Chemists first encountered 1-Methylpyrrolidine back in the early days of heterocyclic amine research, tracing its roots to the broader industrial efforts of mid-20th-century Europe and America. At a time when scientists experimented with functionalized pyrrolidine rings, hopes ran high for molecules that could bring new traits to pharmaceuticals, plastics, and specialty chemicals. 1-Methylpyrrolidine broke away from earlier, less stable amine analogs, offering low volatility and better handling compared to smaller amines. Research journals from the 1950s and 60s show teams, often from agricultural laboratories, putting this compound through its paces in search of crop protection solutions and polymer intermediates, setting the groundwork for what would come next in applied chemistry.

1-Methylpyrrolidine shows up today as a colorless to pale yellow liquid, marked by a fish-like odor. You find it sold by major chemical suppliers in a range of purities, most often above 98%. Its tiny five-membered ring gives it a flexible backbone for many synthetic tasks in modern labs, from catalyst development to new drug candidates. I've often seen it in stockrooms for small-batch synthesis or in bulk at refineries that convert basic chemicals into feedstocks for more complex molecules. Some specialty solvent blends include it for extraction and separation work where cleaner cuts matter more than sheer solvent power.

This compound weighs in at 85.15 g/mol. Its boiling point hovers around 105°C, which stakes out useful territory for controlled reactions without losing too much product to evaporation. Melting happens well below room temperature, near -44°C, meaning storage rarely leads to solidification problems. Its density sits close to 0.85 g/cm³, so it floats on water and separates easily during work-up. Though miscible with many organic solvents and partially with water, it resists hydrolysis better than many amines, thanks to the ring structure. With a pKa around 10.3, it carries enough basicity for quaternization and alkylation processes without being so harsh that it complicates purifications.

Suppliers label 1-Methylpyrrolidine under CAS number 120-94-5, and it's tracked by global chemical regulators. Most bottles carry hazard codes for flammability and health risks, never missing the clear pictograms. Purity and moisture content feature prominently on spec sheets, as even small impurities can wreck catalytic reactions or testing protocols. Many buyers demand batch-specific certificates with GC or NMR data before accepting product, and that comes from a history of trace contamination causing headaches down the synthesis line. Users rely on clear, unambiguous lot codes to track every drop from delivery to disposal.

Synthetic chemists build 1-Methylpyrrolidine by methylating pyrrolidine, and the routes have only become more efficient over the decades. In older methods, methyl iodide or dimethyl sulfate delivered the methyl group under basic aqueous conditions, but today's labs tend toward methyl halides paired with milder, less hazardous bases or phase transfer catalysts. Some processes take a reductive amination approach, reacting 1-pyrroline with formaldehyde and hydrogen. Scale-up teams keep a close eye on vapor containment and side-product formation, making sure reactor pressures and temperatures stay in check. Each method balances throughput, safety, and downstream handling, and most efforts focus on minimizing waste for leaner economics and easier compliance.

Once made, 1-Methylpyrrolidine's lone nitrogen drives most of its chemistry. Alkylation and acylation reactions transform it into building blocks for bigger molecules. The nitrogen's lone pair accepts protons and metals alike, allowing scientists to fashion salts, complexes, or even challenge classical ligands in catalysis. Hydrogenation and oxidation can tweak its ring; chemists often play with halogenation for biochemistry and crop science innovation. The ring's resilience against ring-opening under mild conditions adds value in organic synthesis, where protecting the amine without cleaving the backbone proves crucial. In my own bench work, controlled introduction of functional groups onto the methyl substituent spun out advanced intermediates for agrochemical and pharmaceutical applications.

Beyond its main name, the compound goes by N-Methylpyrrolidine, 1-Pyrrolidinylmethane, and sometimes pyrrolidinemethyl. Regulatory databases often lump it under simple descriptors such as methylpyrrolidine or methyl-tetrahydropyrrole. In commercial catalogs from Sigma-Aldrich, Fisher Scientific, and TCI, you’ll see all combinations of numeric position (1- or N-) and the word “pyrrolidine,” so checking CAS numbers saves ordering mistakes.

No one ignores the hazards around 1-Methylpyrrolidine. It's classed as flammable, and contacting the liquid risks skin and eye irritation. Spill response calls for ventilation and immediate absorption with inert materials, then sealing the waste in clearly marked drums. Standard lab PPE—gloves, goggles, lab coats—covers most scenarios, but larger industrial settings require fire protection and emergency eyewash stations nearby. Respiratory protection grows important when working with the vapor or in closed reactors. Most organizations I’ve worked with train users on the SDS and keep records on hand, satisfying regulatory audits and emergency drills alike. Disposal routes funnel spent or contaminated material through licensed chemical handlers, with strict chain-of-custody forms to close out each transaction.

The compound shows up in a surprising variety of industries. In pharmaceuticals, it enters as a building block for antihistamines and antidepressants, thanks to its basic nitrogen and resistance to metabolic attack. Agrochemical companies blend derivatives into some herbicides and fungicides, pushing for improved activity with less environmental persistence. Chemical plants use 1-Methylpyrrolidine as a catalyst or cosolvent for tough organic transformations, especially where primary and secondary amines fail for reasons of volatility or reactivity. Electronics manufacturers sometimes test it for non-polar extractions and etching solutions, combing for new routes to specialty coatings. In my experience, even the flavor and fragrance sector examines it for traces left during synthesis or in search of new reaction intermediates, though food contact work runs up against regulatory scrutiny.

R&D labs still push the boundaries on 1-Methylpyrrolidine’s potential. AI-guided drug discovery engines now suggest it as a fragment in new bioactive molecules, inspired by decades worth of protein-binding studies. Chemists tune its structure, swapping substituents at the 3- and 4-positions, aiming for boosted receptor activity and metabolic stability. Some academic groups probe its value in asymmetric synthesis, recruiting it as ligand or organocatalyst in reactions demanding high selectivity. In green chemistry, teams analyze how to make or degrade it using benign bio-catalysts or alternative solvents. Suppliers field calls from advanced battery R&D centers looking to this ring as a future component for ion transport media. Research shows no sign of slowing, as regulatory agencies and green standards spur more efficient, safer, and cleaner uses.

1-Methylpyrrolidine lands in a moderate hazard band. Acute toxicity remains lower than many low-molecular-weight amines, though long-term inhalation and high-dose ingestion bring neurotoxicity and organ-level effects, according to animal studies in peer-reviewed toxicology journals. Skin and mucous membrane irritation counts as inevitable at higher concentrations, making exposure controls non-negotiable. Chronic effects data remains incomplete, a gap that researchers and safety agencies aim to close. Regulators in Europe and the US set workplace exposure limits and require clear labeling for all shipments, especially larger drums destined for synthesis. Environmental studies show partial biodegradability, but persistence in aquatic systems spurs closer look at downstream release and remediation. My own conversations with environmental safety officers highlight a steady push for better training and stricter monitoring in facilities that handle hundreds of kilograms per year.

With each passing year, labs and factories find new reasons to revisit 1-Methylpyrrolidine’s bag of tricks. Market analysts predict growth tied to pharmaceutical intermediates and green chemical processes, where ring-functionalization delivers compounds with big commercial promise. Green chemistry campaigns advocate recycling and improved synthesis, reducing the environmental burden. Advances in predictive modeling and AI-led screening unlock new targets in material science and life sciences. Regulatory pressures and consumer demands for safer, cleaner products drive engineers and chemists to keep refining handling and manufacturing standards. Scaling up from small lab batches to reliable, reproducible tons per year tests each producer’s mettle, but the rewards remain clear—more efficient drugs, safer agrochemicals, and next-generation materials all benefit from what 1-Methylpyrrolidine brings to the table.

Step into any lab storage room, and the chemical names on those shelves rarely sound familiar. Take 1-Methylpyrrolidine, for example. This isn’t the stuff of high school science classes or household cleaners. It’s a colorless liquid, kind of pungent, with a knack for helping others do their job. If you make your living in chemistry or any industry that gets deep with molecules, this chemical starts to look a lot more useful.

Ask a chemist about 1-Methylpyrrolidine, and you’ll likely hear the term “building block.” This little ring-shaped molecule has a nitrogen atom that makes it valuable in organic synthesis, where new molecules are pieced together. Pharmaceuticals lean hard on stuff like this. Drug researchers often need a way to tweak molecules so they behave a certain way in the human body. 1-Methylpyrrolidine can slip into reactions, introducing that nitrogen backbone and either sticking around or helping shape bigger, more complex compounds.

Paint companies and plastics manufacturers sometimes reach for 1-Methylpyrrolidine too. Certain solvents need a boost to dissolve things that stubbornly resist. This compound hops in as a co-solvent—sort of like a trusty sidekick alongside more common chemicals. It manages to dissolve both greasy things and water-friendly ones. In plastics, engineers chase strength and flexibility. Tweaking polymers starts at the molecular level, and additives like 1-Methylpyrrolidine can change how those long chains line up.

Workplaces with 1-Methylpyrrolidine don’t treat it lightly. It can irritate skin and eyes, and inhaling vapors isn’t for the faint of heart. Safety doors and fume hoods go into overdrive. Proper gloves and goggles come out before anyone even unscrews a bottle. That’s the reality of handling chemicals in general—you make things safer and smarter by knowing the hazards and having backup plans.

Few people outside industrial circles have heard of 1-Methylpyrrolidine, yet the science world relies on compounds like this to fuel progress in medicine and materials. Regulation can feel stifling in the lab, but clear labeling, updated safety sheets, and better ventilation have real value. Companies could invest more in employee training, focusing not just on procedures but on the “why” behind safety.

Some manufacturers look for alternatives, especially if they want greener or less risky production lines. The push for sustainable chemistry means exploring new reactions that need fewer hazardous chemicals. Still, for a long list of applications, 1-Methylpyrrolidine gets the work done efficiently, so it remains in steady demand.

I’ve seen plenty of colleagues rely on compounds like this to nudge their research forward or fix a hiccup in manufacturing. You rarely see its name in the headlines, but 1-Methylpyrrolidine quietly shapes things we all use, from medicines to plastics. While it calls for careful handling, solutions start with strong safety culture and a willingness to keep improving both products and training.

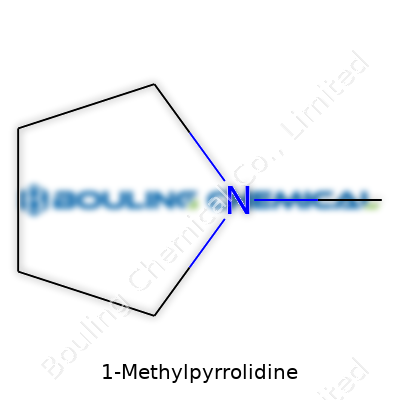

Plenty of folks get thrown off by chemical names, but there’s no magic to 1-Methylpyrrolidine. The chemical formula shows what sits inside each molecule: C5H11N. You read that right—five carbon atoms, eleven hydrogens, and one nitrogen. Whenever I look up a new compound, I always check this first. Without it, you’re left guessing about reactivity or possible hazards. Checking a label or material safety data sheet means nothing until that formula makes sense in your head.

The molecular weight, sometimes called molecular mass, of 1-Methylpyrrolidine is 85.15 grams per mole. It might seem like a dry number, but it helps people across industries measure, dose, or react it properly. In lab work, measuring too light or too heavy can throw off results and waste time. People in pharmaceuticals look at these numbers every day because dose calculations hinge on them. That’s how you stop mistakes before they end up in people’s medicine cabinets.

Pyrrolidine rings show up in everything from medicine to materials science. That little nitrogen tucked in the ring opens up a world of reactivity. 1-Methylpyrrolidine isn’t just a mouthful. Chemists turn to it for synthesis because it brings flexibility and reactivity to the table. I remember working on a project that needed a solid base and found this compound did the trick without throwing off other sensitive groups in the reaction. Not everything out there has the blend of stability and activity this structure brings. The added methyl group on the nitrogen turns a basic ring into something distinctly useful, shaping how it interacts with other chemicals and solvents.

Before working with any secondary amine, including 1-Methylpyrrolidine, I put safety front and center. Its formula might be simple, but it’s a volatile liquid with a smell you won’t forget. There’s always risk in breathing too much in or letting it hit your skin. Anyone stepping into a lab should know that. Even outside the lab, folks moving barrels at manufacturing plants need clear labels and strict ventilation. Too many accidents happen because someone thought a small amount wouldn’t matter—until it did. Clear communication and proper storage beat heroic clean-up any day.

Access to detailed chemical information lets scientists innovate safely. Ignoring formulas or molecular weights invites confusion and can lead to bigger problems. Mistaking one methylpyrrolidine for another might sound like science fiction until you realize real-world incidents trace back to sloppy prep work or gaps in training. Tighter regulations and open databases, like those provided by government agencies or chemical suppliers, give teams the tools they need. Investing in better tools and clearer training means smarter, safer labs tomorrow.

Understanding the backbone of a chemical like 1-Methylpyrrolidine helps workers, researchers, and students alike. Skipping the basics sets people up for accidents and major headaches. Whether mixing in a small-scale lab or handling drums for production, starting with the formula—C5H11N—and knowing the molecular weight—85.15 g/mol—keeps people safe and lets new discoveries happen without unnecessary risks. It comes down to respect for the science and a little care with the details.

Most folks won’t come across 1-Methylpyrrolidine outside a chemical lab or factory, but more industries are using it for synthesis, and that starts to raise a few eyebrows. Plenty of chemicals zoom in and out of product formulas without much fuss, but when safety sheets start spitting out words like “flammable” and “corrosive”, people want answers beyond the alphabet soup that is chemical jargon. I’ve had my share of run-ins with chemicals that look innocent on a label, only to find they demand a lot more respect once gloves and goggles go on.

1-Methylpyrrolidine doesn’t act like sugar water. Its vapors irritate the nose and throat, and skin contact can lead to redness or worse if exposure goes unchecked. Getting the chemical in your eyes can do real damage, so most labs rely on face shields, not just simple glasses, to keep this stuff out. I’ve seen folks brush off a tiny smell or a few drops, only to regret it hours later when their hands burn or their sinuses flare up. Just because it isn’t a household name, doesn’t mean it’s gentle on people.

Breathe in too much, and headaches or dizziness are not out of the question. High concentrations over time might even beat up your lungs, judging by animal studies. Any chemical that bullies organs in rats and mice isn’t something to handle lightly—those tests exist for a reason, and many regulations don’t even cover the long list of weird effects that might turn up decades later, especially for workers exposed day after day.

The numbers haven’t shown 1-Methylpyrrolidine to be “highly” toxic by lethal dose standards. The LD50 sits in the hundreds of milligrams per kilogram for rats. That’s not up there with the truly nightmarish toxins, but it isn’t as safe as bacon, either. Lab techs and line workers know that handling any concentrated solvent or intermediate calls for care—they can all climb up the risk ladder if spilled, splashed, or even just left open in a hot, cramped room.

Goggles, fresh gloves, good airflow—these go a long way with compounds like 1-Methylpyrrolidine. Having spent years in environments where one leak could clear the whole building, I know the comfort of good extraction fans and sealed waste cans. Training makes all the difference, too: I’ve seen offices leave safety posters hanging up, but every spill and splash tells its own story. People cut corners when they’re rushed or bored, which is how the trouble starts.

I often remind folks in labs and plants that even small drops build up over time. If ventilation isn’t up to scratch or gloves don’t get swapped out, minor burns or chronic coughs pop up. Don’t count on luck—proper labeling, regular air checks, and workers who speak up if something stings or smells odd do more to prevent harm than any sentence buried in a safety manual.

More industries jumping onto compounds like 1-Methylpyrrolidine means regular folks who never worked in labs could wind up exposed through runoff or waste. Companies can’t dodge the basics: clear hazard info, solid waste handling, sharp workplace training, and a culture where safety isn’t just an afterthought. If leaders treat this as routine—keeping MSDS sheets current, plugging leaks, and speaking up about bad air—the odds tip back toward everyone staying healthy, accidents and lawsuits kept at bay.

Too many folks handle chemicals like 1-Methylpyrrolidine and forget they’re not dealing with baking soda. A compound like this smells strong and comes with a punch if you get careless. Years of work in labs and small factories taught me the importance of respecting every bottle, no matter how routine the job feels. Breathing in 1-Methylpyrrolidine fumes or letting a drop touch bare skin can start trouble most of us want to avoid.

Storing this stuff starts with the right spot. Heat changes everything, making vapors spread and sometimes kicking off pressure in closed bottles. I always look for cool, ventilated rooms and keep chemicals off the floor. No heaters or sunny windows nearby—dark shelves, solid containers, tight-fitting lids, and labels that jump out. A spill can turn into a headache fast, so keeping it away from acids, strong oxidizers, or anything that sparks just makes sense.

Glass or high-grade plastic containers work better than cheap knockoffs. I learned early on to double-check for tiny cracks—one leak can ruin more than a day’s work. Storing upright and using secondary trays keeps leaking messes from spreading. Label everything, even if you think you’ll remember. I’ve watched folks clog up drains and expose themselves because someone grabbed the wrong bottle or couldn’t read what was on the side.

Handling 1-Methylpyrrolidine gets safer with good habits. Splash-resistant goggles, gloves made for organics, and long sleeves block contact better than faith alone. Ventilation always helps; fume hoods soak up vapor before it creeps across the room. Working in open space, with fans pulling air away, keeps things manageable. Don’t eat or drink nearby—you don’t want to find out how this stuff tastes.

No one likes running for the eye-wash station but one slip could send you there. I keep paper towels and spill kits close by. If a drop lands on skin, water and soap come first—don’t grab the strongest cleaner off the shelf to try and save time. Clothes go straight into the wash, not back in the drawer.

Dumping leftovers down the drain or tossing them in the trash never ends well. Working with local hazardous waste services stops this chemical from playing havoc in water supplies or the air. Pouring through charcoal or neutralizing in a closed system might seem over-the-top, but finding out local waterways tested off the charts makes a strong case for responsible steps.

Good storage and handling don’t just keep the paperwork clean—they keep people healthy. Locking cabinets, regular inventory checks, and real training sessions pay for themselves. Quick meetings, sharp eyes, and plenty of respect for the hazards make a real difference. Trust me, the story you want to tell at the end of the day is “Everything went fine.” And that story starts with doing the small stuff right, every time.

1-Methylpyrrolidine has carved out a modest but meaningful role in research labs and various industrial sectors. The purity you choose points to the tasks at hand. Some buyers pay close attention to purity specifications labelled by manufacturers, because an impure batch brings headaches nobody needs—side reactions crop up, test results wobble, things unravel fast. Laboratory folks often lean toward high-purity versions, typically 98% or above, listed as “analytical grade” or “reagent grade.” This stuff gets used in pharmaceuticals, specialty coatings, or as a synthesis intermediate. Even a small drop in purity throws off sensitive reactions, so most chemists have little patience for impurities dancing around their flasks.

On the flip side, someone ordering up hundreds of kilos for bulk chemical manufacturing often picks a technical grade—sometimes sitting in the 95%+ range. It costs less, and minor byproducts won’t always fuss up the final process if the manufacturer’s filtration setup is solid. Some suppliers stretch it even further, shipping grades below that for less critical applications. If the job is tough but not fussy, technical grade does the trick and saves a few bucks. Bottom line: know the limits. I've watched more than one project screech to a halt over skipping this detail.

Anyone who’s cracked open a new drum or fiddled with chemical bottles knows packaging shapes safety and project flow. Companies supply 1-Methylpyrrolidine in packaging that fits the order size and keeps things stable. For small-scale research, you’ll see clear or brown glass bottles—usually ranging from 100 milliliters up to a few liters. Glass resists corrosion and holds up well against volatile organics like this one. Those tight caps don’t leak vapors, and the labels stay put even if a splash happens mid-experiment.

Larger quantities bring up a different set of challenges. Larger labs and factories get their supplies packed in stainless steel drums or HDPE (high-density polyethylene) containers, often from 25 liters up to 200-liter drums. The choice between steel and plastic boils down to site preferences and disposal limitations. Drums anchor easily onto pallets and shrug off a few bumps, so freight companies don’t lose sleep if the road turns rough. Good packaging stops air and moisture from sneaking in, which makes a real difference—1-Methylpyrrolidine can pick up water from the air, losing punch or changing how it reacts.

One issue that keeps showing up is the risk from shipping in damaged or unsuitable packaging. Leaks aren’t just a loss—they put people and the environment at risk. Years back, I saw a small spill turn into a several-hour cleanup because the drum seal failed. Better oversight at each stage helps. Companies can double-check seals, run training for warehouse teams, and trace sources of damage. Electronic trackers on shipments can flag temperature spikes or impacts prior to delivery, so problems get tackled sooner than later.

Getting suppliers on board with clearer grading reports also solves part of the confusion. Standards sometimes slip, especially with new vendors or tight budgets. Reliable certificates of analysis give buyers a way to check what's inside before things go into the process stream. It’s not all about rules—it just keeps things honest and saves everyone trouble down the road.

| Names | |

| Preferred IUPAC name | 1-Methylpyrrolidine |

| Other names |

N-Methylpyrrolidine 1-Methyl-1-azacyclopentane N-Methyl-tetrahydropyrrole |

| Pronunciation | /ˈwʌnˈmɛθɪlpɪˈrɒlɪdiːn/ |

| Identifiers | |

| CAS Number | 120-94-5 |

| Beilstein Reference | 1209241 |

| ChEBI | CHEBI:34418 |

| ChEMBL | ChEMBL107772 |

| ChemSpider | 12096 |

| DrugBank | DB04208 |

| ECHA InfoCard | 40b4a6be-8c6f-431b-924d-1e8a5b7a2ca0 |

| EC Number | 211-278-5 |

| Gmelin Reference | 8929 |

| KEGG | C06153 |

| MeSH | D017901 |

| PubChem CID | 79790 |

| RTECS number | SY8579000 |

| UNII | O776XYD3C5 |

| UN number | UN2554 |

| Properties | |

| Chemical formula | C5H11N |

| Molar mass | 85.15 g/mol |

| Appearance | Colorless liquid |

| Odor | amine-like |

| Density | 0.863 g/mL |

| Solubility in water | Miscible |

| log P | -0.38 |

| Vapor pressure | 4.7 kPa (20 °C) |

| Acidity (pKa) | 10.1 |

| Basicity (pKb) | 1.98 |

| Magnetic susceptibility (χ) | -24.5·10^-6 cm³/mol |

| Refractive index (nD) | 1.417 |

| Viscosity | 0.72 mPa·s (25 °C) |

| Dipole moment | 2.29 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 298.8 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -70.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3782.5 kJ/mol |

| Pharmacology | |

| ATC code | null |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H226, H302, H312, H332, H314 |

| Precautionary statements | P264, P271, P280, P301+P312, P303+P361+P353, P304+P340, P305+P351+P338, P312, P330, P337+P313, P403+P233, P501 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | 13 °C (closed cup) |

| Autoignition temperature | 273 °C |

| Explosive limits | 5.1–15.2% |

| Lethal dose or concentration | Lethal dose or concentration (LD50, oral, rat): 260 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat 300 mg/kg |

| NIOSH | MH9625000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for 1-Methylpyrrolidine: Not established |

| REL (Recommended) | 1 to 10 ppm |

| IDLH (Immediate danger) | Unknown |

| Related compounds | |

| Related compounds |

2-Methylpyrrolidine 3-Methylpyrrolidine Pyrrolidine N-Methylpyrrole |