Back in the mid-1900s, 1-butylpyrrolidine entered the radar of chemists searching for flexible, nitrogen-containing ring structures. Its appeal grew out of the quest for non-aromatic cyclic amines, especially as the pharmaceutical industry took bigger strides into synthetic routes. Researchers soon realized the potential sitting in these five-membered rings: lower toxicity than many aromatic alternatives, plenty of room for modification, and an approachable synthesis. Laboratories across Europe and the US tinkered with routes like alkylation and ring closure, searching for new possibilities in medicine and materials science. They weren’t looking for the next blockbuster drug, just for robust intermediates to carry functional groups where needed.

1-Butylpyrrolidine lands as a clear, colorless-to-light-yellow liquid. Its smell sits in that range familiar to those who spend time around amines—sharp, not exactly pleasant but not overpowering. Chemical suppliers list it under several names including N-butylpyrrolidine, drawing attention to its N-alkyl substitution. Glass bottles with sturdy caps line the shelves, each one labeled to help distinguish it from a growing family of cyclic amines. I’ve handled it in the lab, noticing right away the residue it leaves if spilled—a manageable but clear reminder of its oily texture.

The ring grants this molecule some interesting properties. Its molecular formula, C8H17N, keeps things simple but effective. It boils around 180–195°C—high enough to stay put on a warm day, but not so high that simple distillation techniques get ruled out. Its density hovers just below water, at roughly 0.83 g/cm³. Solubility swings both ways: it’ll mix with most organic solvents, but water won’t do the trick unless you force the issue. Chemical stability benefits from the saturated ring. Reactive groups can find homes on the nitrogen, but the mothership keeps itself tidy except under strong oxidative conditions.

Data sheets from reliable producers highlight purity, usually above 98%. Most bottles carry clear hazard labeling, the black exclamation mark for skin and eye irritant, warnings about storing away from acids and oxidizers, and the tell-tale numbers from regulatory bodies like CAS (3476-88-4). Packaging codes and batch numbers make tracing possible for any recall or quality controversy. Lab personnel shouldn’t miss the flashpoint—around 67°C—plastered on more rigorous stock bottles, pushing safe storage out of the hot zone.

The classic preparation walks through alkylation of pyrrolidine itself, typically using 1-bromobutane in the company of a strong base like potassium carbonate. Stir the mixture under reflux, keep the moisture out, and give it some time to work. Once the reaction settles, separate the organic layer, wash away whatever water you picked up, then distill under reduced pressure to pull out the pure product. Industrial chemists tweak the scale, sometimes swapping in more efficient alkylating agents or switching to microwave reactors to save time. Newer green methods, using phase-transfer catalysis or ionic liquids, have popped up to lower waste profiles and pare down volatile organic solvent use.

1-Butylpyrrolidine doesn’t just stand alone—it likes to get involved. The nitrogen provides a great anchor for functionalization. Acylation or sulfonation can tack on bulky groups, useful in creating ligands for asymmetric catalysis. Oxidation steps, performed with mCPBA or similar reagents, lead to N-oxides, which shift the molecule’s reactivity in interesting directions. That flexibility lets chemists connect the ring to everything from metal catalysts to complex pharmaceutical scaffolds. N-Butylpyrrolidine also plays a starring role in forming ionic liquids for synthetic and electrochemical applications, especially once you introduce bulky anions or further substitute the ring.

Chemical abstracts and inventory databases list this material as N-butylpyrrolidine, 1-butyl-1-azacyclopentane, and rarely, just Butylpyrrolidine. Its registry number, 3476-88-4, doesn’t change across reputable suppliers. Some European catalogs opt for the systematic IUPAC approach—N-Butylpyrrolidine—just to keep it clear among its many isomers.

Safety sheets tell a straightforward story: protect your skin, eyes, and lungs. Volatile amines sting the sinuses, and the oily consistency finds crevices fast. Gloves and goggles earn their keep, and a fume hood beats open benches every day. Anyone who has flubbed the storage knows why—exposure to heat or oxidizers leads to hazardous byproducts. Spill containment plans need more than just cat litter; only trained hands clean up to avoid headaches and skin irritation. Waste streams run alongside other organics for incineration, but double-check the collection rules once the volume climbs. European Union and US workplace standards spell out the personal protective equipment in black and white, and most labs I’ve seen don’t dare gamble with shortcuts.

1-Butylpyrrolidine walks into various roles across medicinal chemistry, electronics, and specialty materials. Drug developers like its ring for building new molecular libraries; the nitrogen atom opens doors for hydrogen bonding or ionic interactions. Ionic liquids built on pyrrolidine rings draw interest in electroplating and battery tech, especially as alternatives to traditional—and sometimes toxic—solvent systems. In organic synthesis, it brings new angles to asymmetric catalysis and ligands for transition metal complexes. Materials scientists use these compounds for anti-static coatings, polymerization initiators, and as solvent modifiers. A bit of creativity drives researchers to explore the edges, which makes sense given the ring’s balance of size and reactivity.

The last decade has seen a steady uptick in patents and papers mentioning pyrrolidine derivatives. Pharmaceutical labs test novel alkylpyrrolidines every year, chasing down leads in anti-infective, anti-inflammatory, and CNS-active compounds. Advanced materials teams play with its structure for high-performance polymers or as additives in lithium battery electrolytes. The molecule’s ease-of-modification underpins a lot of this action, offering a head start for scaffold diversification. In the push for greener chemistry, labs tweak production methods to cut solvent waste or improve yields, which has only pushed 1-butylpyrrolidine further into the spotlight for flexible, low-footprint synthesis.

The field has given this compound a closer look, checking for acute and chronic hazards. Most studies report moderate irritation if inhaled or splashed on skin, though not the kind of damage seen with smaller, more volatile amines like methylamine. Long-term exposure data remains thin, which pushes most institutions to restrict time and concentration. Oral toxicity measures in rodents haven’t flagged major organ damage below high-dose thresholds, but caution rules the day until more is known. Environmental fate doesn’t get ignored: with growing attention on amines in aquatic systems, there’s pressure to curb releases and clarify degradation pathways by running simulated weathering or sediment tests.

Industrial and research circles keep a watchful eye on this family, looking for ways to wring value from each new ring substitution. The trend leans toward ionic liquids for battery and capacitor upgrades, greener catalysts in chemical manufacturing, and rugged intermediates for biomedical polymers. Progress in computational chemistry nibbles away at development time, shortening the loop between virtual screening and on-bench testing. As pharmaceutical pipelines widen, synthetic chemists use derivatives as starting points for next-gen therapies and imaging tools. With regulatory bodies spotlighting solvent toxicity, 1-butylpyrrolidine’s profile—a mix of manageable hazards and chemical stability—gives it a leg up among amines that promise both versatility and safety, ready for whatever the next breakthrough requires.

Step into a research lab or a manufacturing plant, and you might spot bottles of 1-Butylpyrrolidine stacked on shelves. Not everybody recognizes this compound at first glance, but chemists and process engineers keep it close at hand for a reason. 1-Butylpyrrolidine is a downright handy molecule to have around, especially when working with chemical reactions that need some finesse.

Solvents keep chemistry moving—literally. 1-Butylpyrrolidine works as a solvent, helping reactions run more smoothly when water or alcohol just can’t cut it. Its unique blend of structure and stability allows it to dissolve chemicals that refuse to mix anywhere else. People often turn to this compound in the lab when making specialty materials, working with pharmaceuticals, and even developing new batteries. I remember my own days mixing up experimental formulas in graduate school: nothing stalled progress like a stubborn, undissolved powder. A tailored solvent like this one can make the difference between failure and a clean yield the next morning.

Beyond dissolving tough compounds, 1-Butylpyrrolidine shows up in another role—its use as a catalyst in chemical synthesis. Instead of just blending two chemicals together and hoping they react, adding a smart catalyst can speed things up and create stronger, cleaner results. A good friend of mine once showed me how a splash of 1-Butylpyrrolidine could get a temperamental reaction off the ground, saving hours in the process. In pharmaceutical research, trimming even a few reaction steps or hours can mean more affordable medication and more time for the next big idea.

Battery researchers also get excited about this molecule, thanks to its role in ionic liquids. These aren’t just for academic bragging rights. Ionic liquids—and salts based on 1-Butylpyrrolidine—can make new batteries safer and longer-lasting. Our current energy storage systems face big hurdles, from overheating issues to chemical breakdown. Using a stable, less volatile chemical in lithium or sodium batteries means a reduced fire risk in devices we rely on every day. Imagine a world where your phone battery doesn’t get hot in the summer sun, or a solar power plant stores more energy with less hassle.

No tool in the lab or the factory comes without trade-offs. 1-Butylpyrrolidine should be handled with care—gloves and good ventilation aren’t optional luxuries. Like many nitrogen-containing compounds, it poses toxicity risks if used carelessly. More than once, I’ve watched safety officers drill into new researchers the dangers of inhalation or skin contact. Regulators have flagged this class of compounds as needing close oversight and proper disposal. Keeping harm out of the waterways and limiting workplace exposure takes more thought than simply screwing the cap on tight.

Better handling guidelines and greener synthesis methods would take some pressure off both workers and the environment. There’s energy and creativity going into making these solvents from biodegradable or renewable sources—projects I’ve seen presented at conferences. Stronger collaboration between industry and researchers could show us safer alternatives or improved recycling, reducing waste and hazard without slowing down the science that keeps everything running.

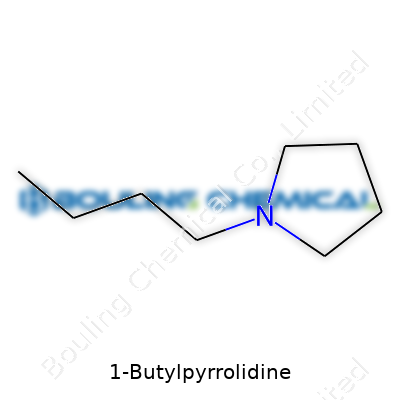

Ask anyone who has cracked open organic chemistry textbooks about 1-Butylpyrrolidine, and you might get a squint or a shrug. Under its quiet name, though, hides a compound with quirks and practical uses, much like that dependable toolbox item you only miss once it’s gone. At room temperature, it shows up as a colorless liquid, skirting the lines between oily and runny—nothing fancy, but very telling if you know what’s happening at the molecular level. That slipperiness comes from a chain of four carbons (the butyl group) attached to a five-membered nitrogen ring. Odd at first glance, but that ring gives it backbone, and that butyl tail nudges it toward oil territory.

Being colorless and typically faint-smelling, 1-Butylpyrrolidine keeps a low profile. People who work with it won’t confuse it with nail polish or other everyday chemicals. Density lands close to 0.85 grams per cubic centimeter, so it’s lighter than water but still feels substantial in a beaker. The boiling point jumps well past 170°C (around 338°F), making this liquid stick around when lighter molecules have long since vaporized. From time spent in research settings, I’ve seen this quality save some headaches; evaporation doesn’t steal it as soon as a hotplate clicks on. Freezing it isn’t straightforward—temperatures need to drop much further than water’s freezing point to see it solidify, so storage on the bench is rarely a problem.

Think of 1-Butylpyrrolidine as a friendly yet selective host in a crowded room. That nitrogen in the ring has a lone pair, which makes the molecule a base. Toss a bit of acid its way, and it’s ready to shake hands, forming salts with hydrochloric or sulfuric acid. That reactive nitrogen also allows it to serve as a building block for more complex molecules, or to act as a solvent where other options fumble the job. Not once have I seen it react violently under routine conditions, but the usual lab warnings for flammable organics still hold true—open flames and sparks have no place around it.

This molecule has survived in the tool kit of synthetic and medicinal chemists for another reason: the butyl side gives increased solubility for organic substances and slightly improved ability to dissolve challenging compounds. From time to time, someone will take advantage of that and use it to help break down stubborn reactants. As a base, 1-Butylpyrrolidine doesn’t compare to heavyweights like sodium hydroxide, but it wins points for being liquid and relatively easy to handle.

There’s no denying 1-Butylpyrrolidine isn’t a household name, but its properties fill a real gap. In synthesis, I’ve seen it act as a smooth operator, helping reactions run with fewer side products. Safety remains a sticking point—gloves and goggles stay on, as the compound can irritate skin and eyes, and good ventilation is always a must. As new pharmaceuticals and specialty chemicals keep popping up, the need for reliable and versatile reagents like this one grows.

One solution to handling challenges: better training and more practical storage protocols. I’ve worked places where careless storage led to ruined samples, and improved labeling or ventilation could have cost nothing but saved months of work. Companies investing in hands-on safety education see fewer accidents and less chemical waste—a win for workers and budgets alike. As for greener alternatives, researchers keep trying to design new bases and solvents with lower toxicity and environmental impact, but so far, the unique mix of stability and reactivity keeps 1-Butylpyrrolidine right in the action. With sharper focus on sustainability, the next breakthrough may spring from understanding these fundamental properties better than ever before.

Anyone who’s spent time in a lab learns pretty fast that everything needs respect, but some chemicals require extra focus. 1-Butylpyrrolidine falls squarely into that group. It’s used in specialty chemistry projects, including synthesis steps that call for stable, relatively reactive solvents. Let’s face it: a single slip-up means someone pays the price, whether it’s a nasty skin burn or a costly contamination problem.

Keep this stuff in a well-sealed container—no leaky jars, no mystery labels. It should live far from any acids or oxidizers. Once, I saw a new guy place an amine solvent next to a shelf of peroxides. It’s a small thing to fix, but a huge problem if it’s ignored. The right storage means a cool, dry area with a steady temperature, away from sunlight. Heat can make volatile compounds unstable, and sunlight sometimes breaks down sensitive molecules. Glass bottles with tight-fitting caps work best.

Put up warning signs. It sounds obvious, but I’ve seen shared storage areas turn into guessing games because nobody took time to label things cleanly. Labels with chemical name, hazard symbols, and last opened date go a long way. Then, only folks trained to handle the substance should get anywhere near it. Sometimes rules get bent because someone’s in a rush, but an ounce of prevention here really does carry weight.

1-Butylpyrrolidine isn’t something to splash around carelessly. Always open containers in a fume hood. The vapor can cause headaches or dizziness pretty quickly if the space doesn’t vent well. Gloves, goggles, and a well-fitted lab coat protect against splashes that could leave a mark for weeks. I still remember the sting of a few drops from an unrelated solvent finding their way through a tear in a glove; it reminded me to check PPE before every shift.

Plan ahead before measuring or transferring. Spills tend to happen during routine moves—tilting a bottle, pouring off, or re-filling a stock container. Keep spill kits in arm’s reach, and have absorbent pads handy for accidents. It’s easy to rush through these steps, but slowing down keeps the cleanup routine and not a disaster story.

Disposing of extra 1-butylpyrrolidine takes more than dumping it down a sink. Set up a dedicated waste container labeled for amines or solvent mixtures. Talk to your waste contractor about safe disposal—never just guess if you’re not sure. Years ago, my lab nearly got fined because a contractor noticed a wrong label on a drum. Fixing a mistake in the moment is far cheaper than a regulatory slapdown.

Keeping a safety binder current feels like tedious paperwork until something goes sideways. Update procedures, review material safety sheets, and run short training sessions each month. If someone sees a shortcut, call it out respectfully. Everyone in the team wins when fewer emergencies land on our desks.

Using 1-butylpyrrolidine calls for habits—label everything, PPE every time, check storage, talk through any odd reactions. Each step tightens the safety net. Nobody walks into a lab planning to make a mess, but with these steps, those messes happen less and clear up faster. Small stuff, done right, protects you, protects your team, and keeps projects rolling.

Take a look at 1-Butylpyrrolidine, and you find a clear liquid, part of the big pyrrolidine family. Chemists reach for it in research labs, and certain industrial applications thrive on its properties. It's got a good reputation for dissolving stuff, so it finds a place in making new chemicals or speeding up reactions. All that clever chemistry attracts both curiosity and concern.

Working with chemicals like this means everything carries some risk. If 1-Butylpyrrolidine gets on your skin, it brings irritation. Redness, itching, or a burning feeling often show up. In one of my jobs, splashing chemicals on bare skin left rashes for days, and stronger stuff can cut through gloves in no time if you're not careful. Eyes really get it worse; a simple drop can make vision blurry and hurt like crazy.

Take inhalation. Breathing in vapors doesn't need to happen over years—one bad moment can bring a parade of coughing, soreness in your throat, and headaches. People working in poorly ventilated labs quickly learn that lesson. One study tracking pyrrolidines, including this one, saw workers complain about dizziness and nausea near open beakers. Those stories stick with you.

Nobody likes to talk about what happens over time, but those daily scraps add up. Chronic exposure matters more than many realize. Some early animal studies linked regular contact with organ stress, mostly hitting the liver and kidneys. Scientists in Europe recorded higher enzyme levels in lab rats, a red flag for tracks of damage. Our bodies handle a little poison every day, but stack enough up and the mess piles high.

Don’t overlook inhaling the vapors in tight spaces. Even small amounts over several months may drag down lung function. Factory workers getting chest tightness and ongoing fatigue can't always pin it on one day’s work. Sometimes everybody shrugs off these issues, calling them “just part of the job.” Looking back, I saw people ignore low-level exposures until something small dragged on for weeks—and then it was too late.

People running experiments need clear guidelines. The basics sound simple: splash-resistant gloves, chemical goggles, lab coats that cover your skin, and a working fume hood. Most trouble starts when someone skips a glove change or lifts a mask just to shout across the room. Having good habits isn't about show—it’s how you finish a career without health scares.

Labs need fresh air to cut down vapor exposure. Recirculating air means old vapors stick around. I've worked in places where fume hoods made all the difference—the room always felt cleaner, and headaches didn’t float in by the afternoon. Regular monitoring with sensors for leaks isn't overkill. People see it as hassle until the day alarms save you from a spill.

Education rarely gets the attention it should. Many folks think chemical warnings belong only in dense rulebooks—nobody really reads those. Training with real-life stories sticks better than some dry list of what could go wrong. Bringing up past near-misses in safety meetings shifts the mood right away. People remember consequences, not abstract risks.

If companies want fewer health problems, open reporting makes a difference. A worker spilling even a small amount should feel safe calling it in. Covering up incidents makes things worse for everyone. Sharing information inside and outside the lab builds habits that last much longer than posted warning signs.

Staying healthy around chemicals like 1-Butylpyrrolidine doesn’t take much—just the right habits, strong equipment, and a culture where people look out for each other before trouble starts.Anyone who’s spent time working in a chemical lab, designing a process, or just trying not to waste hours troubleshooting knows the headache caused by dealing with low-grade chemicals. With something like 1-Butylpyrrolidine, quality can’t sit on the sidelines. Low-purity batches can introduce totally unexpected variables and potentially wreck whole projects. I remember testing reactions with supposed “reliable” reagents, only to find my results made no sense. Turns out, traces of unknown side products kept throwing everything off. There’s nothing fun about re-running weeks of work just because the source of your solvent cut corners.

The standard for higher-end applications hovers at 99% purity or greater. Pharmaceutical and biotech projects regularly ask for that, and sometimes even tighter. That 1% might seem small, but in something like a catalyst screening or a drug discovery run, it’s plenty big enough to ruin the day. Researchers need confidence that the “1-Butylpyrrolidine” in the vial isn’t hiding stray amines, halides, or water.

Checking the specification sheet, the most reputable suppliers spell things out: you’ll see details like water content (maybe under 0.1%), heavy metals (often undetectable or below 10 ppm), and color described in clear language. High-performance liquid chromatography or gas chromatography results usually come attached. If someone’s offering 1-Butylpyrrolidine and can’t back it up with a proper chromatogram, alarm bells should go off.

In practice, one shortcut for anyone sourcing chemicals: always demand the certificate of analysis. Don’t just take an email saying “it’s high purity, trust us.” I’ve seen rogue stocks where the real world product barely cracked 95%—and the rest was gunk you wouldn’t want anywhere near your experiment. A clear certificate, with recent batch data, keeps everyone honest.

Institutions that rely on these chemicals—universities, pharma companies, specialty manufacturers—usually check incoming materials themselves. Sometimes they’ll spot test with a simple NMR run or TLC plate, just to make sure what’s written matches what’s in the bottle. It seems like overkill until a mistake slips through and derails a whole series of tests. Nobody forgets the time it happens to them.

Before locking in an order, grill your supplier about how they verify purity. Are they running routine multi-step purification? Do they use drying agents to keep water out? Have their batches ever failed quality checks? Sometimes you can ask for reference samples if it’s a new source. It saves time, money, and nerves down the road.

For the 1-Butylpyrrolidine product itself, shooting for 99% purity with clear specs on related impurities makes sense for almost any serious use. Lower grades might look attractive on paper, but the cost of rerunning failed reactions eats up whatever savings you thought you had. Trust in clean, transparent numbers over marketing talk—your results will thank you.

| Names | |

| Preferred IUPAC name | N-butylpyrrolidine |

| Other names |

1-Butylpyrrolidine N-Butylpyrrolidine |

| Pronunciation | /ˈwʌnˌbjuːtɪl.pɪˈrɒlɪdiːn/ |

| Identifiers | |

| CAS Number | 54418-34-9 |

| Beilstein Reference | 87736 |

| ChEBI | CHEBI:187485 |

| ChEMBL | CHEMBL131211 |

| ChemSpider | 12649834 |

| DrugBank | DB04119 |

| ECHA InfoCard | 100_132_857 |

| EC Number | 21646-31-9 |

| Gmelin Reference | 82274 |

| KEGG | C16700 |

| MeSH | D04738 |

| PubChem CID | 12514138 |

| RTECS number | HX2975000 |

| UNII | 5Q8FY2TGF8 |

| UN number | UN3276 |

| Properties | |

| Chemical formula | C8H17N |

| Molar mass | 143.26 g/mol |

| Appearance | Colorless liquid |

| Odor | amine-like |

| Density | 0.869 g/mL at 25 °C |

| Solubility in water | miscible |

| log P | 0.94 |

| Vapor pressure | 0.292 mmHg (at 25 °C) |

| Acidity (pKa) | pKa ≈ 11.3 |

| Basicity (pKb) | 3.25 |

| Magnetic susceptibility (χ) | -67.2·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.442 |

| Viscosity | 1.46 mPa·s |

| Dipole moment | 2.51 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 336.4 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -44.8 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3936.6 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | “GHS02, GHS07” |

| Signal word | Warning |

| Hazard statements | H226, H302, H312, H315, H319, H332 |

| Precautionary statements | P261, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | 73°C |

| Autoignition temperature | 215 °C |

| Explosive limits | Explosive limits: 1.2–8.8% (in air) |

| Lethal dose or concentration | LD50 (oral, rat): 280 mg/kg |

| LD50 (median dose) | LD50: Oral rat 302 mg/kg |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for 1-Butylpyrrolidine is not specifically established by OSHA. |

| REL (Recommended) | 1,000 mg/L |

| IDLH (Immediate danger) | NIOSH: IDLH 200 ppm |

| Related compounds | |

| Related compounds |

Pyrrolidine 2-Methylpyrrolidine N-Methylpyrrolidine 1-Ethylpyrrolidine 1-Propylpyrrolidine 1-Pentylpyrrolidine |