In the early 20th century, chemistry shifted from basic alkaloids toward sophisticated heterocyclic compounds. 1,4-Diazabicyclo[2.2.2]octane, more commonly known as DABCO, entered the scene thanks to demand for reliable organic bases and nucleophilic agents. Academic research in the 1940s and 1950s carved the way, with European and North American labs experimenting with piperazine derivatives. Researchers noticed that DABCO presented unique stability compared to older cyclic amines. Through the decades, the substance found its way into industrial settings, especially in polymer and pharmaceutical processing. Factories valued its catalytic punch and ability to cleanly scavenge acids from complex mixtures. Personal experience with catalogues from the 1980s and 1990s reveals DABCO as a mainstay for synthetic protocols, serving a new generation of scientists intent on pushing organic chemistry in greener and safer directions.

These days, DABCO lands on order lists as a fine white crystalline powder. Chemists favor it for its role as a non-nucleophilic, sterically constrained tertiary amine base. Unlike messy or malodorous alternatives, DABCO stores well and resists degradation when sealed from ambient moisture and air. Vendors often sell high-purity grades for laboratory and industrial uses. Standard bulk packing runs from 25-kg fiber drums to smaller bottles for bench work. Strong air-tight seals keep it free from atmospheric water, which can degrade quality or introduce problems during sensitive syntheses. Barcode labeling now tracks batch quality, easing compliance and recalls in regulated industries.

1,4-Diazabicyclooctane crystallizes as small, white, pungent-smelling solids. Its melting point stands near 156°C (312°F); it dissolves easily in water, methanol, ethanol, and many polar solvents. At room temperature, vapor pressure stays low, which matters for volatile workplace exposures. The structure’s bicyclic framework keeps the two nitrogen atoms locked in place, granting notable rigidity. Its pKa value lands around 8.8, providing a balance between base strength and practicality. By locking two nitrogen atoms in a bridge, chemists gain access to strong basicity with little steric hindrance, supporting diverse reactions in both solution and solid phases.

Manufacturers list minimum assay percentages, usually at least 99%. Typical certificates bear out a tight control of moisture, with Karl Fischer measurements confirming less than 0.5% water by weight. Heavy metals, halides, and organics receive tight limits, sometimes at the part-per-million level. Storage notes advise keeping it dry and away from oxidizers. Standard labeling now complies with GHS (Globally Harmonized System), giving hazard pictograms and emergency handling information in clear language. Unique batch numbers let customers trace materials to documented synthesis, essential when product liability enters the conversation. Shipping in cold or cool warehouses slows unwanted polymerization that occasionally plagues tertiary amino chemicals.

DABCO comes to life through a multi-step route starting with ethylene diamine and acrylonitrile. Industrial routes blend these with careful temperature control and then apply hydrogenation to close the ring and yield the bicyclic structure. Catalysis with transition metals enhances the process, and manufacturers rely on purification steps including crystallization and sometimes distillation. Small-scale labs may improvise with brute-force alkylations, though safety and yield both suffer in that scenario. Over years of working in research chemistry, the shift from low-yield improvisation to reliable, reproducible commercial processes marks a major milestone. Robust in-line monitoring keeps undesirable by-products at bay, while greener solvents and lower waste loads reflect a broader movement toward sustainability.

DABCO reacts as both a Lewis base and a nucleophile. In organic synthesis, the compound catalyzes epoxidation, alkylation, and halide displacement. Often, it serves as a phase-transfer catalyst, lending efficiency to slow or temperature-sensitive processes. Some researchers exploit the molecule’s bridgehead nitrogens to build polycationic salts with anions relevant to batteries, water treatment, or even medicinal chemistry. In the polyurethane industry, DABCO’s base properties push isocyanate-polyol reactions toward fast, controlled polymerization. With consistent high yields, it anchors time-sensitive production cycles for foamed and rigid plastics. Chemists modify the core DABCO by N-alkylation, quaternization, or structural extension, customizing it for task-specific catalysts or ionic liquids. These tailored compounds now feature in electrochemical devices and innovative materials.

Chemists recognize 1,4-Diazabicyclo[2.2.2]octane by various commercial and technical names: DABCO, triethylenediamine, TEDA, and DABCO-2. While some catalogs prefer “triethylenediamine,” many reference works default to DABCO out of habit and brevity. International vendors standardize using CAS: 280-57-9. Brand names occasionally use creative twists, especially for pharmaceutical or high-purity grades, but the three-letter format prevails in most technical communities. In shipping and regulatory filings, the full systematic name ensures global recognition and safety alignment.

With moderate toxicity, DABCO demands the same careful handling as most amines. Gloves, goggles, and local ventilation keep lab and production staff comfortable and protected. If inhaled or spilled, it can irritate the respiratory tract and skin. Material Safety Data Sheets (MSDS) urge prompt washing and medical follow-up for accidental exposure. Regular air monitoring, particularly in large production halls, prevents chronic exposure. Workers routinely receive hazard training, including spill response tailored to amine-related risks. Laboratories store DABCO away from acids and oxidizers, since violent or exothermic reactions can occur on contact. Tight control guarantees worker health, clean product, and regulatory compliance all at once.

DABCO powers reactions from polyurethane foam manufacture to advanced organic synthesis. Polyurethane processes rely on it to control reaction speed and polymer texture. Catalyst blends that include DABCO produce everything from automobile seat cushions to refrigerator insulation. In organic synthesis, DABCO’s reliable base strength makes it indispensable for Michael reactions, acylations, and Wittig syntheses. Energy researchers explore its role as a building block in ionic liquids, chasing greener solvents for battery and separation technologies. Pharmaceuticals sometimes incorporate DABCO-derived structures for their basicity and rigid framework. Environmental chemists use it to develop new adsorbents for water purification and controlled release systems in agriculture.

Modern R&D teams continue discovering new uses for DABCO and derivatives. In academic labs, work on DABCO-inspired organocatalysts unlocks catalytic effects without heavy metal contamination. The search for sustainable chemistry drives study into its use for CO2 capture and sequestration. Medicinal chemists experiment with its core structure to design new inhibitors targeting enzyme systems that favor bicyclic amines. Engineering teams adapt DABCO-polycation hybrids for improved conductivity in next-generation batteries. Publications in organic and materials chemistry journals indicate that global research interest continues rising, driving both new applications and process improvements. From personal exchanges with cutting-edge researchers, excitement remains high over its versatility and modifiability.

Animal studies show acute median lethal doses (LD50) for DABCO above 1000mg/kg in rodents, placing it below many industrial chemicals in risk. Chronic exposure data remain limited but caution persists, because long-term inhalation or skin contact could sensitize workers or cause local irritation. Researchers track metabolite profiles after exposure and no major carcinogenic or mutagenic risks have stood out over decades of monitoring. A recent uptick in ecological risk surveys follows DABCO’s expanded use in water treatment and consumer products. Wastewater monitoring and remediation planning now focus on ensuring minimal downstream persistence, keeping both worker and ecosystem safety in balance.

Rising demand for green chemistry and sustainable engineering highlights DABCO’s adaptability. Compound engineers seek novel ionic liquids based on its cationic core, fueling transitions toward safer solvents and battery electrolytes. Polyurethane research leans on DABCO variants as key to lower-VOC foam technologies, helping meet tightening environmental regulations. In pharmaceuticals, the rigid bicyclic scaffold finds appreciation as a drug-like motif, ripe for bioisosteric replacement in enzyme inhibitor work. Agricultural and environmental engineers tap DABCO complexes to scavenge heavy metals and mediate advanced oxidation, extending the compound’s legacy into emerging clean-tech arenas. Ongoing regulatory scrutiny and a need for robust, safe workspaces prompt efforts to reduce toxicity and enhance handling protocols. The future appears firmly tied to chemistry’s need for strong, reliable, and adaptable catalysts.

Staring at a bottle labeled “1,4-Diazabicyclooctane” brings up memories of crowded college labs and the harsh aroma that hangs in the air during late-night syntheses. Usually, people know it simply as DABCO. Not the most famous compound outside research circles, but for chemists or anyone working in manufacturing or healthcare, DABCO shows up in countless places.

DABCO wears many hats, but its main trick lies in its strong basic properties. Chemists get excited about bases because they help reactions move along, breaking bonds and reshuffling atoms in molecules. DABCO stands out because it stays stable even under pressure and doesn’t react unpredictably. I once spent weeks running organic reactions that failed repeatedly with other bases, but when I switched to DABCO, I could count on a clean product—no frustrating reruns.

One of its major roles is as a catalyst for polyurethane foam production. Polyurethane shows up in everyday life—in the chair cushions at home, in car seats, and the insulation behind walls. DABCO helps these foams form by making isocyanates and polyols combine more efficiently, shaving hours off production time and ensuring companies get reliable, quality materials for furniture or vehicles. Industrial numbers show the polyurethane global market crossing $70 billion, and a big reason is how solid catalysts like DABCO support high-volume manufacturing.

Medicinal chemistry relies on quick, clean reactions. Making a new drug sometimes calls for nitpicky steps—forming a specific bond without creating a mess of byproducts. DABCO shines here, too, especially in reactions like the Baylis–Hillman reaction, which pharma labs use to make key molecules for new drugs. The search for new antibiotics or antivirals often hits a wall due to difficult chemistry, but DABCO helps researchers leap over obstacles, keeping costs down and success rates up.

Working with pure DABCO, you notice two things: it smells sharp, and it chafes the skin if you’re careless. Safety data says breathing the dust or vapors can irritate the lungs or eyes. Facilities using it need solid ventilation and personal protection, though its risk profile is milder than that of many other lab or factory chemicals. Environmental agencies recommend containing spills and using good waste management practices, making sure companies don’t cause accidental harm along production lines.

Industries always want cheaper, safer, or greener options. Some research groups try swapping DABCO for new organic catalysts, aiming for lower toxicity and less waste. My conversations with process engineers show that most substitutes still fall short: either they react too sluggishly or they introduce unwanted side reactions. For now, DABCO stays popular because it works so well, but sustainability remains a concern.

1,4-Diazabicyclooctane isn’t a household name, but its fingerprints show up everywhere—from the padding in a gym shoe to the pipeline that delivers clean water. Its ability to speed up tough reactions, deliver safer products, and hold up under industrial stress earns its place on production lines and in research bottles worldwide. That’s not just chemistry on paper; that’s chemistry woven through daily life.

1,4-Diazabicyclooctane—often called DABCO—gets used often in labs and industry, especially as a catalyst. The catch is, while it helps speed up some chemical processes, DABCO asks for careful handling. Safety doesn’t just fall on the facilities or regulations. It’s about every person who opens a jar, cleans up after a spill, or moves inventory from shelf to shelf. Skipping steps puts health, results, and compliance at risk.

DABCO looks like a harmless white powder, and because it comes in that familiar form, it’s easy to forget its punch. It can irritate skin, eyes, and the respiratory tract. Get it on your hands or breathe the dust—you can feel the effects. That risk feels real after hours around chemicals that don’t always smell trouble. DABCO also absorbs moisture from the air, which can mess with its chemical effectiveness and create clumping, so it wants protection from water and humidity as much as people do.

I’ve watched more than one eager chemist leave jars of DABCO sitting open on a bench. Water vapor works quietly, so by the time someone notices, the powder has caked and lost its flow. Keep DABCO in a tightly closed container, and stash it in a cool, dry place. Lab experience reinforces this advice—not even a quick break justifies leaving it exposed. Overhead cabinets beat shelves near sinks or steam sources. Don’t stack heavy things on top, either, since plastic jars can crack. Label everything twice: on the jar and on any secondary container, so no one makes a careless grab.

I once watched a spill turn into an argument: one person grabbed a dry cloth, another wanted a wet mop, and someone else thought it was best to wait for a supervisor. DABCO, like lots of basic amines, deserves glove-and-goggles treatment every time. Use a dust mask when weighing out the powder, since inhaling even a little bit can cause sneezing fits or burning eyes. Clean up spills with a dry, disposable towel. Don’t add water. Collect the residue and seal it until hazardous waste pickup.

In some smaller operations, I’ve seen DABCO crammed into old cardboard boxes or toted in open trays. Reusable secondary containers with tight lids do a better job of preventing both dust escape and accidental dropping. Inventory spreadsheets help spot containers that have sat too long, since even well-protected DABCO can degrade with time. Keeping smaller amounts on hand makes sense, especially in shared workspaces, to reduce the chance of large-scale exposure if a container gets damaged.

Many labs run quick, forgettable safety sessions. Consistent hands-on training makes more difference. Walking new staff through the physical storage area, quizzing on MSDS sheets, and putting up clear signage beat any slideshow. If everyone buys into careful work as a group, mistakes happen less. I’ve seen peer checks and simple checklists catch more problems than top-down orders.

Modern labs can’t do without catalysts like DABCO, but safe use begins with basics: closed containers, dry hands, direct communication, and up-to-date training. These steps don’t just protect users today—they help make sure the results you get can be trusted tomorrow.

1,4-Diazabicyclooctane, often called DABCO, pops up in places far from the average medicine cabinet or kitchen shelf. The compound belongs in chemistry labs and some corners of manufacturing, pulled out for its powerful base and catalyst qualities. It’s not exactly a household name outside academic circles, but its effect on health and the environment deserves a closer look by more than just scientists.

I've worked with DABCO in a lab setting, always wearing gloves and keeping good ventilation. Scientists stick to these precautions for a reason. DABCO catches attention for its ability to irritate skin and eyes. Contact with concentrated DABCO leads to redness, burning sensations, and sometimes swelling. Even a small splash or bit of vapor feels uncomfortable. Respiratory issues can also follow inhaling DABCO dust or fumes. Getting a whiff of strong DABCO during an experiment often leaves a scratchy throat or coughing fit that lingers much longer than one would like.

Chronic effects have not been well studied, but the acute reactions alone make DABCO something to respect. Safer handling keeps accidents low, but mistakes happen, especially in settings without strict protocols. That puts maintenance workers, researchers, and even factory staff at risk if the proper training or safety gear isn’t in place. Risk varies by country, but in the US, OSHA doesn’t list DABCO as highly regulated. That lower profile doesn’t equal harmlessness. DABCO still ranks as a hazardous chemical for shipping regulations and workplace labeling.

The environmental story around DABCO matches some of the tough questions chemists face these days. DABCO doesn’t break down easily in water, so accidental spills stick around. That slow breakdown raises trouble for aquatic life. Fishes and other water animals exposed to DABCO struggle to survive, mostly from irritation or suffocation as gills and skin react. A 2022 study in the Chemosphere journal showed reduced growth in zebra fish embryos placed in water with even modest levels of DABCO.

Some factories keep DABCO emissions low and catch waste streams before they end up in nature. But in places where chemical safety infrastructure falls short, the leak risk grows. Waterways in developing regions can end up contaminated from runoff or improper disposal. Long-term exposure in the soil might also slow down bacteria that keep ecosystems healthy. Risk gets bigger where industries cluster near rivers or where chemical plants operate without strong oversight.

Reducing hazards means investing in better training and real air filtering systems in labs or plants. Those simple steps—wearing gloves, working in fume hoods, monitoring air quality—protect both workers and the people who share their homes. For broader environmental health, setting up treatment for wastewater before it leaves the facility makes a difference. Industries that buy or use DABCO should switch to less persistent materials if possible or find catalysts that break down more quickly outside the lab.

Public pressure sometimes turns companies around faster than laws do. Communities living near industrial parks, schools teaching chemistry, and new scientists all gain when the risks are spelled out in plain language. Choosing safer methods and raising standards can turn DABCO from a hazardous afterthought into a lesson in thinking ahead.

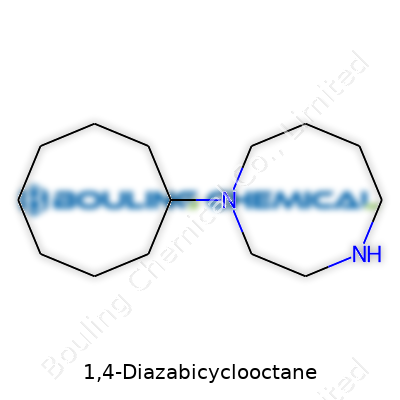

Picture a chemical with a reputation for helping out in a lot of labs. The name 1,4-Diazabicyclo[2.2.2]octane looks intimidating, but it’s better known as DABCO. Its molecular formula is C6H12N2. DABCO grabs the spotlight because of its unique cage-like structure, which gives it qualities that chemists find useful, especially in organic synthesis and catalysis.

1,4-Diazabicyclooctane belongs to a class of compounds called bicyclic amines. It’s got two nitrogen atoms stashed inside an eight-membered ring. Here’s how it breaks down: three two-carbon bridges tie together at two nitrogen positions, meaning you can think of it as a shape with six carbon atoms, two nitrogen atoms, and no branches shooting off the skeleton. The structure almost looks like a tiny chemical climbing frame—a compact, three-dimensional cage.

In shorthand, chemists describe DABCO by the numbers in its name. The “bicyclo[2.2.2]” bit signals the ring system: three bridges, each with two atoms, connecting two points on a ring. Both nitrogen atoms take the 1 and 4 spots, sitting directly opposite each other. This arrangement hands DABCO some remarkable features, including basicity and the ability to coordinate with metals.

My own experience in the lab taught me that DABCO isn’t just another base. Its shape and placement of those nitrogen atoms boost its effectiveness. It's far less likely to get tangled up with other molecules in unwanted side reactions. DABCO is tough, resisting breakdown in air and under normal lab conditions, which lets scientists rely on it as a strong, stable base for deprotonating molecules or as a catalyst in important transformations.

Think about making polyurethane foams—DABCO steps in as a catalyst, speeding up reactions without adding much complexity. In organic chemistry, it finds use in the Baylis–Hillman reaction, where its structure gives access to new carbon–carbon bonds. These are just a couple of spots where this bicyclic amine makes itself valuable in daily work, not just in textbooks.

With all these uses, safety isn’t something to ignore. DABCO's custom shape makes it less volatile than some organic bases, but it still stings if it gets in your eyes or on your skin. Labs need to make sure there’s good ventilation, gloves, and goggles handy. That means training newcomers on safe handling, storage, and disposal so accidents don't upend somebody’s day or worse.

One area to keep watch on lies in environmental impact. While DABCO’s stability reduces some concerns, any chemical spread, whether in manufacturing or waste, can stack up over time. Following responsible procedures and exploring recycling options for spent catalysts can stop unneeded pollution. Some researchers have been working on capturing and reusing DABCO after catalytic reactions, cutting down on both cost and waste.

A chemist can spot DABCO on a shelf by its white crystalline look. It’s available in multiple grades for different needs, but its structure and formula don't change with the label. Knowing exactly what you’re working with, why it matters, and how to handle it smartly makes a big difference—not just in successful syntheses, but also in health, safety, and environmental responsibility.

1,4-Diazabicyclooctane, often called DABCO in the lab, brings its own set of worries. For those who have handled it—smelling its sharp odor, feeling the catch in your throat—its presence is hard to ignore. Lab benches I’ve worked at showed me right away: letting safety slide with chemicals like this never ends well. Health guidelines label it as an irritant for skin, eyes, and breathing, and that's not just legal jargon; it can leave you coughing or worse after even a short encounter.

Pouring DABCO down the drain isn’t just lazy, it runs straight into public health and environmental issues. Sewage treatment plants don’t pull out every last trace of odd organics—they aren’t designed for that. The byproducts can travel into the larger water system and may hurt aquatic life before breaking down. Stories of groundwater ruin often begin with routine lab disposal, not big industrial spills.

Storing DABCO in a sealed, clearly marked container keeps everyone safer right off the bat. You’ll find that even a minor spill can cause confusion when labels are missing or unclear. Tight containers and immediate labeling work better than any written protocol gathering dust in a folder.

On disposal, professional chemical waste collection tops the list for safety. Most academic and industrial labs I’ve worked with have contracts with licensed hazardous waste processors. These handlers combine chemical know-how, proper incineration or solvent destruction, and compliance with government rules. A pickup schedule and a phone number provide immediate answers—no need to invent methods or guess at which waste drum it belongs to.

In my own experience, regulatory reminders from Environmental Health and Safety teams carry meaning. Rules set by OSHA, EPA, and local agencies didn’t appear out of thin air; they answer past disasters. DABCO’s safety data sheet often lives tucked in the binder, but pulling it out and reading possible reactions—like how it forms toxic gases if burned or mixed with the wrong chemicals—puts the risk in plain language. These sheets make it clear why certain disposal paths exist.

I’ve seen plenty of new lab workers assume small volumes don’t matter. That mindset spreads risk among cleaning staff, waste water workers, and even people at home. Keeping a dedicated chemical waste log, and teaching every new team member how to use it, stops confusion before it starts. Peer-learning sessions, and the occasional horror story from past mistakes, stick with people better than any sign on the wall.

Beyond disposal, companies and schools can also look at cutting down DABCO use wherever possible. Green chemistry explores new ways to finish the same work with smaller exposures and easier disposal. Many substitute catalysts exist—some not as efficient, but much easier on people and pipes.

Whether working late in the lab or training new interns, safe disposal of DABCO builds on shared habits. Every time a container is labeled correctly, every call made to a waste company, those actions add up. Landfills and waterways only stay safe when each person takes that small but important step. In the long run, these choices protect both lab teams and everyone downstream.

| Names | |

| Preferred IUPAC name | 1,4-Diazabicyclo[2.2.2]octane |

| Other names |

DABCO Triethylenediamine TEDA 1,4-Diazabicyclo[2.2.2]octane |

| Pronunciation | /daɪˌæzəˌbaɪsɪkloʊˈɒkteɪn/ |

| Identifiers | |

| CAS Number | 280-57-9 |

| 3D model (JSmol) | `3D model (JSmol)` string for **1,4-Diazabicyclo[2.2.2]octane** (also known as DABCO): ``` CN1CCN2CCN1CC2 ``` |

| Beilstein Reference | 17114 |

| ChEBI | CHEBI:30944 |

| ChEMBL | CHEMBL1422 |

| ChemSpider | 7285 |

| DrugBank | DB02109 |

| ECHA InfoCard | 03d0460e-d08b-414c-bb04-cfa297141c22 |

| EC Number | 202-838-7 |

| Gmelin Reference | 10804 |

| KEGG | C06582 |

| MeSH | D003616 |

| PubChem CID | 30383 |

| RTECS number | JO1925000 |

| UNII | 6QE8DT9E0R |

| UN number | UN2382 |

| CompTox Dashboard (EPA) | DJT83WVUOBZCTA |

| Properties | |

| Chemical formula | C6H12N2 |

| Molar mass | 112.17 g/mol |

| Appearance | White crystalline powder |

| Odor | amine-like |

| Density | 1.14 g/mL at 25 °C |

| Solubility in water | soluble |

| log P | -1.29 |

| Vapor pressure | 0.1 mmHg (25 °C) |

| Acidity (pKa) | pKa = 8.8 (conjugate acid, DMSO) |

| Basicity (pKb) | 2.88 |

| Magnetic susceptibility (χ) | -41.5·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.474 |

| Viscosity | 1.37 cP (20°C) |

| Dipole moment | 1.18 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 221.4 J mol⁻¹ K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -77.9 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3523 kJ mol⁻¹ |

| Hazards | |

| Main hazards | Harmful if swallowed, causes skin and serious eye irritation, may cause respiratory irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H319, H335 |

| Precautionary statements | P261, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | > 62 °C |

| Autoignition temperature | 410 °C |

| Explosive limits | 4.2–10.4% |

| Lethal dose or concentration | LD50 oral rat 2390 mg/kg |

| LD50 (median dose) | LD50 (median dose): 1130 mg/kg (oral, rat) |

| NIOSH | RN1993 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for 1,4-Diazabicyclooctane: Not established |

| REL (Recommended) | No REL established |

| IDLH (Immediate danger) | Unknown |

| Related compounds | |

| Related compounds |

1,4-Diazepane Piperazine DABCOnium DABCO hexafluorophosphate 1,5-Diazabicyclo[4.3.0]non-5-ene |