ll spot it behind the curtain in potato chips, breads, crackers, chocolates, and lots of plant-based meat alternatives. A little goes a long way; this isn’t a compound to toss around like table salt. Small concentrations can transform an ordinary food into something that feels like it came fresh off the grill or toaster.

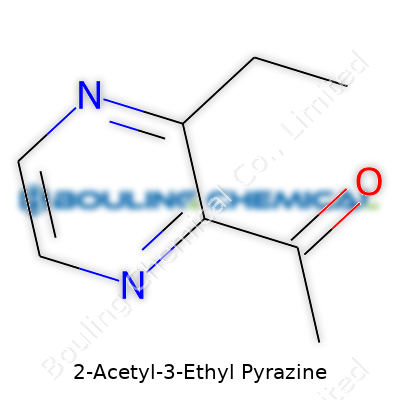

This compound holds a special position among pyrazines, not just because of its aroma, but its physical makeup. It shows up as either a colorless or pale yellow liquid. At room temperature, the aroma seems to leap from the bottle—potent, warm, nutty. With a relatively low boiling point (close to 160°C) and moderate solubility in water, it mixes easily with fats and oils. It doesn’t just sit there, either. Given enough time, open air, and sunlight, the compound starts to break down, and its signature kick fades quickly. Its density and refractive index remain fairly consistent, useful details for chemists and quality control techs.

Most suppliers list purity levels of 95% and up, sometimes hitting 98% for more sensitive food applications. Clear labeling ensures users know what they’re getting. Certificate of Analysis (COA) and Safety Data Sheets (SDS) provide details on storage, transport, and handling. Bottle sizes range from tiny vials meant for lab use to larger containers for industrial production. Every label spells out its chemical structure, batch numbers, date codes, and warnings about possible allergens or combustion risks. Big food manufacturers keep meticulous records of each batch, tracking it from warehouse to production line. Accuracy matters, because even a slight variation can shift a food product’s final taste.

Don’t picture vast fields of pyrazine plants. This compound doesn’t come from farms, but from chemical reactors. The classic route uses the cyclization reaction between ethylglyoxal and acetylethylamine—under controlled temperatures, solvents, and pH. Reaction conditions can tweak the output. Cleanup involves careful distillation to strip off anything that smells off or hangs around longer than it should. Manufacturers avoid shortcuts, since impurities make a world of difference in food safety and aroma quality. Some companies push for more “natural” methods, using enzymatic or microbial approaches to mimic what roasting does in a kitchen, but these cost more and take time to scale.

2-Acetyl-3-Ethyl Pyrazine stands up to moderate processing, but add too much heat or let it sit in acidic conditions and you start to see it degrade. It’s reactive toward strong oxidizers, and mixing it with other flavoring agents or Maillard reaction products can generate new pyrazines with subtle shifts in aroma profile. In food science labs, chemical modifications create analogs with slightly different taste footprints. Tweaking the molecular structure even a little can push the flavor in greener, toastier, or earthier directions, letting flavor houses tailor blends for specific recipes or cultural trends.

Trade names and chemical catalogs list this compound as 2-Acetyl-3-Ethylpyrazine, AEP, 3-Ethyl-2-acetylpyrazine, or using shorthand like FEMA 3843. It’s assigned CAS number 17539-87-4, which helps buyers and regulators keep track. Sometimes food manufacturers just call it by its taste function: “nutty flavorant,” “toast enhancer,” or similar. In global regulatory language, it might show up in different scripts but the code numbers tie it all together for importing, exporting, and labeling requirements.

Despite the appealing smell, 2-Acetyl-3-Ethyl Pyrazine brings some safety needs. Workers in factories keep gloves and goggles handy, and labs use fume hoods during handling. Its strong scent means even small spills linger, sometimes irritating eyes or noses. Regulations treat it as safe at typical food-use concentrations, but food chemists regularly test for both acute and chronic effects. Storage tanks and containers need to avoid heat and sunlight. Emergency plans address accidental inhalation, ingestion, or skin contact, with ready-to-hand first aid instructions. Occupational exposure limits remain conservative, favoring caution. None of this seems like overkill once you have smelled a few accidental spills in tight quarters.

Open a snack bag and the scent rushes out: that’s often 2-Acetyl-3-Ethyl Pyrazine’s handiwork. Its bread-and-butter jobs include ready-to-eat foods, bakery goods, crackers, cereals, and roasted nuts. Chocolate makers blend it into bars for that deep, “just-roasted” edge. Plant-based meat firms love it because it mimics cooked protein notes without animal ingredients. Some beverage companies use it for nutty coffee or cocoa aromas. Its versatility means perfumers and fragrance chemists sometimes borrow it for candles or air sprays aiming for homely, baked-good atmospheres.

Food chemistry labs dig deep to find new uses. Analytical chemists fine-tune detection methods using GC-MS or HPLC, looking for ways to spot the molecule even in complex food matrices. Process engineers study flavor stability, hunting for the best packaging or additives to keep it fresh on the shelf. Some researchers play with biosynthetic production methods, chasing both sustainability and marketing value (“derived from fermentation” turns heads). Universities keep tabs on sensory impacts, running panels that pit the aroma profiles of various analogs against each other. Not all research sticks, but every breakthrough brings flavorists a step closer to natural taste with minimal processing.

No food chemist pours anything into tomorrow’s snack mix without looking at toxicity. Most toxicity studies of 2-Acetyl-3-Ethyl Pyrazine show fairly low risk at typical use levels. Rodent tests find little cause for alarm at doses hundreds of times higher than what people eat. Still, regulators call for careful monitoring, since the compound’s class includes some molecules that raise more questions about cumulative risks. Chronic studies check for carcinogenic or mutagenic properties, and independent panels periodically review the data. The conservative approach always wins—if results ever shift, manufacturers pull back before problems hit store shelves.

Synthetic food flavors face plenty of challenges but also big opportunities. More consumers want both stronger taste and claims of naturalness. Producers keep looking for new biosynthetic routes, including fermentation by engineered yeast or modified bacteria. Regulatory frameworks also keep shifting, and any outbreaks of public concern about synthetic additives can swing demand sharply. Personal experiences in the industry show how much innovation happens in the margins: minor shifts in structure or production method can unlock whole new markets, especially as plant-based foods grow. What works for chips right now could slide easily into tomorrow’s vegan burger, energy bar, or even nootropic chew. As more data comes in on safety and stability, commercial and home cooks alike may find this once-esoteric molecule landing in the heart of familiar foods.

Stroll past a bakery and you catch a scent that tugs you toward childhood. Crack open a fresh bag of chips or munch on a roasted nut, and it’s there—a cozy toastiness, a nutty hint, something hard to put into words but instantly inviting. This note comes from more than skillful roasting or luck. Tucked inside ingredient labels you’ll find 2-Acetyl-3-Ethyl Pyrazine, one of the behind-the-scenes players giving food its memorable aroma and taste.

Chefs and flavorists lean on 2-Acetyl-3-Ethyl Pyrazine because it delivers a roasted, almost popcorn-like essence. In snack foods, it brings out the golden edge in crackers and lifts the grainy notes in breakfast cereals. Chocolatiers drop a dash in to pump up the rounder, browner tones of cocoa. Companies building “smoky” or “nutty” taste profiles often turn to this compound, not just for flavor but for that back-of-the-throat warmth you find in roasted coffee or hearty breads.

Piecing together flavor is a lot like carpentry. A single missing screw or beam sends the whole structure tumbling. Think of 2-Acetyl-3-Ethyl Pyrazine as a critical plank. Anyone who has tried to re-create the comforting smell of a fresh-baked cookie from scratch knows how tough it proves to hit that exact mark. Food scientists, grounded in both chemistry and experience, depend on a roster of flavor molecules like this one to bring recipes close to memories or expectations. That attention to detail is one reason why mass-produced snacks don’t taste bland or flat, but surprisingly homey and familiar.

As someone who towers above store shelves, I notice the relentless search from both companies and consumers for flavor that feels real, even if the source comes from a lab instead of Grandma’s vintage stove. 2-Acetyl-3-Ethyl Pyrazine walks that tightrope. It provides honest-to-goodness roasted flavor at a fraction of the cost and with far more consistency than traditional roasting methods. Food manufacturers love the reliability of working with a stable compound, not worrying about a batch of pecans turning out bitter or uneven.

Not everyone greets laboratory-made flavors with a welcome mat. Some worry that synthetic additives chip away at authenticity in eating, or that chasing intense flavor shortcuts leads to overconsumption and a disconnect from real food. There’s research hinting that people gravitate toward bolder, more engineered flavors, leaving plainer, whole ingredients behind. That trend has sparked debates about health, transparency, and the place of food science on our plates.

It’s easy to blame laboratory ingredients for broader food issues, but convenience and economics shape much of what ends up in our pantries. Instead, there’s room for both innovation and tradition. Regulators might call for sharper labeling so folks who shop can make clear choices. Schools and cookbooks can teach what makes flavors tick, turning chemical names on labels into learning moments. The real task is keeping people curious about what’s in their food and giving them control over the stories their meals tell.

2-Acetyl-3-Ethyl Pyrazine sounds like a mouthful, but it’s something plenty of folks already know, at least by smell. This chemical makes snack foods and baked goods taste and smell like roasted nuts, popcorn, and even some dark chocolates. It comes from the pyrazine family, which is a group of flavor compounds that food producers use to punch up or imitate toasty, savory notes. Walk into a bakery or open a new bag of potato chips and chances are you’ll catch a whiff of something pretty close to this molecule.

Of course, it’s one thing to enjoy flavor, and another to wonder if that flavor is safe. In the United States, the Food and Drug Administration (FDA) classifies 2-Acetyl-3-Ethyl Pyrazine as “Generally Recognized As Safe” (GRAS) when used at concentrations found in food. Internationally, groups like the Joint FAO/WHO Expert Committee on Food Additives also give similar thumbs-up after checking out available toxicology data. Usually, chemicals don't land on these lists without studies in both animals and cell cultures, and—if possible—in humans. In my own work with flavorists and food developers, I've seen that most are careful to use these aromas at very low concentrations, typically below thresholds set by regulators.

The safety of an ingredient like 2-Acetyl-3-Ethyl Pyrazine always depends on how much ends up in the food. Some people get antsy seeing a long, complicated name on an ingredient label, but dose makes the poison. Regulatory guidance puts acceptable daily intake at levels far below what someone would ever eat, even if they loved roasted, nutty candies a bit too much. In product labs, chemists usually target the tiniest amount needed, since going overboard brings off-flavors that nobody wants. In my experience working with flavor houses, the push is nearly always on for more powerful aromas at lower doses.

Another worry that often comes up is the idea of accumulation. Some additives can hang around in the body, but not this one. Research going back four decades found that pyrazines pass quickly through the system and don’t tend to linger. Studies with rats, often the first stop for these tests, show fast metabolism and elimination. None of the data points to buildup, even with regular exposure over extended periods. In those studies, animals that received extremely high doses—much greater than you’d find in any supermarket snack—still didn’t show meaningful health problems.

Curiosity about natural versus synthetic runs deep in food debates. 2-Acetyl-3-Ethyl Pyrazine pops up in nature, showing up in roasted coffee, breads, and nuts as a result of heat-driven reactions called Maillard reactions. Food-grade versions can come from carefully replicated synthesis in a lab or—less often—extracted from natural materials. Both forms match up on a molecular level. From the body’s perspective, whether it’s lab-made or baked into bread, the outcome looks nearly identical.

Many people care not just about safety but about knowing what goes into their food. Labels with unfamiliar chemicals can spark concern. Food companies have a responsibility to tell the truth, using clear ingredient statements and offering info about how flavors are made. One fix is to use everyday terms—like “natural flavor”—when allowed, but also to offer more detail online for the curious. If folks want more natural snacks, there’s room for companies to follow suit by focusing on flavors produced through traditional roasting or fermentation.

No system is perfect, so regulators and companies need to stay alert. If new studies come out showing unexpected effects at the levels folks actually eat, rules may change. For now, the best thing for consumers is to keep asking questions, looking beyond scary-sounding names, and reading up from trusted sources. In my own kitchen, I keep to foods where flavors make sense and don't overwhelm what’s already there. Food safety is all about balance—knowing how ingredients work, trusting science, and staying engaged with what winds up on the plate.

You don’t have to be a pharmacist to notice the numbers on a medicine box or ingredient label. Each one carries a meaning that matters. Most over-the-counter painkillers, for example, come in 200mg or 500mg tablets. It’s not random. These amounts reflect how the human body processes and tolerates each ingredient. Set it too high, and you risk side effects. Set it too low, and the product might not do what folks buy it for in the first place.

You’ll find that many vitamin D supplements list 1000 IU per dose. Toothpaste tubes mention fluoride at around 1000-1500 ppm (parts per million). Hand sanitizers with under 60% alcohol don’t claim much on fighting germs, since the Centers for Disease Control and Prevention reference 60% as their benchmark. In my own life, I started reading ingredient lists on cereal boxes and noticed iron always fell between 10mg and 18mg per serving. There’s a reason: right in that range helps fill the nutritional gap for most people without raising the risk of getting too much.

You can’t really pick up a flavored drink or packaged food without seeing a reference to sodium, sugar, or preservatives like potassium sorbate. Companies watch for doses that hit a sweet spot — just enough for taste and safety, but not too much to cause health officials to give them trouble. Most sodas peg their sugar content around 35-40g per can. That matches up with what people can tolerate for taste and entries from dietary guidelines.

I’ve helped family members shop for pain relief gels and we always look for percentages right on the front, usually in the range of 4% menthol or 2% diclofenac in over-the-counter ones. The amount below or above that doesn’t work well for everyone, so regulators pushed for standards based on what gets the job done safely.

Tinkering too much with dosage leads to problems. Cough syrups for children, for instance, keep dosing low—just a couple milligrams per teaspoon—because little bodies handle things differently. A sports drink company I know tried to sneak calcium levels higher, marketing it for “performance,” but ended up pulling bottles from shelves after complaints about chalky taste and stomach upset.

Prescription medications vary more since dosages often follow strict instructions tied to age, weight, and health history. For instance, antibiotics usually arrive set at 250mg or 500mg per pill, matching infection types and the person’s needs. Doctors worry about both overdose and resistance if people stray from established concentrations.

Solutions often start with testing and honest feedback. Some groups push for clearer labeling, using bold print and color to help people spot what matters. Others urge research into alternatives—think lower-sugar sodas with new sweeteners, or plant-based preservatives that let brands drop salt or chemicals that have built skepticism.

As a regular consumer, asking questions helps. Pharmacists, nutritionists, and even store clerks can point out differences between one product and the next. This empowers people to make better decisions and nudge companies to adjust concentrations if a product comes up short or feels too strong. Open communication, a little trial and error, and careful observation usually guide people to safer, more useful choices in the long run.

Crack open a fresh bag of roasted nuts or break into a classic chocolate bar. Before you eat anything, the aroma always starts the conversation. Sometimes, there's a whisper of something warm and toasty, almost bread-like. That’s not just your imagination; 2-Acetyl-3-Ethyl Pyrazine often plays a part. If you’ve never heard of this molecule, you’ve likely enjoyed the comfort it quietly brings to the table.

I’ve spent years growing up around street vendors and home kitchens. The first crunch of kettle corn or the waft from a bakery in the early morning shares a secret handshake with this compound. It packs a punch—earthy, nutty, a little bit like popcorn, even sometimes boasting a roasted peanut note. Researchers have measured the threshold for human detection in the realm of single-digit parts per billion. This stuff lives loud, even in trace amounts.

Food giants and small-batch chocolatiers both chase after something real, and pyrazines answer that call. One whiff of this molecule and you can get hit with memories of campfire toast, warm wheat bread right out of the oven, or peanuts just snapped from their shells. It’s that honest, mouthwatering pull that keeps people coming back for another handful. The magic isn’t mysterious—it’s how these aromas plug directly into memories of comfort and bite-sized happiness.

Long days in bustling city streets, picking up snacks from carts, I’d always notice: some treats smell way more intense than their plain ingredients suggest. The difference often links back to compounds like this one. International flavor houses keep a close watch on its purity and source because the right profile can tip the scales for snack makers, chocolatiers, and even gourmet pet foods. This molecule doesn’t come from just anywhere; careful synthesis and storage keep its punch from fading.

Here’s a fact: plenty of pyrazines are safe at the trace levels used in food, but nobody likes uncertainty in their snacks. For quality control, food scientists measure and monitor each batch, but there’s always room to go further. It makes sense, as an eater and a parent, to call for clearer ingredient transparency and to support brands that share their sourcing and testing methods. More checks by independent labs and better communication between regulators and the flavor industry would put a lid on any lingering doubts.

I’ve spent late nights around kitchen tables and street corners, always chasing that perfectly toasted, almost sweet kick in a favorite food. 2-Acetyl-3-Ethyl Pyrazine doesn’t need to come with fanfare, but learning more about it builds trust and sharpens the nose for what tastes real. Good food hinges on these invisible helpers, and, just as much, it hinges on folks paying attention not just to flavor, but to the story behind it.

Anyone who’s crossed paths with 2-Acetyl-3-Ethyl Pyrazine—maybe in a lab, a warehouse, or just while reading the back of a snack label—knows it offers a real punch when it comes to flavor. It smells like roasted, nutty goodness and finds its way into everything from chocolates to cereals. But its aromatic charm fades quick when proper storage gets overlooked. My own years working alongside food technologists taught me that the real drama often plays out not in creation, but in what happens after the bottle gets shelved.

A sealed glass or high-quality plastic container goes further than most realize. I’ve watched perfectly good batches go to waste, just from loose caps or cheap packaging. This stuff reacts with air, picking up funky notes or losing its punch. Moisture does not show mercy either. Once water sneaks in, you’ll smell it—and you’ll know the product is off. Humidity can do a number on the profile and, next thing you know, batches fail quality checks.

Some folks have tried storing it at room temperature in bright labs or bustling kitchens. Results follow a pattern: flavor degrades and color shifts. I’ve learned from repeated letdowns that a chilly, dark spot is always a better bet. Somewhere around 2–8°C (standard refrigeration) keeps the profile stable for months. Throwing it right under energy-efficient LED lights makes about as much sense as leaving milk on the porch, so darkness and coolness go hand-in-hand here.

I once opened a container that looked fine, but the label was missing. What sat inside was a well-aged mystery. Old pyrazine can flatten a flavor faster than you can say “missed deadline.” Always date containers and keep a log—old-fashioned maybe, but I’ve rarely seen it fail. Rotate stock so nothing stays in storage longer than a year, unless a supplier or manufacturer says a batch can last. If in doubt, jump on the side of caution and toss the old one.

If you grew up in a house where onions and cookies shared a pantry, you understand how easily scents jump containers. 2-Acetyl-3-Ethyl Pyrazine shares that same tendency. Stack spices, solvents, or any strong-smelling ingredient nearby, and you’ll soon wonder if the flavor chemists swapped places with the cleaning crew. Dedicated shelves or even secondary containment prevents this, and I’ve seen companies save thousands by simply storing materials apart.

Chemical safety matters, even for food flavorings. Rubber gloves and safety glasses should sit near storage areas. Accidental spills call for fast cleanup, not only because of regulations, but because no one wants to mop up after an avoidable mess. Ventilation helps in case someone gets a little heavy-handed pouring or measuring out batches. Any time I’ve cut corners in safety, I ended up spending extra time or money later, dealing with repairs—or worse, explaining an incident.

Every shortcut in storage drills down into margin loss or product failure. Good containers, clear labeling, reliable logs, and a bit of physical separation count for a lot. Strong habits can change a business just as much as state-of-the-art equipment, especially for ingredients as potent as 2-Acetyl-3-Ethyl Pyrazine.

| Names | |

| Preferred IUPAC name | 1-Ethyl-2-(ethanoyl)pyrazine |

| Other names |

3-Ethyl-2-Acetylpyrazine 2-Acetyl-3-ethylpyrazine 2-Acetyl-3-ethyl-1H-pyrazine 3-Ethyl-2-acetylpyrazine |

| Pronunciation | /tuː əˈsiːtɪl θriː ˈɛθɪl paɪˈreɪziːn/ |

| Identifiers | |

| CAS Number | 22047-25-2 |

| Beilstein Reference | 385873 |

| ChEBI | CHEBI:135243 |

| ChEMBL | CHEMBL1626848 |

| ChemSpider | 50405 |

| DrugBank | DB14057 |

| ECHA InfoCard | 03c7d105-3ae8-48e6-b7ac-85bb9b6c5a42 |

| EC Number | 618-267-8 |

| Gmelin Reference | 104622 |

| KEGG | C16615 |

| MeSH | D000197 |

| PubChem CID | 12417446 |

| RTECS number | UE4105000 |

| UNII | 9A8I3QTY3A |

| UN number | UN3334 |

| Properties | |

| Chemical formula | C8H10N2O |

| Molar mass | 178.23 g/mol |

| Appearance | Pale yellow to yellow liquid |

| Odor | Roasted, popcorn, nutty, corn |

| Density | 1.06 g/cm3 |

| Solubility in water | Insoluble in water |

| log P | 1.23 |

| Vapor pressure | 0.000182 mmHg at 25°C |

| Acidity (pKa) | 14.77 |

| Basicity (pKb) | pKb = 10.99 |

| Magnetic susceptibility (χ) | -64.4×10^-6 cm³/mol |

| Refractive index (nD) | 1.515 |

| Viscosity | Liquid |

| Dipole moment | 2.23 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 387.50 J/mol·K |

| Std enthalpy of formation (ΔfH⦵298) | –124.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4628 kJ/mol |

| Hazards | |

| Main hazards | May cause skin irritation. May cause eye irritation. May cause respiratory irritation. |

| GHS labelling | GHS07, Warning, H302, H319, P264, P270, P280, P301+P312, P305+P351+P338, P337+P313 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H319: Causes serious eye irritation. |

| Precautionary statements | P261, P264, P271, P272, P273, P280, P301+P310, P302+P352, P305+P351+P338, P332+P313, P337+P313, P362+P364, P501 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | 61 °C |

| Autoignition temperature | 550 °C |

| Lethal dose or concentration | LD50 (oral, rat): >5000 mg/kg |

| LD50 (median dose) | LD50 (median dose): >5000 mg/kg (Oral, Rat) |

| NIOSH | DA3200000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for 2-Acetyl-3-Ethyl Pyrazine is not established. |

| REL (Recommended) | 1 mg/m³ |

| Related compounds | |

| Related compounds |

2-Acetylpyrazine 2,3,5-Trimethylpyrazine 2,3-Diethylpyrazine 2-Ethyl-3,5-dimethylpyrazine 2-Ethylpyrazine |