People started paying more attention to vinylimidazole in the early days of synthetic polymer research during the 1950s and 60s. Chemists realized early on that imidazole rings, when tweaked with a vinyl group, could create monomers that go beyond what simple acrylates or styrenes can do. The structure seemed promising for industries hungry for functionalized polymers, especially those trying to mimic bioactive systems or develop new coatings. Back then, many labs raced to build stable and scalable preparation methods, setting the stage for 1-vinylimidazole’s later rise in specialty applications. Over the decades, production has scaled up thanks to advances in purification, new catalysts, and cheaper starting materials. Like many fine chemicals, interest gains steam in cycles: every time researchers want a water-soluble polymer or unique ligand in their metal complexes, 1-vinylimidazole steps back into the spotlight.

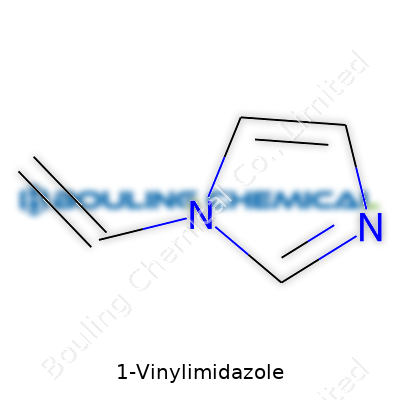

1-Vinylimidazole presents itself as a colorless to pale yellow liquid, carrying a slightly nitrous scent that serves as a signal to handle it with care. Suppliers aim to deliver high purity—usually above 98%—because even slight contamination can bring headaches in polymer synthesis. Its most common roles center around its ability to join polymer backbones or play as a ligand in specialty chemistry. The monomer resists easy categorization because it jumps between jobs in paints, water treatment, electronics, or as a building block for ion exchange resins.

1-Vinylimidazole boils around 222°C and melts at about -44.5°C, so storage rarely poses freezing problems. Its density sits near 1.04 g/cm³, and it prefers polar solvents like water, methanol, or acetone—handy when blending with other hydrophilic monomers or additives. The vinyl group stands out as the main reactive site, but the imidazole ring brings basicity into play and lets the molecule chelate metals or create hydrogen bonds. This dual reactivity allows the compound to take on more roles compared to just vinyl monomers or just heterocyclic compounds. Once you open the bottle, air and light can push the compound toward unwanted polymerization, so air-tight, light-blocking containers are the norm.

Suppliers label containers based on purity, inhibitor content (to prevent premature polymerization), water content, and sometimes color (because tints suggest oxidation or impurities). A typical bottle might state “Purity: 99.0%, Inhibitor: 10-50 ppm MeHQ, Water content: <0.1%.” Customers demand this level of detail, so manufacturers run batch-to-batch checks. Labels must also include hazard pictograms since the liquid counts as an irritant with a risk for skin and respiratory reactions.

Most large-scale production routes react imidazole with acetylene, using a strong base and sometimes copper salts as a catalyst. Some chemists prefer to work with 1-(chloroethyl)imidazole or 1-(bromoethyl)imidazole, turning these into the vinyl derivative by eliminating hydrogen halide under basic conditions. The choice comes down to cost, scalability, and the ease of removing side-products. Factories focus on keeping the process water-free and oxygen-free: these monomers don’t forgive sloppy reactions. I’ve seen smaller scale processes use fine powders and glassware under nitrogen, but industry usually opts for stainless steel reactors and vacuum transfer.

1-Vinylimidazole stands out for its participation in radical polymerization, often joining with compounds like acrylamide or acrylonitrile to make hydrophilic polymers. Copolymers with methyl methacrylate pop up in specialty coatings or as functional layers on membranes. Its imidazole ring can act as a site for quaternization (to make cationic polymers) or as a chelator binding to transition metal ions. Hydrogenation removes the vinyl group, yielding alkylimidazoles for other applications. Halogenation at the ring or on the vinyl group tunes reactivity for more demanding tasks.

Industry catalogues often list this chemical as 1-vinyl-1H-imidazole, N-vinylimidazole, or simply VIM. Some brands give it a house name, packaging the compound with stabilizers or dosing bottles for lab-scale use. Researchers in patents sometimes use the term “N-vinyl imidazole,” so folks in regulatory or procurement jobs get used to watching for the various synonyms.

Every bottle of 1-vinylimidazole comes with safety data, plain and simple. Skin, eye, and respiratory irritation counts as the main challenge in handling. Inhalation of vapor aggravates mucous membranes, so fume hoods, gloves, goggles, and splash aprons always show up in labs where the liquid gets transferred or mixed. Factories emphasize training staff to handle spills quickly—this monomer doesn’t forgive if left on skin. Storage rules require keeping the chemical away from strong oxidizers, acids, and direct sunlight, and storing in amber glass or steel containers with tightly-sealed caps. I’ve seen labs mess up by skimping on inhibitors, but over time users learn never to trust old stock—polymerization in storage tanks leads to costly and dangerous clean-up jobs.

1-Vinylimidazole shapes up as a monomer for water-soluble polymers, often showing up in flocculants and dispersants used in paper manufacturing, mining, and wastewater treatment. Paint and coatings makers value its reactivity and adhesion, especially when looking for layers that resist corrosion or stick to metal and glass. Pharmaceutics and personal care use polyvinylimidazole as a complexing agent in drug delivery systems or as a binder in hair styling products. In electronics, the compound’s chelation capability helps in plating and electrodeposition. Ion exchange resins, built with this monomer, clean up metals from contaminated water in power plants or mining operations. Chemists also turn to it for specialty applications, such as enzyme immobilization matrices in biosensors or as part of ligand scaffolds in catalysis.

Research teams dig into ways to fine-tune polymerization kinetics and molecular weights, looking for applications in advanced hydrogels, membranes, and sensors. Over the past decade, more publications pop up around “smart” polymers that respond to pH or temperature changes—vinylimidazole brings just the right functional group for stimulus-responsive behavior. In biomedicine, labs probe compatibility with proteins, aiming for coatings on implants or carriers for controlled medicine release. R&D pipelines in coatings and adhesives chase after more sustainable options, adding bio-derived content or recycling spent polymer backbones, and 1-vinylimidazole stands as a versatile tool for these evolving demands.

Animal studies show that acute oral toxicity ranges from moderate to high, with irritation for eye, skin, or mucous membrane contact. Chronic exposure studies stay less clear, but researchers flag the risk of allergy or sensitization. Most toxicity reports focus on the monomer, since finished polymers bind the component too tightly for regular leaching. Regulatory filings in the EU and US put restrictions on occupational exposure, and workplace monitoring includes air sampling and strict personal protective equipment protocols. Research continues into metabolic breakdown, with special caution over any possible mutagenicity or effects on aquatic life, especially given the compound’s water-solubility. I’ve seen calls for greener synthesis and removal technologies to lower load in industrial run-off.

Looking at trends, demand for advanced water treatment and greener manufacturing continues fueling interest in vinylimidazole-based polymers. As stricter rules on discharge and emissions roll in, companies revisit their toolkit for more effective, low-dose, and recyclable treatment agents. Coatings and adhesives development pushes the compound into new product classes—think flexible electronics, biomedical implants, and anti-corrosive barriers for offshore platforms. Research in biomedicine chases after more biocompatible and biodegradable polymers, with vinylimidazole offering unique routes for attaching drugs or targeting ligands. Green chemistry, especially bio-based processes and reuse, promises to shape the next decade, as the chemical industry seeks safer, cleaner, and more energy-efficient routes from lab to production. Over the years, the value of 1-vinylimidazole keeps rising as people search for solutions where classic monomers hit their limits.

As someone who has worked with industrial chemicals, I can tell you that 1-vinylimidazole doesn’t turn heads in the world of household names, but it plays a key part in the materials and products that do. This molecule comes with both a vinyl group and an imidazole ring. That makes it a smart choice for specialty polymers. Factories that make high-strength coatings, adhesives, or resins need reliable ways to tweak basic properties like durability, water resistance, or chemical stability. By adding 1-vinylimidazole to their mix, chemists give polymers a boost in flexibility and toughness. It also brings a welcome improvement to how polymers bond to metal or glass surfaces, so things stick together for the long haul.

Water purification doesn’t happen with just big filters and settling tanks. Many water treatment plants use polymer-based additives to grab onto impurities so they can be swept away. I’ve seen how 1-vinylimidazole shines in this area as a component for ion exchange resins. Its chemical structure lets it attract and lock up metal ions like copper or nickel, which can then be pulled out of the water. That skill puts it right at home in both drinking water cleanup and industrial wastewater treatment. A bonus: its selectivity helps keep environmental impact in check, since fewer byproducts slip through.

Digital printing is everywhere now, from labels to large-scale billboards. Many inks and overprint varnishes draw performance and reliability from innovative additives in their formula. I’ve seen print operators swear by ink recipes that include 1-vinylimidazole as a reactive diluent. During UV curing, this molecule helps the ink set quickly and completely, leaving a harder, glossier finish behind. That kind of performance means packaging that resists scuffs, and graphics that survive repeated handling, rain, or bright sun. Fast curing also means higher print speeds and fewer rejects, which always helps any production line.

Pharmaceutical labs chase better materials for drug delivery, and 1-vinylimidazole pops up here too. Modified polymers based on its chemistry can trap drugs and release them slowly as needed. That idea offers patients steady relief instead of the surge-and-drop you get with standard pills. Biotech teams sometimes use it as a building block for specialty enzymes or as a ligand in chromatography — a process that separates molecules with almost surgical precision. These niche uses open doors to better therapies and more precise laboratory analysis.

Like most industrial chemicals, 1-vinylimidazole brings safety and environmental challenges. Its synthesis uses raw materials that can be hazardous, and strict controls keep production safe for workers and the surrounding community. Advances in green chemistry promise to swap out older, harsher synthesis steps for safer ones. Some companies exploring recyclable catalysts and less toxic precursors point the way forward, and that’s something end-users are starting to demand.

Scientists and manufacturers, by choosing responsible supply chains and updating production methods, can help keep the benefits of this versatile molecule while minimizing risks. Moving toward more sustainable chemistry isn’t just about feeling good. It safeguards the skilled workers handling these substances daily, the neighborhoods nearby, and the customers using products downstream.

Working in a lab often leads to a long shelf filled with bottles labeled with long names. A label like 1-vinylimidazole might not raise eyebrows for most folks outside chemistry, but handling it deserves real attention. I’ve come to respect this compound, not just for its usefulness in polymer development, but also for how touchy it gets if you ignore good storage. This isn’t just textbook advice; lapses in storage can mean ruined batches, wasted money, and even bigger safety headaches.

You get 1-vinylimidazole delivered in tightly sealed glass, sometimes flushed with nitrogen. There’s a good reason for this. The compound reacts easily, especially with moisture and light—and that changes what you end up working with. I recall a colleague opening an old bottle only to find a sticky mess instead of a clear, colorless liquid. It had started to polymerize all by itself, turning from a helpful reactant into garbage we couldn’t use.

Moisture is problem number one. Even a little bit slipping past a broken cap starts trouble, as water triggers polymerization. Air exposure runs a close second, and over time, light exposure can add energy to reactions you don’t want. These risks make the difference between having a valuable building block and a disposal problem.

Direct experience shows that 1-vinylimidazole stays safest in a tightly closed bottle, kept in a cool spot, away from light. A fridge works—most labs keep it between 2 and 8 degrees Celsius, just above freezing, to keep reaction rates low. Some big operations use a cold room or chemical fridge set aside for materials that react easily. Keeping it cool isn’t just habit, it slows down the chemistry that can ruin the compound.

A desiccator, filled with drying agents like silica gel or calcium chloride, gives backup protection. I’ve seen colleagues lose expensive material to humidity just from frequent opening of fridge doors. A good desiccator, or even just some drying packs in your storage box, cuts down on that risk.

Most manufacturers pack 1-vinylimidazole in brown glass. The brown tint shields against light, especially ultraviolet. Storing the bottle away from sunlight is enough for day-to-day work, but for long-term storage, keeping it in a dark cupboard or wrapped in aluminum foil keeps unwanted reactions in check.

I learned in my early days that proper labeling reduces most headaches. Always mark the date you open the bottle, and check the manufacturer's recommended shelf life. Once it’s been opened, the clock runs faster. I make it a habit to use older batches first, following “first in, first out.” You don’t want to fish out a forgotten bottle that’s been gathering dust only to see it’s turned to mush.

Problems creep up even with careful storage. Leaks or odd smells signal trouble—sometimes small leaks cause the whole bottle to turn cloudy or change color. At that point, best to treat it as waste. Don’t pour it down the drain. Special disposal arrangements, guided by local regulations and safety data sheets, ensure safe handling. I’ve always found that asking the safety officer early is better than scrambling when something has already gone wrong.

1-vinylimidazole belongs to a class of chemicals that ask for respect and routine. By heeding the lessons I’ve picked up—cool, dry, dark, label everything, never skimping on the right containers—labs get safer, costly disruptions drop, and experiments more often go as planned. Reliable handling pays off, keeping everyone safe and productive.

1-Vinylimidazole pops up in a lot of labs and factory floors, mostly in polymer production and specialty coatings. Folks working with chemicals know the name, but what does it really mean for health and safety? Any time a chemical brings warning labels, it's worth a closer look. The Material Safety Data Sheets don’t sugarcoat it — 1-vinylimidazole can cause burns, trigger allergic reactions, and leave lasting respiratory problems. Splash it on your skin, and you’ll know it right away. Breathe it in, and irritation sets in fast, especially inside cramped workspaces.

Peer-reviewed toxicity studies offer the real backbone for assessing risk. Skin and eye irritation pop up as the most prominent issues, with even minor exposures causing pain and swelling. Inhalation studies in rodents shed light on bronchial inflammation and tissue damage at moderate doses. Researchers haven’t settled on a standard occupational exposure limit, yet toxicologists tend to suggest strong ventilation and containment for good reason. Chronic exposure data runs thin, but the acute risks pile up enough to warrant gloves, goggles, and a good fume hood every time the bottle opens.

Talking to friends working in research and industry, stories come up about rashes, coughing fits, or headaches after handling 1-vinylimidazole in poorly ventilated labs. Workers used to think a standard mask and disposable gloves covered them. After some run-ins with the stuff, they added face shields and bumped up air filtration. Accidents rarely make any headlines, but lessons spread by word of mouth tend to stick. Training sessions that skip scare tactics and explain symptoms and scenarios seem to resonate better than stepping through a checklist.

So far, major spills or contamination events haven’t hit the news, but disposal habits matter. Pouring leftovers down the drain contributes to water toxicity, putting aquatic life at risk. European chemical regulations document its ecotoxicity at relatively low concentrations, so treatment facilities need to know what’s coming their way. Preventing leaks means more than plugging barrels—it involves honest conversations between lab technicians, factory managers, and waste handlers. Community health depends just as much on what leaves the building as what happens inside it.

While safer alternatives exist for some uses, 1-vinylimidazole still brings unique performance for specialty polymers. Industries face a hard choice between ditching it and doubling down on safety. Regular air monitoring and visible warning signs drop risks on the shop floor. Locking up chemicals and digitizing inventory help track who handles what, reducing accidental mix-ups. Education stands out; employees encouraged to speak up about spills or symptoms can fix problems before they escalate. Sharing data across companies turns isolated safety wins into industry standards.

Most chemicals in industrial use come with trade-offs. With 1-vinylimidazole, immediate dangers weigh heavier than long-term, mysterious effects. Transparency about real-world experiences — not just technical studies — gives everyone a stake in staying safe. Worker feedback, ongoing trials for substitutes, and tough environmental rules can keep risks in check without stalling innovation. Protecting health starts with straight talk and smart habits, from the warehouse to the wastewater plant.

Science classrooms have always felt more exciting once you get past the long lists of theory and start seeing the real stuff: white powders that fizz, liquids that change color, smells that clear a room. In that mix, there’s 1-vinylimidazole. This chemical’s formula is simple on paper: C5H6N2. It’s short. Just five carbons, six hydrogens, and two nitrogens.

It’s tempting to stop right there. Put the formula in a table, memorize it, and never give it a second thought. But beneath those letters and numbers sits a substance holding real value for manufacturing, research, and health.

Getting to know C5H6N2 means more than remembering numbers. The vinyl group, for example, makes it reactive and suitable for polymerization. That changes its use entirely compared to plain old imidazole. Now, think about dental materials, coatings, adhesives—many of these slip into daily life, and 1-vinylimidazole contributes to their qualities of strength and resilience.

Take dental fillings. The field didn’t look the same before chemical formulas like C5H6N2 entered the picture. Add it into a formulation, and suddenly you get materials that resist moisture and bond tightly even in the tough environment of the human mouth. There’s data to back up these claims—scientists have observed better mechanical properties once 1-vinylimidazole was part of the mix.

I’ve seen how chemicals get a bad reputation. Talk to someone outside a lab, and “chemical” sometimes means “dangerous.” But honest talk around safety starts with full identification. Stating C5H6N2 as the formula means its hazards and benefits get mapped out more effectively. Information from the European Chemicals Agency shows that proper labeling, storage, and use all start by getting the formula right. In research and industry, that detail saves time, money, and health.

The formula also acts as a safeguard against knockoff or mislabeled materials. Counterfeit chemicals create real harm, especially in medicine or food technology. Verifying that a substance actually is 1-vinylimidazole—by its formula—becomes more than a technicality. It’s a step toward accountability.

Global supply chains wobble more often than many care to admit. A chemical like 1-vinylimidazole relies on specialty suppliers. If producers can’t match demand, backlogs slow down advances in medicine and industry. One approach involves improving tracking and transparency by pinning purchases to proper chemical formulas. That brings in traceability and cuts back on black-market substitutes that don’t perform as promised.

Researchers have also started to explore biosynthetic pathways for key building blocks like imidazoles. That creates new angles for both cost savings and sustainability. Instead of fossil fuels, future batches might pull from renewable feedstocks. The seed of this push lies in knowing and sharing the precise formula—no guesswork required.

The world looks different once simple formulas like C5H6N2 meet real-world needs. Knowing the chemical formula of 1-vinylimidazole is a basic step, but it shapes everything from material innovation and supply chain security to human health and workplace safety. For anyone who handles, buys, or studies chemicals, accuracy in something as foundational as the formula makes a difference that stretches much further than the lab.

Anyone who has clocked hours in a chemistry lab knows certain substances demand extra respect. 1-Vinylimidazole is one of those. You find it in polymer synthesis, specialty coatings, adhesives, and even pharmaceuticals. This liquid opens a lot of doors for researchers and manufacturers, yet the same reactivity that makes it so useful brings real risks to skin, lungs, and eyes. Think of gloves and goggles as your first line of personal defense instead of just another box to check off. OSHA and NIOSH have flagged related imidazole compounds for potential allergic reactions, burns, and headaches. Scrambling for first aid is a bad spot to realize what matters most is old-fashioned caution.

The stories you’ll hear from seasoned techs usually skip straight to the basics: nobody likes headaches from chemical vapors, and cleanup gets ugly fast if a bottle leaks or tips. Always handle 1-vinylimidazole where the airflow keeps gases and vapors from hanging around your face. Fume hoods aren’t just there for show—they really work. When working late or rushing, it’s tempting to pour “just for a minute” out on an open bench. Resisting that urge pays off. Pulmonary irritation and long-term effects such as asthma have gotten linked to repeated exposure. Take it seriously, even if you’re fast-tracking a synthesis. Proper containers should hold up to the chemical, so skip generic plastic. Only glass or specialized plastic bottles should see the stuff. Screw-caps need checking, since accidental spills tend to mean someone overlooked a loose lid.

PPE doesn’t just mean throwing on a thin fabric coat. Put on a decent chemical-resistant lab coat, double up on gloves if possible, and use splash-proof goggles instead of “safety glasses” that leave gaps. 1-Vinylimidazole can soak into latex and nitrile over time, so switch out gloves often. I once saw a colleague discover too late that a quick spill had soaked right through. Skin contact can lead to burns and allergic rashes, and eye contact has put folks in urgent care. Always check the Safety Data Sheet (SDS) for your specific supplier. Labeling standards vary internationally, but hazard codes and pictograms speak clearly in any language.

Spills go from minor to major depending on how prepared you are. No one regrets setting up an absorbent pad or spill kit before beginning work. For small leaks, soak up with compatible absorbents (not paper towels), then double-bag and label the waste. For larger spills, evacuate the area, get help, and let the safety team handle cleanup. It’s better to slow down than risk inhalation or skin exposure. Ordinary sinks don’t cut it; chemical waste collectors are the only real option for disposal. Untreated discharge can harm aquatic life, since research shows imidazole derivatives pose toxicity risks to water organisms.

Good habits protect not just your shift, but the people who’ll use the space after you. Training should focus on hands-on skills rather than just reviewing slides. Supervisors ought to model safe use every day—small shortcuts add up. Regular inventory checks and inspections prevent “mystery” containers from piling up. It helps to treat each interaction with 1-vinylimidazole with real focus. In a field where one accident can sideline a career, diligence beats bravado every time. Lab safety doesn’t get any less important as projects ramp up. By sticking to these basics, you reduce preventable injuries and keep experimental results—and researchers—right on track.

| Names | |

| Preferred IUPAC name | 1-Ethenyl-1H-imidazole |

| Other names |

1-Vinylimidazole 1-Vinyl-1H-imidazole N-Vinylimidazole 1-Ethenyl-1H-imidazole |

| Pronunciation | /waɪˈnɪl.ɪˌmɪd.əˌzoʊl/ |

| Identifiers | |

| CAS Number | 1072-63-5 |

| Beilstein Reference | 2080597 |

| ChEBI | CHEBI:51749 |

| ChEMBL | CHEMBL51795 |

| ChemSpider | 54837 |

| DrugBank | DB13847 |

| ECHA InfoCard | 14a28b94-cf7a-4dde-9241-6fd983b95b93 |

| EC Number | 214-012-0 |

| Gmelin Reference | 68284 |

| KEGG | C19106 |

| MeSH | D014773 |

| PubChem CID | 86604 |

| RTECS number | UM4375000 |

| UNII | A261E9IT1A |

| UN number | UN2206 |

| Properties | |

| Chemical formula | C5H6N2 |

| Molar mass | 82.11 g/mol |

| Appearance | Colorless to yellowish liquid |

| Odor | amine-like |

| Density | 1.017 g/mL at 25 °C |

| Solubility in water | miscible |

| log P | 0.42 |

| Vapor pressure | 3.6 hPa (20 °C) |

| Acidity (pKa) | pKa = 7.1 |

| Basicity (pKb) | 6.75 |

| Magnetic susceptibility (χ) | -44.0×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.508 |

| Viscosity | 2.44 mPa·s (20 °C) |

| Dipole moment | 3.73 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 179.8 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -24.84 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3813 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H315, H317, H319, H332 |

| Precautionary statements | P210, P261, P280, P305+P351+P338, P310, P370+P378 |

| NFPA 704 (fire diamond) | 2-2-2-1 |

| Flash point | 88°C |

| Autoignition temperature | 640 °C |

| Explosive limits | 2.4–18.0% |

| Lethal dose or concentration | LD50 oral rat 1250 mg/kg |

| LD50 (median dose) | LD50 (median dose) of 1-Vinylimidazole: 2,230 mg/kg (rat, oral) |

| NIOSH | WN3567000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for 1-Vinylimidazole: "No specific OSHA PEL established |

| REL (Recommended) | 0.2 mg/L |

| IDLH (Immediate danger) | Unknown |

| Related compounds | |

| Related compounds |

1-Ethylimidazole 2-Vinylpyridine Imidazole N-Vinylpyrrolidone |