The story of 1-Methyl-4-Piperidinemethanol traces back to the mid-twentieth century, an era where research appetite for nitrogen-containing heterocycles exploded across Europe and North America. Scientists hunting for stable backbone structures for pharmaceuticals started probing piperidine derivatives in search of fine-tuned neuroactive compounds. As synthetic routes matured, obtaining 1-Methyl-4-Piperidinemethanol moved from rarefied organic labs into broader chemical manufacturing. The availability of building-blocks like methylpiperidine alcohols allowed medicinal chemists to develop targeted therapies for everything from analgesics to anti-Parkinson agents. My own early forays into medicinal chemistry work included screening similar piperidine analogs, and the nuanced effects of methyl substitution played a major role in early-stage compound optimization. Even now, it feels like each step forward for a compound builds upon layers of trial, error, and creative guesswork laid down by earlier generations.

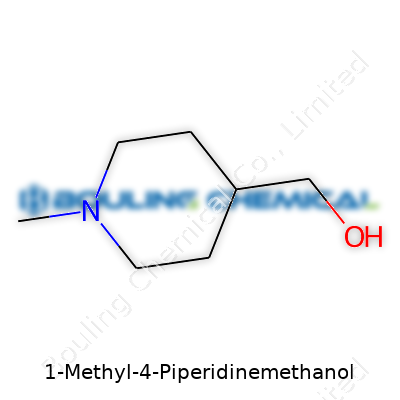

1-Methyl-4-Piperidinemethanol stands as a versatile nitrogen heterocycle with a secondary alcohol group anchored at the fourth carbon, and a methyl side chain at the nitrogen. That substitution pattern attracts those searching for improved solubility profiles or a tweak on base pharmacodynamics in drug design. As I’ve seen in the lab, this structure provides enough chemical handles for diverse derivatizations, which makes it a linchpin for intermediate production in both small-molecule drug and fine chemical syntheses. While big pharma keeps these building blocks under wraps in proprietary analogs, several agrochemical and specialty chemical players also leverage this scaffold in backend syntheses.

This compound usually presents as a colorless to pale yellow liquid at ambient conditions, although purity and trace moisture play spoilsport with physical appearance. Its molecular formula is C7H15NO, clocking a molecular weight around 129.2 g/mol. Solubility in standard organic solvents is broad, thanks to both the heterocyclic core and the hydroxyl arm—making it a good fit for reaction planning across polar and nonpolar conditions. Boiling point creeps toward 222–224°C, which I have found can require careful temperature control during reaction workups. The light basicity conferred by the piperidine ring, alongside the hydrophilicity from the alcohol moiety, gives this molecule an interesting duality: it's reactive but rarely volatile, prized for use where non-reactiveness with air is wanted.

Reliable suppliers define technical specifications covering purity (frequently ≥98%), water content (max 0.5%), and trace impurities logged by GC-MS or NMR. From my practical experience, a good batch comes with a sharp NMR, showing singlet methyl protons and a clear multiplet for the methylene protons next to the alcohol. Labels always detail batch number, storage instructions—usually cool, dry, away from oxidizers—and hazard pictograms warning about skin and eye sensitization. Anything less detailed, and I start asking questions about provenance and quality assurance. Producers typically highlight shelf life and recommend using within two years under recommended conditions.

Typical syntheses use methylation of 4-piperidinemethanol, often in a two-step sequence: first forming N-methylpiperidine by methyl halide alkylation under basic conditions, then introducing the hydroxymethyl group via reaction with formaldehyde. For those with a mind for green chemistry, catalytic hydrogenation starting from pyridine derivatives, followed by selective nucleophilic addition to build the alcohol, provides another viable approach. I've seen teams use both batch and flow setups depending on throughput demand—continuous processing being favored in commercial scenarios due to better control over exotherms and reduced impurity build-up. No matter the chosen path, success hinges on tight reaction monitoring, usually HPLC or TLC, to avoid overalkylation or ring-opening byproducts that can compromise downstream applications.

One remarkable feature lies in the alcohol functionality, which can be esterified or oxidized for extension into other chemical classes. I've witnessed colleagues exploit the secondary alcohol for mesylation or tosylation, prepping the compound for substitution or elimination reactions. The piperidine ring itself supports a host of transformations: acylation, reductive amination, and halogenation all pop up in the patent literature. Medicinal chemists regularly build combinatorial libraries by modifying the methyl group at the nitrogen—swapping with bulkier alkyls or introducing electron-donating groups in a bid to tweak target affinity or metabolic stability. The versatility of this molecule as a precursor for alkaloids or as a scaffold in CNS-targeted drugs underscores its workhorse reputation.

This compound wears many labels in scientific catalogs and product lists. Common synonyms include N-Methyl-4-piperidinemethanol, 1-Methylpiperidin-4-ylmethanol, and 4-Hydroxymethyl-1-methylpiperidine. In different patent filings and distributor inventories, I've seen it sold under shorthand codes or even as part of proprietary blend names, complicating literature searches until you narrow down to structure-based queries. R&D teams typically keep a mental log of these alternate names—more than once, I've found that catching every synonym in a patent search uncovers overlooked competitors or opportunities.

Like many piperidine compounds, 1-Methyl-4-Piperidinemethanol comes with its hazards. Contact irritates eyes and skin, and inhalation can provoke respiratory discomfort—something I've learned firsthand during a rushed weighing session. Labs and plants set up glove-box transfers or local exhaust ventilation around bench operations. Clean-up protocols lean on plenty of water and citrate buffer rinses. For large-scale handling, safety data sheets direct full-face shields, nitrile gloves, and chemical-resistant aprons. Disposal routes comply with regional hazardous waste rules, often routing through solvent incineration or alkaline hydrolysis before landfill. Regulatory compliance stays front-and-center, tuned for both occupational health and local emissions controls.

The broad utility of 1-Methyl-4-Piperidinemethanol means it crops up across pharmaceuticals, agrochemicals, and fine chemicals. Drug developers build on this framework when scaffolding compounds with blood-brain barrier permeability, neuroactivity, or metabolic tweakability. Several antipsychotics and dopaminergic drugs stem from similar piperidine systems. Agrochemists use the molecule as an intermediate in pesticide and herbicide synthesis, often as a linker or blocking group. Specialty chemical manufacturers keep 1-Methyl-4-Piperidinemethanol handy for surfactant and curing agent production. Speaking from experience, its adaptability means the compound rarely gathers dust on the shelf—someone is always angling to use it in a new process or formulation.

Research trends focus on leveraging the structure for novel CNS-active agents, anti-infectives, and new classes of pain modulators. Teams increasingly apply computational chemistry to model receptor interactions with modified piperidine analogs. My own projects have occasionally dabbled in derivatizing the alcohol group for improved oral bioavailability, a persistent challenge in neuropharmaceutical design. Collaboration between academic and industry labs speeds up innovation, especially as open-access databases share reaction results and biological data. Analytical scientists continue to chase after trace impurities and develop more sensitive LC-MS assays, critical for meeting new regulatory requirements. Each year, journals publish more papers examining the pharmacokinetics and metabolic breakdown of methylated piperidines.

Evidence points to relatively low acute toxicity in animal studies, but repeated dose studies document mild hepatotoxicity at high concentration. The molecule’s close relatives have shown neuroexcitatory activity at supratherapeutic doses, meaning that development programs keep a close eye on CNS side effects. My old lab ran cytotoxicity screens in cell lines, showing that concentrations above 100 micromolar begin to impair mitochondrial function. In vivo assays remain crucial for better understanding chronic effects, especially since so many downstream compounds aim at human therapy. Regulatory agencies increasingly demand detailed metabolite profiling, pressing chemists to consider safety earlier in the pipeline.

The coming years promise fresh applications as precision medicine expands. Advances in ring synthesis and sustainable catalysis aim to cut waste and lower costs, making 1-Methyl-4-Piperidinemethanol more accessible even to small- and medium-sized enterprises. Machine learning speeds up analog design, so expect more rapid iterations in both pharma and agrochemical pipelines. Regulatory scrutiny intensifies, pushing manufacturers to refine safety profiles and supply chain transparency. With tighter controls and deeper digital datasets, the journey continues for this useful building block—charting a path intertwined with both scientific progress and practical innovation across chemistry-driven industries.

I first heard about 1-Methyl-4-Piperidinemethanol while working on a pharmaceutical research project. This compound doesn't show up in most mainstream conversations, but it plays a big behind-the-scenes part in several scientific fields. One area that gets overlooked is the work it does in drug synthesis. Chemists use this compound as an intermediate when building more complex molecules, especially within the pharmaceutical industry.

Drug discovery can be slow, expensive, and imprecise without reliable building blocks. Here’s where 1-Methyl-4-Piperidinemethanol shines. Chemists favor it because the piperidine ring structure helps create drugs with central nervous system activity. Think about pain management or certain antidepressant medications. The molecule’s extra methyl and hydroxymethyl groups let scientists tweak properties like solubility and how the body absorbs the final drug.

I’ve seen research labs use it to develop antihistamines, antipsychotics, and muscle relaxants. The chemical’s structure makes it easy to connect with other molecular fragments, setting the foundation for new treatments. Its presence doesn’t guarantee a blockbuster medicine, but it gives researchers more options. Sometimes, a tweak in molecular design offers fewer side effects. Sometimes, it helps the drug last longer in the bloodstream.

Beyond drug making, production facilities rely on 1-Methyl-4-Piperidinemethanol to create specialty chemicals. Some industries build complex polymers and resins starting with a molecule like this. You won’t see the name on a paint can or a cleaning product, but the trace remains in strengthening agents or coatings that need extra durability or chemical resistance.

People working with 1-Methyl-4-Piperidinemethanol should take safety seriously. Chemical suppliers publish safety data sheets for this compound, flagging possible hazards like irritation or toxicity if mishandled. I’ve found that proper lab procedures and personal protective equipment make a vital difference. Regulators and industry leaders stress responsible management, tracking the chemical’s use and making sure waste gets disposed of according to strict environmental rules.

The growth in designer drugs and synthetic chemicals raises red flags. Some compounds built from piperidine-based intermediates appear in illegal drugs, which creates pressure on authorities and labs. Honest researchers and businesses know they have to document chemical flows carefully and cooperate with regulators. Building partnerships with trusted suppliers and conducting thorough employee training can help keep chemicals like this out of the wrong hands.

Not every question about a specialty compound gets a straightforward answer because real-world practice varies by country and application. Open discussions with experts and good access to clear information help everyone use these tools thoughtfully. Improved transparency in chemical sourcing and better tracking technology could reduce risks. Real progress depends on a blend of innovation, vigilance, and integrity, much like in any field where small parts create something much larger.

Years of guiding chemistry students through tricky organic structures have taught me the value of breaking big names into manageable pieces. Take 1-Methyl-4-Piperidinemethanol. The name might sound intimidating, but its formula—C7H15NO—reveals a lot once you understand the building blocks. You’ve got a piperidine ring at the core, methyl stuck to the first carbon, and a -CH2OH alcohol group at the fourth position. One nitrogen, seven carbons, fifteen hydrogens, and a single oxygen. It’s all about putting those puzzle pieces together and really seeing how structure determines potential uses or risks.

The right formula helps researchers, pharmacists, and industrial scientists avoid costly mistakes or safety blunders. The difference between an alcohol group and an ether or an amine changes the game chemically—think of it as swapping a wrench for a hammer. In my own work consulting with pharmaceutical startups, we’ve had meetings derailed by someone confusing a piperidine variant for a similarly named tetrahydropyridine. These kinds of details can decide whether a synthesis goes smoothly or if the factory has to pause for recalibration and safety checks.

Mislabeling or guessing on chemical IDs isn’t just an academic concern. A wrong chemical formula can lead to lab accidents or ineffective products on the pharmacy shelf. The pharmaceutical world depends on tight accuracy, since subtle shifts in formula produce different properties—solubility, reactivity, possible side effects—that impact finished drugs. Years ago, after a close call with a steroid contamination concern, I made it practice to get every formula double-checked, even if it looked straightforward.

Plenty of databases and peer-reviewed resources exist for chemical lookups, but people still misread or mis-copy names. Sometimes a typo finds its way into shipping records and labs end up with the wrong ingredients. I’ve seen a lot of value in cross-referencing notations, checking both IUPAC names, structural diagrams, and molecular formulas rather than relying on a single source. This habit comes from a hard-earned understanding that factual redundancy, in chemistry, keeps workplaces safer.

Over time, I’ve become a big advocate for better software tools in chemical management. Automated verification tools can catch many naming inconsistencies or formula errors before a shipment leaves the supplier. Educational initiatives at the university level could focus not just on drawing molecules, but on spotting errors and understanding the why behind structure-to-formula translation. Real world problems disappear faster when students and workers pay close attention to these details.

A correct formula like C7H15NO isn’t just for the textbook—it’s a backbone for quality assurance, scientific discovery, and workplace safety. People working with these compounds deserve software, training, and culture that supports accuracy at every step. By investing in these parts of the broader research and production ecosystem, we cut down on preventable mistakes and, ultimately, make safer medicines and processes for everyone.

1-Methyl-4-Piperidinemethanol. Not exactly a name that rolls off the tongue, and for most people outside of chemistry labs, the name doesn’t ring any bells. For anyone involved in chemical manufacturing, pharmaceutical labs, or even advanced research, compounds like this pop up more than you might hope. And with every confusing chemical string comes the question: is this stuff safe?

No need to make this more complicated than it is. This compound, like many organic chemicals, calls for some careful handling. Safety data shows that 1-Methyl-4-Piperidinemethanol can irritate skin and eyes on contact and could cause harm if swallowed or inhaled. There’s usually a warning about avoiding direct exposure—think gloves, goggles, and good ventilation. Cases of more serious harm typically involve accidents and the kind of exposure that comes with failing to follow basic safety steps. I’ve worked in a research setting where this class of compounds was stored in sealed glass bottles, always locked away from where people eat or drink—those habits saved a lot of trouble.

Toxicity information tends to stay pretty technical. Acute oral toxicity for this molecule gets categorized as moderate for mammals. Accidental spills or splashes can land someone in the nurse’s office, and the safety sheet will often recommend flushing eyes or skin with water if exposure happens. I’ve known lab mates who let their guard down, thinking a little exposure wouldn’t matter. They spent the day dealing with burning sensations and regretted not being more careful.

Industrial and scientific settings both depend on chemicals like this one to fuel new breakthroughs. But as more research has shown over the years, not every risk is obvious up front. Low-level, long-term exposure elevates health risks, from headaches and respiratory irritation to possible effects on the liver or nervous system. Some solvents and chemical intermediates in this structural family have a record of delayed effects. This chemical hasn’t landed on any major international “banned substances” lists so far, and that usually means regulators have found only moderate hazards, at least with normal, controlled industrial use. But “moderate” doesn’t mean “harmless.”

Labs set strict rules for a reason: spills and lapses pile up over days and months. Good ventilation and personal protective gear aren’t negotiable. I remember a manager pushing for proper labeling and double containment. It started as a hassle, but after an accidental knock knocked a bottle onto the counter, that extra step made the cleanup as simple as tossing out a sealed outer bag. Still, rules aren't enough when management acts as if “more rules” equals “more safety.” It’s engagement that matters—people need refreshers, reminders, even stories about what can go wrong.

This isn’t about demonizing chemicals. It's about building better habits. Workplace training ought to focus on the realities of daily exposure, not just rare, catastrophic events. Companies and universities could invest a bit more in hazard communication—plain-language safety posters and regular hands-on practice. Manufacturers should keep updating safety documentation, especially as new research fills in the gaps. Bringing in engineers to improve ventilation, providing spill kits, and making sure first aid gear stays stocked can’t be the exception. All those measures make the difference between a routine day in the lab and a costly emergency.

For anyone working around 1-Methyl-4-Piperidinemethanol, respect the hazards, don’t cut corners, and help coworkers do the same. Safety starts with good habits, clear information, and honest conversations about risk.

Every chemical tells its own story. In my work with laboratory chemicals, storage mistakes sometimes snowball into bigger problems. 1-Methyl-4-Piperidinemethanol doesn’t sound like a compound you’d handle casually, and that holds up in real-world practice. Its structural features give it reactivity that deserves respect. In a lab, even small lapses—such as ignoring a loose cap or stacking bottles too close to a heat source—can trigger safety incidents or degrade purity. This risk goes far beyond lab benches; improper storage affects manufacturers, shippers, and end-users who all rely on product consistency and safety.

Temperature and light control keep this chemical stable. The industry-standard advice is cool, dry conditions, away from direct sunlight. I’ve learned firsthand that chemicals tucked too near a sunny window or in a steamy storeroom age faster than colleagues kept in the shade. With 1-Methyl-4-Piperidinemethanol, oxidation or decomposition can become a real headache, prompting both safety hazards and loss of valuable material. Simple thermometers have helped me catch temperature drifts in storage areas, and even a slight swing in humidity led to labels peeling and accidental mixing during a past project.

Ventilation is non-negotiable. Odorous vapors or traces can linger even in closed areas. I’ve seen under-ventilated storage closets become hotspots for surprise reactions or breathing discomfort. Whenever I talk with team members or students, I stress that a chemical safe room without an exhaust fan is a recipe for future regret. Installing a monitoring device changes the game, logging the air quality so there’s a digital record—not just a gut feeling whether the room smells "off."

Chemicals with a hydroxyl group, such as 1-Methyl-4-Piperidinemethanol, demand containers that resist corrosion or slow leaching. In my work, glass bottles with tight-fitting caps give peace of mind, though certain high-grade plastics hold up too. I still remember responding to a report about a solution seeping through a cheap plastic carboy. Cleaning it ate up half a day. Labels matter a lot more often than people realize—blurry lettering or missing hazard information lead to confusion and costly mistakes. Permanent markers and chemical-resistant labels aren’t just good practice; they’re the simplest insurance policy in a crowded stock room.

Over the years, keeping a log of chemical batches and storage locations cut my stress tremendously. Whenever an audit or safety review came up, I found that simple spreadsheets documenting batch numbers, shelf life, and handling notes kept everyone in sync and compliance officers happy. This approach saved money by pointing out expired stock before someone grabbed the wrong bottle for a synthesis. Regulatory guidance from organizations like OSHA and the European Chemicals Agency exists for a reason; following their advice on segregation and periodic checks isn’t about box-ticking but about going home at the end of a shift without surprises.

Too many accidents come from storing incompatible substances together. Mixing 1-Methyl-4-Piperidinemethanol near oxidizers, acids, or reactive metals invites unplanned reactions. Storing it separately—whether on another shelf or inside a labeled, locked cabinet—counts as basic diligence. Making chemical inventories digital makes segregation easier to track, keeping the whole team updated as contents shift.

Unexpected spills or breakage can’t always be avoided, but planning helps. Absorbent mats, spill kits, and PPE within arm’s reach make all the difference. Training new team members to spot risk and organize storage by hazard class pays off. I’ve seen accidents drop when companies treat chemical storage as a team issue, not just an individual’s problem.

Respect for storage best practices grows from lived experience—the best safeguard for 1-Methyl-4-Piperidinemethanol remains a culture of attention and responsibility, backed by solid documentation, proper containers, and plenty of common sense.

There’s always a lot of talk around chemical purity, especially among those who actually handle or order chemicals every day. In the case of 1-Methyl-4-Piperidinemethanol, asking about purity isn’t just splitting hairs. The way chemists, manufacturers, and researchers work with this compound depends heavily on what’s in the bottle––or more to the point, what isn't. The difference between a sample that’s 95% pure and one that’s certified at 99% can decide whether a project runs smooth or gets sidelined by contamination.

Out there in the real world, suppliers commonly offer 1-Methyl-4-Piperidinemethanol in several grades, with purity levels that range from technical grade (hovering around 90–95%) up to higher purities, such as 98%, 99%, or even higher. Reagent grade and analytical grade set the bar the highest, often above 99%. Labs using this compound for research, pharmaceutical formulations, or specialized synthesis usually insist on analytical or reagent grade, often bundled with a certificate of analysis (COA) to prove it actually holds up under scrutiny.

For someone working in the chemical industry, the COA means more than numbers on a label. It spells out details about water content, residue on ignition, and any trace solvent left behind after synthesis. Even tiny differences matter. For instance, trace metal or residual solvents throw off reactions or sully test data.

I remember a project where one batch of 1-Methyl-4-Piperidinemethanol came in at 96.5%, while another was certified at 99.3%. The difference felt obvious during synthesis. The lower grade had trace organics not listed on the spec sheet, enough to create side reactions and muddy up product yields. Clean-up steps dragged longer, and the project’s timeline went right out the window. Teams relying on this compound in medicinal chemistry face steep losses if purity slips, so they learn quickly to check each lot, and not just the brand.

Downstream, impurities risk triggering safety issues in pharmaceuticals, or creating regulatory headaches. Regulators like the FDA or EMA need strict proof of chemical purity, and the paperwork behind each batch must stand up to audit. Nobody wants to face a recall or safety investigation because of a tainted reagent, especially when the fix is as simple as picking the right grade.

Sourcing high-purity 1-Methyl-4-Piperidinemethanol demands more than price shopping. Not all suppliers offer transparency about possible contaminants. It takes trusted relationships with vendors, access to batch-testing reports, and an understanding of where to draw the line between “good enough” and “spectacularly reliable.” A good supplier won’t just share a COA—they’ll answer questions about their purification steps and storage practices, and they won’t hesitate to pull a batch that doesn’t meet the claimed spec.

For buyers navigating a crowded chemical market, I always suggest contacting established, accredited distributors or manufacturers who routinely work under strict ISO or GMP standards. Ask specific questions about purity, impurity profiles, and batch variability. By keeping communication open and documentation thorough, both sides avoid surprises.

No amount of wishful thinking replaces hands-on verification. It’s standard in well-run labs to check the COA, run a quick analysis such as HPLC or NMR on a new batch, and compare results against the paperwork. If each step tightens confidence, projects run smoother, and everyone sleeps better at night, knowing what's in the flask truly matches expectations.

So, the story boils down to vigilance. When you know what grade you need—and you work with people who take purity as seriously as you do—there’s no need to cross your fingers whenever a new bottle shows up on the bench.

| Names | |

| Preferred IUPAC name | (4-Methylpiperidin-1-yl)methanol |

| Other names |

(1-Methylpiperidin-4-yl)methanol 1-Methyl-4-(hydroxymethyl)piperidine 4-(Hydroxymethyl)-1-methylpiperidine |

| Pronunciation | /waɪˈmɛθɪl fɔːr paɪˌpɪrɪˌdiːnmɛθəˌnɒl/ |

| Identifiers | |

| CAS Number | # 6457-49-4 |

| Beilstein Reference | 1105480 |

| ChEBI | CHEBI:34611 |

| ChEMBL | CHEMBL15618 |

| ChemSpider | 98610 |

| DrugBank | DB08317 |

| ECHA InfoCard | 03c12e69-2397-4689-87dc-2702fd36b821 |

| EC Number | 223-457-0 |

| Gmelin Reference | 130435 |

| KEGG | C19597 |

| MeSH | D010871 |

| PubChem CID | 104236 |

| RTECS number | TK3150000 |

| UNII | 8H3JP0C5LU |

| UN number | UN2810 |

| CompTox Dashboard (EPA) | DTXSID70866118 |

| Properties | |

| Chemical formula | C7H15NO |

| Molar mass | 157.24 g/mol |

| Appearance | Colorless to light yellow liquid |

| Odor | Amine-like |

| Density | 0.97 g/cm³ |

| Solubility in water | slightly soluble |

| log P | 0.34 |

| Vapor pressure | 0.03 mmHg (25°C) |

| Acidity (pKa) | pKa = 10.37 |

| Basicity (pKb) | 5.94 |

| Magnetic susceptibility (χ) | -63.13·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.462 |

| Viscosity | 30 cP (25°C) |

| Dipole moment | 2.15 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 296.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -331.9 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -5287.6 kJ/mol |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. May cause respiratory irritation. |

| GHS labelling | GHS05, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H315, H319, H335 |

| Precautionary statements | P264, P280, P302+P352, P305+P351+P338, P310 |

| NFPA 704 (fire diamond) | '1-1-0' |

| Flash point | 87°C |

| Autoignition temperature | 290 °C |

| Explosive limits | Lower: 1% Upper: 9.7% |

| Lethal dose or concentration | LD50 oral rat 1530 mg/kg |

| LD50 (median dose) | LD50 (median dose): 940 mg/kg (rat, oral) |

| NIOSH | WI5880000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for 1-Methyl-4-Piperidinemethanol: Not established |

| REL (Recommended) | Not established |

| Related compounds | |

| Related compounds |

Piperidine 4-Piperidinemethanol 1-Methylpiperidine N-Methylpiperidine N-Methyl-4-piperidone 4-Piperidone 1-Methylpiperidin-4-one N-Methylpiperidinol |