Curiosity in chemistry often brings about unexpected results, and 1-methylimidazole stands as a testament to that curiosity. In the late 19th century, researchers pursued ways to play around with imidazole molecules. The goal wasn’t fame but a better understanding of nitrogen-based heterocycles. By adding a methyl group, chemists stumbled across new territory, opening up unique reactivity patterns. Over decades, this compound evolved from scientific oddity to an anchor in applied chemistry. This journey shows how incremental, sometimes accidental, advances can lay the groundwork for whole sectors years later, proving how research rarely grows in a straight line.

Rarely do folks outside of the industry know the name 1-methylimidazole, but spotlights shine on it from several angles. This colorless liquid does a quiet dance in labs and manufacturing, acting as a base, catalyst, and solvent. Companies buy it by the drum, not for reputation, but for utility. The chemical finds a home in the production of active pharmaceutical ingredients, electronic materials, ionic liquids, and resins. Much of its usefulness comes from the balance it strikes—stability mixed with enough reactivity to get things moving in a reaction flask or industrial reactor.

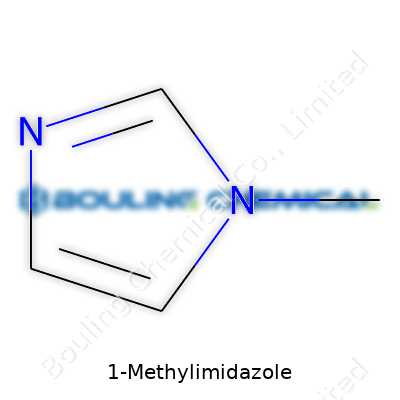

Pour 1-methylimidazole into a glass beaker and you’ll see a clear, water-like liquid. It goes by the formula C4H6N2, with a boiling point sitting at 198°C, which lets it handle a good bit of heat without breaking down. Relative density lands just over water, at around 1.03 g/cm³. Don’t expect strong smells—its odor stays on the mild, amine-like side. It dissolves in water and most organic solvents, making it easy to mix into both aqueous and organic environments. This versatility comes directly from its structure: the methyl group on the nitrogen atom subtly shifts the electron cloud, lending both stability and a reactive edge. Its basicity measures up well, giving it an edge in acid-base chemistry without going overboard.

On the label, quality takes center stage. Reputable suppliers specify purity above 99%, with moisture levels measured down to fractions of a percent—these details matter for both consistency and safety. Labels also note flash points (73°C) and melting points (as low as -20°C). This information holds value well beyond the datasheet, protecting workers and equipment from unpleasant surprises. Long lists of impurities like imidazole or dimethylimidazole show up on quality control logs, further reflecting how much detail the industry tracks to ensure reliability, whether you need just a few grams or an entire tanker truck.

Large-scale preparation doesn’t involve magic tricks. Industrial chemists use N-methylation of imidazole, often choosing methyl iodide or dimethyl sulfate as methyl donors. By choosing precise ratios and monitoring reaction temperature, they can squeeze maximum yield out of the process while sidestepping side-reactions. Neutralization and solvent extraction steps clean things up before final distillation. A sharp eye keeps track of environmental impact—waste minimization, closed-loop solvent handling, and process improvements sit high on the list of priorities. These real-world practices serve as a reminder that modern chemistry operates under both regulatory and ethical spotlights, far from the freewheeling days of early synthesis labs.

In the lab, 1-methylimidazole stands out as a steady partner in catalysis, acylation, and alkylation reactions. Its methyl group keeps the molecule from digging into certain reactions at the N1 position, while leaving the rest of the ring open for action. This fine-tuning has paved the way for new ionic liquids, important in fields from electrochemistry to green solvent technology. In pharmaceuticals, the molecule lays the foundation for custom derivatives, helping researchers ready new candidates for the clinic. The interplay of electronic and steric influence from the methyl group carves out reaction paths unavailable to the parent imidazole—a small shift with big consequences.

Language holds power, and in the chemical market, synonyms tell their own story. You’ll see names like N-methylimidazole, 1-methyl-1H-imidazole, or simply MMI on technical bulletins. Catalogs sometimes list it under CAS 616-47-7. These aliases often pop up during supply deep-dives, compliance paperwork, or comparison shopping. Having worked through industrial procurement myself, cross-referencing synonyms can save days of delay and sidestep costly misorders, especially when suppliers use regional or legacy terms from earlier decades. The lesson here is that lingo isn’t just filler; it’s the bridge between global players trying to get the same job done.

Walk onto a plant floor or research lab where 1-methylimidazole is handled and you’ll see PPE, ventilation hoods, and emergency showers ready to go. While the liquid doesn’t explode on contact, splashes can cause skin and eye irritation, and breathing in vapors means trouble for your airways. Material Safety Data Sheets reference the need for chemical goggles, nitrile gloves, and work done away from open flames due to its moderate flash point. Spill response teams practice drills, and waste must head off to responsible incineration. With ever-tightening regulations, safety managers now factor in everything from chronic exposure studies to environmental release monitoring—realities driven by both science and strong enforcement.

Industries use 1-methylimidazole as more than a generic solvent. In epoxy resin production, it plays matchmaker, connecting resin and curing agent during hardening. Electronics manufacturers lean on it as a precursor for advanced functional materials in batteries and capacitors. Specialty pharmaceuticals build key side-chains using its structure. Environmental chemists test its use in green solvents, seeking replacements for more toxic materials. Having worked with product development teams in polymer science, I’ve seen first-hand how iterations on chemistry like this can tip the scales in performance, durability, or sustainability—real-world impact tied to seemingly tiny tweaks in base molecules.

Research labs invest time and grant money to investigate new uses and improvements for 1-methylimidazole. Scientists focus on ionic liquids, energy storage materials, and biocompatible compounds. Groups tune electronic properties by swapping out ring substituents, searching for new catalysts that operate efficiently and reduce environmental footprint. Having reviewed scientific proposals myself, the level of creativity shown in modifying this modest molecule surprises even seasoned chemists. Each round of R&D takes advantage of prior learning mixed with a readiness to follow obscure leads, all with hopes of hitting on the next blockbuster application or greening up industrial workflows.

Toxicologists continue to probe 1-methylimidazole, tracking acute and chronic effects, not just in workers but in the environment. Data collected over decades show that skin and eye contact present the greatest risk. Prolonged exposure at higher concentrations spells trouble for respiratory and nervous systems in animal studies. Waterway release remains another concern, as breakdown pathways and persistence get scrutinized under new regulatory guidelines. Ongoing work includes screening for endocrine disruption, gene toxicity, and even unforeseen long-term health impacts. Experience in environmental monitoring reminds me how vigilance never truly ends when fresh data always bring new questions or hint at a risk previously overlooked.

Opportunities for 1-methylimidazole look bright, but not without challenges. Demand from battery technology, pharmaceutical innovation, and sustainable chemistry continues to rise, pressed by renewable energy goals and stricter waste control laws. Efficient synthesis routes, greener reaction partners, and closed-loop manufacturing top everyone’s wish list. Legislative changes could shake up supply chains or open gaps for biobased alternatives. Collaborative efforts between universities, startups, and heavy industry often provide the spark for major shifts. If history in specialty chemicals teaches anything, it’s that even modest tweaks in molecules can fuel major leaps in technology and safety, assuming we keep our eyes open and brains engaged.

There’s no thrill quite like peeking into the world of chemistry and finding a compound that shows up in unexpected places. 1-Methylimidazole sounds like something only scientists whisper about, but this little molecule carries a lot of weight. In labs and factories, it holds a regular spot on the shelf, often pulling more than its fair share of the workload.

Start with solvents. I remember my first year working in a chemical plant, watching techs set up glassware and grabbing bottles labeled with long, odd names. 1-Methylimidazole stood out since it carried a punch—dissolving things stubborn to break apart in water or regular alcohols. This quality gives interns and old hands both a reliable shortcut, especially during challenging syntheses. You can’t underestimate a solvent that lets you side-step hours of trial-and-error.

Pharma makers keep coming back to this compound. When chemists need a building block for making active drug ingredients, they often rely on 1-Methylimidazole as a starting point or a helper that smooths the reaction. One study from the Journal of Medicinal Chemistry shows how sticking a methyl group on imidazole can nudge a reaction toward cleaner, faster results. Nobody likes a slow process, especially with pills that need strict timelines.

Polyurethane turns up in beds, car seats, sneakers—a big chunk of daily life. Factories rely on specific chemicals to glue the puzzle pieces together, and here comes 1-Methylimidazole again, nudging reactions without leaving behind a mess. I once chatted with a line supervisor who joked that things fell apart faster than a house of cards when his team ran low on this catalyst. That stuck with me because it showed how a single compound can underpin big manufacturing operations.

Cleaner air and water often hang on complicated chemical reactions. Environmental engineers sometimes turn to 1-Methylimidazole because it interacts well with metals in wastewater systems. Some facilities use it to help trap or separate dangerous ions before releasing water downstream. Success comes from clever chemistry and picking the right tools—of which this compound is one—though it’s not without controversy. Night-shift workers I know sometimes raise concerns about waste management and safe disposal, challenging everyone to find greener routes.

With such popularity come questions. What happens after dumping, spilling, or simply wearing out a batch of solvents containing 1-Methylimidazole? Regulators keep an eye on its toxicity and whether it lingers in the environment. The European Chemicals Agency lists potential risks, especially with skin contact and inhalation. For small labs, this means more gloves, more ventilation, and an honest conversation about costs. Responsible outfits try to reclaim and recycle whatever they can, not just for compliance, but because it makes business sense in the long run.

Innovation rarely travels in a straight line. Researchers are on the hunt for alternatives, ways to use this compound less, or reuse it better. Green chemistry movements encourage folks to rethink processes, looking for reactions that shave off waste and energy hits. Some startups use closed-loop systems where solvents—including ones like 1-Methylimidazole—get cleaned and run through cycles multiple times before going out with regular waste pickups.

I’ve worked with more chemicals than I can count over the years, but 1-methylimidazole always keeps me paying attention. It doesn’t smell harsh or look threatening, and in small amounts it can seem downright ordinary. That’s part of the danger. Breathing in the vapor or getting splashed can spark headaches, dizziness, or skin and eye irritation. Nasty stuff if it lands where it shouldn’t. Inhalation can make a healthy person cough and bring on sore eyes. If you work with higher doses or get it on your skin repeatedly, you’re looking at bigger problems down the road, like allergies or chronic health issues. The material safety data sheets highlight these risks for a reason.

Back in my student days, I figured gloves and goggles were mostly for other people. That bravado fades fast the first time something stings your finger or burns your sleeve. With 1-methylimidazole, full protection keeps you in the game. Donning nitrile gloves, chemical splash goggles, and a decent lab coat isn’t going overboard — it’s just self-preservation. A friend once skipped the eye protection, thinking a fume hood was enough. One irritated eye later, he never made that mistake again.

Some chemicals let you fudge the rules on airflow. This isn’t one of them. Open windows don’t manage vapor exposure like a proper fume hood will. I once tried a shortcut by mixing small amounts on an open bench, and the sharp, almost sour smell hung around for hours. Modern fume hoods suck vapors away before they drift to your face, cutting exposure to nearly zero. Installing carbon filters helps in tight spaces, especially for labs set up in older buildings.

Easy access sometimes tempts folks to store chemicals right next to where they’ll be used. 1-methylimidazole belongs behind closed doors in a cool, dry spot, far from acids and oxidizing agents. Once, I saw a bottle jammed between cleaning products under a sink; nobody read the label until after a small spill. Keeping a proper cabinet for these reagents avoids unexpected reactions and wild clean-up jobs. Labels matter, too. Write the opening date, and never trust fading ink.

Accidents don’t play along with schedules. Spills show up at the worst moments, often when someone’s in a hurry. Absorbents like sand or vermiculite should stay within reach, and disposable pads can mop up small puddles before they spread. I keep a spill kit ready, with neutralizers and heavy-duty gloves. After soaking up, everything goes in a sealed bag for hazardous pickup. Pouring leftovers down the drain isn’t just careless — it risks water contamination and hefty lab penalties.

Every safe lab has a rhythm. Regular safety drills, open chats about exposures, quick reminders before starting a new batch — these habits cut down on mistakes. It’s worth updating protocols whenever new info comes in. Folks share close calls at the weekly meeting, swapping advice on what works and what’s a waste of time. Taking safety seriously with 1-methylimidazole turns from a chore into second nature, and everybody walks out healthier at the end of the day.

For anyone dealing with chemicals like 1-Methylimidazole, purity holds more weight than a line on a datasheet. As a chemist with a decade spent juggling solvents, reagents, and all their quirks, I’ve learned you can’t take shortcuts with something so foundational. Pharmaceutical groups want nothing hiding in the bottle besides the labeled compound, especially when those trace impurities could end up as byproducts in the next synthesis step. At the bench, subpar purity can stall reactions, leave residues behind, and drive up costs with extra purification.

In most labs and pilot plants, the 1-Methylimidazole sold comes in at 99% or even 99.5% purity. That figure comes from actual analytical testing, often by GC or NMR. It's not just a company’s bragging point—this level supports everything from catalyst formation to serving as a corrosion inhibitor. If the product slips by with too much water, halides, or unknown peaks, you’re gambling with your whole process. Mistakes here show up later when reactions run sluggish, or worse, when someone needs to explain why the batch failed quality review.

Specifications for 1-Methylimidazole usually spell out its assay, water content, color, and common contaminants. Colors get measured using APHA, which helps catch many impurities without needing a fancy mass spectrometer. For water, you’ll see tight limits—Karl Fischer titration pulls the numbers so everyone knows the product won’t dilute someone’s moisture-sensitive process downstream. Density is often listed for those batching by volume, and the sheet usually covers the usual suspects—heavy metals, chlorides, and other imidazoles that shouldn’t sneak in during production.

Early in my career, a single missing line on a product sheet sent a polymerization entirely sideways. Sure, the drum said “over 99%,” but those few hundred ppm of water changed the mechanism. Ever since, I always look twice at every line of the specification. The team that draws up those sheets knows what’s at stake—the quality promise travels all the way through research, manufacturing, and final application.

In some corners of the world, vendors push out batches that read fine on a basic purity check but hide minor byproducts that only show up once the process ramps up. I’ve watched operators scramble to troubleshoot bottlenecks caused by “mystery” contaminants that standard quality testing missed. Industries relying on this building block—from resins to dyes—pay the price whenever a shipment skirts under-spec. Each poorly tracked impurity can cost time, waste thousands of dollars, or even require making a regulatory report.

Trust builds over time between technical buyers and their suppliers. Both sides get ahead when they prioritize transparency and full disclosure. Lot-to-lot certificates, full impurity breakdowns, and honesty about source of raw materials all shape a relationship built to last. Audits and external lab confirmations help weed out “good enough” batches before they reach a live process. From my side of the table, pressing for better specs hasn’t slowed my work—it’s saved dozens of projects from preventable headaches.

As new uses for 1-Methylimidazole emerge—think advanced polymers, electronics, and pharmaceuticals—the pressure only grows for the type of detail that goes beyond just “99%.” Reaction pathways today keep getting sensitive to the smallest contaminants. Open communication between supplier and user matters as much as the numbers themselves, and there’s no shortcut to insisting on clarity up front. You learn this not from a textbook, but from the frustration of cleaning up messy outcomes. Specs keep projects out of trouble and pay back in confidence when the next experiment needs to work the first time.

Ask anyone who’s spent enough time working with chemicals and they’ll tell you: slip up on storage and you’re begging for trouble. 1-Methylimidazole, with its strong, sometimes fishy smell and energetic reactions, leaves no room for mistakes. This isn’t just any office supply — chemical safety isn’t a place for shortcuts or “that’ll do for now.” Most labs I’ve worked in dedicate real effort to making sure anything with imidazole in the name stays in proper condition. It’s a story of respecting not just your own safety but also the guy who grabs the bottle after you.

Open a bottle of 1-Methylimidazole even once, and that stuff will suck up water from the air like a sponge. You might think a few drops of humidity can’t do much, but they change the game for purity and shelf-life. Water in the mixture can mess with results, especially for anyone who cares about steady chemical processes. In one busy shared storage room I used back in university, we left a bottle open for half an hour. Next week, every sample in that batch reeked — and purity levels tanked. After that, our department made tight-lid and desiccator storage non-negotiable.

Shelving it in a plain glass-front cabinet usually leads to disappointment. UV rays and room light turn 1-Methylimidazole yellow and compromise strength over time. Real-world safety guidelines call for amber glass containers, not just because they look good on the shelf, but because they filter out damaging wavelengths. I’ve walked into more than one supply room where someone’s skipped the amber container, and over a few months, you spot color shifts — you just know a batch is compromised before testing confirms it.

Polystyrene or polyethylene containers also don’t cut it with corrosive vapor. Stick with glass that seals well. Make sure the cap actually fits — there’s nothing worse than finding an old bottle smeared with crusty residue, knowing all sorts of fumes have snuck out for who-knows-how-long.

Big, sharp labels matter. I’ve seen disasters averted just because someone double-checked a date or hazard mark on a bottle during a midnight shift. Don’t lump it next to acids or oxidizing agents — that’s a messy risk with runoff reactions you really don’t want to clean up. Dedicated shelves for base-type organics keep life a lot simpler and safer, especially in communal spaces with shifting rosters.

Heat speeds up everything you don’t want to happen. 1-Methylimidazole does best between 15 and 25°C. Too hot, and you risk a cloud of vapor or a sudden reaction; too cold, and you might deal with awkward separation or solids forming inside the bottle. I’ve always preferred lockable fridge spaces for sensitive organics. This isn’t just about preserving product — it’s about keeping folks from panicking over weird smells or surprise leaks.

A smart storage routine doesn’t come from reading some guideline once and forgetting it. People who handle 1-Methylimidazole need refreshers on safety, regular checks, and clear rules about what goes where. Bringing up these procedures in staff meetings or onboarding means fewer screw-ups and calmer workplaces. Real organization in storage keeps the whole team—old hands and newcomers—out of the ER and focused on good work.

1-Methylimidazole pops up on chemical order forms almost everywhere labs and factories run. At a glance, the details look simple—just choose a container. To someone outside chemistry or industry circles, that might sound like grabbing a bottle of something off a grocery shelf. The reality is grittier and, truthfully, a lot more interesting. Packaging size does more than fill a shelf; it shapes budgets, workflow, safety, and even waste downstream.

Opening a product catalog from a supplier—Sigma-Aldrich, Thermo Fisher, or smaller regional outfits—gives a clear idea what sizes are on offer. Labs often rely on glass bottles holding 100 mL, 250 mL, and 500 mL for everyday tasks, allowing for quick open-and-use setups without much risk of contamination or spoilage. It’s not a secret in chemical supply: lower volumes give finer control and safety, take up less space, and make accidental spills less disastrous.

Bigger operations ordering for pilot or production lines lean toward larger packaging—2.5-liter glass bottles, 5-liter plastic jugs, and even 20-liter drums. Some industrial suppliers also provide custom fitments up to 200-liter drums, and tank trucks for really heavy use. These numbers mean something to people in the trenches. A five-liter jug is easy to carry and pour, doesn’t strain the arms on a busy bench, but a 20-liter drum makes sense only in a warehouse with spill trays and heavy gloves nearby.

Chemical storage laws, site safety rules, and your daily volume needs shape the decision. Each package size speaks to a different rhythm of work, too. In my early days handling solvents, the standard one-liter bottle ruled the shelves. Low waste, easy to track, and if something dropped and broke, the cleanup didn’t turn into a hazmat event. As research work scaled up, suddenly bigger jugs and metal cans arrived. Gone was the quick pour; now we hauled materials, checked expiration dates more seriously, and the risk of a leaking drum kept a few of us up at night.

Cost plays a big role, especially if you burn through lots of 1-Methylimidazole. Larger drums almost always bring the price per liter down. Small labs might balk at the upfront outlay or dislike tying up cash in inventory; bigger shops find collecting many small bottles wasteful, both in time and in the awkward piles of empty containers headed for disposal. I've seen both sides misjudge their needs more than once and wind up with excess product collecting dust, or, worse, scrambling to borrow from nearby labs on deadline.

Nobody loves running out unexpectedly. Instead of guessing, regular users can track how much gets used over a month or two, then match their actual needs with what the suppliers ship. It helps to ask suppliers about less common sizes—a good one can suggest intermediate options, not always advertised up front.

For anybody still new to handling this chemical, start with small packaging. It keeps the risk down, especially if you don’t use much or need time to dial in procedures. For high-volume or repetitive use, consider standardizing bulk orders—just make sure storage and safety gear are up to the job. I’ve watched lab managers save money not by ordering the biggest containers, but by running smarter reordering systems and reducing leftovers.

So, while 1-Methylimidazole arrives in sizes big and small, the right size and packaging always comes down to how you work and how you protect your team and your bottom line.

| Names | |

| Preferred IUPAC name | 1-Methyl-1H-imidazole |

| Other names |

N-Methylimidazole 1-Methyl-1H-imidazole Methyleniminazole 1H-Imidazole, 1-methyl- |

| Pronunciation | /waɪˌmɛθ.əl.ɪˈmɪd.əˌzoʊl/ |

| Identifiers | |

| CAS Number | 616-47-7 |

| Beilstein Reference | Beilstein Reference: 107100 |

| ChEBI | CHEBI:17415 |

| ChEMBL | CHEMBL50489 |

| ChemSpider | 6531 |

| DrugBank | DB02025 |

| ECHA InfoCard | 03d2ea093c0002 |

| EC Number | 214-671-3 |

| Gmelin Reference | 604753 |

| KEGG | C06222 |

| MeSH | D000432 |

| PubChem CID | 7000 |

| RTECS number | MF3325000 |

| UNII | G59M7S0WS3 |

| UN number | UN2206 |

| Properties | |

| Chemical formula | C4H6N2 |

| Molar mass | 82.11 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | amine-like |

| Density | 0.999 g/mL |

| Solubility in water | miscible |

| log P | 0.02 |

| Vapor pressure | 0.55 mmHg (25 °C) |

| Acidity (pKa) | 7.1 |

| Basicity (pKb) | 6.99 |

| Magnetic susceptibility (χ) | -46.5·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.488 |

| Viscosity | 2.02 mPa·s (25 °C) |

| Dipole moment | 3.67 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 192.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -23.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3667.8 kJ/mol |

| Hazards | |

| GHS labelling | GHS02,GHS05,GHS07 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H314 |

| Precautionary statements | P264, P280, P301+P312, P305+P351+P338, P337+P313, P330 |

| NFPA 704 (fire diamond) | 1-2-0-ALK |

| Flash point | 52 °C |

| Autoignition temperature | 470 °C |

| Explosive limits | 1.6–12% |

| Lethal dose or concentration | LD50 oral rat 1300 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 = 950 mg/kg |

| NIOSH | NIOSH: NS1750000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for 1-Methylimidazole: "no OSHA PEL established |

| REL (Recommended) | 1 ppm |

| IDLH (Immediate danger) | 900 ppm |

| Related compounds | |

| Related compounds |

Imidazole 2-Methylimidazole 4-Methylimidazole Ethylimidazole |