2,6-Dimethyl pyrazine moved out of the lab and into factories around the mid-20th century, riding a wave of interest in flavor compounds. Early chemists chased the aromas wafting off roasted meat and coffee, teasing apart what gave both their distinctive taste. Through repeated separation, trial, and nose fatigue, 2,6-dimethyl pyrazine stood out for its roasted, nutty, and cocoa-like notes. With more refined mass spectrometry and gas chromatography in the later decades, researchers consistently found it in everything from roasted peanuts to malted barley. That recognition pushed manufacturers to scale up its production—not just for natural extractions but also through chemical synthesis—so flavorists and food scientists could rely on a steady, predictable ingredient.

This chemical shows up mainly as a pale yellow to colorless liquid. Folk in the food and fragrance sectors know it more as "the punch that gives a chocolate bar or roasted coffee its addicting aroma." A whiff brings to mind fresh bread crust or caramelizing sugars, something that almost everyone has stopped to savor at some point. Companies who supply flavor chemicals box it up in sealed drums and bottles, keeping it shielded from sunlight and humidity so that it doesn’t break down or lose its punch. Once ready, panels of sensory experts sniff and taste small doses blended into model foods, looking for a sweet spot—not so little it vanishes, not so much it overwhelms everything else.

At room temperature, 2,6-dimethyl pyrazine typically appears as a mobile, faintly yellow liquid. It clocks in with a boiling point just under 170°C and sits comfortably under 1.5 on the density chart (g/cm3), marking it lighter than water but nowhere near as flighty as something like acetone. You won’t find it mixing easily with water, but give it a nonpolar organic solvent—think ether or hexane—and it blends right in. Its stability lets it hold up through typical food processing conditions, from high-heat baking to prolonged shelf storage. That dependability makes it a stalwart in both flavor formulas and analytical standards.

Suppliers package it as “2,6-dimethyl pyrazine” or under its most common flavor-use registration numbers (FEMA No. 3275, CAS No. 108-50-9). Labs running quality checks dive into gas chromatography to test for purity, aiming for 98% or better unless customization is requested for research. Labels outline the minimum purity, main contaminants, recommended storage temperatures, and transport cautions as required by local and international chemical safety guidelines. For flavor and fragrance blends, sign-off doesn’t just stop at chemical analysis—panelists flag bottles with intense notes or odd backgrounds, guarding the signature aromatic effect sought by end users.

Large-scale production leans on the condensation of acetoin and methylamine, spurred along by an acid catalyst at moderate heat. Factories have dialed in timing and temperature to maximize yield and minimize funky side-products. Once the reaction winds down, teams filter out unwanted compounds, wash and distill, then collect the heart cut, where the aroma lands squarely where food technologists want it. Smaller batches sometimes pull it straight from spent coffee grounds using solvent extractions and repeated purifications, but synthetic methods make the end result more predictable batch after batch.

Anyone looking to tweak the molecule for unusual flavors or different performance in complex processed foods plays with alkyl group substitutions or oxidations. Knock a hydrogen off and tack on something bulkier, and you change the aroma profile—sometimes to toasted cereal, sometimes more earthy or sharp. Under oxidative conditions, the structure gives way, sometimes breaking aroma down toward simpler acids and amines. Food chemists have tested blends with other pyrazines and different Maillard reaction precursors, aiming for overall effects that fit diner expectations for “fresh roasted” or “lightly toasted.” None of these tweaks are random: years in the trenches with gas chromatographs and sniff panels have sorted out which alterations hold real value.

You’ll find 2,6-dimethyl pyrazine listed under a small library of names, depending on the industry. “Pyrazine, 2,6-dimethyl-” hits regulatory forms; flavor houses sometimes tag it “roasted nut pyrazine.” Its CAS number, 108-50-9, and FEMA identifier, 3275, serve as shorthand for technical buyers. In some older technical documents, “Vicinal-dimethyl pyrazine” turns up, but the modern trade stays consistent with the familiar nomenclature to cut out confusion when ordering or blending.

No compound lands on the bench without a rundown on safety, especially something headed for flavors and fragrances. Regulatory agencies keep the allowable concentration on the lower side—well beneath the levels that might trigger adverse effects in animals. Factories that handle bulk quantities rely on sealed transfer lines, eye shields, gloves, and, where indicated, respirators, since skin and eye contact can cause irritation. Emergency procedures stay on hand for spills, leaks, or accidental ingestion, and the MSDS breaks down each of those risks clearly. Warehouse workers keep it in cool, ventilated spaces, away from anything that sparks flames. Most flavorists work with microgram to milligram quantities, keeping exposure low. At those levels, safety boards and food agencies have signed off under current guidelines.

2,6-Dimethyl pyrazine makes its mark in the food world, showing up in microwave popcorn, roasted meat flavors, instant coffee mixes, and chocolate bars. It heightens the sense of “cooked” or “fresh from the oven” in baked foods and has a hand in plant-based meats to nudge the aroma away from grassy or legume-heavy notes into “browned and meaty.” Beverage companies use it sparingly to round out cocoa and malt profiles in soft drinks and syrups. Outside the kitchen, fragrance chemists slip it into certain perfumes or air fresheners that call for a grounding, warm base that hints at home baking. Pharmaceutical firms have looked at it as a masking agent for bitter medicines, but the food arena remains its bread and butter.

Teams in both academia and industry keep looking for ways to push its sensory contribution further. Novel encapsulation methods help flavor system designers reduce volatility and keep aroma locked in until the cooking or eating moment. Some research explores controlled-release forms for ready-to-eat foods, so unopened products don’t lose their “just roasted” punch on the shelf. Food companies also use advanced analysis to study its breakdown products and interactions during high-heat cooking, searching for better markers of doneness and flavor quality. Taste panels test out slight changes in structure to see if other modified pyrazines might work better in dairy-based or vegetarian foods, or to lower off-flavors in special nutrition products for hospitals.

Regulatory panels, especially in North America and the EU, reviewed animal studies and in-vitro tests before green-lighting its use in food. Short-term and chronic exposure studies tend to show that, at recommended usage levels, no acute or ongoing health issues arise in animal models. High-dose studies have shown mild irritation at levels far above anything used in foods. Food safety teams track total daily intake from all likely sources, keeping the numbers below thresholds set by toxicology experts. These findings get updated with each round of new data, and monitoring continues to ensure dietary levels stay well inside recommended bounds.

Interest won’t dry up while consumers crave the genuine flavor of roasted and baked foods from shelf-stable products. As plant-based and alternative proteins expand their hold at dinner tables worldwide, food chemists keep hunting for cleaner, more “natural” preparation routes—think biotechnological fermentation, or engineered yeast and bacteria strains that produce 2,6-dimethyl pyrazine using ingredients from renewable sources. That could reduce costs and supply chain headaches, while also checking off the “clean label” box for major grocery retailers. Advances in flavor delivery—microencapsulation, spray-drying innovations, or combination-release pellets—may further improve shelf life and taste impact. Scientists expect that safer, greener synthesis, paired with better masking of off-notes in high-protein or low-sugar foods, will keep this compound relevant for years to come.

Walk into any kitchen rich with the smell of toasted bread or roasted coffee, and chances are, 2,6-dimethyl pyrazine is there somewhere in the mix. It's a compound your nose knows before your head does, showing up in flavors and scents that draw us to the table. I remember growing up catching the smell of fresh-baked bread, not really knowing there was chemistry like 2,6-dimethyl pyrazine at play. Now, I spot it listed on food science articles and flavoring ingredient lists more often than I see the recipe for pancakes.

This compound comes with a nutty, roasted flavor that rounds out everything from chocolate to cereal. Food companies add it in small amounts to bump up the “cooked” or “roasted” note in prepared foods. If you’ve ever wondered why instant coffee can still smell inviting, or why breakfast cereal right out of the box carries that bready aroma, this molecule is likely working its magic.

Data from industry reports put 2,6-dimethyl pyrazine among the most common additives in flavor houses. More than 60% of modern snack products use a cocktail of pyrazines to strike the right note, and this one sits at the center of that group. Snack giants and boutique chocolatiers both agree on its usefulness, which keeps it in steady demand even as trends shift between plant-based and conventional categories.

Years back, questions about synthetic flavorings stuck in everyone's mind — especially for folks like my aunt who kept her kitchen as close to “all-natural” as possible. 2,6-dimethyl pyrazine actually starts out in roasted and cooked foods, and food safety panels see it as safe when used as intended. That’s not a ticket to overuse. European Food Safety Authority and the US Food and Drug Administration look at the amount found in an average diet and keep intake limits conservative, so most people won't bump up against unsafe levels just from eating regular food.

There’s a second world where this chemical shows up: fragrances. Candles, cleaning sprays, even some types of tobacco lean on it to copy that “fresh bakery” or “comforting roast” vibe people go looking for. Shops play with the scent as a way to influence shoppers — studies have shown people spend more time in stores that smell like chocolate, and pyrazines help make that possible without hauling in cocoa beans every morning.

The story gets tricky where companies lean on pyrazines as a shortcut, using the chemical crutch to mask cheap ingredients or overprocessing. Sometimes this leads to disappointment; foods start to lose the complexity you get from real roasting or fermenting. As someone who grew up with scratch cooking, I recognize the shortcut right away. Flavorings have their place, but if every product tastes suspiciously similar, the point gets lost.

Instead of hiding behind additives, food developers can use 2,6-dimethyl pyrazine to complement solid, honest cooking. I’ve seen chefs use trace amounts for vegan baking to evoke authentic brownie depth without animal fats. The trick is balance — not letting convenience erase the real stories behind food. With transparency, better recipes, and careful tweaks, everyone can appreciate that roasted, inviting smell, knowing what’s in it and why.

Walk through any kitchen where chocolate or roasted nuts come to life, and you’ll likely breathe in the scent of 2,6-dimethyl pyrazine. This flavor compound cranks up those familiar profiles, turning basic foods into favorites. That’s not some chemistry class tidbit—bakers, chocolatiers, and snack makers use it to boost flavors people crave. For someone who grew up watching my grandmother roast coffee beans on the stovetop, that toasty smell draws a straight line from the pan to the table.

Roasting, baking, and grilling set off natural reactions inside food, especially in grains, coffee, and nuts. These reactions launch a crew of flavor molecules, and 2,6-dimethyl pyrazine is front and center. Companies now make this compound in the lab for consistent results, which means manufacturers don’t depend only on long roasts. The molecule slides right into processed foods, snacks, and flavor syrups, creating a familiar, comforting profile.

Folks like the U.S. Food and Drug Administration (FDA) and Europe’s food safety authorities track flavor chemicals closely. Both have marked 2,6-dimethyl pyrazine as safe when used in small amounts, and there’s a decent stack of research behind it. Eating large amounts straight, outside of food, has shown problems in animal tests, but tables and pantries don’t serve pure chemical by the spoonful.

Most people get microscopic exposures, mixed into chocolate or roasted snacks at low levels. Scientists say normal food use keeps intakes far below any amount tied to harm in studies. Looking around the world, it’s hard to find a documented case where eating food with this compound put someone in the hospital—or even their doctor’s office.

Like any manmade or natural additive, sensitivities sometimes pop up. Someone with an allergy to pyrazines probably reacts to other roasted or grilled food too, since these molecules turn up in the cooking process. Stories about flavor chemicals causing irritation are rare, so the chance of surprise side effects from this particular pyrazine seems pretty slim.

People care more than ever about what goes into their food. Just flipping over a snack bag in my own kitchen, I run into a list of ingredients I barely recognize. There’s a push for short ingredients lists and clear labeling, and synthetic flavorings land right in the debate. Some folks argue that sticking with flavor molecules made by roasting nuts at home creates a more “natural” experience, but that doesn’t mean lab-made versions hold a secret risk.

If people want to steer clear of anything with a name they can’t pronounce, that’s a personal call. Transparency upfront builds trust and lets everyone make the choice that fits. As someone who likes to experiment in the kitchen, I find it useful to know when a food’s flavor comes from nature or the lab, but the safety line gets drawn by the science, not the spelling.

Advances in food chemistry make grocery shelves more interesting, but keeping a close eye on research and regulation matters. Food safety relies on good science and honest labeling. Anyone concerned should scan packages and ask questions—food companies and regulators need to keep those doors open. In the end, 2,6-dimethyl pyrazine lines up next to a whole cabinet of flavor molecules: useful, safe in sensible amounts, and best served with information right on the label.

Lots of people don’t think about what brings flavor to everyday products. Yet something like 2,6-Dimethyl Pyrazine shapes the taste and aroma behind snacks, baked goods, and even some beverages. Working in food science, it becomes clear quickly that even tiny tweaks to an additive like this break or make a recipe. In most commercial food applications, the concentration stays incredibly low. We’re talking about levels down around 1 to 20 parts per million (ppm), so a dash in a thousand liters makes a big difference. It’s almost strange how such a low amount can shift everything from nuts to chocolate, giving that roasted, nutty depth so many people chase after.

Sitting with flavorists in a sensory lab drives home how critical restraint becomes. More isn’t always better — especially not with pyrazines. At 5 ppm, an almond brittle can taste perfectly toasted. Push up toward 30 ppm, and folks in the taste panel start picking out sharp, chemical notes that crowd out the warmth. Overuse not only spoils the genuine taste but can bump up health concerns. Regulations also keep a tight leash on usage: bodies like FEMA and the European Food Safety Authority regularly check whether these molecules stay at safe limits. Nobody wants to eat something that overpowers or throws a shadow over the real flavor, let alone something not proven safe in long-term use.

Formulating a product doesn’t just ask what level works, but what’s safe. In the lab, our team starts well below the sensory threshold for 2,6-Dimethyl Pyrazine and creeps up, batch by batch. It’s not only about taste tests. We check stability during storage, see how it holds up to heat, and watch for reactions with other ingredients. A lot of trial and error flows from there. For candy or snack coatings, we end up recommending less than 10 ppm, sometimes closer to 4. In baked bread or crackers, maybe 8 to 15 ppm. For beverages, particularly those inspired by nut or coffee flavors, it’s rare to reach the same upper limits — even 3 ppm can be enough.

Speaking to other pros or reviewing the literature, the consensus stays firm on tiny doses. Most food labs avoid pushing above 20 ppm; real-world experience matches those formal safety opinions. Nobody wants recalls or consumer blowback. People expect products to taste familiar. Switching a tried-and-tested formula just to shave a cent or chase a richer taste usually backfires. Years in development have shown me it’s better to work with the rounder flavors drawn out by roasted grains or nuts, while leaning on 2,6-Dimethyl Pyrazine just as a highlighter, not the main paint. Think of it as giving a boost, rather than rewriting the whole flavor story.

Companies looking to bring out new products often pilot at the lowest flavor-active level, check in with a sensory panel, and always review the latest safety studies. Investing in staff training helps spot any product drift or risky habits. Digital tracking of batches and controls over supplier purity plays a big role too, especially since you’re working with such faint but punchy ingredients. Tighter dialogue between regulatory consultants, chemists, and flavorists keeps the formulation process honest and keeps everything in the tasty, safe zone that customers expect and deserve.

Most folks in the flavor, fragrance, or chemical sectors have seen 2,6-Dimethyl Pyrazine show up on a supply sheet. With its roasted, nutty twist, it livens up plenty of products. But before loading shelves or hooking up the next batch, people need a clear plan for keeping it safe. In any manufacturing spot, letting a chemical sit around unsecured or stacked beside incompatible stuff can land someone in real trouble. This isn’t just about ticking off a regulatory box. Mishandling brings real risks—from skin and eye irritation to bigger fires if nearby flammable materials catch a stray spark.

Don’t overlook the basics. Working in a site barely above freezing or hotter than summer in Texas challenges any chemical. 2,6-Dimethyl Pyrazine keeps best in a cool, dry place, away from sunlight or heaters. Most people I know set aside a chemical storage cabinet or a shelf in a temperature-controlled room. Dampness is a dealbreaker—left unchecked, a humid spot triggers clumping or even alters chemistry. I used to keep a dedicated area lined with desiccant packs, just in case moisture found its way in. It pays off.

Keep every container sealed tight. This may sound obvious, but an open jar or loose lid often sneaks under the radar in shared labs or crowded warehouses. An airtight seal prevents it from releasing vapors, which might not just stink up the place, but also bump up exposure for folks nearby. Choose glass or high-density polyethylene jars, not plain plastic. Both handle the compound well and keep leaks at bay. Always date your stock, rotate inventory, and never stack next to acids or oxidizers. Too many folks have lost samples by getting lazy here.

Handling rules matter just as much. Never work with unprotected skin. At minimum, slip on gloves and eye protection. The one spill I ever saw—from someone rushing to weigh out a small scoop—proved how splashy even a tiny amount can get. Cleaning up sticky, pungent powder means everything else on your bench starts to smell and your hands burn a little if you forget the gloves. Ditching the idea of “just being careful” saves hassle in the long run.

Ventilation can’t be skipped. Stick to a fume hood or open windows wide if you don’t have lab-grade gear. Nobody needs throat or eye irritation slowing down a shift. Nearly every guide calls for local exhaust or at least a basic fan. The goal? Don’t let vapors collect and build up near your workspace.

Policing a storage protocol isn’t glamorous, but it works. Instead of piling everything up in a “chemical closet,” smart setups with marked shelves, spill kits at the ready, and proper labeling keep everyone on the right side of safety. In places I’ve worked, quick refreshers or walk-throughs for new hires made a big difference. Nothing beats seeing a storage space that’s actually organized.

Ignoring training or relying on hastily printed guidelines invites mistakes. Small companies should look at investing in better ventilation and actual chemical storage fixtures. Larger operators—which usually have more hands-on deck—should step up routine inspections and maybe rotate responsibilities for weekly checks. Tracking container age helps curb surprises with degraded chemicals. Lastly, talking to suppliers about container quality can stop leaks or breakage before the product even lands on your shelf.

Anyone who likes to pay attention to food labels knows the flood of certifications these days. Kosher and halal marks make a difference for millions. People buy them for religious reasons, but it’s about trust, too. Food companies carrying those labels open themselves up to big markets—from Orthodox Jews to practicing Muslims, parents who want transparency, cooks who want the real deal. I’ve seen it in stores: some folks won’t pick up a snack without at least one certification.

Chemists love molecules like 2,6-Dimethyl Pyrazine. It’s got a nutty, roasted hit that turns bland cereal into “nutty wheat” or coffee into a “freshly brewed” aroma. I looked at plenty of ingredient panels during my time working in bakeries and food tech, and this one pops up more than you might think. It’s not some obscure additive; companies lean on it for flavor in everything from granola to candy.

Folks always ask if something so chemical-sounding gets kosher or halal approval. Surprisingly, religious certification isn’t about how long the word looks—it’s about where it comes from and how it’s made. Kosher and halal both care about animal origins, processing steps, cross-contamination, and cleaning standards. Most 2,6-Dimethyl Pyrazine comes from synthetic or plant-based sources, which usually gets an easier path for certification.

Some suppliers advertise powders or liquids with kosher (from groups like OU or Star-K) or halal (from certifiers like IFANCA or JAKIM) badges. The process? It’s not a rubber stamp. Inspectors check paperwork, sources, and sometimes equipment to avoid any slip-ups. Even if the raw materials check out, companies still invite audits, keep clean production lines, and fill out extra documentation. I’ve met production managers who almost treat these audits like exams—nervous, but they know what it means for their customers.

Here’s the catch: not every product using 2,6-Dimethyl Pyrazine will mention its status. Regulations don’t demand the breakdown of every sub-ingredient. A cookie might say “natural flavoring” and that’s it, even though the flavor was checked out and approved. Large manufacturers know buyers care; if they market in kosher or halal aisles, they’ll pay for full certification and tell you. Smaller companies sometimes skip it because of costs or red tape, even if their sources are technically fine.

Sometimes the supply chain trips things up. A flavor house might source from two places—one certified, one not. Blended products need batch-by-batch tracking. I’ve seen ingredient rooms with whole shelves set aside “for kosher runs” and others for non-certified batches, to avoid confusion. It takes real organization.

In the last few years, ingredient suppliers have responded to steady demand for both kosher and halal certificates. More 2,6-Dimethyl Pyrazine is offered with ready documentation. Some companies share certificates up front on their websites. This level of transparency only happened because buyers kept asking. If you want to know for sure about a product, starting with a simple email to the manufacturer often gets a quick answer and sometimes a PDF with the actual certificate for your files.

People want clearer, more trustworthy labels. It means real effort for everyone down the chain—from flavor chemists to packagers to shop owners. Certification is a tool that opens doors, but it only matters if companies are honest, track their batch sources, and actually listen to customers. More demand means more certified choices in the future, which is only good news for those who care what goes into their food.

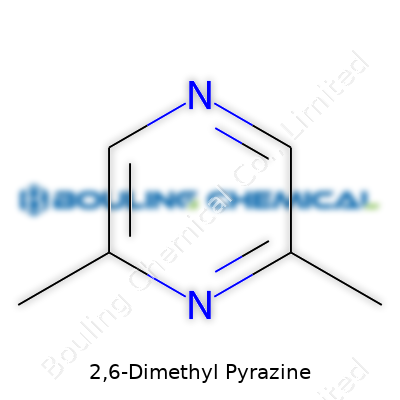

| Names | |

| Preferred IUPAC name | 2,6-dimethylpyrazine |

| Other names |

2,6-Dimethylpyrazine 2,6-Dimethyl-1,4-diazine 2,6-Lutidine pyrazine |

| Pronunciation | /tuː sɪks daɪˈmɛθɪl paɪˈreɪziːn/ |

| Identifiers | |

| CAS Number | 108-50-9 |

| Beilstein Reference | 120924 |

| ChEBI | CHEBI:34523 |

| ChEMBL | CHEMBL14170 |

| ChemSpider | 134398 |

| DrugBank | DB04238 |

| ECHA InfoCard | 21e9a3e6-5ae5-4b1a-836c-b7d4ea0fa2fe |

| EC Number | 121-32-4 |

| Gmelin Reference | 775070 |

| KEGG | C07329 |

| MeSH | D016600 |

| PubChem CID | 12173 |

| RTECS number | UY7350000 |

| UNII | Y9Q3A5R8G9 |

| UN number | NA9086 |

| CompTox Dashboard (EPA) | DTXSID9020711 |

| Properties | |

| Chemical formula | C6H8N2 |

| Molar mass | === 108.14 g/mol === |

| Appearance | Colorless to pale yellow liquid |

| Odor | nutty; roasted |

| Density | 0.981 g/mL at 25 °C (lit.) |

| Solubility in water | Soluble |

| log P | 0.86 |

| Vapor pressure | 0.39 mmHg (25°C) |

| Acidity (pKa) | pKa = 13.6 |

| Basicity (pKb) | 2.83 |

| Magnetic susceptibility (χ) | -51.8·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.502 |

| Viscosity | 2.7 mPa·s (at 25 °C) |

| Dipole moment | 1.34 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 222.4 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | –20.9 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3810 kJ/mol |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes skin and eye irritation. May cause respiratory irritation. |

| GHS labelling | Not a hazardous substance or mixture according to the Globally Harmonized System (GHS) |

| Pictograms | ☠️🔥 |

| Signal word | Warning |

| Hazard statements | H315, H319, H335 |

| Precautionary statements | Precautionary statements: "P261, P305+P351+P338, P337+P313 |

| Flash point | 67 °C |

| Autoignition temperature | 420 °C |

| Explosive limits | Explosive limits: 1.4–11% |

| Lethal dose or concentration | LD50 (oral, rat): 710 mg/kg |

| LD50 (median dose) | LD50 (median dose): 1620 mg/kg (oral, rat) |

| NIOSH | DN9450000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 1 mg/m³ |

| Related compounds | |

| Related compounds |

2-Methylpyrazine 2,3-Dimethylpyrazine 2,5-Dimethylpyrazine 2,6-Diethylpyrazine Trimethylpyrazine |