Curiosity drives chemists to find avenues for making drug building blocks more stable and easier to handle. In the story of N-Cbz-3-piperidone, the narrative kicked off decades ago when researchers noticed that piperidone cores served as useful links in creating larger, more elaborate molecules. As chemists moved through the world of pharmaceutical precursors, they found that adding the Cbz (carbobenzoxy or benzyloxycarbonyl) group protected the amine, making it manageable in multistep synthesis. It’s a classic example of bench-top ingenuity transforming routine laboratory headaches into scalable methods that help scientists push drug discovery further.

N-Cbz-3-piperidone belongs to the family of protected piperidones, offering a reliable intermediate for researchers working toward novel small molecules, especially those aimed at CNS targets or antiviral agents. The Cbz-protected amine sets it apart, acting as a shield against unwanted side reactions. Countless research teams working on route development favor this compound because it handles moisture better than unprotected piperidones and keeps unwanted polymerization at bay, sparing labs from painful product losses. Reliable suppliers like Sigma-Aldrich and TCI offer it under catalog numbers that pop up again and again in medicinal chemistry papers.

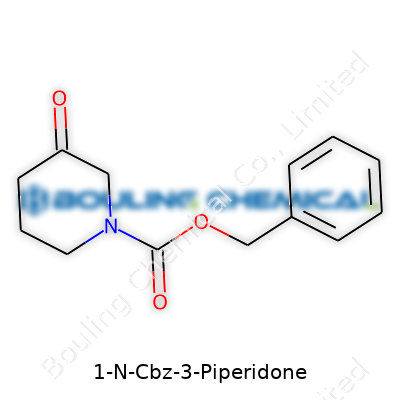

In solid form, N-Cbz-3-piperidone sits as a white to off-white powder, a sight familiar to anyone who’s spent hours in a chemical storeroom. Its melting point hovers near 77–81°C, letting chemists purify it by recrystallization without worrying about decomposition. The molecular formula (C13H15NO3) brings a manageable molar mass (233.26 g/mol), allowing quick in-lab calculations. Its structure contains a six-membered piperidone ring with a benzyloxycarbonyl group, and infrared spectroscopy shows distinct carbonyl stretches while NMR spectra make structure confirmation straightforward. In practice, it dissolves well in DCM, ethyl acetate, and methanol, giving flexibility for both workup and purification.

Reputable suppliers report a purity above 98%, supported by HPLC, and display storage information directly on packaging—often advising users to keep it at 2–8°C, away from light and humidity. Labels indicate the CAS number (14007-58-8), batch number, and safety pictograms. Having these details right on the bottle streamlines audits and compliance checks for both academic and industrial settings, so no time gets wasted hunting for crucial certificates.

The preparation often begins from 3-piperidone or its hydrochloride salt, reacting with benzyl chloroformate in the presence of a base like sodium carbonate in a biphasic system with water and an organic solvent. Some researchers use phase-transfer catalysts for smoother conversion, while others modify the process depending on available equipment. After reaction, extracting and drying the organic layer delivers the crude product, which usually fares well after a single recrystallization. From experience, the scalability of this route makes larger synthesis possible without needing specialized equipment.

Chemists value N-Cbz-3-piperidone for its versatility. Its protected piperidone center allows N-alkylations, reductive aminations, and ring transformations without disturbing the Cbz group. Once further transformations wrap up, the Cbz group sheds easily by catalytic hydrogenation—palladium on carbon works wonders. The resulting free amine finds a home in further coupling steps. By picking orthogonal conditions, project teams avoid side reaction traps, keeping projects on track and meeting funding deadlines.

Catalogs and journals list this chemical under several aliases. The most common are 1-(Benzyloxycarbonyl)-3-piperidone, 1-Benzyloxycarbonyl-3-piperidone, and N-Cbz-piperidone. CAS 14007-58-8 acts as the universal identifier, handed down in safety sheets, procurement lists, and business deals. Synonyms keep things clear when teams swap protocols or publish cross-lab collaborations.

If handled carelessly, exposure can cause respiratory irritation or skin sensitivity. Long days in the lab teach the importance of working inside a chemical hood, wearing gloves and goggles, and using proper containment for weighing and transfer. Safety data sheets warn of the need to avoid direct inhalation or repeated skin contact. Cleanup with activated carbon and waste segregation cut down on cross-contamination and hazardous waste. Regulatory bodies, such as OSHA or REACH, guide safety attitudes on the shop floor just as much as they guide purchasing standards.

Scientists use N-Cbz-3-piperidone both as a starting point and as a way station in synthesizing designer molecules. Its most compelling applications include acting as a scaffold in pharmaceutical development, with leads targeting neurological disorders and antiviral research. Contract research organizations and medicinal chemistry departments bank on its predictable behavior, helping streamline SAR campaigns and scale-up operations. Specialty chemical firms also use it to develop agricultural agents and advanced polymers. When supply chain snags arise, researchers feel its absence—highlighting its essential status.

N-Cbz-3-piperidone has earned a prime place in the stories of hundreds of patents and publications. Research teams stay busy designing new analogs and optimizing batch processes, fishing for better yields and safer conditions. Work in green chemistry has prompted the use of milder bases or greener solvents, nudging the field toward more sustainable methods. Mobility between academia and industry often fosters knowledge sharing, turning troubleshooting sessions into process improvements that benefit everyone. New routes, mechanistic studies, and scaled-up syntheses keep surfacing every year.

Toxicology reports highlight the relative safety of N-Cbz-3-piperidone compared to free 3-piperidone, though caution remains essential. Animal models show low acute oral toxicity, but repeated exposure has not been fully characterized in every system. There’s a need for more chronic exposure data, especially as it enters more manufacturing cycles. Respiratory exposure remains the biggest professional risk, along with accidental splashes to eyes and skin. Established labs rely on rigorous training and up-to-date SDS protocols, which cut accident rates and keep teams healthy.

N-Cbz-3-piperidone stands ready for new applications as the biotech and pharma sectors expand their quest for novel bioactive molecules. Greater automation in chemical synthesis points to stronger demand for reliable, modifiable intermediates like this one. Advances in flow chemistry and biocatalysis may reshape how this and related compounds are prepared on scale, making them safer and more environmentally friendly. Broader adoption of green chemistry principles could spur suppliers to rethink packaging and offer new grades. Meanwhile, ongoing research into new CNS and antiviral drugs will likely keep N-Cbz-3-piperidone in heavy rotation for years to come.

Holding a sample of 1-N-Cbz-3-piperidone in the palm of your hand, one question pops up: how pure is this stuff, and why should anyone care? In a lab environment, cutting corners never ends well, especially with building blocks like this. The fiction is that “close enough” works. The fact is, impurities create headaches, extra steps, and sometimes dangerous outcomes in pharmaceutical synthesis or even research scale-ups. Purity here isn’t some fancy marketing term — it’s the difference between signal and noise, results and repeat experiments, cost control and financial drain.

Standard suppliers list the purity for 1-N-Cbz-3-piperidone from 95% to 99%. Some freedom exists as to what “purity” really covers. In my early experience, buying a cheaper batch with 96% purity, that four percent impurity ended up as a major hassle. That four percent isn’t just “filler.” Sometimes it’s a byproduct, sometimes unreacted starting material. Either way, chasing residual junk with extra chromatography or filtration never looks good on a budget sheet or timeline.

Companies hawking 99% batches admit in small print to trace bits of solvents, chlorides, or related piperidone isomers. The math works differently on small projects versus kilo-scale demands. Research teams with tight aims — say developing a new API — don’t want to risk any ambiguity. Clinical teams face tighter scrutiny, where an impurity under 1% can spell the difference between a regulatory nod and a compliance backlog.

Getting a certificate of analysis (CoA) tells part of the story. Sometimes, results from the supplier don’t quite line up with in-house HPLC data. For example, what looked like a “pure” batch on the supplier’s sheet once showed extra peaks during our verification. The only way to know for sure involves running your own tests: NMR and HPLC analyses weed out bluffers. It’s not about trust, it’s about track record.

In big universities, grad students know the scramble — running tests, spotting unexpected ghosts on spectra, racing to get things cleaned up. That experience drills the importance of clear QC processes home. Lip service to purity always vanishes under pressure to meet deadlines, especially in synthesis labs.

If you’re serious about scale, suppliers must provide more than a generic CoA. Full traceability, detailed batch history, and open impurity profiles build trust quickly. It pays to ask for chromatograms or authentic spectra, not just a line on a spreadsheet. Push for information on synthetic routes used ― some routes leave stubborn byproducts that regular purification misses. By keeping an open dialogue, labs can avoid the ugly surprise of discovering issues a month too late.

Purity headaches force teams to revisit standard operating procedures. Tricks I’ve seen work well: grinding for improved recrystallization, adopting double-column purification, trusting less in “trusted” suppliers, and investing in portable analytics for quick checks. Some teams go straight to custom synthesis partners who make bespoke batches at >99% and back it up with transparent data. That costs more but saves money and time in the long haul.

In synthesis chemistry, purity isn’t a luxury — it’s the guarantee that sets the stage for everything downstream. Every scratch on the purity line means more time in the fume hood and more uncertainty on the balance sheet.

There’s a big difference between keeping regular pantry flour and a chemical like 1-N-Cbz-3-Piperidone. A simple slip with a compound like this can spoil a research batch, send costs through the roof, or put people at risk. So, getting the storage right counts for a lot. I’ve worked with similar organic compounds in the lab, and overlooked details have led to ruined samples and, once, a frantic after-hours cleanup. Sticking to proven storage methods saves time, money, and headaches.

From what’s published about 1-N-Cbz-3-Piperidone, it’s clear that it won’t behave like sugar. It’s sensitive to moisture, light, and air. If a technician leaves it on a benchtop near a window, the compound’s stability could get compromised. I’ve lost count of the times when poor lighting led to discoloration and batch waste, especially with delicate organics.

A dry space with consistent, moderate temperatures works best. I always look for a cool, dark cabinet, ideally one around 2-8°C, like a laboratory fridge. These fridges aren’t meant for drinks or food—they’re designed so stuff doesn’t get cross-contaminated or go through warming cycles each time you reach for a snack. Direct sunlight or fluctuating temperatures have spoiled more than a few of my working samples before I got serious about decent storage.

Chemical stability depends on good packaging. It’s a rookie mistake to scoop a few grams into an old plastic bag. Airtight glass vials or amber bottles do a lot more than just look professional—they keep light and moisture out. Labs with budget trouble sometimes use polystyrene tubes; those often let in more air than you’d expect.

Tightly screwed caps and a clear label—the date, contents, maybe even your initials—prevent confusion. Some of my colleagues think labeling takes too long, right up until they end up measuring out from a mystery container after a shift change. Add a desiccant like silica gel for a finishing touch, especially if you work somewhere humid. In one summer project, neglecting the desiccant turned a solid into a sticky mess, and I never forgot the lesson.

Safety rules exist for a reason. 1-N-Cbz-3-Piperidone might not make headlines like cyanide, but it doesn’t belong in open-access spaces. Picking a storage location that locks is more than just a bureaucratic checkbox—chemicals walk off when left unwatched, especially with too much foot traffic.

A functional lab keeps an inventory log. A digital spreadsheet often works, but a paper log taped to the fridge door works too. If you’re tempted to skip it, consider the chaos after a surprise inspection or audit. I once spent hours retracing borrowed bottles, missing time from actual research.

Old chemicals build up in forgotten corners. If you spot a vial with caked residue or a date that goes back a few years, don’t play guessing games. Many labs partner with professional disposal services for expired organics. Winging it, or just throwing things in the regular trash, never ends well—ask anyone who’s dealt with a leaking bottle.

Taking proper care of 1-N-Cbz-3-Piperidone isn’t about following a random rule. It’s about respect for your safety, your team’s results, and the cost of wasted material. Anyone who’s worked in a real lab knows the difference between “good enough” and “actually good.” The difference is usually about how you treat your chemicals when no one is watching.

1-N-Cbz-3-Piperidone plays a steady role in the world of chemical synthesis, especially for medical researchers and organic chemists trying to whip up something useful. Shopping for this compound isn’t like grabbing a bag of sugar from a grocery store shelf. Buyers face a real mix of packaging sizes, shaped by purity, shipping concerns, and who plans to use the stuff.

Most chemical suppliers don’t leave buyers guessing. They lean on some tried-and-true packaging strategies. Labs grab smaller bottles—often 1 gram, 5 grams, or 10 grams. These glass bottles or sturdy plastic flasks keep spills and environmental factors to a minimum. I’ve worked with enough tricky organics to appreciate the safety margin that amber vials and tight screw caps offer. For smaller research setups wanting a working amount, these packages cut risk and cost at the same time.

As the need for 1-N-Cbz-3-Piperidone scales up, the choices stretch. Researchers chasing a multi-step synthesis may need 25-gram or 50-gram containers, often double-sealed for transport. Bulk demands open up kilo-sized drums—say, 100 grams, 500 grams, or even 1 kilogram. Production folks or pilot plant chemists know it’s a different world at that scale, so FDA-grade HDPE drums and secondary containment look less like overkill and more like common sense.

There’s one thing you figure out fast after a few years in a chemistry lab: nobody likes wasting money on too much stock. Small packaging lets research teams pick up exactly what they need for a particular round of synthesis. Less volume, less chance of degradation, better for budgets. These sizes shield against moisture and stray light, which can quietly undermine quality—sometimes those details make or break a project.

On the flip side, manufacturers who run through hundreds of grams at a time don’t want to fiddle with ten tiny vials. Ordering in bulk leads to lower unit prices and less plastic waste. Handling larger packs takes more careful storage. Most facilities dealing with kilo-sized containers invest in ventilation, dedicated shelving, or chemical-resistant floors. That’s not overdoing things—it’s experience speaking.

The demand for specific sizes shifts with each customer. Some suppliers put extra effort into custom fills—maybe a 500-milligram bottle for a one-off experiment or a streamlined 2-kg carboy for an industrial partner. These custom fills close the gap between waste and scarcity. Nobody wants leftover material sitting on a shelf turning into hazardous waste, or worse, running out just as a reaction hits its stride.

Factors like country, transport method, and end-use purpose nudge sizes and packaging types in one direction or another. Shipping companies apply strict rules on what they’ll handle, and some packagings earn approval thanks to their leak-proof seals and resistance to shocks. Temperature swings or accidental drops during transit—these are real problems with real solutions, and good packaging sits right at the intersection of safety and practicality.

From the bench chemist to the industrial buyer, there’s a lot to be gained by talking with suppliers and spelling out every storage and safety need. The more buyers ask for smart, reusable packaging and right-sized packs, the easier it should get for the industry to cut down on waste and pass along real savings. Direct communication clears up confusion, avoids overspending, and matches packaging to the job at hand.

Working in labs and chemistry spaces has shown me that the certificate of analysis does more than just check a box. It’s easy to spot the label on the bottle and trust the supplier, but a real COA builds trust in every batch and every dataset. For researchers messing with 1-N-Cbz-3-Piperidone, especially in pharmaceutical development or specialty chemistry, getting a COA is not just about bureaucracy. It's about verifying that what’s inside matches what’s promised.

I’ve lost track of how many times someone assumed that purity was a guarantee just because they bought from a “well-known” chemical provider. It only takes one misplaced decimal or one contaminated drum to blow months of work. A valid COA can save a lot of headaches here. For academic researchers, grad students grinding through synthesis projects, or startups exploring new drugs, these certificates lay out purity, moisture, trace metals, and impurity content. You see the testing methods right there, no surprises, no flourishes.

Some companies slap a spreadsheet online and call it a day. They won’t always send a COA for every batch, or sometimes they’ll roll out one generic file from years ago, which is next to useless if you need reproducibility. I’ve seen groups switch suppliers without checking the paperwork, and suddenly their yields go south or reaction times drag on. If you rely on the COA or plan to publish, getting a document tied directly to your lot number matters. If you reach out and the supplier hesitates, that’s a red flag.

With chemicals tied to drug synthesis or high-value applications, a solid COA becomes even more important. Some intermediates, like 1-N-Cbz-3-Piperidone, drive tight regulatory attention because they might connect to pharma supply chains or industrial uses. Research budgets aren’t bottomless. Buying dodgy material with unknown byproducts could blow a whole cycle of experiments, or even run afoul of compliance checks.

It pays to ask for the COA up front—before money changes hands. Don’t wait until the box is already at your door. Ask for a sample COA by email. Review which tests they include—NMR analysis, HPLC, and moisture content are standard. If the supplier can’t give batch-specific documentation, consider switching. Trust me, trying to backtrack through a sketchy chain of custody wastes more time than a few extra emails before purchase.

Labs and companies can push for improvements here. Open conversations with providers help, but certified tracking tools, digital records, and customer feedback actually drive change much more quickly. Some chemicals cost a bit more through distributors playing by these tighter rules, but the reduced risk for failed syntheses and regulatory audits is no small advantage.

Getting in the habit of double-checking COAs means fewer headaches and much better reproducibility down the line. The chemical supply chain only works as well as the weakest link. Invest a little more energy up front and you save yourself the late nights chasing mysterious batch inconsistencies. A real, current COA solves more problems than it causes, especially with high-stakes intermediates like this one.

Talking about lead times for chemicals like 1-N-Cbz-3-Piperidone, it often feels less like shopping online and more like waiting for that specialty coffee from a far country. Most suppliers quote anywhere between two to five weeks, depending on how much you need and whether the company even keeps it in stock. If you’re asking for a truckload, production often takes longer. For folks in R&D or manufacturing, this means supply planning should look forward at least a month. Quick fixes rarely show up in these cases.

Last year, I had a colleague juggling a kickoff deadline. The material arrived just days before a project started, even though he’d tried to build in a two-week safety net. The supplier had no raw material and needed extra time for synthesis. This isn’t unusual in specialty chemicals. Many batches are made to order—no warehouses full of 1-N-Cbz-3-Piperidone sitting around collecting dust. If you’re a buyer, it makes life easier to set timelines with a healthy buffer.

Most chemical shipments, especially those with controlled status, rely on air freight for international orders. Air moves faster than sea, which helps keep lead times reasonable. At the local level, trucks handle most deliveries—protected, labeled, and checked through several hands until it reaches your dock. The paperwork isn’t just a formality. My own team once spent more time haggling with customs over certificates and SDS documents than waiting for the shipment itself.

Freight companies don’t cut corners here. Proper UN packaging, documentation, and adherence to IATA or IMDG rules decide how fast the order clears. If you’re dealing with a well-organized supplier, your box travels with all its papers in place. Fly-by-night operators sometimes gamble on regulations, but that’s a bigger risk—a shipment delayed in customs can throw off your entire schedule.

Supply chains for specialty chemicals stretch across continents. Every added day, every customs check or missing document, throws a wrench in daily operations. I’ve watched research teams sit idle, burning dollars and time, because active ingredients sat in a warehouse somewhere at the port. That’s why buyers gravitate toward suppliers with experience shipping across borders, who can answer questions about lead time, provide order tracking, and jump in if something gets held up. Fast, predictable shipping can mean the difference between hitting a project milestone or missing out on a contract.

Temperature sensitive chemicals like 1-N-Cbz-3-Piperidone sometimes need cold-chain shipping; delays here don’t just mean lost time, but spoiled or degraded product. Reliable shipping choices usually include temperature logs and quick customs clearance; better planning on the front end always pays off.

Before placing an order, I check the supplier’s track record and grill the sales team on production timeline, air vs. sea options, and likely customs issues. I request tracking updates at each stop, not just a one-off notification. For repeat orders, I push for framework agreements, so the supplier starts production before I run out.

If you’ve ever lost a week waiting for a product stuck somewhere, you know how much difference a few simple preparation steps can make. Pick well-rated suppliers, ask about stock levels and fastest shipping routes, and pad project calendars. Competition for these compounds keeps growing, so attention to lead time and shipping details never feels wasted.

| Names | |

| Preferred IUPAC name | 1-[(Phenylmethoxy)carbonyl]piperidin-3-one |

| Other names |

1-Cbz-3-piperidone N-Carbobenzoxy-3-piperidone N-Benzyloxycarbonyl-3-piperidone 1-(Benzyloxycarbonyl)-3-piperidone |

| Pronunciation | /wan en zəbɛz θri paɪˈpɛrɪdoʊn/ |

| Identifiers | |

| CAS Number | 1802-85-3 |

| Beilstein Reference | 1208192 |

| ChEBI | CHEBI:132773 |

| ChEMBL | CHEMBL2266797 |

| ChemSpider | 21629008 |

| DrugBank | DB08382 |

| ECHA InfoCard | 03b5e6b2-6e04-4d41-a9ce-22a6c83cc3c8 |

| EC Number | 821-448-2 |

| Gmelin Reference | 128271 |

| KEGG | C14383 |

| MeSH | D010407 |

| PubChem CID | 10433496 |

| RTECS number | TT2976000 |

| UNII | X3Y27423L6 |

| UN number | 2811 |

| Properties | |

| Chemical formula | C13H15NO3 |

| Molar mass | 247.29 g/mol |

| Appearance | White to off-white solid |

| Odor | Odorless |

| Density | 1.14 g/cm3 |

| Solubility in water | Slightly soluble |

| log P | 0.02 |

| Vapor pressure | 0.000195 mmHg at 25°C |

| Acidity (pKa) | 19.09 |

| Basicity (pKb) | 4.68 |

| Magnetic susceptibility (χ) | -79.37 × 10^-6 cm³/mol |

| Refractive index (nD) | 1.552 |

| Dipole moment | 3.51 D |

| Thermochemistry | |

| Std enthalpy of combustion (ΔcH⦵298) | No standard enthalpy of combustion (ΔcH⦵298) data found for 1-N-Cbz-3-Piperidone. |

| Pharmacology | |

| ATC code | |

| Hazards | |

| Main hazards | Harmful if swallowed, causes skin irritation, causes serious eye irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302 + H312 + H332: Harmful if swallowed, in contact with skin or if inhaled. |

| Precautionary statements | P261, P264, P271, P280, P301+P312, P305+P351+P338, P337+P313, P405, P501 |

| NFPA 704 (fire diamond) | 1-2-0 Health:1 Flammability:2 Instability:0 |

| Flash point | Flash point: 170.7 °C |

| NIOSH | NA3480000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 1 mg/mL |

| Related compounds | |

| Related compounds |

N-Boc-3-Piperidone 1-Boc-3-Piperidone 3-Piperidone 1-Benzyl-3-Piperidone 1-Benzyloxycarbonyl-4-piperidone |